Engraving and cutting a material using laser techniques stands out as a major milestone in the industry due to the utmost carefulness and efficiency required in metalworking.

Advanced instruments such as laser engraving and cutting machines enable precision for maximum speed and unrivaled flexibility in various applications, ranging from small-scale hobby programs to large-scale industrial fabrications in jewelry design. As a result, these machines have become vital in multiple fields. This guide aims to provide comprehensive laser cutting and engraving for metals with all features, benefits, and considerations crucial for seamless operation at all scales. With thorough research, every user, whether a small business owner or an industrialist, will be optimally equipped to design and unlock endless appealing designs from optimized workflows.

A laser cutting and engraving machine is essential for every metal worker seeking to maximize precision and efficiency. Thanks to the machines’ transforming technology, users can take advantage of diverse interesting possibilities.

What is a Laser Cutting and Engraving Machine?

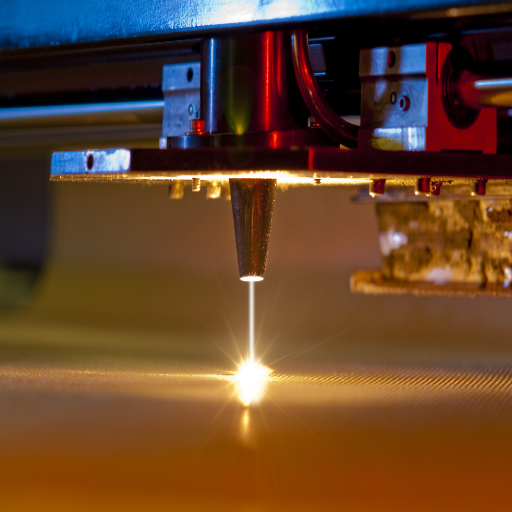

Using laser technology for engraving and cutting a material is called laser engraving or cutting. The process employs a focused beam of light known as a laser for precise and detailed cuts and can operate on various materials, including metal. The operation involves expelling intense heat using the head beam on the material to a state where the material’s surface is altered by melting, burning, or vaporizing. As with typing laser machines for cutting purposes, “laser engraving” refers to permanently marking or engraving shapes into materials, such as designs. Their precision, versatility, swiftness, and overall effectiveness make these machines helpful in industrial and creative work.

How does a Laser Engraver work?

The working principle of laser engraving devices is focusing the light beam on the surface of a material so that the marks made are accurate. The laser starts by giving off energy, which heats the material to a temperature beyond the melting point. This results in either evaporation or oxidation, thus marking it permanently. Today’s laser engraving technologies make it possible to have step-driven systems capable of executing complex and minute designs with great accuracy. These machines are frequently used simultaneously with design tendering software, allowing users to customize the patterns, logos, and text they wish to input.

The type of laser used and its power depend on the material to be engraved. CO2 lasers are the most commonly used for organic materials such as wood, leather, and acrylic. On the other hand, fiber lasers are more effective with metals and plastics. CO2 laser engravers are observed to function with a power capacity level of between twenty and thirty watts, while flexible industrial usage is claimed for fiber lasers from twenty to two hundred watts.

Analyzed data reveals laser engraving is not only quick, but also precise. For instance, modern laser engravers can cut at speeds between 1 and 2000 millimeters per second, depending on the material’s type and thickness. Moreover, the accuracy of these machines can achieve resolutions up to 1000 dots per inch (DPI). This means that even the finest details can be accurately captured. Speed and precision make laser engravers essential in many industries, including manufacturing and custom product design.

Social responsibility is equally important when performing laser engraving. Modern laser machines are built to limit power usage and contain filters to control the smoke and particles generated during engraving. These features help make these operations safer and ensure a greater degree of sustainability in engraving.

What are the different types of Laser Machines?

- Lasers for Engraving

The most common mixing gas lasers used are CO2 or carbon dioxide gas lasers. These lasers utilize a CO2 gas mixture (most notably containing carbon dioxide) to create a laser beam. These machines perform exceptionally well when engraving non-metal materials such as wood, glass, leather, and acrylic. It is commonly used in nearly all industries for cutting and carving tasks due to its accuracy and productivity.

- Fiber Laser Machines

Fiber lasers have the best industry applications when marking and engraving metals like aluminum, steel, and brass. They utilize an optical fiber to generate the laser beam. These lasers are sturdy, need little care, and are used for industrial purposes like branding, barcoding, or deep engraving applications.

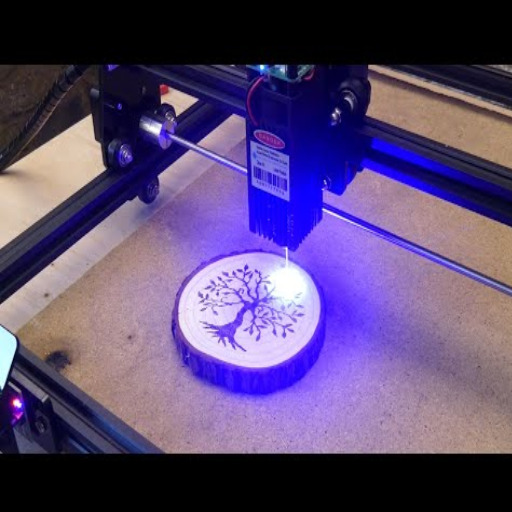

- Diode Laser Machines

Affordable and compact, diode lasers best serve small businesses and hobbyists. They can easily etch thin wood, plastics, and papers. Their portability means that beginners can use them, too.

- UV Laser Engraving Machines

Due to their short wavelength, UV lasers offer engraving results that are extremely precise and remarkably clean. Because they do not cause thermal damage, they are ideal for marking fragile materials such as glass, plastics, and medical devices. These machines are commonly used in detailed applications that require high-quality marks.

- YAG Laser Machines

YAG lasers (Yttrium Aluminum Garnet) are industrial-grade solid-state lasers popular for their use in industrial-grade applications. They are particularly effective in engraving hard metals, ceramics, and certain plastics. Most of these machines are found in manufacturing settings demanding high levels of durability and precision.

In this regard, these laser machines differ from and complement each other, with features and specialties tailored to users’ specific requirements and materials.

What are the Benefits of Using a Laser Cutter for Metal?

What makes laser cutters so effective in metal fabrication?

- Consider the benefits:

Precision and accuracy laser cutting technology is unparalleled in achieving precise cuts and complex, detailed engraving with intricate designs and deep cuts with minimal error.

Laser-clean edges: The edges created from laser cutting leave no mess, are smooth, and require almost no touch-ups to achieve completion since the focused laser yields a result that reduces post-refinement requirements.

- Speed and efficiency

Compared to many olden day methods, traditional cutting methods, carving with a laser is at the top of the list when measured over time, allowing for far greater productivity.

Versatility: Laser cutters can cut aluminum, titanium, and steel, providing amazing flexibility when it comes to undertaking new projects.

- Reduced material wastage

Due to the highly focused beam used, excess materials are removed very little, which leads to maximal efficiency when utilizing raw materials.

The above factors further strengthen the demands for higher standards and requirements within several industries, necessitating precise batched laser cuts and advanced trim technology for metal works.

Why choose a Fiber Laser over a CO2 laser?

Fiber lasers are particularly advantageous compared to CO2 lasers for metal cutting and engraving applications. Here’s why, as per the most recent research:

- Energy Efficiency

CO2 lasers are less energy efficient than fiber lasers. CO2 lasers operate within a 10-15% efficiency range, while fiber lasers enjoy 35-40% efficiency, which means less power consumption and lower operational costs over time.

- Faster Cutting Speeds

Fiber lasers have an edge over CO2 lasers as they have enhanced cutting speeds on thin metal sheets. When slicing through 1 mm-thick stainless steel, CO2 lasers take 3 times longer than fiber lasers. The extent of the speed advantage can enhance productivity and reduce turnaround times for multiple manufacturing processes.

- Lower Maintenance Costs

CO2 lasers depend on mirrors and other fragile optics which have to be constantly aligned and maintained. This also creates greater maintenance costs. Fiber lasers, on the other hand, employ solid-state technology which has fewer cumbersome components that need maintenance and has a longer service life. Industry reports state that the operational lifespan of a fiber laser source is 100,000 hours.

- Material Flexibility

Cutting aluminum, brass, and copper is easier with fiber lasers due to their short wavelengths. These materials can also damage CO2 lasers because they could redirect laser beams back into the machine. Fiber lasers do not have this issue, which gives them a greater range of fabrication applications.

- Compact Design

Compared to CO2 laser systems, fiber lasers are much smaller and easier to move. They do not need large optical and cooling systems, contributing to their compact size. This design enables fiber lasers to be placed in workshops without taking as much floor space and can be more easily integrated into preexisting production facilities.

- Environmental Impact

Compared to other forms of lasers, fiber lasers consume less energy, don’t require as much maintenance, and are overall more eco-friendly. Their efficient performance is linked to lower fumes emitted, which works towards sustainability goals.

The shift is clear: aerospace, automotive, and electronics industries are incorporating fiber lasers for their precision and efficiency. Fiber lasers technology helps reduce costs and enhances long-term performance and reliability, which is preferred over CO2 lasers.

What advantages does a Metal Laser provide?

The benefits of metal lasers appeal to industries that require lasers in their processes. Some of these benefits include the following:

- High Precision and Accuracy

Metal lasers offer high speed and superior precision. They can cut and engrave metals without noticeable errors. This is particularly beneficial for industries such as aerospace and medical device manufacturing, where highly detailed designs and tight tolerances are necessary.

- Faster Processing Speeds

Metal lasers operate at significantly higher speeds than traditional cutting methods. Traditional methods of laser cutting include CO2 lasers, which are slow, inefficient, and require extensive maintenance. This efficiency boosts productivity and reduces Processing time, which means that process throughput is much higher than before.

- Low Operating Costs

Despite their supercharged efficiency, lasers require attention to maintenance. This lowers overhead business costs, while energy and maintenance transform these devices into real money savers in the long run.

- Versatility with Various Materials

Metal lasers can process various metals, including stainless steel, aluminum, copper, and titanium. Due to this versatility, manufacturers can work across industries without much hassle.

- Minimal Material Waste

Lasers directly aligned with other forms of technology can produce clean cuts, reducing the material needed during the cutting process. This feature not only decreases business expenses but also assists companies in furthering their stance in the sustainability movement, making it easier to contribute to a greener manufacturing process.

How to Choose the Best Laser Engraver for Metal?

In choosing the best laser engraver for metal, the following factors have to be taken into account:

- Material Compatibility

Ensure the engraver handles the metals you intend to work on, such as stainless steel, aluminum, or titanium.

- Power and Precision

Engravings done on metal surfaces require sharp detail to be clear and clean. For this reason, the machine should have an intense laser with great accuracy.

- Software and Ease of Use

User-friendly software that meets your design requirements is essential, as is easy setup and operation, so check if the machine features such a design.

- Engraving Speed

Depending on project demands, select an engraver whose speed meets your production objectives for quality work.

- Durability and Build Quality

For industrial or heavy-duty use, select machines built from robust materials for reliability and endurance.

With these considerations, picking a laser engraver will be straightforward.

What features should you look for in a Laser Cutting and Engraving Machine?

These types of machines can be very complex to deal with. To understand them more, start by checking the web pages of the most downloaded paper on laser instructions. You should confirm the document’s veracity by cross-referencing URLs from Google Scholar.

- Running Diagnostic Tests:

It is critical to understand a machine’s evaluation fully before purchasing it. This includes assessing properties such as the rotation of the tool head and changes and quirks in response to servos and encoders as the machine starts moving.

- CAD Software

Every CAD drawing uses actual dimensions to keep the model close to reality and reduce mistakes that may occur while modeling.

- Bed Size And Work Area

These parameters specify the dimensions and range of movements within which the machine carries out its operations.

Beam Quality And Power Both Are Keys In Cutting and Engraving Materials

The zenith range on tools like drills and saws specifies cutting materials that could be resolutive, which is a matter of precision. In the confines of any machine, it becomes gratifying to work on projects of your sub-relevance.

- Speed and Precision

The speed of cutting and engraving ranges from as low as 500mm/s to well over 1,000mm/s, depending on the model. While operational speed is important for production efficiency, precision is equally necessary. Machines with 1,000 DPI settings and more provide detailed engravings suitable for intricate designs.

- Cooling System

An efficient cooling system is essential in protecting one’s investment, commensurate with performance and longevity, regarding the cutting and engraving machine. In this case, look for models that have built-in or external water coolers that can operate at higher wattages.

- Software Compatibility and Control Options

Adobe Illustrator, CorelDRAW, and AutoCAD are some of the design tools that modern laser systems utilize as add-ons. Ensure that the machine of choice comes with an easy-to-use control panel and a broad range of software for easy design and customization.

- Budget and Costs for Maintenance

In terms of sophistication, entry-level models cost $500, while professional ones exceed $10,000. Also consider the expenses that come beyond the initial purchase, like those for CO2 laser parts that need constant replacement, such as lenses and laser tubes. CO2 laser tubes have a lifespan of 1,000-2,000 hours depending on how they are used.

- Safety Features

Look for machines with safety walls to improve users’ overall wellness. An emergency stop button can help quake panic caused by thorough ventilation systems that lessen laser radiation.

When you understand a laser cutting and engraving machine’s features relative to your budget and project requirements, you can strategically decide how to invest in it.

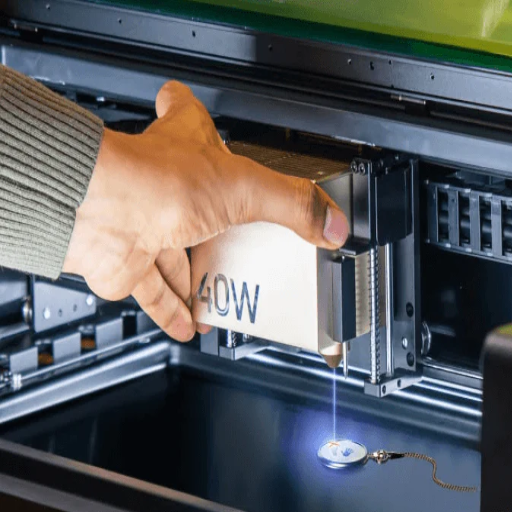

What is the importance of Laser Power?

The effectiveness, accuracy, and even the functions of a laser cutting and engraving machine is heavily based on the laser’s power. The rating, usually indicated in watts (W), determines the various types of materials the machine can process, the speed and depth of cuts or engravings, and the speed at which the processes can be carried out.

As an example, lower-powered lasers ranging between 20W and 50W are perfect for engraving more delicate materials such as wood, leather, or acrylics, as they require precision without generating much heat. Alternatively, higher-powered lasers, like 100W to 150W machines, are critical for cutting thicker or denser materials such as metals because they can have deeper cuts and faster processing speeds. Data shows that cutting through an 8mm thick acrylic sheet requires, at a minimum, 60W, while cutting steel or aluminum requires, on average, over 150W, depending on the material’s thickness.

The factors of laser power go beyond just cutting speed and depth; it also affects the quality of results. For example, if a laser is higher powered, it can reduce charring or rough edges by cutting softer materials in a single pass with a clean cut. However, higher laser power can increase the chances of burning or distorting the material if the material is thin or sensitive. This illustrates that careful selection based on the application’s requirements is critical.

These industrial machines are very complex and highly priced gadgets,” said someone trying to understand how a laser engraver works. In this approach, businesses with divergent needs try to cater to everyone without understanding the machine’s identity, functionality, and innovation. It can be concluded that when selecting the machine, balancing the laser’s power and the project intent is fundamental for performance, efficiency, and budget reasons.

How to compare different Engraving Machines?

|

Parameter |

Diode Laser |

CO2 Laser |

Fiber Laser |

UV Laser |

|---|---|---|---|---|

|

Power Output |

Low to Medium (5- 40W) |

Medium to High (40- 150W) |

High to Very High (20- 100 + W) |

Low (3- 10W) |

|

Material Range |

Wood, leather, and plastics |

Non-metals, acrylic, glass |

Metals, plastics |

Glass, ceramics, and plastics |

|

Initial Cost |

$300-$2500 |

$1500-$45,000 |

$5000-$50,000+ |

$7000-$10,000 |

|

Speed |

Moderate |

Fast |

Very fast |

Very fast |

|

Cutting Ability |

Thin materials |

Thicker non-metals |

Metals |

Limited cutting on glass |

|

Portability |

Lightweight and portable |

Fixed setup |

Generally fixed |

Compact for specific uses |

|

Maintenance Cost |

Low |

Medium |

High |

Medium |

|

Best Use Case |

Hobby, small crafts |

Businesses, versatile tasks |

Industrial metalwork |

High-precision multi-materials |

|

Engraving Precision |

Good |

Excellent |

Superior |

Exceptional |

|

Durability |

Medium |

Long-lasting laser tube |

Very sturdy, high-end |

High, low physical degradation |

How to Set Up Your Laser Engraving Machine?

- Rethink the Placement of the Machine

The machine must be positioned on a flat, stable surface, allowing good airflow to avoid overheating. The surrounding space must be sufficient for safe operation and maintenance.

- Configure Power Supply Options

A power supply is needed for operation, so the machine should be plugged into a reliable power source while maintaining adherence to the manufacturer’s voltage and safety requirements.

- Install Necessary Software

As per the above recommendations, install the supplied software by the manufacturer. Ensure the computer is up to speed with the version requirements for seamless execution during operations.

- Perform Laser Calibration

Before commencing engraving tasks, set and adjust the laser according to the guidelines provided in the user manual. This will allow you to carry out clean, precise engraving tasks, increasing efficiency.

- Test it Out

Use a sample material to test the machine. Check the engraving quality and be ready to make additional adjustments if necessary.

Consider the model’s details and possible dangerous steps related to the device’s use in the user guide.

What are the initial steps for Laser Cutting and Engraving?

- Check Material Compatibility

Verify that the material used is suitable for engraving or laser cutting. Typically suitable materials include wood, leather, acrylic, cloth, and metals. The machine specifications should also be checked to confirm that the material contains no harmful substances that can be emitted while cutting or engraving.

- Instructions on completing preparatory design tasks

Design your file using compatible software such as Adobe Illustrator, CorelDRAW, or LightBurn. Use vector graphics files and ensure etched text is bold in descriptive subclasses. Lines that are used for cutting should also be complete and unbroken. Ensure the file is in SVG, DXF, or PDF formats, as most laser machines can recognize these.

- Adjust the settings for the laser.

Set the power, speed, and frequency for the selected material and design. You can minimize the cut length for a 1/4-inch piece of acrylic to 1/4 inch by using 20mm/s with the power set at 50%, but these values are completely dependent on laser wattage, so one must do some testing to determine the optimum settings for any given material and laser system.

- Setting Up The Work Area

Position the material on the laser bed and ensure it is flat, preventing cutting or engraving issues. If needed, use clamps for added support. Furthermore, ensure that the workstation is well-ventilated and that the exhaust system is functioning correctly for smoke and fume removal.

- Changing The Focus

Depending on your machine, the laser focus can be adjusted manually or automatically. Adequate focus is critical for precision cutting and engraving without damaging the material. Some machines have focus gauges or autofocus features, while others do not.

- Preliminary Testing

Shallow cuts and engravings can be made on a small section of scrap material or along the edge of the main material. Carefully observe the results and assess them for conciseness, sharpness, depth, and consistency. Fine-tuning settings can be made as required.

- After Starting Up The Machine

Once the cutting or engraving process has been started, constant presence is needed to ensure the machine isn’t mishandled. Operators must watch out for potential issues like smoke, misalignment, or fire risks. For reference, the manual or guide that comes with the machine usually indicates the best cutting speed and power depending on the machine’s wattage.

As always, remember that laser cutting and engraving require meticulous attention to detail. Keeping track of software updates and new technological features will always provide optimal results. Proper upkeep of the machinery, along with regular safety protocol measures, makes consistent performance attainable.

What safety measures should you take while using a Laser Cutter?

- Put On Correct Safety Equipment

Wearing proper laser protective eyewear pertinent to the laser’s needs will keep your eyes safe from harm. Never look directly at the laser beam, regardless of the time duration, as it may result in severe eye damage.

- Make Sure Partitions Allow for Sufficient Ventilation

Use a well-ventilated area, as laser cutters produce gas or smoke that can be harmful to the user. Sufficient care must be taken during the laser cutting process lest you inhale harmful gases.

- Do Not Treat Hazardous Materials

Do not separate or engrave materials that produce dangerous or highly flammable substances, such as PVC or foam. Care must be exercised at all times, as materials placed beyond the machine’s material compatibility can cause severe damage to it.

- Do Not Leave The Machine Unattended

Ensure that the laser cutter is used constantly during operation. Each detail must be tended to as machines use up the power source, have excess materials fed, and even burn randomly. Leaving such a machine unattended increases millitary grade fire risks and equipment destruction.

Periodically clean all parts of the machine, such as the lens, mirrors, and other components, to ensure they function optimally and do not cause shatter faults to the user and maintainer alike. Also, take time to inspect the laser’s cooling system and ensure other safety components are at optimal performance to fully avoid overheating the device and causing breaks.

What Techniques Can Be Used for Metal Engraving?

The following are some of the most effective techniques of metal engraving:

- Laser Engraving

Laser engraving employs the use of high-powered laser beams to cut into the surface of the metal, marking it permanently. It is most useful for detailed designs and text because it is accurate and efficient.

- Etching

Etching uses a chemical solution to corrode the surface of the metal to create a design or pattern. This technique is sometimes used for more artistic, intricate engravings.

- Rotary Engraving

Rotary engraving involves carving into the metal using a spinning tool or cutter. This method is often used when engravings have to be deeper and more durable.

- CNC Engraving

CNC engraving uses machines controlled by a computer to do the engraving. The machines grant the engraving uniformly and perfectly, which saves time for complex, larger-scale designs.

Every technique is best at its intended purpose, and not one metal worker’s technique works for all materials, designs, and outcomes.

What are the differences between laser cutters and other cutting machines?

| Key Parameter | Laser Cutters | Plasma Cutting Machines | Water Jet Cutters | CNC Machines | Die Cutting Machines |

|---|---|---|---|---|---|

|

Initial Cost |

$2,000 – $200,000 |

$1,000 – $20,000 |

$70,000 – $350,000 |

$5,000 – $500,000 |

$10,000 – $150,000 |

|

Operating Cost |

Medium to high |

Low to medium |

High |

Medium to high |

Low |

|

Material Compatibility |

Metals, non-metals, plastics, ceramics |

Conductive metals only |

Metals, ceramics, composites, plastics |

Metals, plastics, wood |

Flexible sheets, thin metals |

|

Precision |

Very high |

High |

Very high |

Very high |

Medium |

|

Speed |

Fast |

Very fast |

Slow |

Fast |

Medium |

|

Maintenance |

Medium to high |

Low |

High |

Medium |

Low |

How do you engrave it on coated and bare metal?

When considering engraving on coated or bare metal types, I would choose the appropriate laser type first, either a CO2 or fiber laser, based on the material. When working with coated metal, I set the parameters to remove the coating without damaging the base metal. For bare metal, the primary concern would be no overexposure, and that the power, speed, and frequency would need to be adjusted to achieve the desired depth and clarity. Proper focus and alignment play a vital role in achieving accurate results, so testing on sample work before engraving the actual piece is something I always do.

Reference Sources

1. Design and Fabrication of Portable Laser Cutting and Engraving Machine 2:

- Key Findings: The study developed an Arduino CNC-controlled portable laser cutting and engraving machine, which is economical and ideal for small-scale industries. It can process materials such as paper, wood, and thin sheets.

- Methodology: The machine components were designed on SolidWorks, and precision control with Arduino Nano and Eleksmaker software integration was incorporated.

2. A Review: Effect of Different Laser Types on Material Engraving Process3:

- Key Findings: This review evaluated the range of engraving lasers, including CO2 lasers. The focus was primarily on the material type and the quality of engraving, and the benefits of CO2 lasers in engraving stainless steel were noted.

- Methodology: A comparative analysis of the parameters for the different lasers and the materials used was conducted.

3. Top Laser Engraving and Cutting Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a CO2 laser engraver, and how does it work?

A: A CO2 laser engraver is a marking machine that uses a CO2 laser to engrave and cut materials like wood and metal. The laser head emits a focused beam of infrared laser light that can precisely etch designs onto surfaces.

Q: Can a laser engraver cut metal?

A: Yes, a laser engraver and cutter can cut metal, depending on the machine’s power and the metal’s thickness. Metal laser engraving typically requires a higher wattage laser for effective cutting.

Q: What materials can I engrave with a desktop laser engraver?

A: A desktop laser engraver can engrave various materials, including wood, coated metal, acrylic, and some plastics. A more powerful machine, like a metal laser engraver, may be necessary for deep engraving on metal.

Q: What is the difference between a laser cutter and an engraver?

A: A laser cutter is primarily designed for cutting materials, while a laser engraver is used for engraving or marking the surface of materials. Some machines, known as laser engravers and cutters, can perform both functions.

Q: How do I maintain my laser engraving cutting machine?

A: Regular maintenance of a laser engraving cutting machine includes cleaning the lens and mirrors, checking the alignment of the laser head, and ensuring the cooling system functions correctly to prevent overheating.

Q: What is the engraving area of a laser engraver?

A: The engraving area refers to the maximum material size that the machine can process. It varies by model and is essential when choosing a laser engraver for your projects.

Q: Is a fiber laser engraver better than a CO2 laser engraver for metal engraving?

A: Fiber laser engravers are generally more efficient for marking on metal surfaces due to their higher absorption rates with metals. However, CO2 lasers can also effectively engrave coated metal and other materials.

Q: Can I use a diode laser for engraving metal?

A: Diode lasers are typically not powerful enough to engrave metal effectively. They are better suited for engraving materials like wood, while a metal laser engraver or CO2 laser machine is recommended for metal engraving.

Q: What safety precautions should I take when using a laser marking machine?

A: When using a laser marking machine, always wear appropriate safety goggles, work in a well-ventilated area, and ensure the machine has proper safety features like an emergency stop button.

Q: Can I engrave photographs with a laser engraver?

A: Yes, you can engrave photographs with a laser engraver, but the quality of the engraving will depend on the resolution of the image and the capabilities of the laser engraving machine. Proper image preparation is crucial for achieving good results.

- Discover the Power of the Mini Handheld Fiber Laser Marking Machine

- Laser Engraving Machine: Wood Laser Cutter and Engraver

- Harnessing the full potential of technology Fiber Laser: A Step by Step Guide

- CNC Router vs. CNC Mill: Key Differences Between a CNC

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide

- Unveiling the Power of Laser Cleaning: How Does It Really Work?

- Do Laser Cutting Machines Use a Lot of Electricity Understanding Power Consumption

- Mastering Pipe Cutting: The Ultimate Guide to Professional Tools and Techniques