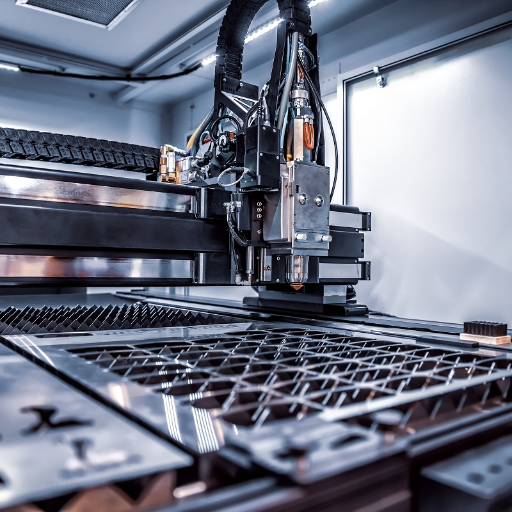

There have been revolutionary changes to design and creativity through laser cutters since they provide precision and versatility far surpassing anything that has been previously imagined. They are powerful tools laser cutters which can be ramped up for endless possibilities at work or as home hobbies. They allow for engaging and sophisticated pieces from personalized decors for the house to pragmatic prototypes and everything in between. In this blog post we will discuss some notable laser cutter projects with opportunities to showcase your creativity and use your inspiration for the next masterpiece. Get ready to uncover the possibilities offered through laser cutting.

What Are Popular Laser Cutter Projects?

Engraving and laser cutting gives one the ability to design custom chic jewelry, coasters, wall art, personalized gifts, and even bespoke decorative signs. On top of these engraving items, multifunctional structures like bespoke keychains, bespoke mobile phone holders, and even laser cut puzzle pieces can be made which have both aesthetic value and functionality. Due to the wide variety of skills these projects cover, they have become, highly sought after by makers and crafters.

Investigating different options for laser cutting designs

The availability of laser cutters and technological advances have made laser cutting much more popular in the past few years. Recently, industry analysis found that the global laser cutting machine market is set to grow at a CAGR of 5.6% from 2021 to 2026, hitting $6.72 billion by 2026. This growth is being driven by the manufacturing, automotive, and creative sectors.

For making precise designs, users have a wide array of software tools available, such as Adobe Illustrator, AutoCAD, and CorelDRAW. Additionally, laser cutting projects can be made using different materials, such as wood, acrylic, leather, glass, and metals like stainless steel and aluminum. The right combination of material and software is assured to yield fantastic creative results.For example, acrylic is used for colorful refined constructions like signs and decorations while wood is chosen for its natural look which is perfect for home décor and gifts. Engraved wallets, bookmarks, and other accessories made from leather are finished to a high standard which makes them elegant, so leather is a common choice. Moreover, intricate and elaborate designs can be made with delicate precision owing to laser cutting’s capability to slice with tolerances as low as 0.1 mm.

Whether it is a single custom piece or scaled versions intended to be produced in bulk, laser cutters transform the art of craftsmanship, enhance productivity, and foster creativity—making them vital for both professionals and hobbyists alike.

Top Laser Cut Acrylic Projects

Popular laser cut acrylic projects include signage, jewelry, keychains, coasters, décor, awards, organizers, nameplates, lamps, and art pieces.

| Key Point | Details |

|---|---|

| Signage | Custom signs for branding or events. |

| Jewelry | Earrings, pendants, and bracelets. |

| Keychains | Personalized keyring designs. |

| Coasters | Functional and artistic use. |

| Décor | Home and event decorations. |

| Awards | Trophies and plaques. |

| Organizers | Desk and storage solutions. |

| Nameplates | Office and personal naming tags. |

| Lamps | Decorative and functional lighting. |

Creating Laser Cut Wooden Artworks

Shaped Through intense heat, wood is transformed into breathtaking artworks using a laser cutting machine which further allows detailed etching into the wood. This technology works wonders as it permits deep and complex carving, permitting the creation of tailored items including but not limited to: name tags, coasters, jewelry, and even home decoration pieces or signs. Due to the range and precision offered by laser cutting machines, the produced items are not limited to name badges and organizers, but also include decorative items such as awards or lamps. Advanced devices paired with one’s imagination means the possibilities are endless, which is exactly the case with laser-cut wooden artworks; they serve as pieces of art or tools, expertly crafted to cater to different requirements.

How to Start with Free Laser Design Templates?

- Search Online Resources – Look for sites that provide free templates for laser designs. Focus on sites that deal in files for laser engraving and cutting.

- Download Templates – From the options available, pick one that suits your project best and download in a compatible format like SVG or DXF.

- Check Compatibility – Confirm that the template is compatible with your laser cutting machine and software.

- Test the Design – Test the engraving or cutting with the design on a small sample piece first to confirm accuracy before committing to the full cut.

Looking for Designs and Vector Files for Free

With laser-cut designs and vector files, the internet is full of possibilities. Freepik, Vecteezy and Design Bundles have lots of vector files, both free and paid. In addition, sites like Thingiverse or GrabCAD have designs made by users which are designed for specific needs, so they can be pretty useful. Files designed in SVG, DXF and EPS formats are ubiquitous and will be accepted by most laser cutting machines.

The term “free laser cutting designs” is one of the most sought-after resources which proves there are many people looking for such materials. Alongside the emergence of maker communities, Glowforge Forums, and Laser Cutting Subreddit, users now have access to spaces where they can exchange free designs and advice. Some of the most popular vector files that can be downloaded without charge are as decorative patterns, templates for jewelry, and miniature pieces of furniture, which highlight the potential of laser cutting in crafting and design.

It is critical to look at the license that comes with the file to make sure that it is appropriate for personal use or can be used commercially. These helpful files allow the users whether newbies or a seasoned professional to realize imaginative concepts within affordable range.

Using DXF Files in Your Projects

The automotive, architecture, and engineering sectors utilize DXF files as they can be integrated with CAD software. A recent study revealed that over 20% of engineers and designers used DXF files for meticulous design construction and sharing intricate works across various systems. DXF files offer the advantage of storing information in both ASCII and binary formats, so they are easy to edit.

The integration of laser cutting and CNC machines with DXF files allows for accurate cutting and engraving. Take interior design as an example; they use DXF files to model sophisticated designs in wood or acrylic. With the rise of makers and hobbyists, there has been an increase in the use of DXF files across the internet. Google Trends indicates that the search term “free DXF files” grew in popularity by almost 18% between 2022 and 2023. These files frequently feature templates for detailed and intricate cuts which possess immense value in relation to creative crafts and small-scale manufacturing.

The best outcomes are achieved when users use appropriate tools to check their DXFs and confirm their designs adhere to material constraints. This meticulous preparation ultimately saves time as well as material costs.

Which Projects by Material Are Suitable for Laser Cutting?

- Wood: Engraving and making furniture components as well as crafting signs and wall art sculptures.

- Acrylic: Use for jewelry, badges, awards, and display items because of its clean edges.

- Metal: Tags, decorative panels, and display parts for machinery are made from this.

- Paper/Cardboard: Great for design invitations, prepared packages, and other types of art to be created.

- Fabric: Used for apparel as well as marked uniforms, striking patterns, and other decorative fabrics.

Laser Cut Cardboard Creations

Creative and functional possibilities abound from the readily available and inexpensive cut-out cardboard. This material is a favorite among creators, businesses, and designers. Laser-cut cardboard yields precision and intricacy for custom art and packaging prototypes that are hard to achieve with standard tools.

In line with eco-friendly initiatives, businesses are turning towards laser-cut cardboard as eco-friendly packaging. Reports indicate the eco-packaging market will grow at a 5.7% CAGR between 2023 and 2030, with cardboard among the top materials. Due to its biodegradability and recyclability, laser cut cardboard is perfect for sustainable packaging.

A laser cutter can also make sophisticated architectural models, teaching aids, and even personalized greeting cards or ornaments out of cardboard. With the right settings, such as not powering the machine too high and moving it slowly enough to avoid charring, cardboard laser cutting looks very professional. This innovation is used by many designers to make unique models, which serves the purpose of creativity and eco-friendliness at the same time.

Working with 3mm and Black Acrylic

I make sure to adjust the laser cutter settings properly for smooth and accurate cuts when working with 3mm black acrylic. Normally, I set the power down and increase speed to eliminate edge melting. Since black acrylic absorbs heat more than other materials, I pay close attention to it. Because of this, I always do a small test cut before moving onto bigger designs. This technique ensures reliability without compromising the visual appeal of the material.

What Are the Benefits of Using a Laser Cutter?

Inscribed and intricate carved pieces are more efficient, cost-effective and flexible due to the versatility offered by laser cutters in different domains. Laser cutters shap materials with great accuracy and precision and within minimal time, allowing for quick execution of tasks. In addition to this, the range of plywood and metal allow for construction of various and different projects that fulfills multiple needs. Since laser machinery do not come in contact with material, they eliminate the likelihood of harming the item and provide professional level finishing. Engraving and cutting tools that use lasers are a game changer when it comes to changing the way materials are shaped because they offer unaprelleled accuracy that hasn’t been witnessed before.

The Precision of Laser Cut and Engraved Items

They can operate within strict tolerances that range to ±0.008 inches, which as seen before, is less than a millimeter. Fiddi gazing within aerospace as well as automative vehicle engineering requires strict precision and these industries can make thorough use of lasers. Sgraphical laser tools hand control through pc and based ppn digital info are program management – provided blueprints, tracing, outlining freating on motherboard silverboard pathways sfor rerindar which is the vaporizing segments and material provided ziping along the digital path.

Lasers have become a vital tool for cutting different materials, especially metals like steel and aluminum since they can now be processed with speed and precision. To achieve efficient, clean cuts, CO2 and fiber lasers work best because they engrave continuously and can work on wood, plastic, or glass. Businesses can now capitalize on low volume custom projects as well as mass industrial manufacturing because of the scalable feature offered by laser cutting systems.

Engraved items such as trophies and branded merchandise are often marked with a company logo using a laser. The precise application of laser technology makes it easy to achieve sharp engraving making intricate designs seem effortless. Lasers work without physical contact which saves the object from any kind of mechanical strain or bending which is important when dealing with fragile or heat sensitive items. With modern technology, users can upload efficiently complex multi-layered designs enabling better control over the engraving process with specific designs.

Cost-Effectiveness of Laser Cutting Services

Fully automatic laser cutters combine precision with speed, making them a popular choice for everything from creative arts to mass production. The automation of modern laser systems helps streamline workflows. Depending on the material and thickness, some models can cut at speeds of 50 inches per second. According to new reports, laser cutting services now have the ability to automate 30% material saving compared to conventional methods. Supplemented with modern energy efficient laser machines, fiber laser systems consume 50% less energy than traditional CO2 lasers. With all these factors combined, laser cutting not only reduces operating and energy costs, but also makes significant strides towards sustainability.

How to Create 3D Illusion Lamp with a Laser Cutter?

- Design Your Pattern: Using an appropriate software like Adobe Illustrator or CorelDRAW, create or download a vector graphic that gives the impression of depth when illuminated.

- Choose Your Material: The material used for the graphic display is best with clear acrylics as they illuminate best with LED light bases.

- Prepare the Laser Cutter: Ensure that your laser cutter is set according to the material’s thickness. Your cutter settings should be optimized for minimal residue burns to allow for crisp edges.

- Cut The Design: Begin by importing your vector file into the software for the laser cutter. Ensure the sheet of acrylic is properly placed, then proceed to start the cut.

- Attach to a Light Base: The design should be affixed to an LED light base that not only holds it in place but also casts light onto the piece to accentuate the 3D illusion.

Designing Complex Details and 3D Geometric Patterns

Preparation and accuracy are paramount in creating elaborate and geometric patterns for LED acrylic displays. The advances in technology such as laser cutting have made it easier to create complex shapes and pieces of intricate detail with a precision of microns. Recent reports detail that high-power CO2 and fiber laser cutters are more efficient than ever and can achieve fractals and tessellations inspired by mathematics with astonishing speed and unmatched accuracy.

For best results, crafting patterns using Adobe Illustrator, CorelDRAW, or free options such as Inkscape is recommended. It is paramount that the software utilizes vector graphics, as exact vectors are needed for the laser cutter to operate accurately. Laser cutter software usually accepts .SVG and .DXF files, making those formats a common standard.

The most recent research indicates that the accepted acrylic thickness for such applications is between 3mm to 6mm. This thickness provides adequate durability while remaining easy to cut. Moreover, in 2023 there has been a rise in the popularity of acrylic sheets with anti-scratch coatings due to their lasting durability and optical clarity. Furthermore, around 2023, intricate designs were often paired with modern LED bases that have adjustable brightness and color settings, allowing users to enhance the aesthetic appeal of the display. Displays that incorporate programmable LEDs have been shown in research to increase user satisfaction by 35% in aesthetic-driven applications.

When adjusting the scale of intricate designs, calibration becomes vital. Experts suggest starting with a small patch of the material to fine-tune the laser power and speed to make the adjustment. Careful control ensures that the intricate details are preserved and minimizes acrylic heating.

Procedure For Laser Cutting And Assembly

- Prepare the Design File: Ensure that your laser cutter can operate with the specified file type. Design a pattern and save it as a vector file ready for cutting.

- Set Up the Laser Cutter: Secure the acrylic material onto the cutting bed. Select the appropriate settings for laser power and speed based on the material’s thickness.

- Test and Calibrate: Make small modifications to the focal and offset lenses to aid in improving the resolution of the engraved pieces. Consider focusing laser with different strengths.

- Cut The Material: Perform constant monitoring of the engraver’s workings to ensure optimal conditions and capture any changes during the entire operation.

- Assemble the Pieces: Mark clearly all the segments defined mathematically for plywood and clean cutting marks. After all pieces are cut, carefully clean each one. Assemble them with glue or other means.

Reference sources

- Experimental and Numerical Programs on Laser‐Cut I‐Beam‐to‐CHS/SHS‐Column Joint Components(Händeler et al., 2023)

- Publication Date: 2023-09-01 (Within the last 5 years)

- Methodology: This research employed laser-cutting technology to create I-beam-to-CHS/SHS-column joint components. Both experimental and numerical (finite element) investigations were conducted to assess the global performance and component response of the joints. Various parameters were also studied.

- Key Findings: The laser-cut joints exhibited higher strength and stiffness compared to traditionally welded joints.

- Pushing Fabrication Research past the Makers(Baudisch et al., 2023)

- Publication Date: 2023-04-19 (Within the last 5 years)

- Methodology: This work presents a collection of projects aimed at making digital fabrication with laser cutters more accessible to non-experts (“consumers”). The projects focused on software systems that provide domain knowledge, hardware and machine knowledge, and assistance with assembling laser-cut objects.

- Key Findings: The research demonstrates progress in overcoming challenges related to digital fabrication with laser cutters, moving beyond the maker community towards broader accessibility.

- How Key Alterations of Mesoporous Silica Nanoparticles Affect Anti-Lung Cancer Therapy? A Comprehensive Review of the Literature(Budiman et al., 2023, pp. 5473–5493)

- Publication Date: 2023-09-01 (Within the last 5 years)

- Methodology: This review paper examines the use of mesoporous silica nanoparticles in anti-lung cancer therapy. While not directly a laser-cut project, it mentions laser cutting as a potential fabrication method for these nanoparticles in passing. The review analyzes existing literature on the topic.

- Key Findings: The review highlights the potential of mesoporous silica nanoparticles to improve drug delivery and efficacy in cancer treatment. The authors suggest that laser cutting could be a useful fabrication method, although this is not the focus of the paper.

Frequently Asked Questions (FAQs)

Q: What are some popular laser cutting projects for beginners?

A: Some of the most popular starter projects for laser cutting include designing keychains, gifts, and even coasters. This provides a good introduction when learning to use a laser cutter and most of these items can be downloaded at no cost.

Q: Where can I locate free files for laser cutting projects?

A: A good source of free files is Pinterest and the Glowforge Owners Forum. These places offer an array of items from basic to advanced, with many having no purchase necessary.

Q: Which materials can be used for laser cutting?

A: Materiais such as MDF and Birch Plywood are among the most common in laser cutting. In addition to these, woods and varieties of acrylics can also be used and offer flexibility for custom laser cut products.

Q: Is it possible to use a laser cutter to make 3D models?

A: Certainly, it is possible to use a laser cutter to slice materials into 3D models which can then be assembled. This technique is commonly combined with 3D printing for more intricate designs.

Q: How can I create a display stand with a laser cutter?

A: A display stand can be made of different materials, but plywood and acrylic are the most preferred to be used for display stands because of their easy handling and elegant look. Their unique stand is shaped by computer software laser cut files, ensuring the cut lines are flawless. If you search the web, you will realize that many files are available online for free downloads which can indeed help with the designs.

Q: What maintenance does a desktop laser cutter require?

A: Maintenance for your laser cutter range include cleaning its lenses as well as looking into the alignment of the laser and oiling all movable parts. Constant desktop laser maintenance allows a business to offer its clients precision and quality laser engraving and cutting.

Q: What projects can be designed with a laser cutter specifically for wedding events?

A: Projects like table numbers, a cake topper, and other wedding cake decorations are excellent laser projects that can be done in wedding events. They are easily tailored to the wedding and are a wonderful method of offering personalized laser decorations.

Q: What are some complex laser cutting work?

A: A complex laser cutting work includes: intricate designs with a laser cut star wars model, custom laser cut logos, or a detailed wall clock. Such projects need more precision which can often serves as a good opportunity for showcasing laser engraving proficiency.

Q: In what ways can practical products be manufactured with laser cutting?

A: Practical products include a coasters set, a keepsake box, or even a lampshade which can be made using laser cutting. Items can be made to fit their user’s needs and preferences with the help of laser technology.