From design to fabrication, industries have greatly benefited from the technologies brought by laser cutting. Powerful and precise is the technology, and regardless of whether you practice engineering, crafting, or even industrial production, you can put into practice the most intricate ideas to life. But what makes laser cutting so different and how can you make the most of its abilities? In this blog post, we will dig deeper into the workings of laser cutting, from how it works to its applications in various industries. Prepare yourself to explore the undiscovered possibilities and get helpful knowledge that will make your projects even more advanced.

What is Laser Cutting and How Does it Work?

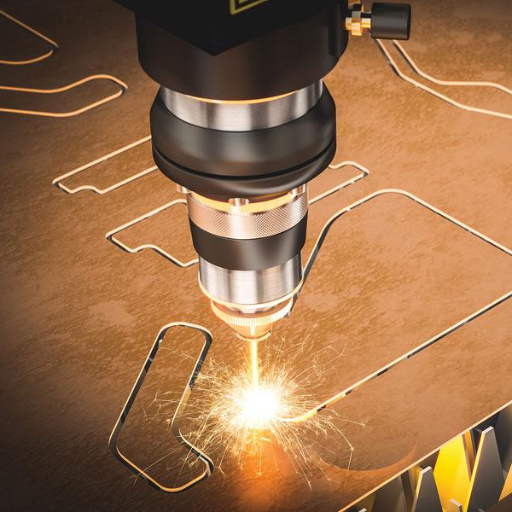

Laser cutting is regarded as one of the most precise laser machining processes because it can cut, engrave, or shape materials with an outstanding degree of precision through a focused laser beam. The laser can be set to a specific power which determines the degree of heat it produces. Excessive heat will melt, burn, or vaporize the material to produce razor clean cuts. Laser cutting processes are governed by a computer, which provides unparalleled accuracy and precision. Its effectiveness and ease of use with various materials such as metal, wood, plastic and even fabric makes laser cutting an invaluable resource in many sectors including manufacturing, design and engineering.

Understanding the laser cutting process

Combination of technology and energy, as well as high precision, works hand in hand to achieve laser cutting. The entire process starts with a CAD file that specifies the cuts or engravings to be made for a particular design. After this step, a laser cutting machine equipped with a focused laser beam receives the design information. The laser, set to the burning range, is then focused on the material’s surface. The heat melt, burn or vaporize the area of contact with the material. Different types of materials have different requirements considering the laser’s focus. Control of the process leads to less waste, cleanliness, and high quality bordering any level of design. Moreover, laser power and speed are adjustable per material.

Essential Parts of a Laser Cutter and Cutting Machine

- Laser Source – This is the part of the machine that matters most. The laser source produces the high-power laser beam that cuts or engraves the selected material. It can be CO2 lasers, fiber lasers, or diode lasers as each one has it’s specific use.

- Beam Delivery System – This system is made of mirrors and lenses which capture and burn the laser beam onto the material’s surface. The focal point of beam delivery system must be well aligned to enhance precision.

- Work Table – The work table can also be known as the lower fixture which keeps the work piece stable during cutting or engraving operations. It is sometimes configured to eliminate bounce for a better airflow in debris removal.

- Controller – The controller is the heart of the machine and users will upload design files and topics through it. The machine parameters like the cooling cylinder energy rating, shaft rotation speed, and resolution are adjustable so the set values will be fulfilled.

- Exhaust System – This works as an air cleanser. An exhaust or ventilation system supplies air, smoke, dust and anything else that hinders vision in the cutting area through a clean view window.

- Cooling System – The cooling system preserves the operational efficiency and life span of the machine by preventing overheating of the laser source and other components.

Principles Behind Laser Cutting Work

In layman’s terms, laser cutting utilizes a high-powered laser beam to sever materials by melting, burning, or vaporizing them. The beam is focused through optical components and mechanically directed by a CNC (Computer Numerical Control) system to guarantee precision. With the aid of an assist gas, the intense heat produced by the laser and the vaporized material are expelled, enhancing the speed and efficiency of the cutting. The effectiveness of laser cutting on different materials stems from the combination of precision and energy.

Different Types of Lasers Used in Cutting

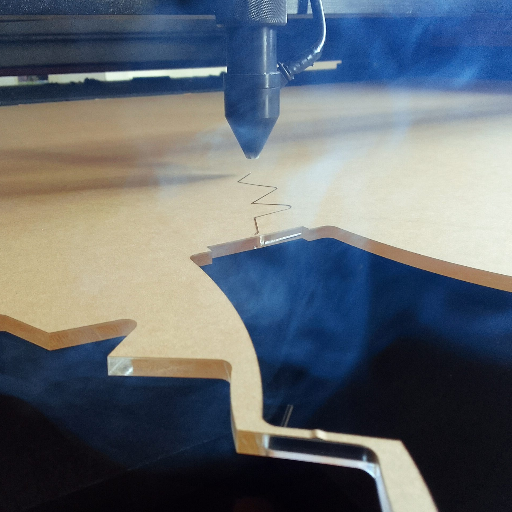

- CO2 Lasers: These tend to be effective in cutting non-metal materials such as wood, plastic and acrylic because they are cost efficient.

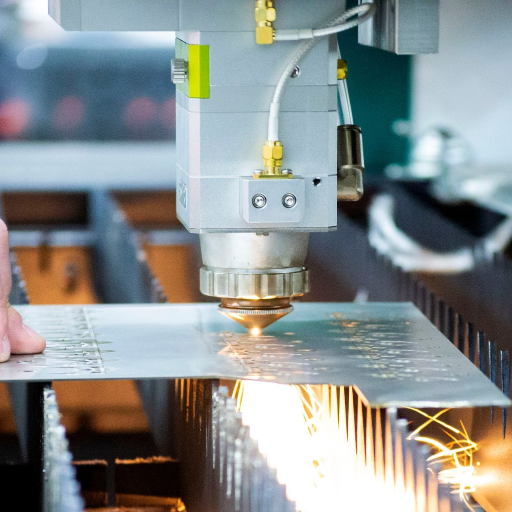

- Fiber Lasers: These are very useful for cutting metals such as steel, aluminum and brass with great speed and precision.

- Nd:YAG Lasers: Mostly used for tasks that need a lot of power and precision such as cutting thick metals or detailed patterns.

Exploring Fiber Lasers and Their Applications

Fiber lasers have one of the most extensive sets of applications when it comes to laser cutting. They can cut most metals, including stainless steel, aluminum, brass and copper. The most notable strength of fiber lasers is the accuracy and quality of cuts provided, even on complex patterns. Moreover, their speed is faster than other types of lasers which is advantageous for industrial usage. Due to the low upkeep and energy needed, fiber lasers are primarily used in industries like aerospace, automobile, and electronics due to the need for accuracy and dependability.

Benefits of Solid-State Laser

Solid-state lasers set themselves apart from other lasers by using crystal or glass as the solid gain medium. They are able to achieve excellent beam quality which is unparalleled, and beam stability as they are used in precision demanding tasks such as medical surgeries, scientific research and micro-machining. The fact that they are able to accomplish remarkable work with precision makes them well suited for medical.

Solid-state lasers are known for their energy efficiency when it comes to the energy conversion rates, and their energy efficiency in comparison to gas or dye lasers is remarkable as well. A great example are the new Released, the diode-pumped solid-state lasers (DPSSLs), which in some configurations are achieving output efficiencies of 35 to 45 percent, which is a lot compared to traditional gas lasers which sit at 10 to 15 percent. Traditional lasers will spend a lot more energy and operational cost, whilst the environmentally friendly option would lie with solid-state lasers.

An area where solid-state lasers are also industry dominating is their compact design and reliability. The reliability of the solid-state systems lies in their low mechanical wear combined with lack of maintenance, which is a notable advantage thanks to the sturdy solid gain mediums. Super low maintenance makes them great for precision industries such as semiconductor manufacturing which care about product quality.

The versatility of solid-state lasers stems from how they can be configured to emit different wavelengths based on the type of dopant used. Nd:YAG lasers emit at 1064 nm, ideal for materials like metals and ceramics, and Ti:Sapphire lasers offer tunable outputs from 650 to 1100 nm making them ideal for a variety of scientific applications. These characteristics demonstrate adaptability to serve differing needs.

As a whole, the ease of use coupled with advancements in the laser technology and materials science have propelled the use of solid-state lasers in honing precision and accuracy across different industries, solidifying their position as the go to option in dealing with multifaceted industrial and research tasks.

The Benefits of Pulse Lasers for Precise Cutting Tasks

The introduction of pulse lasers to the industrial ecosystem has allowed for an unprecedented level of precision and accuracy when executing cuts, and this technology continues to delve into new territory. Out of all the options in pulse lasers, pulse ones are far superior with high efficiency. Different from continuous wave lasers, pulse lasers emit short bursts of light and high energy, which help in providing superior cutting control. This cuts down any material-related thermal harm, which is beneficial in fields such as polymers, semiconductors, and composites, making them perfect for any heat-sensitive or delicate operations.

The latest innovations in pulse laser technologies have improved the processing streaks of manufacturers by increasing productivity and reducing downtime. For example, ultra-short pulse lasers, including femtosecond and picosecond lasers, can cut materials into micrometer scales with minimal deformation of the material. A study conducted in 2023 showed that femtosecond lasers are capable of processing materials at 200 mm/s velocity, and achieve exceptional edge quality. This surpasses other methods in microelectronics and medical device fabrication.

Pulse lasers have proven to consume less energy compared to other systems. Their precision targeting minimizes energy waste, which is customary in old systems. This feature not only reduces the cost of operations, but meets the increased need for green manufacturing solutions. These advancements make pulse lasers essential for providing the required sharp detail and smooth surface finishes needed for advanced engineering applications.

What Materials Can Be Laser Cut?

Laser cutting is applicable to an array of materials which include metals, plastics, wood, glass and even textiles. Commonly used metals are steel, aluminum, and stainless steel, while plastics such as acrylic or polycarbonate also work well. In addition, materials like plywood, MDF and some ceramics can also be laser cut depending on their composition. It is this versatility that makes laser cutting so popular across industries.

Plastics and metals as common materials

Due to its precision and adaptability, laser cutting works with an extensive range of materials. Metals like aluminum, stainless steel and steel are commonly used in industries due to their durability and strength. Similarly, plastics like acrylic and polycarbonate are preferred for signs and displays as well as creative projects because of the smooth edges achieved after cutting. Wooden materials such as plywood and MDF can also be laser cut which makes them ideal for furniture, crafts, and architectural models. Moreover, glass and certain textiles are often used in decorative or customized designs and some ceramics and composite materials are also possible to laser cut with certain settings. The effectiveness of laser cutting is further enhanced by its compatibility with such a diverse range of material types.

Factors Influencing Laser Cutting of Thicker Materials

In laser cutting of thicker materials, a combination of factors such as the composition of the material, machine settings, and laser power must be balanced. For materials such as steel, aluminum, or dense composites, high-power lasers are required, 1000W to over 10,000W, depending on the thickness of the material. For instance, a 4,000W laser can cut carbon steel sheets up to 20mm thick, while more powerful systems can tackle even greater thicknesses.

Cutting quality greatly improves with the use of proper assist gases like oxygen, nitrogen, or air. These also enhance the seamless removal of dross, cuts, and smoothens edges. Oxygen is best used for carbon steel, while nitrogen serves better on stainless steel and aluminum to prevent oxidation. Other equally important parameters include cutting speed, focus position, and kerf width. All must be optimized because thinner or thicker kerfs impact cut accuracy.

Recent developments, like beam shaping and automated focus changes, allow processing of thicker materials. Research and industry studies indicate that new lasers, along with modern cooling systems, are able to cut up to 50mm thick materials with tremendous precision, satisfying the requirements of heavy industry and construction. In general, these features strengthen the efficiency of lasers when dealing with difficult and tough materials.

Benefits of Laser Cutting Different Materials

Cost efficiency is one of the primary benefits of laser cutting as it fulfills the needs of numerous industries. The most popular benefit of laser cutting is its accuracy. Laser technology allows for high precision cutting of metals, plastics, wood, and ceramics. The waste of raw material and operations is done to a minimum. The disadvantage of tools wearing quickly, with the reduced need for contact, is negated which in turn saves on maintenance costs. In addition, as previously mentioned, contact with the cutting tools is not required and reduces maintenance costs. Due to the speed of laser operations, productivity is increased while time lines for production are lowered. Different materials and thicknesses can be catered to due to customizable changing settings including the beam intensity and focus. It is easy to see why lasers are becoming the most trusted and efficient solution for other industrial requirements needed across the globe.

How to Optimize Laser Cutting Performance?

- Choose Accurate Laser Settings: Adjust the power (W), speed (mm/s), and focus according to the type of material (and its thickness). “Calibration” or setting the machine properly, prevents clean cuts and waste.

- Regular Charge of the Optics: Cleaning lenses and mirrors off regularly improves beam strength and avoids interruption.

- Material Quality: When a specific standard is kept on the material used, the amount of changes is erradicating during the cut thus improving precision.

- Equipment Control: Having the equipment serviced at least once a month assures precision and reduced functional problems of the equipment.

- Use A Cutting Software: Dedicated computer software can allow more control. Effective drones have been developed to control machines and maximize with cutting.

The relevance of the thickness of the material and kerf

For laser cutting, material thickness and kerf width are very delicate defining features. Kerf is defined as the width of the cut of the material in this case laser cutting. The laser power and speed significantly affects kerf, along with other factors such as material properties. Out of a number of examples, one of them is simpler. In the case of smaller materials, the requirement is to have a lower laser power, however, the setting for the cutter must guarantee minor kerf. The opposite is true for three materials, the power must go up, and the pace down.

Attention to detail is crucial when it comes to considering material thickness. Scientific research claims that for cutting work on stainless steel or aluminum, a thickness of less than 0.2 inches yields faster processing results. However, handling materials which are thicker than 0.5 inches require meticulous control of power and speed to avoid overheating, burrs or edge damage. These systems are often characterized by real-time monitoring devices, adaptive technologies, and precision controls.

Accurate data enhancing software for simulating kerf width ensure improved results. Businesses have reported an 18-25% reduction in material waste as a result of material usage optimization through nesting algorithms advanced mapping tools, while achieving optimal cutting precision. That is why a clear understanding of material thickness and kerf is essential in the applications of industrial lasers.

How Laser Power and Speed are Set for Precision Cuts

Achieving precision in cutting with a laser requires meticulous adjustment of laser power and cutting speed relative to the material’s type and thickness. Typically, thinner parts only require lower laser power while thicker materials lasers require more power due to their higher thickness. Deformation and burning can also occur during cutting if the required laser power is not properly adjusted. Cutting speeds must also be modified, faster cutting speeds may lower the extent of heat-affected areas however the quality of edges will be poor while slower speeds will improve the quality of edges. Operators can evaluate the outcomes of the test cuts and adjust the precision parameters for the optimal set point, high repeatability, and accuracy.

What Affects Efficiency in Vector Cutting

Fortunately, for achieving optimal results in vector cutting there are many other aspects to consider beyond just the primary parameters of speed and power. One very significant has to do with the type of material. For instance, wood and acrylic usually have a moderate range of power and speed that will cut them neatly while metals will require significantly higher power.

Furthermore, the selection of the lens’s focal length can affect the precision and quality of the cuts. Shorter focal lengths are best for fine details and longer ones are better for thicker materials because of their deeper focus. Some experiments show that using a 2.5-inch focal length lens increases cutting depth by 30% compared to using a lens with 1.5 inch focal length for the thicker mediums.

One important consideration is the use of air assist systems. Air Assist speeds up the flow of gas to the cut surface, which aids in cooling the material, decreasing the chance of burning, and removing chips from the cut area. Studies indicate that air assist improves edge quality and reduces time spent cutting by as much as 20%, making it a necessary accessory for precise workflows.

Lastly, optimal performance over time depends on the regular upkeep of the laser system which includes cleaning the lenses and mirrors, and calibrating the laser beam. Skipping maintenance can reduce efficiency in cutting by 15% which demonstrates why it is important in professional vector cutting operations.

The Advantages of Laser Cutting Over Other Methods

In various Laser cutting is well known as a preferred option in various industries due to the advantages it offers over other forms of cutting. Its unparalleled precision minimizes material waste because complex patterns and precise cuts can be achieved. Since it is a non-contact process, the edges are clean and the possibility of material damage is minimal. In addition to these factors, laser cutting is also highly flexible as it can be employed on different types of materials such as metals, plastics, wood, and fabric. Whether it is bulk production or custom projects, its speed and efficiency is fitting for both.

Advantages of High Speed Cutting and Precision

Various industries have different needs, and the requirements for high precision and speed make laser cutting an industry favorite. Depending on the material and its thickness, modern laser cutting machines can achieve incredibly cutting speeds e.g. 30 meters in a minute. This means that production time can be greatly reduced without making sacrifices to accuracy. A great example is the CO2 and fiber lasers capable of cutting materials with tolerances as tight as ±0.1 mm. These kinds of performance guarantee intricate designs and detailed finishes.

Laser technology has thoroughly optimized the process to improve the laser cutting system. For instance, fiber lasers have now included beam quality improvements that increase accuracy and allow the cutting of thin and highly reflective materials like aluminum and stainless steel. This flexibility amplifies value in the automotive, aerospace, and electronics precision engineering industries. Also, with automated systems integrated into the process, workflows are more streamlined, which lowers human error and increases operational efficiency.

The combination of cutting speed with precision not only guarantees the quality but reduces the amount of materials that would otherwise have been wasted. Studies show that compared with traditional methods, laser cutting systems increase material utilization by up to 15%, making it a more sustainable option. These attributes is why laser cutting is a manufacturing key.

How Laser Cutters Can Also Engrave and Vaporize

Besides a laser cutter’s exemplary cutting capabilities, it can also engrave and vaporize with outstanding precision. Laser engraving is performed by focusing a laser beam of high power onto the surface of a material, thereby removing several layers to create markings or designs intricate in nature. Increasing the speed, focus, or intensity of the laser results in engraving of greater depth and detail. Such versatility makes laser engraving suitable for everything from intricate crafts to industrial marking.

On the other hand, vaporization is a process that occurs when enough laser energy is absorbed by a material, causing it to convert directly from solid or liquid state into vapor. This is common in industries that require extreme precision, such as microelectronics, where material removal has to be done at a microscale. A study mentions that the efficiency of laser vaporization highly depends on the thermal conductivity, absorption rate of the material, and laser wavelength used. For example, CO2 and fiber lasers are often employed for vaporization due to their compatibility with a wide array of materials like metals, glass, and polymers.

The most recent figures show that laser technology has improved the marking speed and energy use by 20 percent within the last five years. These advancements have lowered the cost of operations and increased the range of materials that can be processed. This is further proof of the innovative nature of the manufacturing industry’s lasers systems.

Why Select a Laser Cutting Machine For Your Assignments

The details of a project can greatly influence the tools needed to complete it. Laser cutting machines are one of the preferred options because precision, versatility, and efficiency are guaranteed with their use. Such machines can cut through diverse materials like metals, wood, and even plastics, which provides great flexibility depending on the different laser cutting applications. The non-contact cutting technique ensures minimal material damage, resulting in superior edge definition. In addition, with the recent advances in laser technology, these machines have become increasingly user-friendly and energy-efficient which makes them suitable appliances for small-scale and industrial projects alike.

Reference sources

-

“Laser Cutting Technique: A Literature Review” (2022)1:

- Key Findings: This study reviews the application of laser cutting across various materials, including metals, plastics, and composites. It highlights the optimization of parameters like laser power, cutting speed, and gas pressure to improve cutting quality and efficiency. The research also discusses challenges like dross formation, kerf width, and surface roughness.

- Methodology: The paper evaluates experimental and theoretical studies, focusing on CO2 laser cutting and its applications in industries like automotive and medical devices. It also explores optimization techniques using software and quality management tools.

-

“Laser Cutting: A Review on the Influence of Assist Gas” (2019)2:

- Key Findings: This paper emphasizes the role of assist gas in laser cutting, particularly its impact on cutting quality and speed. It identifies challenges like shock waves and boundary layer separation and suggests new nozzle designs to enhance efficiency.

- Methodology: The study reviews aerodynamic interactions between assist gas and workpieces, using computational fluid dynamics (CFD) and experimental setups to analyze gas dynamics and molten material removal.

Frequently Asked Questions (FAQs)

Q: What is laser cutting and how does it work?

A: Laser cutting is the process of cutting materials using a laser beam. The laser cutting machine focuses the cutting laser to the surface of the material he is working on. At the surface, the heat of the laser burns the material away, thus giving a cut along the cutting path.

Q: Which materials can have a laser cut done on it?

A: A number of different materials can be cut with the use of lasers, such as: sheet metal, plastics, wood, mild steel, etc. The type of material being cut determines the particular parameters and class of laser to be used.

Q: What are the different types of laser cutters?

A: Different types of laser cutters include CO2 Lasers, Fiber Lasers and Nd:YAG Lasers. Each of these is best suited for specific materials used and the method of cutting whether it is metal cutting or cutting non-metal materials.

Q: In what ways does laser rastering differ from laser cutting?

A: In laser cutting a full depth of cut is made along a contour or path, but for laser rastering the laser head is moved to and fro to engrave an image or a pattern on the surface of the material.

Q: What is the role of the cutting head in laser cutting?

A: In a laser cutter, the cutting head is the part which focuses the laser beam on the workpiece with precise accuracy and might contain a cutting device or nozzle which help control the direction of flow of the laser and gas for circulation of the molten matter away from the cut region.

Q: How does fusion cutting differ from flame cutting in laser processing?

A: Fusion cutting is a type of cutting that applies laser energy to the material together with gas which blow heated material to remove it from the cut area while flame cutting is a method that employ an additional burning flame that cut through material and is common for cutting on thicker metals like mild steel.

Q: Can laser cutting be used for complex shapes and designs?

A: Definitely, with laser cutting techniques complex carvings and shapes can be formed on materials as the laser beam is capable of cutting detailed patterns and designs that are extremely complex without the need for other auxiliary cutting instruments.

Q: What are the differences between plasma cutting and laser cutting technologies?

A: Both laser cutting and plasma cutting serve the same purpose of cutting metals, but laser cutting is often regarded to be more accurate and preciser. Laser cutting also can cut thinner materials while plasma cutting is more suitable for thicker ones.

Q: What kind of precautions should be taken with regard to safety when using a laser cutting machine?

A: Ensuring proper ventilation for fume removal, consistent monitoring of surrounding areas for flammable materials, the wearing of laser safety glasses and following the manufacturer’s instructions are the laser machine safety precautions.

- CO2 laser marking machine and fiber laser

- Best Laser Cutter & Engraver: Wood Laser Complete Guide

- The Ultimate Guide to Choosing Your First CNC Machine for Home Workshop

- Unlocking the Power:Advantages of Pulsed Laser Technology

- Discovering the Benefits of UV Laser Marking Machines: A Comprehensive Guide

- Complete Guide to Laser Marking Machine Maintenance: Fiber & CO2 Laser

- Laser Dental Cleaning vs Traditional Methods: Revolutionizing Dentistry with Laser Teeth Cleaning

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide