From crafting exquisite patterns on acrylic to making exact cuts for industrial uses, cutting and engraving plastic with a laser is perhaps the most efficient and creative of all modern processes. Whether you have years of experience or are just beginning to discover the magic of this technique, the ability to cut and engrave plastic will certainly bring with it a myriad of opportunities. In this article, you will learn the most important aspects starting from which materials are appropriate for laser cutting and how to achieve the best results using proper methods. Prepare yourself to unlock the tools, techniques, and best practices that transform your working met with plastic and elevate plastic working skills to new heights.

What is Laser Cutting & Engraving in the Context of Plastic?

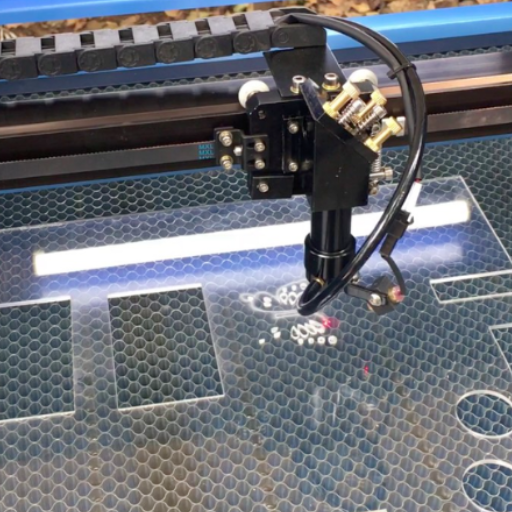

Laser cutting and engraving on plastic refers to the use of a laser beam to cut or engrave designs on the surface of plastic. It is very precise, adaptable, and capable of forming complex cuts which include patterns, shapes, and letters. While cutting, the laser removes the material completely to create smooth edges. In engraving, the laser etches the surface to add custom marks or designs. Commonly used plastics includes acrylic, polycarbonate, and ABS because they endure the laser’s power and have smooth professional results. This is popular in the signage, product design, and crafting industry since it is cost-effective and very accurate.

How does a laser cutter work?

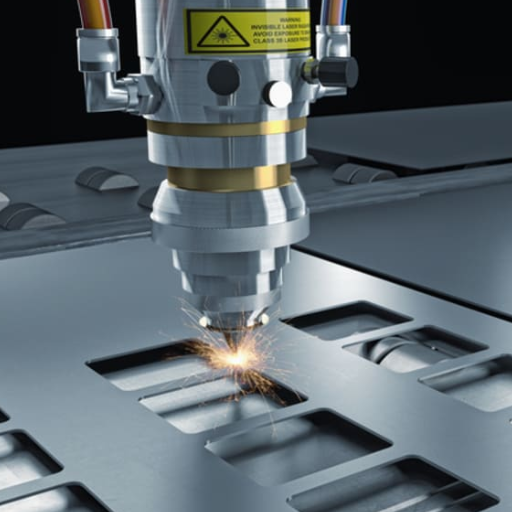

A laser cutter operates by directing a concentrated beam of light onto a material to cut, engrave, or etch precise patterns and shapes. The process begins with the laser source generating a beam, which is then intensified using mirrors and lenses to focus it onto a specific point on the material. The high-energy density at this focal point causes the material to rapidly heat, melt, vaporize, or burn away, effectively cutting into the surface. Laser cutters often rely on CNC (computer numerical control) systems to guide the beam with extreme accuracy, following pre-programmed designs or CAD files.

Modern laser cutters are capable of achieving cutting precision up to 0.001 inches (or 0.0254 millimeters), making them ideal for intricate designs. They can also reach speeds exceeding 100 inches per second, depending on the material and the complexity of the design. Different types of lasers, such as CO2, fiber, or diode lasers, are suited to different applications and materials. For example, CO2 lasers are commonly used for cutting non-metallic materials like wood or plastic, while fiber lasers excel at cutting metals like steel or aluminum.

Material thickness plays a pivotal role in the effectiveness of laser cutting. For instance, a CO2 laser with a power of 100 watts can efficiently cut through acrylic up to 0.5 inches thick or plywood up to 0.2 inches thick. Higher-power machines can tackle thicker materials, but the efficiency and finish depend on proper calibration of settings like power, speed, and focus. Additionally, many modern machines include features like air assist, which blows pressurized gas at the cutting point to reduce heat-affected zones, minimize debris, and enhance the final quality of the cut. This balance of precision, speed, and adaptability underscores why laser cutters are hailed as indispensable tools in industries ranging from manufacturing to creative design.

What types of plastic materials are suitable for laser use?

Laser cutting is an effective method for working with a variety of plastic materials, but not all plastics are safe or efficient for laser applications. Below is a detailed breakdown of common plastics suitable for laser use:

- Acrylic (PMMA): Acrylic is one of the most popular plastics for laser cutting and engraving. It is available in cast and extruded forms, with cast acrylic being preferred for engraving due to its high-quality finish. Laser cutting acrylic produces smooth edges and excellent clarity, making it ideal for signage, display cases, and decorative items.

- Polycarbonate (PC): While thin sheets of polycarbonate (under 1mm) can be laser engraved, cutting thicker sheets may result in discolored or burnt edges. Polycarbonate is generally used for specific applications where strength and durability are required, such as industrial machinery components or safety features.

- Polyester (PET/PETG): PET and PETG are widely used due to their ease of processing with lasers. PETG, in particular, offers more flexibility and durability. These plastics are often utilized for packaging, medical devices, and display fixtures.

- ABS: ABS can be laser engraved, though its cutting process requires careful monitoring as it emits a dense odor and releases particulates. It’s commonly employed in prototyping and manufacturing for items such as enclosures and housings.

- Polystyrene (PS): Polystyrene is easily cut and engraved by lasers and is often used in lightweight consumer packaging, model making, and crafting products. Thin sheets of polystyrene perform especially well in precision cuts.

What is the difference between laser cutting and laser engraving?

Laser cutting and laser engraving are two distinct processes within the realm of laser technology, each serving unique purposes and utilizing different techniques. Laser cutting involves using a high-powered laser beam to slice entirely through a material, creating parts, shapes, or patterns. This method relies on precision to separate pieces from a larger piece of material, often used in industries like manufacturing, automotive, and prototyping. Laser cutters can achieve intricate cuts on materials such as wood, acrylic, metal, and fabric, with the cutting speed and quality often influenced by the material’s thickness and type. For instance, modern CO2 lasers can efficiently cut up to 20mm in acrylic, offering high accuracy and clean edges.

On the other hand, laser engraving focuses on the surface of the material, using a laser to etch or burn a design without cutting through. This technique removes a small amount of material, leaving behind grooves or marks that visually stand out due to color or texture differences. Laser engraving is commonly employed for aesthetic or identification purposes, such as customizing products, adding serial numbers, or creating artwork. It excels in detail, with some fiber lasers capable of engraving at resolutions up to 1,000 DPI (dots per inch), allowing for exceptionally fine designs on surfaces like glass, plastic, wood, and metal.

The primary difference lies in the depth and purpose of the process — cutting fully separates a material, while engraving enhances its surface. Both methods provide unparalleled precision, but their applications depend on project requirements, material compatibility, and desired outcomes. Leveraging advancements in laser technology, both laser cutting and engraving have evolved into critical tools in modern industries, enabling faster workflows, detailed craftsmanship, and reduced material waste.

How to Choose the Right Laser Machine for Plastic?

- Compatibility with Plastic Types

Ensure the laser machine is designed to handle the specific type of plastic you plan to use, such as acrylic, polycarbonate, or ABS. Some lasers work better with certain plastic materials, providing cleaner cuts or more detailed engravings.

- Power Requirements

Choose a machine with the appropriate laser wattage. Lower power is suitable for engraving, while higher power is better for cutting thicker plastics.

- Bed Size and Machine Capacity

Consider the size of your projects. A larger bed size allows for processing larger pieces or multiple items at once, improving efficiency.

- Precision and Resolution

High precision and fine resolution are critical for detailed engravings or tight-tolerance cuts. Check the machine’s specifications to match your quality requirements.

- Ventilation and Safety Features

Laser cutting and engraving plastics can produce fumes. Select a machine with built-in ventilation or fume extraction systems for a safer working environment.

- Budget and Maintenance

Assess your budget, taking into account the initial cost and ongoing maintenance. A reliable machine with minimal upkeep will save costs in the long run.

By evaluating these factors, you can choose a laser machine suited to your specific plastic applications, ensuring efficiency and high-quality results.

What are the different types of lasers available?

Lasers come in various types, each designed for specific applications, offering unique capabilities determined by their core technology. Below are the most common types of lasers and their details:

- CO2 Lasers

CO2 lasers are widely used for applications such as cutting, engraving, and welding non-metallic materials. Known for their efficiency and versatility, they operate at a wavelength of 10.6 micrometers and are excellent for working with wood, plastics, glass, and certain types of fabrics. These lasers are capable of high precision and are used extensively in industries like manufacturing and crafting. CO2 lasers usually range in power from 25W to over 400W depending on their application.

- Fiber Lasers

Fiber lasers are among the most powerful and efficient types of lasers available. They operate at wavelengths near 1 micrometer, making them ideal for cutting and engraving metals, including stainless steel, aluminum, and brass. Their design provides high energy efficiency and low maintenance. Furthermore, fiber lasers often feature compact setups and long operational lifespans, making them a cost-effective choice for industrial usage. These lasers typically range from 20W for marking systems to several kW for heavy-duty cutting.

- Diode Lasers

Diode lasers are compact and highly adaptable, primarily used in applications such as barcoding, telecommunications, and some light-duty cutting or engraving processes. They operate across a range of wavelengths (usually between 800 and 980 nanometers) and provide precision with lower power levels, often ranging from 5W to 100W. Diode lasers are also widely used in consumer electronics and medical devices due to their affordability and reliability.

- Nd:YAG (Neodymium-Doped Yttrium Aluminum Garnet) Lasers

Nd:YAG lasers are solid-state lasers known for their high power and ability to produce intense light at a wavelength of 1.064 micrometers. These lasers are often used in manufacturing for tasks that require very high energy levels, such as deep engraving, welding metals, or drilling into hard materials. They are also employed in medical procedures like tattoo removal and certain dermatological treatments. Power levels can start at 50W and extend into the kilowatt range for industrial systems.

- Excimer Lasers

Excimer lasers use a combination of noble gases and halogens to produce ultraviolet light. Their extremely short wavelength (ranging from 193 to 351 nanometers) makes them perfect for precision applications such as micro-machining, semiconductor production, and delicate medical surgeries, including LASIK eye surgery. They are highly valued for their ability to create fine and precise patterns without thermal damage to surrounding materials.

- Green Lasers

Operating at a wavelength of 532 nanometers, green lasers are ideal for applications requiring high absorption in reflective materials like copper and gold. These lasers are often used in electronics manufacturing for tasks such as PCB marking, soldering, and in some medical fields. They provide superior control in processing fine, delicate components and are typically available in low-to-mid power ranges.

When selecting a laser, understanding the specifications, wavelength, power output, and intended material compatibility is vital to ensure optimal performance and safety for your application. Each laser type offers tailored advantages, making them indispensable tools in their respective domains.

Which laser engraver is best for plastic?

When engraving plastic, selecting the right laser engraver is essential to achieve clean, precise, and durable markings. Among the various options available, CO₂ laser engravers are widely considered the most effective choice due to their excellent compatibility with plastic materials. They operate at wavelengths (typically 10.6µm) that interact efficiently with plastics like acrylic, ABS, polycarbonate, and polyethylene, producing high-quality results.

For instance, the Glowforge Plus and Epilog Fusion Edge are popular CO₂ laser engravers commonly recommended for plastic engraving. The Glowforge Plus offers a powerful 40-watt laser and intuitive software, making it accessible for beginners and professionals alike. It can engrave designs with exceptional accuracy, such as intricate logos or text, on various plastic surfaces. On the other hand, the Epilog Fusion Edge boasts higher customization potential with options for increased wattage (ranging from 30 to 120 watts), making it suitable for industrial-scale or high-speed operations.

Additionally, the Trotec Speedy series is renowned for its precision and advanced features, like the JobControl software for managing detailed designs. With a CO₂ laser power of up to 120 watts and broad material compatibility, it’s a highly efficient option for professional use. Data from manufacturers indicates that these machines deliver engraving speeds up to 170 inches per second, ensuring time efficiency while maintaining quality.

While CO₂ lasers dominate the field, fiber lasers can also be used for certain plastics, especially engineered plastics or when creating permanent markings, such as barcodes or serial numbers. However, fiber lasers are generally less versatile and more suited for specialized needs compared to CO₂ systems.

When choosing a laser engraver for plastics, it’s crucial to consider factors such as the type of plastic, the desired engraving depth, production speed requirements, and budget. Combining these considerations with the capabilities of leading CO₂ engravers ensures optimal performance for your project’s unique needs.

How does a CO2 laser compare to a fiber laser?

CO₂ lasers and fiber lasers each offer distinct advantages, and the best choice depends on the specific application. CO₂ lasers operate at a wavelength of 10.6 microns, making them highly effective for non-metal materials such as wood, acrylic, glass, and most plastics. They provide smooth and precise engraving for these surfaces, making them ideal for industries focused on signage, packaging, or decorative designs. On the other hand, fiber lasers have a much shorter wavelength, typically around 1.06 microns, which allows for higher energy absorption in metals. This makes fiber lasers the preferred choice for engraving or marking metals, including stainless steel, aluminum, and brass, as well as some high-contrast applications on certain plastics.

A key difference is the speed and efficiency of each system. Fiber lasers generally offer faster processing times, especially when working with metals, due to their higher intensity and focused beam. For example, fiber lasers can mark metals up to three times faster than CO₂ systems in many cases. Additionally, fiber lasers tend to have lower maintenance requirements and longer operational lifespans, with the diodes lasting approximately 50,000 to 100,000 hours, compared to the average CO₂ laser tube lifespan of 20,000 to 30,000 hours.

Another consideration is cost. While the upfront cost of a CO₂ laser is usually lower, fiber lasers may provide better long-term value, especially for high-production environments where speed, durability, and minimal downtime are critical. However, if your project primarily involves non-metal materials, a CO₂ laser remains the more cost-effective and practical option.

Understanding these nuances ensures that your investment aligns with your specific material needs, production demands, and budget, maximizing efficiency and quality across applications.

What Are the Best Practices for Laser Cutting and Engraving Plastic?

- Choose the Right Type of Plastic

Not all plastics are suitable for laser processing. Materials like acrylic and polycarbonate are ideal, while PVC should be avoided due to toxic fumes.

- Optimize Laser Settings

Adjust the power, speed, and frequency of the laser to suit the specific type of plastic. Lower power settings are generally better for engraving, while cutting may require higher power.

- Ensure Proper Ventilation

Use an appropriate exhaust system to remove fumes and particles generated during the process for both safety and quality results.

- Test Before Production

Conduct small test runs on scrap material to ensure the settings produce clean cuts and precise engraving without melting or discoloration.

- Keep the Surface Clean

Clean the plastic surface before and after processing to avoid residue buildup, which can impact the quality of the cut or engraved design.

By applying these practices, you can achieve precise and efficient results while maintaining safety and quality standards.

How to achieve the best results when using a laser?

To achieve the best results when using a laser, I focus on proper preparation and machine settings. I ensure the material is clean, secure, and compatible with my laser’s capabilities. I always double-check the laser parameters, like power, speed, and focus, to match the material and desired outcome. Conducting small test runs on scrap material helps me fine-tune the settings for precision. Staying attentive throughout the process and maintaining the equipment regularly ensures consistent, high-quality results.

What safety measures should be followed during laser processing?

When it comes to safety during laser processing, I always wear appropriate protective gear, including laser safety glasses specific to the wavelength of the laser I’m using. I ensure the workspace is well-ventilated to avoid inhaling harmful fumes or particles. Keeping flammable materials away from the laser area is crucial to prevent accidental fires. I never leave the machine unattended while it’s operating and always follow the manufacturer’s safety guidelines. Regularly inspecting the equipment for any signs of damage or malfunction also helps maintain a safe working environment.

How to minimize fumes and ensure a clean cut?

To minimize fumes and ensure a clean cut, I use proper ventilation systems, such as exhaust fans or air purifiers, to efficiently remove smoke and particles. I also select appropriate materials that are safe and optimized for laser cutting, avoiding those that produce excessive toxins or residue. Adjusting the laser settings, like speed and power, helps achieve cleaner cuts while reducing unnecessary burning. Regularly cleaning the machine’s components, including lenses and filters, ensures optimal performance and minimizes buildup that can affect both safety and cut quality.

How to Select the Best Plastic for Laser Cutting and Engraving?

When selecting the best plastic for laser cutting and engraving, prioritize materials that are laser-compatible and produce clean, precise results. Acrylic is widely regarded as the top choice due to its excellent cutting and engraving qualities, as it melts cleanly and creates smooth edges. Polycarbonate, on the other hand, is not ideal, as it can discolor and release harmful fumes. Avoid plastics containing PVC or vinyl, as these emit toxic gases when lasered. Always confirm the material’s composition and opt for cast acrylic over extruded for finer engraving details and a polished finish. Safety and cleanliness should guide every selection.

What plastic parts are safe for laser use?

When selecting plastic parts for laser cutting or engraving, precise knowledge of material properties ensures both safety and high-quality results. Cast acrylic is widely regarded as one of the safest and most effective plastics for laser use. It produces clean cuts, smooth polished edges, and detailed engravings without harmful byproducts. Polyethylene and polypropylene, while less commonly used for fine engraving, are also considered safe due to their low toxicity levels when exposed to laser beams.

Thin sheets of ABS plastic can be used with caution, but they may release minor fumes, so appropriate ventilation is critical. Delrin (POM) is another suitable option for specific laser applications since it cuts cleanly and engraves well, though it can emit a slightly acrid odor during processing.

Plastics such as polycarbonate, PVC, and vinyl must be avoided entirely for laser use. Polycarbonate tends to discolor and produce a burnt, poor-quality edge, while PVC and vinyl release highly toxic chlorine gas when exposed to heat, posing significant health and environmental risks.

To ensure safety and maximize efficiency, always refer to material safety data sheets (MSDS) and verify the specific properties of the plastic before use. Selecting known safe materials backed by evidence-driven insights enhances successful outcomes while maintaining a healthy and secure working environment.

What are the properties of acrylic, polycarbonate, and pvc?

Properties of Acrylic

Acrylic, also known as polymethyl methacrylate (PMMA), is a lightweight, transparent thermoplastic material widely used as a durable glass substitute. It has excellent optical clarity, allowing for up to 92% light transmission, which surpasses even standard glass. Acrylic is highly resistant to weathering and UV radiation, making it ideal for outdoor applications as it does not yellow or degrade over time. Additionally, it is scratch-resistant but not as impact-resistant as some other plastics, such as polycarbonate. Acrylic has a density of about 1.18 g/cm³ and a melting temperature of approximately 160°C (320°F). It is easily machinable and can be thermoformed into various shapes, making it popular in signage, aquariums, lenses, and decoration industries.

Properties of Polycarbonate

Polycarbonate is a highly durable and versatile thermoplastic known for its exceptional impact resistance—it is approximately 250 times stronger than glass, making it nearly unbreakable in most applications. It has a transparency level of up to 90%, offering excellent optical clarity. Its density is around 1.2 g/cm³, and it can withstand continuous service temperatures up to 115°C (239°F). Polycarbonate also features a high degree of thermal stability and fire resistance, often rated as self-extinguishing. Despite its toughness, it is lightweight and can be easily cut, drilled, or thermoformed without cracking. Common uses of polycarbonate include safety goggles, lighting fixtures, bulletproof windows, and roofing panels.

Properties of PVC

Polyvinyl chloride (PVC) is one of the most widely manufactured and versatile plastics available today. It exists in two main forms—rigid and flexible—each with distinct characteristics. Rigid PVC is known for its high tensile strength and durability, boasting a density of approximately 1.4 g/cm³. It has a maximum service temperature of around 60°C (140°F), making it suitable for pipes, construction materials, and window frames. Flexible PVC, on the other hand, is made softer and more malleable through the addition of plasticizers, making it ideal for wiring insulation, medical tubing, and flooring. PVC is chemically resistant to acids, alkalis, and many solvents, adding to its utility across various industries. However, it is important to note that processing or heating PVC can release harmful substances, emphasizing the need for proper handling measures.

How does polyethylene and polypropylene perform under a laser beam?

When exposed to a laser beam, both polyethylene (PE) and polypropylene (PP) demonstrate distinct behaviors due to their material properties. Polyethylene, particularly low-density polyethylene (LDPE), tends to absorb laser energy at specific wavelengths like those from a CO2 laser, making it suitable for laser engraving or cutting. It melts and vaporizes with relative ease, leaving behind a smooth edge, although excessive energy can lead to charring or deformation.

Polypropylene also responds effectively to laser processing but often requires finely tuned laser parameters. Its semi-crystalline structure allows it to withstand higher temperatures than polyethylene, making it resistant to deformation under laser exposure. PP is commonly used for marking applications due to its capability to produce high-contrast, precise engravings when processed with fiber or UV lasers.

Data from industrial applications highlight that a CO2 laser operating at a wavelength of around 10.6 micrometers can cut both materials effectively at rates dependent on thickness — for instance, cutting 1mm thick PE or PP at speeds ranging from 10 to 50 mm/s. Despite these capabilities, laser processing may pose challenges, such as potential melting during high-intensity exposure, requiring accurate power and speed adjustments for optimal outcomes.

What are Common Challenges and Solutions in Plastic Laser Cutting?

- Melting or Burning of Edges

-

-

- Challenge: Excessive heat from the laser can cause plastics to melt or burn, leading to rough edges and distortions.

- Solution: Use precise power settings and adjust cutting speed to minimize heat exposure. Employ cooling methods, such as air assist, to reduce localized heating.

-

- Fume Generation

-

-

- Challenge: Cutting plastics can release harmful fumes that may pose health risks and damage equipment.

- Solution: Operate in a well-ventilated environment and use an appropriate fume extraction system to ensure safety.

-

- Material Variability

-

-

- Challenge: Different types of plastics, like PE or PP, may react differently to laser cutting, affecting the quality and consistency of results.

- Solution: Test laser settings on sample materials beforehand to determine optimal parameters for each plastic type.

-

- Alignment and Precision Issues

-

-

- Challenge: Slight misalignment can lead to inaccuracies in cuts.

- Solution: Regularly calibrate the laser system and ensure proper placement of the material on the cutting bed.

-

By addressing these challenges with tailored solutions, the efficiency and quality of plastic laser cutting can be significantly improved.

How to prevent melting and achieve clean edges?

When working with plastic materials during laser cutting, minimizing melting is crucial for achieving clean, professional-quality edges. Here are several strategies and techniques backed by modern practices and industry insights:

- Optimize Laser Power and Speed

Using the correct balance of laser power and cutting speed ensures cleaner cuts with minimal heat impact. High power at slower speeds often causes excessive heat buildup, leading to melting. Instead, lower power settings combined with higher speeds allow the laser to cut through the material without overheating. For instance, when cutting acrylic sheets, a power setting of approximately 40-60% coupled with a speed that matches the material thickness typically yields optimal results.

- Use Advanced Cooling Methods

Implementing air assist systems effectively prevents excessive heat and reduces melting. An air assist nozzle directs compressed air onto the cutting area, dissipating heat and sweeping away debris. Studies show that setups with active cooling systems can lead to up to a 20% improvement in edge smoothness, further enhancing the cutting results.

- Select Proper Focal Length and Position

Ensuring the laser beam is properly focused at or slightly below the surface of the material optimizes precision. A misaligned focus can spread heat unevenly, risking melted edges. Using a focal lens with a suitable distance, often around 1.5 to 2 inches for thin plastics, provides better control and sharper cuts.

- Work with Suitable Plastic Grades and Thicknesses

Different plastics react uniquely to laser cutting. Materials like cast acrylic tend to produce cleaner edges compared to extruded acrylics, which are prone to melting. Additionally, thinner plastics (under 5mm) typically achieve smoother edges due to reduced heat absorption. Always refer to material specifications to determine their compatibility with laser cutting.

- Perform Regular Maintenance

Clean and properly maintained laser equipment is vital for achieving precision cuts. Residue build-up on laser lenses or mirrors can scatter the beam and increase heat production, leading to irregular cuts. Regularly inspecting and cleaning optics ensures consistent performance.

By employing these techniques and understanding the unique properties of plastics, laser cutting projects can achieve cleaner edges, reduced melting, and overall superior results, elevating both the efficiency and quality of the final product.

What are the effects of wavelength on different plastic sheets?

When it comes to laser processing of plastic sheets, the wavelength of the laser plays a critical role in determining absorption, precision, and material compatibility. Different plastics have varying absorption rates depending on the laser’s wavelength. For instance, CO2 lasers operating at a wavelength of 10.6 µm are highly effective for cutting and engraving most thermoplastics such as acrylic (PMMA) and polycarbonate, as these materials readily absorb infrared radiation. This absorption leads to efficient melting and vaporization, which ensures clean cuts and smooth finishes.

On the other hand, fiber lasers with shorter wavelengths, such as 1.06 µm, demonstrate optimized performance for materials like polyimide and other specialty plastics. These wavelengths often penetrate deeper into denser plastics, but they can cause discoloration or charring in materials with low absorption thresholds. A notable example is polyethylene, which can exhibit unwanted thermal effects under certain wavelengths if not precisely controlled.

Ultra-short wavelength lasers, such as ultraviolet (355 nm), are ideal for applications requiring minimal thermal impact, such as processing thin or transparent plastics like PET. Due to their higher photon energy, UV lasers achieve cold ablation, reducing heat-affected zones and preventing warping or damage to delicate materials.

Studies indicate that selecting the appropriate wavelength can influence energy efficiency and cut quality significantly. For example, acrylic exhibits more efficient energy absorption with CO2 lasers, achieving smooth edges, while fiber lasers may lead to surface imperfections. Recognizing these interactions enables manufacturers to optimize their process for every material type, elevating both precision and productivity in laser-cutting applications.

How to troubleshoot issues with engraving machine?

- Check Power and Connections

Ensure the machine is properly plugged in and the power supply is stable. Inspect all cables and connections for damage or loose fittings.

- Verify Material Compatibility

Confirm that the material being engraved is suitable for the machine. Some materials may require specific settings or may not be compatible at all.

- Inspect the Laser Lens

Clean the laser lens if it appears dirty or obstructed, as debris can affect precision and engraving quality.

- Review Software Settings

Double-check the engraving design settings in the software, including power, speed, and resolution. Incorrect settings can lead to poor results.

- Test and Calibrate the Machine

Run a test engraving on a scrap material to identify any inconsistencies. Calibrate the machine if needed to ensure alignment and accuracy.

- Monitor Cooling Systems

If the machine has a cooling system, verify that it is functioning properly to prevent overheating during operation.

- Consult the User Manual

Refer to the manufacturer’s troubleshooting guide for specific error codes or recommended solutions tailored to your machine model.

- Seek Professional Assistance

If the issue persists, contact the manufacturer or a professional technician for support to avoid causing further damage.

Reference Sources

-

An Overview Study on Laser Technology and Applications1:

- Focus: Explores the use of laser technology in various industries, including plastic cutting and engraving.

- Key Findings: Laser cutting offers high precision, smooth surfaces, and the ability to handle complex designs. It is effective for materials like acrylic and other plastics, providing clean cuts and intricate engravings.

- Methodology: Overview of laser applications, principles, and benefits in industrial settings.

-

Laser Beam Drilling and Cutting of PMMA2:

- Focus: Investigates the effects of CO2 laser cutting on polymethyl methacrylate (PMMA).

- Key Findings: Laser cutting of PMMA results in minimal surface roughness and preserves optical properties. Thermal imaging and simulations were used to analyze heat distribution and surface effects.

- Methodology: Experimental cutting of PMMA with CO2 lasers, roughness measurements, and thermal imaging.

-

Research and Development of Laser Engraving and Cutting Machine from 3D Printer5:

- Focus: Adapts 3D printers for laser engraving and cutting applications.

- Key Findings: Modified 3D printers can effectively engrave and cut thin plastics like acrylic. The study highlights the importance of proper cooling, safety measures, and firmware adjustments for optimal performance.

- Methodology: Design and testing of a 3D printer modified with a laser module for engraving and cutting.

- Top Laser Engraving and Cutting Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What types of plastic can be laser cut?

A: Various types of plastics can be laser cut, including acrylic, polyester, and other polymers. These materials are ideal for laser applications due to their high impact resistance and versatility in creating custom plastic products.

Q: Is laser engraving plastic safe?

A: Yes, laser engraving plastic is generally safe when appropriate safety measures are followed. However, some plastics may release toxic fumes when engraved, so it’s important to use proper ventilation and protective equipment.

Q: What is the best laser engraver for plastic?

A: The best laser engraver for plastic depends on your specific needs. Generally, CO2 laser systems are popular for their precision and efficiency in engraving and cutting a wide range of plastic products.

Q: How does a laser cutting service work for custom plastic projects?

A: A laser cutting service uses advanced laser systems to cut custom designs from plastic sheets. The process involves inputting a design into the laser system, which then follows the path of the laser to accurately engrave and cut the plastic material.

Q: Can a diode laser be used to cut plastic?

A: While diode lasers can be used to cut certain types of plastic, they are generally more suitable for engraving due to their lower power compared to CO2 lasers, which are better suited for cutting thicker materials.

Q: What is the advantage of using laser engraving and cutting for plastic?

A: Laser engraving and cutting offer high precision, speed, and versatility. They allow for intricate designs and patterns on plastic products without physical contact, reducing wear and tear on the materials.

Q: Why is acrylic sheet popular for laser cutting?

A: Acrylic sheet is popular for laser cutting due to its clarity, durability, and high thermal conductivity. It allows for clean cuts and detailed engravings, making it suitable for a range of applications from signage to decorative pieces.

Q: What should I consider when choosing plastic for laser cutting?

A: When choosing plastic for laser cutting, consider factors such as the material’s thickness, thermal conductivity, and whether it releases toxic fumes when cut. It’s important to select plastics that are suitable for laser cutting to ensure quality results.

Q: How does laser marking differ from laser engraving plastic?

A: Laser marking alters the surface of the plastic without cutting into it, often used for adding logos or serial numbers. Laser engraving plastic involves removing material to create a design, offering more depth and contrast.

Q: What are the environmental considerations of using a laser to cut plastic?

A: Environmental considerations include the potential release of harmful fumes and the energy consumption of the laser system. Proper ventilation and energy-efficient machines can help mitigate these concerns while ensuring safe and effective plastic cutting.

- CO2 laser marking machine and fiber laser

- The Ultimate Guide to Laser Surface Cleaning Safety: Protecting Yourself While Using a Laser Cleaner

- Pulse vs Beam vs Burst Lasers: Continuous Weapon Comparison?

- Laser Marking vs. Engraving vs. Etching: Understanding the Key Differences and Applications

- Complete Guide: ATC vs MTC – Understanding Automatic Temperature Compensation and Manual Controls

- Learn the Main Distinctions: CNC Engraving and Laser Engraving

- Unlocking the Power of Laser Cleaning for Glass Surfaces: Revolutionary Mould Cleaning Technology

- Discover the Versatility of a CO2 Laser: What It Can Cut, Etch, or Mark?