The advent of laser cutters has transformed the approach of hobbyists and professionals engaged in crafting and manufacturing. With a laser cutter in hand, you can now masterfully make custom prototypes, signposts, and jewels, turning your creative imagination into reality. However, material, technique, and laser cutter configuration all play critical roles in achieving perfection, which is why one needs to go through substantial amounts of information before starting off. This article will help you in achieving a high level laser cutting precision by establishing the right choice of material, optimal setting configuration, and common misconception avoidance. This guide will most definitely act as a solid foundation in whatever transformative project you are looking to undertake.

What is Laser Cutting Plastic and How Does it Work?

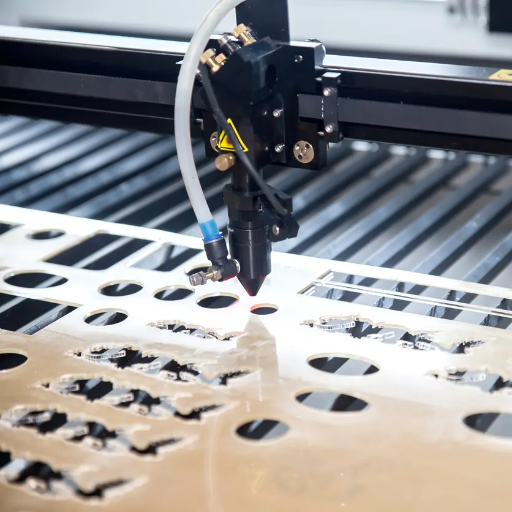

The process of laser cutting plastic employes a focused laser beam to melt, cut, or engrave plastic materials. Certain types of plastics can benefit from this method such as acrylic (which is capable of smooth melting) due to the nature of the material being processed with a laser. To get the results one needs, such as accurately shaped cuts or detailed patterns, users must modify the power and speed settings of the machine.

Grasping the Application of Lethal Ray

Typically, CO2, fiber, or diode lasers are the ones to generate high powered beams which are supplied for cutting through fibers or mirrors towards specially designed optics that will focus the light’s energy onto the plastic’s surface to with high precision. As long as the intensity of the beam is strong enough, the material can be vaporized, melted, or heated along the cutting path. To maintain cleanliness and accuracy of the formed cuts, it’s common practice to use some form of compressed gas like air or nitrogen to remove the molten particles.

Today’s laser cutting centers incorporate modern technology that can simultaneously control multiple parameters like energy, velocity, focus height, and others with exquisite precision. For instance, a conventional CO2 laser cutter works with a power bandwidth of 40 to 150 watts, with the ability to sever acrylic to a depth of anywhere between 1/16 inch to over an inch. More efficient, fiber lasers are capable of cutting thinner plastics and are one third faster than CO2 lasers, thus reducing the time needed to produce detailed designs by 30%.

Moreover, other recent investigations have focused on the time efficiency laser cutting offers in comparison with other traditional methods like mechanical sawing. Evidence suggests that laser cutting improves material yield by about 20% since the strategy used to cut materials is more precise and efficient. Because of this, laser cutting as a method is eco-friendly, especially when applied in industries that rely on impeccable standards such as signage, packaging, or electronics. The integration of precision engineering along with adaptive capability ensures that laser cutting technology continues to lead the modern fabrication methods.

How to Choose the Right Plastic for Laser Cutting

Selecting the correct plastic for a specific task is vital for ensuring safety, efficiency, and an end product of high value. It is important to note that not all plastics can undergo laser cutting due to their distinctive characteristics and how they respond to lasers. The following is a list of some common plastics and their applicability:

- Acrylic (PMMA) – It is among the most used plastics for laser cutting today. Acrylic cuts with precision, yielding polished edges that do not require any post-processing. Recent studies indicate that acrylics maintain cutting accuracy within a tolerance of +/- 0.005 inches. It is widely used in the fabrication of signs, decorative pieces, and showcase display boxes.

- Polycarbonate (PC) – PC is more difficult to work with than other plastics because of its burning and discoloring issues. Although polycarbonate is capable of being laser cut, it tends to discolor and melt at the edges more than other plastics which pose a problem. For thinner layers especially under 2mm, it can be managed, however, thicker sheets require adjustments in order to avoid imperfections.

- ABS (Acrylonitrile Butadiene Styrene) – This is another commonly used plastic which is also highly efficient. Laser cutting capability of ABS is very low as it emits dangerous fumes and burns easily. In comparison with acrylic and PETG, ABS falls behind by a large margin when it comes to safety and effectiveness.

- Polyethylene Terephthalate Glycol (PETG) – PETG is a more useful plastic than ABS as it cuts cleanly and is easier to handle. PETG is often used for a wide array of items including enhanced flexible and durable coverings, encasements, and even packaging, as well as prototypes.

- PVC (Polyvinyl Chloride) – Due to toxic chlorine gas being released during the process of PVC Laser Cutting, PVC is harmful not only for equipment but individuals as well; therefore, should never be used for Laser Cutting.

The Importance of Laser Cutters in Plastic Manufacturing

In contemporary plastic manufacturing, laser cut technology remains crucial; these high precision machines increase the productivity plastic products by facilitating quick and flexible production of varying intricate patterns. Plastic pieces with complex shapes can now be manufactured in one hit owing to the use of laser cutters, in contrast to older methods that needed to be cut in several stages. This technology spans industries in automotive, aerospace, packaging, and even consumer goods.

An additional perk to laser cutting is the precision in producing polished edges as an acrylic material. The accuracy with which laser cutting treats edges makes it an ideal method of processing acrylic glass and therefore, it is widely used for signage and display products.

The advantages of laser cutting technology pertaining to plastic fabrication are well documented. As noted in industry studies, laser systems can cut up 500 mm/s depending on the material and its intricacies. Moreover, laser cutters achieve a remarkable accuracy of ±0.1 mm, which guarantees consistency in mass production tasks.

In addition, new developments on CO2 and fiber lasers have brought about a wider variety of plastics that can be worked on. CO2 lasers are very accurate on acrylic, PETG, and polycarbonate, not damaging the substances while cutting them with precision. As mentioned before, not all plastics can be laser cut as PVC lasers are cutter pose safety threats. So, laser cutting PVC is inadvisable.

The use of laser cutters in the plastic fabrication business has greatly sped up the processes while reducing turnaround times, waste, and improving design adaptability. The precision provided allows creativity for plastic fabrication. This technology continues to drive innovation to require the expectations of most markets with excellent results.

Which Plastic Materials are Suitable for Laser Cutting?

Different varieties of plastic possess favorable characteristics that make them easy to laser cut. The most common used plastic is acrylic, which yields clean edges and a good surface finish. Polycarbonate can also be laser cut, but the damage scope is higher, so the settings need to be more rigid. Other options include PETG and Delrin (acetal) which can be effectively handled by laser cutters. Materials like ABS can be cut too, but may generate more fumes therefore proper ventilation needs to be ensured. Avoid materials such as PVC at all costs as they emit noxious gasses when subjected to laser cutting. Always check the material specifications and safety documents prior to embarking on any laser cutting projects.

Common Plastic Materials Used in Laser Cutting

Laser cutting is widely used in various industries for its precision and efficiency, and selecting the right plastic material is crucial for achieving optimal results. Below are some of the most common plastic materials, their properties, and recommendations for laser cutting:

| Material | Cuttable | Fumes Safe | Durability | Notes |

|---|---|---|---|---|

| Acrylic (PMMA) | Yes | Yes | High | Most popular material for laser cutting; produces polished edges and comes in a variety of colors and finishes. |

| PETG | Yes | Yes | Medium | A versatile material with low fumes; ideal for intricate shapes but less resilient to high heat. |

| Delrin (Acetal) | Yes | Yes | High | Offers excellent mechanical properties; works well for cutting gears or precision parts. |

| ABS | Yes | Requires | Medium | Requires proper ventilation due to toxic fumes; prone to melting, which may affect edge quality. |

| Polycarbonate (PC) | Yes | No | High | Can be cut but produces undesirable smoke and discoloration; not recommended for fine details. |

| Polypropylene (PP) | Yes | Requires | Medium | Offers flexibility and durability, but releases moderate fumes requiring proper ventilation. |

| High-Density Polyethylene (HDPE) | Yes | Yes | Medium | Works well for signs and displays; produces smooth cuts but has a lower melting point compared to others. |

Plastics That Cannot Be Cut with a Laser

In my experience, some types of plastics cannot be laser cut because of the risks associated with their properties and for safety reasons. Consider for example, PVC (Polyvinyl Chloride) which should never be laser cut because it produces toxic chlorine gas on heating. Also, ABS (Acrylonitrile Butadiene Styrene) is not preferred because of excessive smoke and dirty residues that are produced. Dangerous fumes and smoke, toxic materials, as well as, threats to laser cutting tools need to always be avoided.

How to Achieve a Perfect Cut and Engrave with Laser Technology?

To get an effective cut and engraving using laser technology, make sure to pick the right material that works with your laser cutter. Balance the power and speed of the laser with the desired result and material. Ensure cleanliness of the material so that dirt or any debris does not affect the surface. Align the beam properly using focusing techniques to increase precision. Finally, for the best results, regularly clean the lens and cooling parts of the laser cutter so that the performance does not weaken over time.

Achieving a Sharp Inspection on the Acrylic Sheet

Achieving a sharp inspection and ensuring attention to detail helps achieve clear cuts on an acrylic sheet. As per the latest studies and industry standards, it has been found that the settings of the laser cutter are fundamental for getting accurate results. For example, one of the most effective CO2 laser cutters is known for cutting acrylic sheets and giving them a smooth polished edge in no time. The power setting of 60% to 80% along with the speed of 10mm/s to 20mm/s work well on 3mm thick acrylic sheets. But the settings need to be adjusted in accordance with the thickness of the material.

It is also important to have air assist mechanisms during the process. An air assist system will reduce the chances of flaring and the build-up of debris smoke that leads to scorching. Studies show that cast acrylic provides cleaner edges than extruded acrylic because of less melting during the process, thus being better for intricate designs.

LightBurn and RDWorks, for example, have advanced laser engraving features that focus on optimization, making further enhancements to cuts. Multi-pass cutting and critical focus point adjustments are beneficial for denser material sections, such as 6mm to 10mm acrylic sheets. To ensure best results, always begin by testing settings on a scrap piece first.

Optimizing Laser Beam for Greater Precision

Balancing power, speed, and focus is critical when using a laser cutter to achieve the highest level of precision. The right adjustments must be made regarding the focal distance and the material being cut. The most precise cuts are achieved when the focal point of the laser is tightly focused, yielding maximum energy concentration. Energized materials are cleanly cut or engraved at the targeted depth, and focus should be adjusted precisely for acrylic sheets between 6 to 10 mm thick. Focus adjustment with tight focus dramatically reduces edge burrs and enhances cut sharpness.

Moreover, speed and power settings are critical for precision. Considering lower speeds for more stubborn materials and higher speeds for lighter engraving works best. For sample tests, 60-80% power with 10-15mm/s speed works well with wood and acrylic, and finer adjustments afterward work best for precision.

Lastly, proper air assist must be applied. During operation, active air flow plays a crucial role in removing debris and heat accumulation while mitigating burn marks, leading to enhanced clean cuts. Burning materials are often assisted with efficient air flow between 0.5 to 1.0 bars, yielding optimal outcomes.

To conclude, precision is influenced by material properties. For instance, plywood and cast acrylic with consistent grain patterns outperform warped and uneven materials. Moreover, lightburn and laser-engraving software further enhances precision through features like path optimization or dynamic power settings that maintain accuracy down to the smallest details. Regular maintenance of the laser lens and mirrors combined with these techniques guarantees sustained accuracy and effective combustion.

Understanding Wavelength and Its Impact on Cutting and Crafting Plastic

When using lasers for cutting plastic, the efficiency, accuracy, and finishing quality of the most-cut edges is dependent on laser wavelength properties. The optic and thermal characteristics of different sorts of plastics pose different responses to distinct laser types due to their interaction with laser wavelengths.

laser grade polycarbonates and acrylonitrile butadiene styrene (ABS) sheets respond particularly well to CO2 lasers at the 10.6 micron wavelength. It is one of the best products for engraving and cutting acrylic plastics. These polymers have a 10.6 micron absorption peak, which allows for higher precision cutting and engraving. Research suggests plastics such as acrylic surpass the 95 percent mark in absorption efficiency when exposed to 10.6 microns, demonstrating minimal waste.

Conversely, fiber lasers working at a considerably shorter wavelength of 1.06 microns are not ideal for most plastics. Because of low absorption at this wavelength, these lasers work better with metals or harder materials, as they tend to plastic cut uneven edges proportional to the degree of efficiency.

Striking the right balance between settings requires pairing them with the appropriate wavelength; for example, CO2 lasers cutting cast acrylic perform best at 50 to 70 watts of power with 20 mm/s speed relative to polished frosting-less edge yield data. On the other hand, thinner plastic sheets such as polyester benefit from a power setting around 20W which prevents excessive warping and melting.

Coupling laser wavelength with a material’s composition allows tailored adaptation of preset values and configurable alterations to variable parameters such as result sequence repetitancy for plastic laser cutting reliability.

What are the Safety Precautions for Laser Cutting Plastic?

- Use Precautions When Operatig The Device: The overheating of plastic will occur when not laser multipass cutting, which leads to the formation of toxic smoke. Always operate the machine breathing fully only in areas with proved laser-cutting fume eliminator systems to avoid problems.

- Eye protection is very important: Safety goggles should be worn when as the laser is being employed, and the eyes should never be safeguarded from any direct laser assault.

- Prevent ignitable materials from being close: Provide a workspace devoid of any ignition tinder and laser cutter materials because high temperature within the zone can easily start the surrounding objects ablaze.

- Observing is a requirement: The device must have a human operator fulfilling the role of a guard using machine until he gets ant problems arising in case it becames faulty and starts containing fire.

- Observe the limitations: Always offer the right kind of working plastics in the market but do not offer any other richer types because people use certain items like hoses made by people out PVC.

Regulating Fumes and Gaseous Emissions

Laser cutting is a common practice in many industries, as it enables enhanced precision in achieving intricate designs on various materials. However, the process generates harmful hydrocarbons and gases that must be adequately controlled. To ensure a safe working environment, exposure to hazardous fumes must be adequately mitigated. Research indicates that laser cutting emissions differ from one material to another. Acrylic cutting, for instance, yields methacrylate vapors and certain wood species release organic particulates during mesquite to subalpine wood cutting. As per the most recent safety guidelines, such harmful toxins would be effectively captured and neutralized utilizing air filtration systems with HEPA filters and/or activated carbon filters.

Over time, laser cutting fumes exposure may be associated with developing chronic respiratory issues. Industrial workers, for example, have been reported to experience a significantly high risk (~15%) of chronic respiratory conditions due to heavy exposure to fumes and particulate matter (2020). In light of these findings, it is therefore critical to equip laser cutters with extraction hoods or local exhaust ventilation systems to improve air circulation and safeguard workers. Regular maintenance checks of such ventilation systems are crucial as well to ensure compliance with safety regulations and efficiency.

Avoiding Common Hazards When Using a Laser

Effective and precise lasers come with a plethora of dangers that must be tackled in order to ensure safety within the workspace. As mentioned by OSHA, some common risks include inversed exposures to laser radiation, fire hazards from flammable materials, as well as harmful smoke and fumes produced from cutting and engraving. In one recently conducted study, it was brought to light that operations in a laser cutter are capable of emitting hazardous airborne particles which include, but are not limited to, nanoparticles as well as volatile organic compounds (VOCs). These pose a risk of short term irritations as well as long term respiratory issues if not properly protected against.

As outlined by the NIOSH, using HEPA filtration systems capable of reducing airborne contaminants greater than 99.97 percent while maintaining air quality during laser operations can mitigate these risks. Furthermore, real-time air quality monitors can also be used to track the levels of particulate matter exceeding the required thresholds, allowing for prompt action to be taken. Along with local exhaust ventilation and routine upkeep, the use of these devices can greatly limit the harmful exposure of these contaminants to workers.

In addition, there is a risk of sustaining permanent ocular injury if one does not put on specialized goggles for lasers safety with the specific wavelength used. Other types of personal protective equipment (PPE) also need to be used, such as ensuring that combustible materials are not placed within the vicinity of the laser and there are fire extinguishers available in case of an emergency. An organization’s policy on written procedures under standard operating procedures paired with supervision will encourage employees to appreciate the risks involved and work with equipment in a health protective manner, thus enhancing productivity.

How to Choose the Right Laser Cutting Service for Custom Parts?

- Material Capabilities: Check to see if the service can work with materials like metal, plastic, or wood. Be sure to check their proficiency with your specific material.

- Precision and Quality: Consider looking for a contractor who is noted for accuracy and performing clean cuts as per your design specifications.

- Turnaround Time: Pick a service that meets your delivery date without sacrificing quality.

- Experience and Reputation: Check client testimonials and the reviews of the completed projects to gauge trustworthiness and experience.

- Cost Transparency: Choose a service provider with straightforward pricing structures that does not include additional charges.

Assessing Custom Laser Services

It is critical to track recent changes and statistics in the industry while selecting custom laser cutting services to make the right choices. A recent study of the market revealed that the laser cutting market globally is projected to expand at a compound annual growth rate (CAGR) of 9.1% from 2023 to 2030 largely due to the rising demand in the automotive, electronics, and healthcare sectors. This data further emphasizes the need to work with a contractor that constantly updates his or her equipment, for example, by using fiber lasers which are more efficient and accurate than the traditional CO2 lasers.

Moreover, modern companies that offer laser cutting services have incorporated sophisticated software tools, which allow for accurate designs and quick prototyping. As an example, the integration of CAD makes custom changes easy and reduces mistakes, helping ensure stringent tolerances are maintained. Also, automation improves service levels which is critical for most businesses with compressed timelines.

Prices are high or low for different materials and projects. Recent studies estimate laser cutting services at $15 to $30 per hour, but specialized high-end jobs could reach over $50 per hour. This shows the importance of seeking detailed quotes and understanding the range and structure of services early on. Utilizing this information, businesses can select laser cutting services to suit their specifications and receive the highest possible value.

Important Considerations When Cutting Plastic

Plastic is one of the most commonly used materials in today’s world. As an artificial material, it is imperative to consider some factors in order to enhance the precision, quality and cost-efficiency while cutting it. The method you choose to cut the plastic is of uppermost importance, since most lasers offer enhanced precision and clean cuts. Moreover, the type of plastic determines the cutting method to be used. For instance, laser cutting is often ideal for acrylic (PMMA) dies since it offers smooth and clear edges. However, some plastics like PVC pose serious health risks because of the toxic fumes they emit. They often require different cutting techniques than laser cutting.

Another equally important factor is the thickness of the plastic. Generally, lasers perform best on 10 mm thick plastics. In addition to this, accuracy when cutting the plastic is ideal. In case the machine is operated by skilled professionals, any form of technology can cut plastics which are thicker than 15 mm, however, it might consume more time as well as cost.

Another key concern is plastics temperature sensitivity. For example, thermoplastics are prone to softening, deformation and melting at excessive temperatures, particularly during heat intensive cutting operations. This issue can be mitigated with the application of ventilation, machines with controlled heated input, and properly set optimized power settings []. Recent studies suggest that for heat sensitive plastics, CNC routing can be more beneficial in some cases when compared to laser cutting.

Lastly, for any given job, materials, thicknesses and designs greatly influence the cost, often increasing or decreasing it. Pricing for standard laser cut acrylic sheets ranges between $20 – $40 per sheet for a thickness of 6mm; however, increasing the machine time due to more complex designs will raise the price to $60+ per sheet. Always ask for personalized quotes tailored to your expectations and guidelines and seek recommendations on the most efficient cutting technique that complies with your specifications .

Fulfilling Your Requirements Through Finding the Most Suitable Service

In search of the right service, we suggest you start looking for providers closer to your location and check their reviews and past experience with projects similar to yours. It’s important to request quotes from multiple providers to evaluate the pricing, turnaround time, and materials offered. Verify that the precision and customization requirements are supplied by the chosen provider. Select someone who offers flexible terms, understands your particular goals, and communicates clearly.

Reference sources

- Novel Crevice Corrosion Assemblies with Laser-Cut Shim(Javed et al., 2025)

- Publication Date: March 1, 2025

- Methodology: This study describes the creation of crevice corrosion assemblies using laser-cut plastic shims. This allows for a wide range of crevice patterns and sizes, providing a relatively rapid method to produce assemblies for evaluating material performance under simulated real-world scenarios.

- Key Findings: The article examines the effect of applied torque on the formation and dimensions of crevice gaps. The laser-cutting method offers a flexible and efficient way to create customized crevice corrosion assemblies.

- Detecting residuals at plastic samples to optimize laser cutting processes(Madrin et al., 2023, pp. 125270G-125270G – 11)

- Publication Date: June 13, 2023

- Methodology: This study evaluates two image processing methods for detecting residuals on laser-cut plastic samples. The goal is to accurately identify residual locations and convert image information into laser machine coordinates for precise removal without damaging the sample. The methods compared were template image matching and light intensity comparison.

- Key Findings: The template image-matching method provided more accurate results, but required consistent sample positioning. The light intensity comparison method had limitations in detecting small residuals. The study resulted in a system capable of removing residuals without sample damage.

- Evaluation of Cutting Parameters on Heat-Affected Zone in Wood Plastic Composites by Pulsed Fiber Laser(Domadia et al., 2024)

- Publication Date: May 30, 2024

- Methodology: This study experimentally cut 1 mm thick wood-plastic composites (WPCs) using a pulsed fiber laser to determine the minimum laser energy required for cutting and the influence of cutting parameters on the heat-affected zone (HAZ). Analysis of variance (ANOVA) was used to determine the statistical significance of cutting parameters on HAZ.

- Key Findings: A minimum linear energy of >9 J/mm was needed to cut the WPC. Cutting speed was the most significant influence on HAZ, followed by pulse width. Higher gas pressure minimized HAZ. Understanding these parameters can improve laser cut quality by minimizing thermal effects.

Frequently Asked Questions (FAQs)

Q: Which Laser Cutter Can Best Cuts Plastic Materials?

A: If you’re looking for a laser cutter to cut plastic materials, then a CO2 laser cutter will do the job best. It CO2 laser cutter give hobbyists and professionals alike the required laser energy to successfully cut several types of plastics.

Q: Are all plastics eligible to be cut through lasers?

A: No, not all plastics can be cut with a laser. Some types of plastics, such as polycarbonate (Lexan) do not cut well and can produce toxic or corrosive fumes. It is of utmost importance to check the material prior to laser cutting to ensure they are compatible.

Q: Tell me the ideal materials to be used for laser cutting?

A: The best materials to be laser cut are acrylic, polypropylene and acrylonitrile butadiene styrene (ABS). These materials have proven to be easy to work with as they can be cut into specific shapes without loosing any detailing.

Q: Does the kind of plastic used affect the function of the laser cutting process?

A: Sure, the kind of plastic used does play a role in how effective the laser cutting will be. Factors regarding thermal conductivity as well as the melting point, and the ability to give off toxic fumes need to be evaluated for effective cutting and safety.

Q: In what ways does the course of the laser affect quality of cut?

A: As for now, accuracy and smoothness of the cut is determined by the course of the laser. Achieving a design’s desired result entails a vector path in the design file, assisting the laser machine in achieving cuts free from excessive kerf or fraying.

Q: What safety measures should be considered releative to styrene laser cutting?

A: Styrene cutting requires the utmost attention to detail, for instance a well thought and sophisticated system of ventilation due to potentially harmful gasses being expelled is crucial. Additionally, perfect cut striaght marks require proper setting of laser energy to prevent plastic overheating.

Q: For mass production, does one consider using laser cutting services?

A: Consider them for your mass production needs. They manufacture processes to achieve an identical multiply parts are fast as with every single part manufactured in a separate step custom programmed.

Q: Is it possible for a laser machine to go as far as cutting out 3D plastic shapes?

A: A laser machine’s scope remains to cutting flat plastic sheets. From fully formed 3D parts, seams that can be assembled into 3D shapes are the limit to what it can produce.

Q: Lasers are said to enhance the accuracy of cutting polypropylene. Does it have any implications on the strength to weight ratio of plastics like HDPE?

A: As long as proper settings are applied, laser cutting neither enhances nor reduces the strength to weight ratio of plastics like HDPE. In fact, HDPE is a resilient material, and its durability allows it to withstand precise laser cutting with minimal alteration to its properties.