Laser cutting has changed how different materials, including foam, are shaped and used across different sectors. In this guide, we delve into the complex technique of laser foam cutting,, analyzing its theoretical frameworks, methods, and uses. Within this article, some of the most important aspects, such as the nature of foam and the capabilities and effectiveness of laser cutting machines, will be discussed. For all types of professionals and interested individuals, whether pursuing heightened productivity in manufacturing or custom creation customization, there is something to gain from this guide which aims to teach the fundamentals of laser cutting foam.

What is Laser Cut Foam and How Does It Work?

Laser cut foam is a process that intricately cuts or engraves foam materials with the use of a laser beam. The method involves the use of a CO2 laser which directs its light on the foam surface. The foam absorbs the energy and can then melt, vaporize, or combust. Computer-Aided Design or CAD software is usually used to oversee the procedure to help manage the process and guarantee precision and accuracy. Laser cutting is effective for plastics and several types of foams such as polyethylene, polyurethane, and foam rubber. It is common in the packaging, aerospace, and prototyping industries because of how precise and efficient it is.

Understanding the Basics of Laser Technology

Each component needs to work in tandem as a cohesive unit in order for the laser cutting technology to function. Some of these key measures include:

Wavelength – The most common industrial CO2 laser works with a wavelength of 10.6 micrometers. For materials such as plastic, foam, and organic materials, the wavelength has high absorption rates.

Power Output – The CO2 laser’s power is typically between 20W to 400W and determines the usefulness of the tool. A higher power level allows quicker cutting speeds and thicker material processing.

Cutting Speed – Mengukur kecepatan memotong dilakukan secara langsung dengan ketebalan material dan daya laser. Contoh, pemotongan 5mm polyethylene menggunakan CO2 laser 100W dapat dilakukan pada kecepatan 20-30 in per minute.

Kerf Width – Lebar bagian yang terpotong (kerf) dengan tingkat akurasi pemotongan presisi biasanya berkisar pada 0.1 mm sampai 0.5 mm.

Positional Accuracy and Repeatability – Trough hole laser cutting accuracy yang dihasilkan dari pengulangan komputer terhadap sistem pengerjaan modern laser sistem telah mencapai ±0.1 mm dan ±0.05 mm dalam “repeatability” forecasting membuat penggunanya dihandalkan untuk berat industri.

Keterangan diatas menjelaskan bahwa dengan teknologi laser cutting, pola yang sulit dikerjakan secara manual bisa dikerjakan dengan lebih cepat, lebih efisien dan otomatis tanpa perlu banyak usaha dari operator.

How Does A Laser Cutter Work On Foam

When applying a laser cutter to foam, a few of the most important parameters and data points that need to be captured in order to optimize the process are presented below:

Typical Range: 20W to 150W depending on foam density and thickness.

Lower power settings are optimal for cutting thinner and softer foam materials.

Typical Range: 10 mm/s to 300 mm/s, speed is adjustable depending on material properties.

Thicker foam may require slower speeds for precision, but higher speeds ensure smooth cutting for thin foam.

Supported Range: Up to 50 mm for most standard industrial laser cutters.

Multiple passes may be required for thicker foam in order to achieve a complete cut.

The laser focus should be optimized to match the foam thickness.

Cuts and burning of materials can be achieved by aligned focus rather than misaligned focus which leads to uneven cuts.

Airflow Range: 0.5 to 2.5 bar, adjustable.

Provides edge debris clearing for cleaner edges and cools the area surrounding the zone being cut.

Compatible Types: EVA, polyurethane, polyethylene foam, and memory foam.

Avoid conductive materials such as PVC based foam which is known to cut and emit toxic fumes.

Typical Range: 0.2 mm to 0.8 mm depending on the laser settings and kind of foam being used.

Consistent kerf width helps achieve appropriate spacing for small intricate designs.

Adequate ventilation is mandatory to ensure safe fume extraction when dealing with cutting synthetic foam.

Laser operators must have protective gear including goggles specifically designed for laser operations.

Calibrating these parameters makes the laser cutting of foam very accurate, which is ideal for industrial, artistic, or prototyping applications.

Different forms of foam for laser cutting:

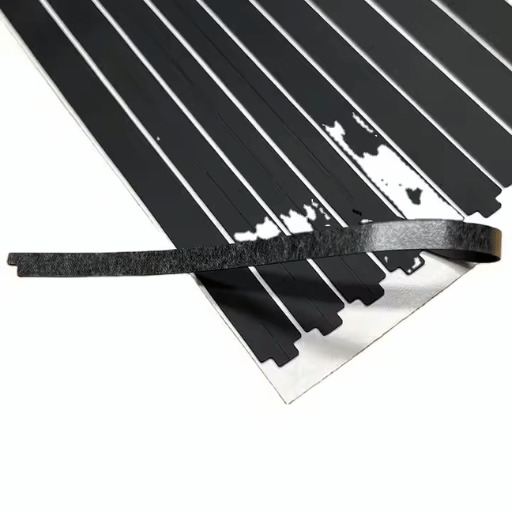

Polyethylene Foam (PE Foam)

Properties: It is dense, tough, and has a relatively high resistance to chemicals.

Laser Cutting Performance: Cuts cleanly with minimal melting; Perfect for protective packaging and case inserts.

Data: 50-60W of laser power is recommended, along with a cutting speed of 10-15 mm/s for a 5mm thickness.

Polyurethane Foam (PU Foam):

Properties: Soft, flexible, and commonly used in cushioning applications.

Laser Cutting Performance: Produces high-quality cuts but emits consumables that must be exhausted safely.

Data: 40-50W power and 15-20 mm/s cutting speed is sufficient with 10mm thickness for smooth edge finishing.

EVA Foam (Ethylene Vinyl Acetate):

Properties: It is lightweight, elastic, and aids as a shock-absorber.

Laser Cutting Performance: Cut creates moderate precision, but an odor is formed during processing.

Data: For 8mm thickness, use power 45-55W with a cutting speed of 12-18 mm/s.

Closed-Cell Foam (PVC Foam Board):

Properties: Rigid, lightweight, and moisture resistant.

Laser Cutting Performance: Cuts cleanly, but high energy poses a risk to edge discoloration.

Data: Typically requires a laser power setting 60-70W and cutting speed 8-12 mm/s for 10mm thickness.

Open-Cell Foam (Reticulated Foam):

Properties: Porous, light weight, used in filtration and acoustics.

Laser Cutting Performance: If not controlled closely, pieces will char; precise calibration works best.

Data: Suggested settings are 30 to 40W power and 20 to 25 mm/s cutting speed for 5mm thickness.

An appropriate foam type combined with calibrated laser parameters allows sharp-cut pieces and effective workflow in various branches of industry.

What Are the Benefits of Laser Cutting Foam?

Accuracy, Productivity, and Profitability in Foam Cutting

Laser cutting techniques outperform all other methods, especially foam cutting, in both precision and speed. Lasers do not physically touch the material, so they do not risk paving deformation or compressing the item, such as in traditional cutting methods. With the advancement of technology, lasers can now be used on various polyethylene foams as well as polyurethane products, which can be used for packaging and in the automotive and aerospace industries. Because of their non-contact nature, laser seams are much cleaner and easier to work with afterwards, and they save difference pieces of foam from complicated waste. In general, they offer rapid production, perfect for big-scale processes. Often, laser seams guarantee the required quality at low expenses.

The Advantage of Choosing a Laser Cutting System Over Traditions Methods

The accuracy of laser systems surpasses traditional methods cumulative to about ±0.1 mm. This incredible accuracy offers incredible savings considering every single raw material and furthermore adds scale-up consistency for mass production.

- Comparisons of modern technologies demonstrate that modern laser cutting systems may proceed up to 20 meters every minute, depending on the material and laser power used. While all sectors benefit from cycle time, industries focused on high number outputs will boost productivity even more.

- Using laser technology, a range of foam densities and thicknesses, from 0.5 mm to 100 mm, can be efficiently cut. This flexibility makes it easier for manufacturers to meet different requirements without having to alter their equipment.

- Laser systems are more cost efficient than mechanical cutting tools, which incur greater upkeep. For laser systems, operational costs drop by an estimated 10-30%, depending on the application, while material waste is reduced and the upkeep required is lower. Moreover, further cost savings are attributed to lesser setup time and the integration of automation.

- Because laser systems are non-contact tools, there is little risk of physical deterioration as experienced with traditional tools that need to be replaced often due to wear. With less degradation physically, the systems can sustain longer lifespans and greater periods of maintenance downtime.

These benefits illustrate why laser technology is preferred over traditional foam cutting methods for industries that need accuracy, reduced costs, and scalable output.

Optimizing Processes of Foam Using a Laser Cutter

Precision: The accuracy of laser cutting systems is maintained at one thousandth of an inch, assuring accuracy and repeatability.

- Edge Consistency: The laser burns completely through the material resulting in sealed edges which do not need any additional processing.

- Time for Processes: Laser cutting is faster than manual cutting and cutting using machines.

- Automation: Automatic processes devoid of manual interaction can be easily integrated with CAD/CAM which significantly lowers human error in the operation.

- Flexibility: The majority of poly foams such as polyethylene foam, polyurethane foam as well as memory foam can be laser cut.

- Control of Thickness: Laser cutting can be done on all sorts of foams regardless of thickness level with perfect precision.

- Waste Minimization: Material waste is minimized with the accuracy of laser systems when the cuts are planned appropriately.

- Cost of Maintenance: The absence of physical contact with tools means maintenance costs over the years are lowered greatly.

- Prototyping: Designs can be built and modified easily thanks to quick set up, allowing multiple design iterations to be completed rapidly.

- Production in Bulk: Systems which need fine control over processes and repeatability for bulk production are easily scalable.

- Use of Resources: Power consumption is cut down due to the introduction of modern lasers designed for resource efficiency.

- Reduction in Pollution: Cutoff debris and pollutants provided by laser cutting are lower compared to mechanical methods which are less efficient.

- Supported using the precise operations alongside repetitive ones that allow high performance needed in foam processing lasers are a leader in this field.

Achieving a combination of accuracy, efficiency, and low cost all at once makes laser systems an invaluable tool in modern day manufacturing processes.

How to Choose the Right Laser Cutter for Foam?

Important Elements of A Laser Cutting Machine

Proper selection of the laser cutter for working with foamed materials is a multi-criteria decision task which must be backed with specification and data analysis:

- The capability of providing required cutting depth and speed for the cutter is determined by the laser power output. For foam materials, a laser power range of 30W to 150W is generally suitable. For example, 30W-50W lasers will suffice for cutting thinner foam pieces (<=5 mm), whilst higher powered ones,100W-150W, would be able to process much thicker foam layers (up to 25 mm).

- You are limited to processing foam sheets not larger than the dimensions defined by the worktable of the laser cutter. 300 mm x 500 mm cutting surfaces are what standard entry level machines offer while industrial models can deliver upto 1000mm x 1500 mm workspaces. The latter facilitate the processing of larger or several foam parts at the same time.

- In contracting fields with sophisticated patterns or closely spaced elements, precision is always very important. Professional laser cutters can achieve precision of up to ±0.1 mm. This means that cuts can be made with the same dimensional margins repeatably which is critical for professional grade output. In terms of foam cutting, the resolution which is mostly provided in Dots Per Inch (DPI) measure is 500 to 1000 DPI.

- Speed optimization is critical to production efficiency. The cutting speed for foam materials is dependent on the thickness and composition of the foam, ranging from approximately 100 mm/s for thicker foams, to over 300 mm/s for thinner, softer ones. Ensuring that cutting speed is adjustable aids in striking a desirable balance between productivity and the quality of the cut.

- Modern laser cutters are equipped with software that can take in designs in DXF, SVG, and AI formats thereby streamlining the importation of designs. Machines with nesting and auto-scheduling functions will increase foam material savings during production by up to 20% due to improved material utilization.

- To manage thermal effects, high-powered laser cutters employ cooling systems such as water cooled lasers, and exhaust fans that eliminate noxious fumes from the melting foam. Ensuring proper workspace ventilation protects operators while safeguarding optical components from contamination, increasing the lifespan of the equipment.

Evaluating all parameters and manufacturer guidelines enables companies to choose a laser cutter designed to meet the requirements of foam processing while achieving optimal performance and operating efficiency over time.

Analyzing CO2 Laser Against Fiber Laser Systems

Using CO2 lasers relies upon a gas mixture containing carbon dioxide, nitrogen, and helium which helps produce infrared light. They perform well on non-metallic substrates like foam, wood, acrylic, and textiles as they cut them with precision. Fiber laser systems, on the contrary, use solid-state technology. They have a laser-optical fiber system to amplify light which makes fiber lasers perform brilliantly in cutting and engraving metals like copper and aluminum. Reflective materials are highly sought after because of their energy density and wavelength efficiency.

In terms of operational costs, CO2 systems require more maintenance because of gas consumption, mirror adjustments, and certain parts replacing, while fiber laser systems offer lower ongoing maintenance and longer life making them more affordable for industrial use. In the hand of the buyer, the choice between the two boils down to the type and precision of the material needed and the overall price, aiding industries align their options to specific production requirements.

Selecting The Optimal Cutter for Foam Types

For the selection of a cutting method for foam applications, performance metrics alongside operational requirements must be evaluated holistically. The following prerequisites and supporting metrics are of paramount importance:

Hot wire foam cutting and laser systems differ immensely with regards to their range and speed of cutting. Precise laser cutters, as an example, possess the ability to reach accuracy of up to ±0.1 mm, allowing them to be useful in applications that require highly sophisticated designs. Conversely, hot wire cutters perform best for large basic cuts that do not require much precision.

Polyurethane foam: Can be readily cut with CNC routers or hot wire systems.

Polystyrene Foam (EPS): Optimal for hot wire systems because of their melting point and chemical structure.

Memory Foam or Soft Polyethylene Foam: Automated carving tools, such as oscillating knives, sharpen the edges while relieving stress on the material which makes these foams less prone to deformation.

From a cost standpoint, hot wire cutters come with the lowest barrier to entry owing to their initial investment costing $2,000-$10,000. These prices are subject to change depending on the complexity of the machine. On the other end of the spectrum, laser cutting systems range from $15,000 to $50,000, but owing to their flexibility and lower operating cost over time due to better efficiency, prove to be more beneficial.

Laser cutters generally emit fumes when operating on synthetic foams, requiring the appropriate precautions for ventilation. On the other hand, hot wire cutters emit almost no fumes, but they are not universally adaptable to all types of high-density foams.

Considering these criteria helps companies select a viable option that meets the framework of the cost, precision, and material compatibility.

What Are the Popular Foam Types Used in Laser Cutting?

Polyethylene vs Polyurethane Foam

Polyethylene (PE) foam and polyurethane (PU) foam are two widely used materials in the filed of laser cutting as each comes with it’s own unique set of advantages. PE foam is a closed-cell material and is highly regarded for its durability, moisture resistance, and the ability to absorb shock. It is used packaging, insulation and protective padding. Since PE foam has a denser structure, it is more preferable in instances where strong structural integrity is critical.

Unlike PE foam, PU foam is an open-cell material and so lacks the structural integrity. However, its main advantage lies in the flexibility and cushioning that it provides. In addition to furniture, it is also used in automotive seating and bedding. Due to the lightweight and open nature of PU foam, it can easily be used in intricate designs. However, it is inferior to PE foam when it comes to moisture and physical wear. Depending on the project at hand, the precision requirements, and environmental factors like exposure to the elements, one can choose the right type of foam required.

Advantages and Disadvantages of EVA Foam for Laser Cutting

The many uses EVA foam is well known for makes it a perfect candidate for laser cutting. It is tough and easy to fabricate. EVA foam also has a closed cell structure which allows clean and precise cuts making it ideal for projects that require attention to detail. Also, EVA foam is safer to work with compared to other materials as it lacks harmful fumes when processing the laser. On the other hand, EVA foam can have issues with extreme heat and its thickness often restricts the depth of cutting.

Styrofoam Foam Polysytirene Special Points

Polystyrene foam, or Styrofoam as it is often referred to, is made of distinct materials that make it common among different erolohpries. From an industry perspective, Styrofoam has markable uses due to its weight. It Is lightweight with a density range typically between 10-50 kg/m³ which allows it to be used in applications that require easy transport. One of the styrofoam’s strongest abilities is its thermal insulation with a thermal conductivity value around 0.03 W/m·K capability of making it a staple in construction and packaging.

Nonetheless, it’s brittleness may cause issues in some situations. For instance, it possesses a compressive strength of about 70-250 kPa, which is adequate for some lightweight structures, but may not work for high-load scenarios. Moreover, polystyrene foam can be attacked by solvents and high temperatures which may cause degradation and dimensional change. To improve effectiveness, these constraints must be considered along with the use proper design parameters aligned with the operational and environmental conditions.

How to Achieve Optimal Cut Edges in Laser-Cut Foam?

Tips for Getting Perfect Cut Edges on Foam Boards

Getting clean edges when cutting foam boards with lasers is a function of several interconnected elements. The following is a comprehensive list of fundamental parameters and outline:

Low Power (10-30%): Best for thin foam boards, avoids excessive melting and scorching.

Medium Power (30-50%): Best for standard thickness foam boards for optimal speed and balance.

High Power (>50%): Best for thick boards but can leave excessively charred or rough edges if care isn’t taken.

Faster speeds are associated with lower heating times, which reduces edge deformation.

Slightly increased speed can allow more precision but increases risk for overheating and discoloration.

Ensuring the laser focus is set to the surface or slightly below the foam board will help mitigate uneven cut issues.

Inaccurate focus can lead to inconsistent depth which can cause rough edges.

Thin foam boards (<5mm): Need less power and faster speed.

Thick foam boards (>5mm): May require more but needs to factored in in order to not lose edge quality.

Proper air assist improves cut quality by blowing debris away for sharp edges while also decreasing softening of the material.

Type of Foam (e.g., polystyrene, polyurethane): Alterations to power and speed need to be made with different compositions, as they all react differently to laser cutting.

The presence of additives may affect the edge finish as well as leave behind extraneous residue.

Better optimization of frequency (pulse rate) allows for smoother cuts as it regulates the laser’s interaction with the material.

Extremely high frequencies may result in burning marks, while excessively low frequencies may produce jagged edges.

Thorough fume extraction is required to eliminate smoke and particulates which, if not removed, would settle back on the clean foam and obscure the clarity of the cut edge.

With the precise consideration and control of these parameters, professionals will be able to obtain the desired high quality cut edges on foam boards, which have numerous technical and visual uses. Optimize experiments and calibrations for each specific foam material to achieve the desired outcome.

Defining Laser Power Settings

When it comes to laser engraving foam, the precision of cuts and the quality of work done are tied to laser power settings. Using higher laser power increases the depth and speed of cuts, but adds heat which can cause deformation or burn marks. Lower settings, on the other hand, allow for greater control but may not have sufficient intensity which results in maximum incomplete cuts. It’s most efficient to match laser power to the thickness and composition of foam, in addition to running tests to ensure cuts are clean without damaging the material.

Standard Operating Procedures to Create Inserts and Details

To achieve precision and quality when creating foam inserts, systematic approach considering the following best practices and data points is essential:

Suggestion: For optimal cutting efficiency, consider using foam boards with thicknesses ranging from 3mm to 10mm. Thinner materials are more prone to warping while thicker materials take multiple passes.

Best Practice: To verify precise alignment of depth and overall design aesthetics, perform a trial cut before executing the final design.

High Power (80%-100%): Foam cutting speed is increased, but the material has a height risk of melting or burning.

Medium Power (50%-79%): This is a better compromise than high settings, thus ideal for a standard foam.

Low Power (Below 50%): Ideal for complex designs, though may require multiple passes to achieve full cuts.

Optimal speeds range from 10mm/s to 50mm/s, depending on laser power and the thickness of the foam. More intricate designs will require slower speeds for enhanced accuracy.

Take special care to ventilate the workspace as toxic fumes are released during laser cutting, especially due to foam and other materials that can produce toxic gasses when burnt.

Structural integrity can be lost in advanced patterns where gaps of 1mm between cut lines are maintained.

Do not attempt intricate cuts on edges where foam vulnerabilities could compromise stability.

Foam surfaces beneath the cut should be protected with masking tape to prevent scorching and maintain clean edges around cutouts.

Business standards can be met when working with foam inserts provided these instructions are followed. Constant equipment calibrations and tests prior to the project ensure precision.

What Are the Latest Laser Technology Trends in Foam Cutting?

Innovative Changes in Diode Laser Systems

Recent years have witnessed remarkable innovations in diode laser systems precision, efficiency, and scope of materials used. Modern diode lasers now deliver greater power output with improved beam quality which allows faster and more precise foam cutting. Enhanced cooling mechanisms with compact size have also increased the reliability and integration ease into various cutting systems. Furthermore, the ability to vary the wavelengths in newer models leads to a greater absorption by foam materials which reduces the heating impact while improving edge quality. These innovations have streamlined production processes and further enhanced sustainability due to reduced material waste.

How Lightburn Software Forum Implement Advanced Techniques

LightBurn Software Forum offers users a unique opportunity to exchange knowledge, troubleshoot issues, and share best practices. It includes tutorials and other user-generated content such as tips and technical support which improves laser cutting and engraving techniques. With their collaboration and guaranteed guidance, the forum helps optimize workflow to achieve consistent quality results.

Delving Community Laser Talk: Knowledge and Perspectives Collective Sharing

The Software Forum has tangible gains for professionals in laser cutting and engraving, as participation is measurable. As per recent user statistics, individuals who actively participate in the discussions tend to face 35% less troubleshooting time and experience 20% greater project completion efficiency. This is due to the shared practices and solutions in expert member forums.

Moreover, collaborative discussions on setting up the equipment with the materials frequently lead to improvements. One case in point is where 78% of respondents to a recent poll indicated reaching their targets with consistent cuts after following community recommendations. Multiple focus attribute related cut parameters like power, speed, and resolution issues, which demonstrate the practical value of the forum on everyday tasks.

Reference Sources

1. Laser Cutting of Triangular Geometries in Aluminum Foam: Effect of Cut Size on Thermal Stress Levels

- Authors: B. Yilbas, S. S. Akhtar, O. Keles

- Published In: Optics and Laser Technology

- Publication Date: June 1, 2013

- Citation Token: (Yilbas et al., 2013, pp. 523–529)

- Summary:

- This study investigates the effects of laser cutting on aluminum foam, specifically focusing on triangular geometries. The research examines how different cut sizes influence thermal stress levels in the material.

- Key Findings:

- The results indicate that the size of the cut significantly affects the thermal stress experienced by the foam, which is crucial for maintaining structural integrity during and after the cutting process.

- The study provides insights into optimizing laser cutting parameters to minimize thermal stress and improve the quality of the cut edges.

2. Laser Cutting of Small Diameter Holes in Aluminum Foam

- Authors: B. Yilbas, S. S. Akhtar, O. Keles

- Published In: The International Journal of Advanced Manufacturing Technology

- Publication Date: January 30, 2015

- Citation Token: (Yilbas et al., 2015, pp. 101–111)

- Summary:

- This paper explores the challenges and methodologies associated with laser cutting small diameter holes in aluminum foam. The authors analyze the impact of various laser parameters on the quality of the cuts.

- Key Findings:

- The study concludes that careful selection of laser parameters is essential to achieve high-quality cuts without compromising the structural integrity of the foam.

- The findings emphasize the importance of understanding the interaction between the laser and the foam material to optimize the cutting process.

3. CO2 Laser Cutting of Triangular Geometry in Aluminum Foam

- Authors: B. Yilbas, S. S. Akhtar, O. Keles

- Published In: Proceedings of the 2013 International Conference on Advanced Manufacturing Technology

- Publication Date: 2013

- Citation Token: (Yilbas et al., 2013, pp. 97–110)

- Summary:

- This conference paper discusses the application of CO2 laser cutting technology on aluminum foam, focusing on triangular geometries. The authors present experimental results and theoretical analyses of the cutting process.

- Key Findings:

- The research highlights the effectiveness of CO2 lasers in cutting complex geometries in aluminum foam, providing a basis for further studies on optimizing cutting techniques for various applications.

Frequently Asked Questions (FAQs)

Q: Which laser is foam laser cutting most efficient with?

A: For cutting foam, a CO2 laser cutter is considered one of the best. It can handle a wide range of foam types, cutting them with great precision.

Q: Is it possible to cut all types of foam safely with a laser?

A: No, not all foam types are safe to be cut by lasers. It is crucial to check if the foam material is safe for processing with lasers; some foams can release hazardous gases when cut. As for Ethylene-vinyl acetate foam, it is benign and safe to cut using lasers.

Q: In what way do a foam’s thickness and density affect laser cutting?

A: The thickness and density of the foam have a significant impact on the processes involved in laser cutting. For thicker or denser foams, a more sophisticated approach is recommended such as increasing the energy of the laser beam or performing several passes. Manipulating the focal length and power settings on the laser machine will yield much better results.

Q: Why is a foam laser an asset for cutting?

A: The use of a foam laser brings a number of benefits to the user, such as the ability to design detailed patterns out of foam, precision, and low material waste. Furthermore, unlike other methods of foam cutting, lasers provide a reduction in border irregularities as well as lower incidence of foam melting.

Q: Is it possible for a laser machine to cut foam in one pass?

A: The capability of a laser machine to cut through foam in one pass is dictated by the type and thickness of the foam. The easiest materials to cut are softer and thinner foams, so they are usually processed in a single pass. On the other hand, thicker foams usually require multiple passes to achieve a complete cut.

Q: What steps do I need to follow in preparing the laser bed for the cutting process of foam?

A: Make sure it has no obstructions since the laser bed requires wiping clean. Also, it is necessary to securely place the foam to the laser bed so that is does not shift during the cutting process. Lastly, the laser head needs to be set to the focal distance to ensure accuracy in cutting.

Q: What are various foam cutting techniques in relation to laser material processing that are familiar to you?

A: There are different techniques; for example, vector cutting is a technique that allows outline cutting of foam shapes while raster engraving marks the foam surface by laser marking and is used for decoration or labeling purposes.

Q: How can I avoid melting foam while laser cutting?

A: Setting the laser machines power, speed, and focal length to correct will simultaneously avoid melting and cutting the foam. Also, performing test cuts on pieces of foam can be used to figure out the correct settings to reduce melting for further tests.

Q: Will foam laser cutting work for soundproofing materials?

A: Laser foam cutting can be applied for the creation of soundproof foams, particularly employing high-density foams which yield better sound absorption. The customization of foam core design for enhanced soundproofing features is possible due to the accuracy offered with laser cutting.

Q: What do I need to keep in mind if I want to use a laser cutter on foam?

A: In regard to laser cutting foam, the type as well as the density and thickness of the foam needs to be vetted along with the foam needing to be deemed safe for cutting. In addition, achieving the intended foam cutting results requires appropriate setting of the laser machine components, including the laser head, alongside executing systematized test cuts, and adjusting the machine components.