Aluminium laser cutting is a transformative process in manufacturing and design that requires a deeper understanding due to its unmatched precision. Accuracy benefits professionals like engineers and designers while captivating technology enthusiasts. This post reveals sophisticated details about aluminium laser cutting that explains its advantages, capabilities, and applications. Modern fabrication is transformed using laser cutting machines which turn raw aluminium into flawless, precise pieces. Prepare to learn the astonishing innovation of this technique and uncover its revolutionary impact on contemporary fabrication.

How Does a Laser Cutting Machine Work for Aluminium?

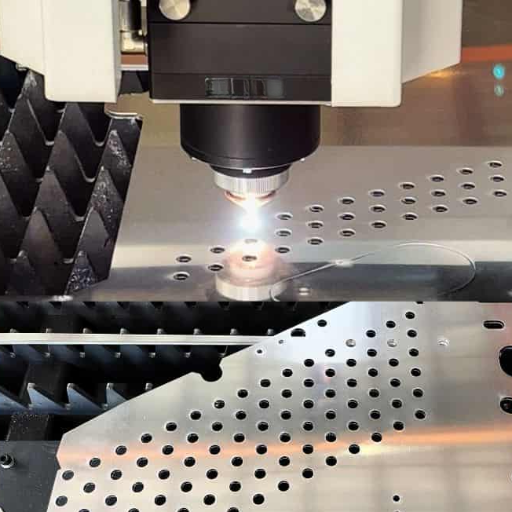

A laser cutting machine utilizes a focused laser beam to heat and melt aluminum along a predetermined cutting line. Because the laser beam is precise, the cut surfaces are clean, and there is very little wasted material. To improve the process, a gas—nitrogen or oxygen—is used to blow the molten aluminum from the cut surface, resulting in a smooth edge. This approach works well to manufacture very complex shapes or highly accurate parts.

Working With the Laser Cutting Technology

Laser cutting is one of the most sophisticated production methods. It has precision, effectiveness, and versatility all in one. This technique is based on a focused laser beam that applies heat to the material to be separated at a specific point and either boils, melts, or vaporizes it to make the necessary cut. These materials include aluminum, which is usually cut with fiber lasers because they are good at cutting metals that are difficult to cut using CO2 lasers.

The cutting process initiates when a beam of laser light is fired using a lens system aligned with mirrors to focus the energy to a thin and fine point on the aluminum surface. A CNC computer numerical control system is used to ensure precision which controls the movement of the laser, guiding it to the predetermined design and outlines the complex patterns and shapes. Depending on the thickness of the aluminum, the rate can differ. For instance, 2mm thick aluminum can be cut using a fiber laser at a rate of 1200 to 2500 inches per minute which boosts efficiency in production greatly.

Also, assisting gases like oxygen and nitrogen are very important in this regard. Oxygen can assist in accelerating the rate of cutting by aiding in a combustion reaction while nitrogen is used often to provide a clean, oxidation free cuts. With the advancement of technology, the modern laser cutters have also seen an improvement in power efficiency where in some machines, the rate of energy transfer can reach 40% which in turn lowers the cost of running the machine.

With its adoption in automotive, aerospace and electronics, the global laser cutting market is projected to exceed a value of $6 billion by 2026 indicating significant growth. This also shows how important laser cutting is as technology for modern manufacturing processes.

The Importance of Fiber Lasers in Aluminum Cutting

When it comes to fiber lasers, they are now regarded as one of the most advanced technologies for laser cutting, especially for aluminum which is quite difficult to work on due to its reflective properties. Fiber lasers have a more effective cutting mechanism as compared to CO2 lasers since they work on a shorter wavelength. With fiber lasers, the chances of beam reflection are much minimized due to the shorter wavelength.

Due to their remarkable efficiency, fiber lasers also offer high-speed cutting. Unlike cutting aluminum through CO2 laser systems, aluminum can now be sliced six times faster with fiber laser systems. A classic demonstration is with the 4 kW fiber laser where 1 mm aluminum sheets can be cut to a maximum of 60 meters per minute. Not only does this enhance productivity, but it also meets the precision standards required in the aerospace and automotive sectors.

Moreover, the efficiency and energy saving benefits of fiber lasers are well known. Unlike traditional laser systems, operational costs are greatly reduced due to power consumption being less than 40% of power is consumed during energy transfer. As reported recently, adopting fiber lasers has enabled large-scale aluminum manufacturers to cut costs by nearly 30%.

Also, new developments in beam quality and adaptive focusing have resulted in increased fiber laser cutting capabilities. Such advances are essential for industries which require aluminum products to be immaculate as they help reduce the need for extensive smoothing post-processing.

Cost effectiveness coupled with performance, adaptability, and flexibility put fiber lasers at the forefront of the industrial revolution as they transform aluminum processing in the modern age. As industries are on the lookout for sustainable, high-speed metal cutting and fabrication solutions, the expectation is for fiber laser technology to expand in scope further.

What are the Advantages of Using a Laser Cutter for Aluminium?

- Precision and Accuracy: Frosted laser cutters provide clean, dimensional accuracy, as well as precise outlines and cuts. They are unparalleled in the market for their clean frosted edges.

- Efficiency: They are the most dominant in terms of quick output, increasing the overall productivity whilst saving simulteneously saving time.

- Versatility: Their ability to manage different thicknesses as well as designs and outlines of varying complexities makes laser frosted cutters multipurpose.

- Minimal Material Waste: Compared to other traditional devices, laser cutters are more modern and efficient in the manner that they save on excess materials.

- Consistency: Laser cutting their pieces ensures that they have exact consistency in duplication of circles and as such precision and quality in every item.

The Advantages of using laser cutters for aluminum frosted materials

Frosted aluminum is preferred for a lot of industries due to the numerous advantages of laser cutting. Given below are the primary advantages:

- Increased Precision Alongside Frosted Edges: Aerospace or auto motives circles use laser cutting to ensure precision and sharp frosted edges alongside accuracy within the range of ±0.1mm. It is now a competitive necessity in these fields.

- Reduced Throughput Time: Quicker project turnaround is achieved by a reduction in production through laser frosted cutters with an operating efficiency of 60 inches per minute.

- Design Flexibility: The versatility is increased as custom cuts like unique designs can be more complex with laser cutters with no additional outboard tools unlike traditional shape molds.

- Reduced Material Waste: Using laser cutting technology reduces waste materials by 10-15% when compared to traditional cutting techniques. This innovation conserves both materials and eco-friendly resources.

- Non-Contact Cutting: Laser cutting is considered non-contact which means there will be no mechanical forces exerted on the aluminum, preventing physical alteration or damage. This function helps maintain the shape of thin and fragile elements.

- Support for Different Thicknesses: Depending on the machines used, laser cutters can process aluminum sheets ranging from 0.5mm to 30mm, which requires varying levels of thickness. This feature allows flexibility in the projects undertaken.

- Quality Assurance in Mass Production: The automated systems used in laser cutting ensures duplicates of pieces are generated which match the design details. This feature increases efficiency in mass production of electronics and construction materials.

Alongside these benefits, the constant improvements in laser cutting technology make it an essential asset towards industries that prioritize precision, speed, and waste reduction.

Comparing Laser Cutting with Other Methods

Laser cutting can be compared with methods like plasma cutting, waterjet cutting, and mechanical cutting.

| Method | Precision | Speed | Material Range | Cost | Waste |

|---|---|---|---|---|---|

| Laser Cutting | High | Fast | Wide | Moderate | Low |

| Plasma Cutting | Medium | Fast | Metals | Moderate | Medium |

| Waterjet | High | Slow | Wide | High | Low |

| Mechanical | Low | Slow | Metals, Limited | Low | High |

Plasma cutting is more economical for working with metals as compared to laser cutting which focuses on precision and eliminating waste. Although waterjet cutting is often more expensive and takes longer than other methods, it does not thermally distort materials and offers a wider range of uses. Compared to other methods, mechanical cutting is more affordable. However, it is not as accurate and produces greater waste than the other methods. Each method differs in unique advantages which makes choosing one highly dependent on the specific project needs.

Aluminium Laser Cutting Applications

Aluminium laser cutting has gained prominence in different sectors because of its unmatched speed, versatility, and accuracy. This technique is common in the automotive industry, aerospace sector, construction and even in design and artistic ventures. Advanced industry statistics suggest laser cutting can achieve tolerances of ±0.1 mm which is perfect for intricate and detailed parts. In addition, modern fiber laser machines can effectively cut aluminum sheets of different thicknesses, usually up to thirty mm.

Laser cutting saves materials and minimizes waste. Studies show that sophisticated nesting algorithms in cutting software can reduce scrap material by 20%. Moreover, this method does not use harmful gases and emits a very small amount of gas, making it eco-friendly. This meets the new focus on self-sufficient manufacturing methods all over the world. Aluminium laser cutting is favored for high-performance manufacturing because it combines efficiency, precision, and sustainable practices.

What to Consider When Choosing a Laser Cutting Machine for Aluminium?

- Power Output: It is wise to select a machine that can effectively cut through the amount and thickness of aluminium required. This might mean that a chunk of extra wattage will be needed for thicker cuts.

- Cutting Speed and Precision: Fulfill the production requirements with a balanced combination of high speed and precision for the cutting machine.

- Compatibility with Aluminium: Always check that the equipment deigned for aluminium cutting is meant or specifically adjusted for working with aluminium since some machines are made to work with other materials.

- Cooling System: Cutting aluminium can be a hot task to perform and powerful lasers can generate considerable heat for performing a single task at hand. A good cooling system is required for the equipment to maintain proper performance without the risk of warping material.

- Cost and Maintenance: Ensure that your set operational cost and budget gets aligned with the set value of the equipment while maintaining a decent value with regard to the upkeep expenses countered over time.

Evaluating laser Power for Aluminum Cutting

While taking into account the numerous factors concerning how much laser power is actually needed, thin sheets of aluminium (1-2mm thick); assuming they are 500-1000 watts, can be cut with ease. On the opposite end if thick aluminium materials ranging from 3-6mm or more, those tend to need a whole different ball game, upwards from 2000 to 6000 watts for a clean and sharp finish cut.

Manufacturers are now able to utilize fiber lasers to achieve more efficient aluminum cutting due to recent breakthroughs in fiber laser technology. Edge finishing and processing speeds are enhanced due to better absorption CO2 lasers have on aluminum. Leading manufacturers suggest that a 4kW fiber laser can easily slice through 10mm of aluminum with precise cuts at 1.2 meters a minute.

In regards to aluminum components that have oxidization issues, using oxygen, nitrogen or air prevents oxidation from occurring around the edges during the cutting process. This feature maintains a clean cut and improves the overall aesthetic of the finished product.

Automation and monitoring systems have simplified industrial applications on large scales. For components that have material of different thickness, machines that come fitted with smart sensors are now able to adjust power output, focal length and carve quicker. This allows for consistent results and a reduction in material waste. This kind of technology removes the need for human input and reduces production times.

Significance of Cutting Speed and Accuracy

In the laser cutting business, the primary Konzentration of factors are efficiency, cost, and quality of products which are directly related to cutting speed and precision. As the most recent information shows, cutting speeds on fiber lasers have improved significantly when compared to CO2 lasers. Now, thin sheets of stainless steel or aluminum can be cut at a staggering 20 meters per minute. Not only is this a remarkable feat, but it also greatly enhances the production cycle time and lowers operating expenses.

Particular sectors such as aerospace or electronics require intricate designs and detail, and with advancements in technology, precision has drastically propelled too. Modern laser cutters have the capability to achieve tolerances of ±0.001 inches. Therefore, advanced robotics with tighter adaptive optics and beam shaping which provides more control of the laser beam have also been increasing their accuracy Even more startling, industries that incorporate these technologies are said to have less material waste, roughly equating to 15-20%. Efforts toward achieving precise and accurate components further demonstrate how such surgical enhancements improve sustainable manufacturing processes.

Deciding From Fiber Laser and CO2 Laser Classification

In terms of selecting a fiber laser or a CO2 laser, it is important to think about material use, efficiency, and cost. Metal working industries have benefited from fiber lasers due to their ability to cut reflectively metals such as aluminum, copper, and brass with minimal energy loss. Reflective metals absorb energy at around 1 micron wavelength. This allows precise energy focusing which results in fast and efficient cutting. Studies show that CO2 lasers use approximately 50% more energy than fiber lasers without yielding better results.

CO2 lasers excel at cutting non-metals like wood, plastic and acryllic. These are often favored for engraving and applications requiring smooth edges as they produce a cleaner cut edge compared to other lasers. However, CO2 lasers typically require more maintenance including gas refills, parallel alignment of mirrors, high operational costs and refill expenses for the gas. According to data, CO2 lasers may have a reasonable operational efficiency of about 10-15%. In contrast, fiber lasers can exceed a 25-30% efficiency because of their all-solid state design.

The final choice invariably hinges on the particular needs of the application. As an example, businesses that specialize in metal fabrication may especially appreciate the throughput and cost savings offered by fiber lasers, whereas companies dealing with various non-metal materials may find more benefit from CO2 laser systems. Looking at purchase price alone, fiber lasers usually incur a higher upfront cost, but tend to be more cost-effective over time due to reduced maintenance costs and increased longevity.

How to Achieve the Best Cut Quality in Aluminium with a Laser Cutting Machine?

With regard to the selection of fiber laser equipment, it is best to use it on aluminum, as it is highly reflective. It is also important that the correct parameters, power and speed are set for the thickness of the part. Adhere to high purity class assist gases and nitrogen for best results. Always inspect and maintain the machine for best performance and results.

Optimizing Laser Settings for Aluminum

In laser cutting, the selection of parameters plays a crucial role due to the unique characteristics of aluminum materials. Typically, the assist gas and cutting bed gas pressure are tuned at the same level as the cutting speed. For aluminum with a thickness upto and including ten mm, a fiber laser with output power settings between 2 to 6 kw is appropriate. Lower power settings of around 2kw are recommended for thinner sheets of aluminum to avoid damage, while 6 kilowatts will enable accurate and quick cutting of thicker parts.

Faster speeds are suitable for thin sheets of aluminum, while slower speeds yield cleaner cuts for thicker pieces. For 3 mm thick aluminum, a 3 kW fiber laser’s cutting speed ranges between 3 to 4 m/min, influenced by the material and surface reflectivity.

For shiny and smooth edges, nitrogen should be used instead of oxygen as the assist gas. Nitrogen purity levels should exceed 99.99% to achieve optimal results. A slight positive pressure creates efficient removal of molten material and minimizes the risk of dross or surface imperfections.

Vertical and sideways shifting focus lenses can sharply improve accuracy utilizing auto-focus systems which change the cutting beam focus. Calibrating the focus lens to the material enhances cutting repeatability.

Real-time analyzers can be integrated into systems for monitoring parameters like cut precision. Effective adjustments will increase the productivity and quality of processes involving aluminum.

Strategies to Enhance Cutting Accuracy and Finishing

Achieving the best possible cut accuracy and finish requires that all laser parameters like cutting speed, power settings, and gas pressure are optimally set. I pay close attention to the alignment of the nozzles and ensure they are of high quality to maximize the outcomes. Periodic maintenance tasks like cleaning the optics and checking the lenses enhances a system’s effectiveness. Moreover, the use of sophisticated autopilot gas systems and autofocus mechanisms help in further tailoring the cut to the material being processed. I am able to achieve accurate and through clean cuts all the time by applying these strategies.

Aluminum Laser Cutting: Problems and Solutions

As with all other forms of laser processing, aluminum laser cutting is faced with numerous challenges including issues with cutting quality, accuracy, and productivity. Aluminum’s high reflectivity often leads to common problems like the reflection of laser beams. This not only increases the chance of cutting damage, but it also diminishes overall cutting effectiveness. One commonly accepted solution is the use of CO2 lasers because they are more effective when dealing with reflective materials. Also, the critical components of the laser can be treated with anti-reflective coatings to protect them from potential damage.

Formation of burrs along the edges of cuts is another major problem. Incorrect gas pressure or a misaligned nozzle may to a defect like this. As noted in recent studies, switching to appropriate assist gas, like nitrogen for clean cuts and oxygen for faster cuts, can reduce burr formation.

Another problem that can arise is the overheating of machinery when cutting thin aluminum sheets. Cooling systems can improve the cut quality by reducing the warping above the heat distortion. As advanced systems become more prevalent in industry, adaptive cutting systems which have the capability of counteracting heat accumulation can greatly enhance the accuracy of the cut.

Equipment remains cleaner and undergoes less frequent recalibration when unchecked for longer amounts of time. Equipment lifespan is cited to benefit by as much as 25% while consistently maintaining the same cutting and equipment quality. Adherence to recommended practices combining precise equipment setup ensures that professionals can laser cut aluminum while overcoming all challenges when they incorporate advanced laser systems.

What are the Safety Measures When Operating a Laser Cutter?

- Always Wear Proper Protective Gear: Use specific safety goggles made for the particular wavelength of laser in use, safeguarding against toxic exposures for your eyes.

- Use Adequate Ventilation: Exhaust systems should be installed to get rid of the smoke and fumes as well as particles produced during cutting processes.

- Never Leave the Machine Unattended: Supervision of the laser cutter’s operation is critical and has to be done at all times to identify overheating devices and other fires risk.

- Manufacturer instructions should be followed: A malfunction of any sort can be avoided by using the instructions given by the manufacturer as the basis for operating the laser cutter.

- Keep the Area of Work Clean: Fire risks and hazards are minimized when flammable materials are removed and the vicinity surrounding the laser cutter is tidy.

Personal Protective Equipment when Laser Cutting (PPE)

With the introduction of laser technology, the use of appropriate personal protective equipment (PPE) fulfills animportant requirement that assists in protecting the risks involved. The key effective PPE details are as follows:

Laser Safety Goggles: They defend you against the devastating effects of powerful lasers by absorbing some of the unwanted energies and thus preventing exposures to those wavelengths in harmful levels. Brief encounter of exposing or being exposed to laser beam or reflection of it can result to devastating permanence to one’s eyesight. This is the reason why goggles are laser class specific compliant.

Heat-Resistant Gloves: The materials that have undergone laser cutting can often be hot to the touch or sharp. Adequately protecting gloves are able to shield your hands from burns, cuts, and abrasions.

Respirators or Masks: For wood or acrylic materials, lasers are capable of cutting fine and toxic smoke as well as miniature particles. Studies suggest that respirable fume exposure can be harmful to your lungs over time. Filtering harmful particles and chemicals, an approved NIOSH respirator can be of great aid.

Protective Clothing: To avoid and reduce the risk of coming into contact with flammable materials or laser beams, clothing should be made out of non-flammable material and fit tightly to one’s body.

The above mentioned PPE recommendations should be followed to ensure an efficient and flawless workspace that is safe and free from risks related to laser cutting work. For more information, consult the manufacturer’s documents as well as occupational safety regulations.

Keeping a Work Environment Safe

Staying up to date on safety protocols makes it easier to leverage insight data and ensure a safe work environment. Using the latest data issued by the OSHA (Occupational Safety and Health Administration Office), workplaces with robust safety protocols tried implementing them are seeing a 58% reduction in serious accidents. Furthermore, industry safety reports found that innovative technologies are also helpful; real-time monitoring systems and laser safety sensors are capable of reducing potential risks by 30%. That’s a game changer!

Regular maintenance on laser cutting equipment is essential in avoiding accidents and equipment failures. For instance, regularly replacing certain parts decreases overheating issues that cause nearly 25% of laser workplace incidents. Along with thorough maintenance, proper training and detailed instructional workshops help employees deal with onsite potential dangers.

Staying updated with changes made to personal protective equipment (PPE) is equally important. More recently, self-monitoring systems that alert working personnel of environmental changes are embedded in PPE. Increased temperature, as well as declining air quality, are examples of changes personnel may be alerted to. These proactive systems are essential for personnel operating in areas with hazardous lasers or fumes.

Remember that fostering a comprehensive safety strategy requires ongoing training and compliance with modern standards, coupled with a commitment to protective and safety measures. Organizations can integrate traditional safety strategies with contemporary innovations, significantly enhancing risk governance while creating a culture where operational effectiveness is achieved without sacrificing safety.

Safe Operation of Laser Equipment

The Safe Operation of a Laser Equipment focuses on practices operators need to observe so as to protect themselves and the environment. The users of laser equipment need to be trained on the equipment being used, the environment and risks involved. One example is safety glasses that filter dangerous laser wavelengths.

Safety measures are often approved by laser manufacturers and need to incorporate the environment in which they work. The workplace should not only be properly marked and restricted to the necessary personnel, But also should have the necessary safety signs. The eyeds needed for the equipment should also include barriers to reduce the chances of being exposed to lasers.

Regular inspection boosts the performance and efficiency of an equipment. Equipment that is not fully optimised or in peak condition may provide further danger or risk for exposure in malfunctioning and provide relief. Having procedures to control computerized technologies will aid in preempting unallowed usages for the equipment when maintenance or intervals can allow for control on automation.

Finally, nurturing a culture where employees feel comfortable reporting issues and proposing changes to improve workplace safety enhances the overall working environment. Organizations can mitigate the dangers related to operating laser machines with the right training, equipment, and established procedures.

Reference sources

- Fablight FL4500 Laser Cutter – UC San Diego Makerspace – This page provides details on a laser cutter capable of cutting aluminum up to 0.1875 inches thick.

- Effects of Laser Machining Aluminum Alloy in Different Media – PubMed Central – A research article discussing the quality of laser processing aluminum alloys in different environments.

- Experimental Study on Laser Cutting Process – PubMed Central – A study analyzing the effects of various laser cutting parameters on materials, including aluminum.

Frequently Asked Questions (FAQs)

Q: What is a fiber laser cutting machine and how is it used on aluminum?

A: Fiber laser cutting machines are a class of industrial laser cutting machines that use fiber optic laser sources. They can also cut aluminum like most metals. They are used a lot in the industries for the cutting of sheet metal and thin light aluminum sheets with good accuracy.

Q: How efficient is a 1500w CNC fiber laser cutting machine in aluminum cutting?

A: A 1500w CNC fiber laser cutting machine can usefully work on thin aluminum sheets and other lighter non-ferrous materials. It has a reasonable mark in the speed and accuracy which gives it the ability to cut aluminum sheets of up to 4 mm thick within reasonable time with good quality. This level of power is typically adequate for most of the mid and smaller industrial applications.

Q: Is it possible to use a raycus laser source for cutting aluminum?

A: Indeed, a raycus laser source is frequently integrated into fiber laser cutting machines designed for aluminum cutting. Its reputation for stable performance and efficiency makes it a favorable choice for metal fabrications, including different alloys of aluminum. Fiber laser cutting machines that process mild steel and non-ferrous materials also utilize raycus laser sources without any issues.

Q: What advantages do CNC fiber laser cutting machines offer for processing thick aluminum?

A: With a CNC fiber laser cutting machine, harsh thick aluminum becomes meticulous as it entails spending less gasp while precious carbons aren’t wasted, precision together with speedy cutting. The machines process various thicknesses of aluminum easily, they can cut and engrave intricate shapes, which boosts productivity in industrial processes.

Q: What is the preferred laser power for cutting 4 mm aluminum thickness?

A: Recommended laser power for 4 mm thick aluminum is between 1000w and 2000w. At this range, laser cutting will be both efficient and consistent in maintaining quality during the cutting process. 3000w or 6000w are also available, enabling faster feeding rates or processing thicker stock.

Q: In what manner does high thermal conductivity of aluminum affect laser cutting?

A: With high thermal conductivity comes faster heat dissipation, however, this makes working with aluminum more challenging due to the distortion and overheating concerns a workpiece faces to it’s surroundings. To ensure clean cuts, the correct settings and a reliable laser cutting head are mandatory.

Q: What metal characteristics determine a laser source specialization towards its cutting?

A: As with any metal, focus on the type of material, dimensions, acceptable tolerances, lead time, and level of detail desired needs to be met to achieve satisfactory results. Fiber optic laser sources are recommended due to their proficiency and effectiveness while performing laser cutting on metals, including aluminum and steel.

Q: What are the benefits of a laser that possesses 6000w?

A: Not all applications require it, but thick aluminum cutting and accelerating the pace of work get a boost from it. Furthermore, they make for a good industrial laser cutter because they deal well with high powered applications and diverse materials and thickness range.

Q: What functions does a filter serve in a laser cutting machine?

A: A filter protects a laser cutting machine’s fumes and cutting part filtration systems from damaging fume and particulate waste generated during cutting. Proper filtration improves the cleanliness of the surrounding atmosphere which guarantees a better working environment, extends the life of the machine, and helps prevent contamination that would degrade performance and quality during laser cutting.

- Graphite Melting Point: Understanding the Science Behind Carbon’s High Temperature Resilience

- Unlocking the Power: How Does Laser Cleaning Technology Function?

- How to Choose the Right Laser Cleaning Machine for Effective Cleaning

- The Fascinating World of Toluene: Understanding Its Melting Point and Chemical Properties