These days, industries have to deal with Cleaning Laser technology, which optimally manages rust removal, maintenance surfaces, and upkeep tasks. Indelible marks do not have to be solved by stupid marks anymore. It is cleans through rough abrasives, surface laser beams is the concentrated form of energy obtained from a laser that can clean surfaces effectively, strongly, and without much damage to the surroundings . What clues us in to it actually functioning? What differentiates it from traditional methods? In this guide we will cover considered cleaning, it’s uses all over the world, and the reasons it’s preferred for tap modern de-rusting problems. If you are looking forward to going professional with your tools or are a bit more than curious about modern technology, this article is going to satisfy all of your requirements on this transformational process. Rest assured, all the details that you require concerning laser cleaning and its futuristic laser cleaning will be laid out clearly.

What is Laser Cleaning and How Does it Work?

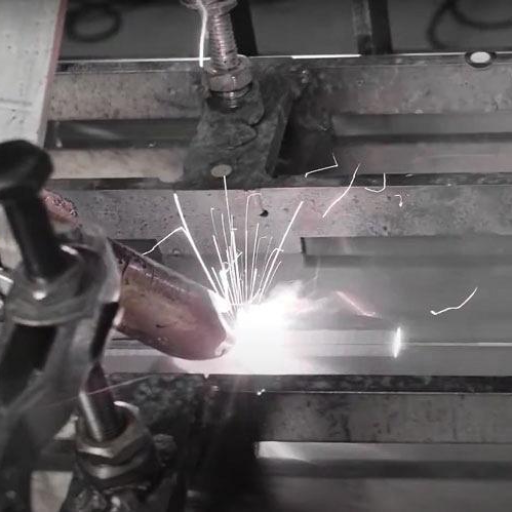

Laser cleaning is evolving as a highly effective method for cleans any surface by zapping with precision lasers, as it eliminates rust paint contaminants effortlessly and efficiently without causing any damage. Emphasizing on both power and precision, this laser burns away anything that could dull or dirty a surface, all without touching the body beneath.

Benefits of Laser Cleaning

Cleaning lasers adapt precision and effectiveness across multiple sectors, all thanks to its environmental footprint and reduced cleaning time. Moving away from the traditional cleaning methods, the first benefit is the lack of abrasives and toxic chemicals for cleansing, as it’s done solely with light. While laser cleaning systems leave enormous amounts of residual waste after cleaning, it is dirt free sans contamination residue and chemicals which means there’s up to 80% less waste and processes needed to complete bulk cleaning.

Furthermore, studies have shown these systems eliminate anywhere from 80 to 95% depending on how powerful the set lasers they are being hit with. These sharpening systems drastically reduce operational costs because there’s way less need for soaps, chemicals, and tedious processes. As the tech’s is aligned with the clear and harsh environmental standards, its a huge step in sustainable advances of our time.

Its versatility also plays a pivotal role. More recently, aerospace laser cleaning systems can function optimally on metal, plastic, glass, and stone substrates. This expands the operational boundaries of aerospace technology to cultural heritage preservation. For instance, laser-cleaning technologies have restored ancient artifacts with delicate engravings and intricate details that were previously masked by a layer of dirt and damaged without harm.

Such industries are progressively adopting laser cleaning due to its reliability, lower costs, and long-term cost savings. This shift reflects the use of technology focused on precision and reducing the need for further maintenance.

How Does Laser Ablation Work

In efficiency, it works by directing high-intensity laser pulses to the top layer of the material to be cleaned, effectively vaporizing or breaking contaminants without damaging the underlying substrate. Varying laser parameters such as wavelength, pulse duration, and energy density must be executed with care to ensure effective cleaning. Total energy output per pulse and pulse duration must also be adjusted for specific contaminants.

The efficiency of laser ablation has been improved due to the recent development of nanosecond and femtosecond lasers. Research shows that, for example, the chance of incurring thermal damage is mitigated with the use of femtosecond lasers because of their ultrashort pulse intervals. Further research indicates that femtosecond lasers are capable of cleaning fine features on surfaces including semiconductors or pieces of art with an accuracy better than one micrometer.

Laser cleaning also has a strong quantitative basis for its use. For example, there are reports from many sectors that laser cleaning leads to a 40% reduction in cleaning duration compared to previous techniques. Additionally, laser systems have proven to consistently eradicate over 95% of contaminants in one cleaning pass, varying on the material and application. This information reinforces the importance of laser ablation as a precision instrument for many industries, automobile industry and high-tech manufacturing industries, for repeatable outcomes.

Progress in Laser Cleaning Technologies

The progress made in the last couple of years on the design of lasers and their controlling systems have greatly improved the efficiency of the laser cleaning technology. Another one of the advancements made is the accuracy when it comes to the assignment of cleaning laser parameters and the damage of the base material. Sturdier materials like metals as well as more fragile ones such as glass and ceramics can be worked on due to adjustable power levels and pulse length settings on modern systems.

Recent stats showcase the effectiveness of these systems. For instance, research indicates that optimized wavelength cleaning pulse lasers are capable of achieving an astonishing 1.5 square meters of surface area cleaned per minute without compromising quality standards. Furthermore, automated laser cleaning systems equipped with AI sensors can now perform real-time adjustments, monitoring, which minimizes downtime and increases productivity. These advances not only provide increased sustainability from the reduced need for chemical solvents, but also respond to the rising shift toward environmentally responsible industrial solutions.

What Are the Different Types of Laser Cleaning Machines Available?

- Low-Power Laser Cleaning Machines: Specialized in stripping coatings or contaminants from sensitive surfaces like artwork or small electronic parts.

- Medium-Power Laser Cleaning Machines: Appropriate for more advanced industrial processes such as rust removal, paint stripping, and the cleaning of molds and machine parts.

- High-Power Laser Cleaning Machines: Aimed at removing thick industrial coatings, rust, and preparing large surfaces for works in shipbuilding, aerospace, and other similar industries.

Advantages of Fiber Laser Cleaning Systems

- Environmentally Sustainable: The systems don’t need chemicals and abrasives, both of which have a detrimental impact on the environment.

- Accuracy: Fewer underlying damages are incurred on the material while cleaning.

- Effectiveness: The cleaning is achieved at industrial levels within a short time span.

- Long-lasting: These systems undergo little wear and tear, have a long operational life, and low maintenance costs.

- Flexibility: The systems can be used on a variety of materials and in different sectors.

Handheld vs. Industrial Laser Cleaning Machines

In the comparison between handheld laser cleaners and industrial laser cleaning equipment, factors like portability, power, application range, and return on investment are important. Mobile handheld laser cleaners are lightweight, portable, and meant for small to medium scale cleaning jobs. Their power ranges from 20W to 200W, sufficient for thin coatings, rust, and localized contaminants. These systems are flexible and easy to move forUser Friendly Systemposed as effortless in poorly accessible spaces.

In contrast, industrial laser cleaning machines are designed for bulk work and greater efficiency as their output power surpasses 1,000W for more agressive cleaning tasks. Most work with such machines is automated and caters for use in production flow. For example, research demonstrates that 1,000W industrial lasers can achieve speeds of over 30 square feet per minute depending on the material and coating.

Moreover, industrial systems are advantageous in the realms of aerospace and automotive manufacturing because these systems perform intricate precision cleaning on complex geometries showing no damage to the substrate. Although industrial laser systems have a higher initial cost, the throughput efficiency, operational life, and streamlined production processes offered often result in lower overall costs for large-scale operations in the long-term.

In the end, the consideration of handheld versus industrial laser cleaning equipment hinges upon how the specific application will dictate the project’s size, the speed with which cleaning is to be done, and the budget slotted for equipment purchase. The two categories of equipment clean surfaces to modern standards of surface treatment technologies and are influential to low-impact surface treatment standards.

How to Choose the Right Laser Machine for Your Needs

In the case of selecting which laser machine to use, deciding on the laser power output, beam quality, and type of materials to be used are crucial. Lasers that deliver more than 500 watts, as an example, will lead to faster cleaning times and successfully tackle tough jobs like cleaning contaminants, thick coatings, or rust off industrial machines. Such power makes industrial fiber laser cleaning systems a go-to option for massive undertakings because almost 15 square meters of surface can be cleaned in just an hour.

Cleaning precision is highly dependent on beam quality. Smaller beam diameter lasers are optimal for more intricate operations because energy delivery is more focused, making it possible to remove delicate oxides while protecting the substrate. In addition, the adaptability of today’s laser systems is highly commendable because it can be used on a wide range of materials, both metals such as aluminum and steel, and non-metals like plastics or composite surfaces.

Moreover, the latest innovations in laser cleaning technology focus on green solutions, thus eliminating chemical solvents and the waste associated with them. These systems suit industrial productivity and environmental concerns at the same time. Meeting technical specifications adapted to the application requirements provides a sound investment for the most appropriate laser cleaner.

What Advantages Does Laser Cleaning Offer Over Traditional Cleaning Methods?

Laser cleaning has numerous benefits compared to traditional methods, including being more accurate, efficient, and eco-friendly. Laser cleaning differs from abrasive or chemical-based techniques as it does not inflict damage to the underlying material. It is highly efficient as it does not require any preparation and does not have to deal with hazard waste material post cleaning. Furthermore, these processes are environmentally friendly as there is no need for harmful chemicals or excessive water. These reasons contribute to laser cleaning being safer for the environment and more effective for a wide variety of applications.

Recent Advancements of Laser Cleaning Technology

In the last few years, the advancement of laser cleaning technology has been remarkable, making it an advantageous remedy in almost all areas. Its precision is one of its greatest benefits; today’s lasers can be adjusted to a level that allows them to clean materials to the granularity of a micron, making them ideal for sensitive objects like aerospace parts and heritage artifacts, floorby accurate cleaning.

The latest systems might improve efficiency tremendously with the ability to clean surfaces up to 15 square feet per minute depending on the power and type of laser used. In addition, newer model laser cleaning machines are becoming more and more energy-efficient. Some models are now 30% more efficient than previous versions while offering better results. Improved results are also achieved with the ability to adjust parameters like pulse length and frequency, allowing cleaning on a wide range of surfaces from sensitive alloys to industrial parts.

These facts, together with the environmentally-friendly factors such as the reduction of harmful chemical usage and waste, make laser cleaning an industry-competitive option for eco-conscious industries like manufacturing automotive parts, shipbuilding, and recycling electronic devices.

Precision and Efficiency of Laser Cleaning Technology

Further development of laser cleaning technologies is focusing on the precision and efficiency of these systems, driven by research and real-world applications of different industry sectors. As recently reported, modern laser cleaning devices achieve over 90% cleaning efficiency which further decreases preparation and industrial downtime. An example of this would be the automotive industry, where laser cleaning increases adhesion for welding and surface coating by reliably removing rust or oil contamination.

Much like AI, real-time monitoring ensures that laser cleaning services can adjust to surface discrepancies with minimum mistakes, delivering consistent results. These breakthroughs boost productivity while simultaneously aligning with company goals that require decreased energy spending, removal of dangerous cleansing substances, and reduction of resources expended on cleaning.

Financial Viability When Compared to Chemical Solutions

The benefits of laser cleaning solutions are noteworthy, especially when considering chemical cleaning alternatives. Despite the price of laser equipment being somewhat steep, no further chemicals are needed, and with minimal maintenance and no maintenance chemical disposal required, the purchase is worthwhile. Additionally, the accuracy and efficiency laser cleaning systems offer means that projects can be finished in record time, optimizing financial resources spent.

What Can Laser Cleaning Be Used For?

Laser cleaning is effective for rust removal, grease removal, paint removal, and cleaning other contaminants from metal surfaces. It is also used on antique raw materials since it is safe for the surface and more accurate than traditional methods of surface treatment. As a result, laser cleaning services can be found in the aerospace, automotive, and manufacturing industries where surfaces must be cleansed for welding or coating to be performed.

Advances in Laser Cleaning Technology and Its Applications

In many fields, the precision and efficiency of cleaning surface using laser technology has dramatically increased due to rapid evolution of technology. Use of high-powered lasers increases the efficiency and thoroughness of the cleaning process; however, damage to surfaces underneath must be kept to a minimum. For example, modern laser cleaners are able to adjust their power: one can choose strong settings for cleaning robust steel components and low settings for fragile glass.

Current industry report data indicates that the popularity of laser cleaning is set to grow, with the global market for laser cleaning projected to reach USD 936.16 million by 2026, increasing with a compound annual growth rate (CAGR) of 4.7% from 2021 to 2026. The growth is attributed to this technology being environmentally friendly since there is no need for harmful chemical solvents, as well as waste production being minimized. In addition, the level of automation and integration of AI in laser cleaning systems has greatly increased their accuracy and speed, making laser cleaning widely used in precision-dependant industries such as aerospace.

Applications of laser cleaning technology include the removal of mold in the injection molding process, graffiti on public property, and the removal of oxide layers on welded components. For instance, some studies report that incorporating laser cleaning with abrasive blasting yields a 35% reduction in processing time when compared to using traditional abrasive cleaning. These time and cost savings in conjunction with providing enhanced equipment maintenance and supporting long-term ROI demonstrate why laser cleaning should be considered a modern solution for surface preparation and restoration.

Performance Indicators and Advancements in Laser Cleaning Technology

The laser cleaning technology has dramatically advanced with the integration of new features that increase its effectiveness, accuracy, and even its green credentials. This is in consideration of the versatility of the fiber laser system because of its unmatched precision and control in different areas of industries. Recent data suggests that modern fiber lasers can operate with an efficiency exceeding 40%, which is a great deal of energy savings in comparison to older technologies.

Moreover, researches indicated that with the right conditions, settings and power of the laser, surface rusts and oxides can be removed at the rate of 1m squared per minute. With such capabilities, range of industries such as aerospace, automotive, and shipbuilding achieve sharper productivity alongside strict precision that complies with the demanding standards of quality needed in these fields. Importantly, reports indicate that the lifespan of surfaces treated with laser cleaning outlasts those not treated owing to provided contaminant free surfaces without the application of damaging heat, abrasions, or suction.

Equally as remarkable are the eco-friendly advantages of laser cleaning. Unlike the usual cleaning by blasting or using chemicals, abrasive cleaning is devoid of any solvents and other forms of primary waste that can abrasive blasting chemical treatment as well as blasting supports global sustainable objectives. There is heightened productivity, but even surface preparation and restoration work receives a more eco-friendly option.

Cleaning Sensitive Surfaces and Materials

Laser cleaning is exceptionally effective for delicate surfaces and materials that are usually susceptible to damage from conventional methods. Laser systems, through their focus and control capabilities, are able to transform structures in a stepwise manner and may strip layers without damaging the substrate. For instance, industrial tests have shown that laser cleaning abrasively strips aluminum and bronze composites and carbon composites that are mechanically and chemically treated with rusty and oxide paint without damage; the components are painted over.

More recent research shows that high-precision laser systems function with a precision of up to a few micrometers. This precision strengthens the value of laser cleaning in aerospace and aircraft industries as well as in the restoration of aged objects where detailed structures are essential, since the thermal effect of the process, when set to proper parameters, is dimensionally small. Another reason for value is the small shift of quiescence or distortion of the substrate that claim is the shielded soften.

Moreover, data from case studies show that delicate design of laser systems for particular operations chances these figures to over 99% depending on material and machine settings. Such outcomes reinforce laser cleaning for other laser-based industries that require absolute surface treatment.

How to Choose the Right Laser Cleaning System?

- Material Compatibility – Make sure that the system suits the material you need to clean in order to avoid damage or inefficiency.

- Power Level – Allocate low power for delicate tasks and use a higher power for heavy-duty cleaning.

- Application Requirements – Analyze how the system’s accuracy and effectiveness align with your cleaning requirements, like removing rust or preparing the surface.

- Ease of Use – Choose a system that has straightforward controls and is easy to move, if needed, to multiple locations.

- Vendor Reliability – Acquire items from reputable suppliers. you know will durable equipment and high-quality, reliable support.

Key Insights into Laser Power and its Effect on Speed Marking the Laser

Marking the laser works most efficiently when the power level is set appropriately. The speed and efficiency also improves significantly for marking at higher powers. For example, having a 50W laser will outperform a 20W laser not only in speed but with thick and resistant materials as well. The only drawback is how much precision is lost. Adjustments will need to be made to optimize the speed.

Deep engraving applications or marking on harder metals usually require relatively higher power levels to effectively penetrate harder surfaces. Plastic and thin films are more delicate, hence high power is avoided to minimize distortion and damage. Recent tests indicate that a 10W to 100W laser with adjustable power settings offers flexibility for different materials and depths.

To achieve the best results, laser power must be balanced with marking speed, beam quality, and the material being worked on. Striking a balance between these factors increases productivity while ensuring excellent marking sharpness for various industrial purposes.

Important Attributes of Laser Cleaning Devices

Marking accuracy aims to achieve industrial standards through improved productivity. Careful consideration of specific factors determines the most suitable cleaning performance and application for the needed laser cleaning devices. One of these factors is the laser’s power level. Lasers designed with variable power output typically set from 20W to 200W allow fine-tuning and adjustment depending on the contamination and surface material to be cleaned. Also, low power protects delicate surfaces and high power removes robust contaminants such as rust and thick coatings.

The beam delivery system also stands out as a notable distinguishing feature. Effective cleaning, in this case, is achieved by careful control of energy delivery thanks to the advanced optics and beam focus. For instance, the cleaning process performed by femtosecond and nanosecond pulse lasers is unrivaled in precision with minimal zones of heat damage.

The cleaning task can be accomplished more quickly due to automation features as well. These include software controls that modify parameters such as repetition rate, pulse width, and scanning patterns. Such automation features improve the speed and consistency of the cleaning process. Recent estimates indicate that the operational time for automated systems of laser cleaning surfaces is up to 50% less than the time-consuming, traditional sand blasting approaches.

Last, but not least, aspects related to equipment durability, ease of mobility, and overall portability must be given equal attention. Prioritize rugged housing with efficient cooling systems plus designs that facilitate transport and seamless workplace integration. Emphasizing these aspects will ensure smarter investments for businesses in laser technologies, enabling high precision and efficiency in achieving surface cleanliness.

Reference sources

- Study: An Overview Study on Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry1

- Objective: To provide an overview of laser technology and its applications, including cleaning.

- Key Findings:

- Laser cleaning is highlighted as a cutting-edge method for removing contaminants and residues from surfaces with precision.

- The process relies on the high energy of laser beams to vaporize or ablate unwanted materials without damaging the underlying surface.

- Applications include cleaning metal parts, removing rust, and preparing surfaces for further processing.

- The study emphasizes the efficiency, environmental friendliness, and adaptability of laser cleaning in various industrial contexts.

- Study: Analyzing Costs of Space Debris Removal Using Laser Cleaning and Other Methods2

- Objective: To evaluate the feasibility and cost-effectiveness of using ground-based laser cleaning for space debris removal.

- Key Findings:

- Ground-based laser cleaning is effective for medium-sized debris (1–10 cm in diameter), using laser pulses to alter debris orbits until they burn up in the atmosphere.

- The study developed a dynamic model to simulate the debris removal process, estimating that an average of 4.36 laser passes is required per debris piece.

- The method is cost-effective for medium-sized debris but less suitable for larger objects due to increased energy requirements.

- The research highlights the potential of laser cleaning for space applications, showcasing its precision and ability to operate remotely.

- Top Laser Cleaning Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: How does laser cleaning work for Industrial applications?

A: Laser cleaning works by aiming high power laser shots at a surface that has contaminates on it. Surfaces that have contaminants, such as rust, paint, and oxides are blasted with surface energy, which vaporises contaminants without harming parts lying underneath. Surface cleaning using laser technique is precise and controllable enabling the cleaning of parts of the surface to designated areas. Unlike normal cleaning processes, in the laser rust removal process, there is no contact with the surface to translate. Most industrial settings work with the puled fiber laser as they have proven to handle cleaning very well and require little maintenance. The cleanliness and contamination levels that the laser souce is tailored to cleanse makes it suitable for different pre-defined industrial cleaning tasks.

Q: Which industries commonly use laser cleaning and for what purposes?

A: The use of laser cleaning is extensive in industrial applications. Some other examples include the removal of rust and other oxides from metallic surfaces, preparation of surface before welding, mold sand blaster cleaning in industries, paint stripping, preservation of historical items, cleansing of electric components, and reconditioning automotive components. The laser cleaning process has specific importance in aerospace and automotive manufacturing and electronics where cleaning accuracy is paramount. Also, laser cleaning surface treatments may be employed in removing foreign substances from equipment used in production, industrial molds, and preparing surface for coatings or bonding. With laser cleaning, a greater flexibility is possible in tailoring processing parameters which makes it applicable for bulk cleaning industrial artifacts as well as fine cleaning of artistic pieces.

Q: What Makes Laser Cleaning a Green Technology Compared To Other Methods?

A: The Environmental Protection Agency recognizes laser cleaning as green technology because it reduces the risk of chemical spills and environmental contamination. As compared to traditional means of cleaning, laser cleaning does not require chemical solvents, abrasives, or water. Water, which is regulated by government agencies, needs to be treated as well as chemicals. The amount of waste created during laser cleaning is also limited. Contaminants that undergo laser cleaning can be vaporized into clean smoke or dust that can then be filtered. This non-contact cleaning method reduces how much chemicals are disposed of and also alleviates Blue Water issues where wastewater treatment plants dilute not remove waste. Energy consumption is usually an issue during cleaning processes, but in this case, the opposite is true. Laser solutions require less energy as compared to industrial cleaning processes. The most important point is the absence of hazardous chemicals, which makes laser cleaning a preferred choice to lower practicality without jeopardizing standards.

Q: Which industries benefit from laser cleaning the most?

A: The technology for laser cleaning is helpful to several industries. In the automotive sector, laser cleaning is used for the removal of coatings and rust as well as preparing surfaces for bonding. Aerospace manufacturers rely on laser cleaning for critical component contaminant removal. Heavy manufacturing sector is reaping the benefits of laser rust removal on tools and machine parts. For civilian electronics, laser cleaning is used for the cleaning of delicate circuit boards. Professionals engaged in historic preservation use it for the restoration of artifacts. In oil and gas, laser cleaning is used for maintaining pipelines. Laser cleaning of processing equipment is done in the food and pharmaceutical sectors for its non-contaminating properties. Laser cleaning is also used in foundries and metal fabrication businesses for maintenance of molds and pretreatment prior to coating, welding, and other processes.

Q: What types of equipment are used for cleaning with laser technology?

A: There are different laser cleaning equipment systems available for different purposes. For various cleaning tasks including places that are difficult to reach, the Handheld laser cleaning systems offer the most flexibility. The Stationary laser cleaning workstations offer precision for more intricate cleaning tasks. For non-stop function in high volume production settings, there are Conveyor laser cleaning machines. Automated cleaning for complicated parts is done via Robot-integrated laser systems. A laser source (most often a pulsed fiber laser), beam delivery parts, control software, and class-1 laser safety enclosure as a minimum safety feature are included in most systems. These systems also have laser markers and control systems that can be set up to follow specific cleaning lines and intensity levels, which makes these systems highly customizable. The choice of equipment is based on the required cleaning accuracy, volume to be produced, and the shape of the surfaces to be cleaned.

Q: What factors should be considered when choosing a laser cleaner?

A: While choosing a laser cleaner, aspects like laser power requirements, type of contaminants, and the materials to be cleaned should be reviewed. Review the laser energy needed for your specific application **as well**. Determine the size of the workstation and the required mobility; while handheld laser cleaning systems are portable, stationary workstations offer more stability. Focus on the protective features and the required protective enclosures alongside workplace safety protocols as well. Consider cost efficiency regarding energy consumption and maintenance as well. Assess the optimal speed that meets the standards you need for production. Examine if user-friendly interfaces are available alongside the level of automation of the system. Make sure the laser cleaning system allows for customization and has adjustable parameters to suit different materials, surfaces, and contaminants.

Q: How does the process of cleaning with lasers measure up against more traditional techniques?

A: Aside from laser cleaning, other cleaning methods incorporate chemicals along with numerous tools, internally or mechanically. Compared to these cleaning methods, laser surface cleaning (cleaning using lasers) is considered to be better for many reasons such as avoiding contact, but is still hindered while cleaning large areas. Unlike methods such as sand blaring which requires some sort of physical contact, laser cleaning makes use of non contact cleaning techniques avoiding any damage to the surface, and is more precise yielding greater results such as surface etching. Not only is there a lack of wastewater forage, but chemicals straining wounds also isn’t required which helps the environment. In cases where dealing with complex host geometries, laser surface cleaning is more beneficial. As a rule of thumb, simpler jobs with large exposed surfaces are still prone for cost effective marking. Expenditure in laser attack cleaning machinery is often criticized, but it helps the ozone layer and lowers routine expenditure in the process. The selection between laser and traditional cleaning rests on the level of accuracy one intends to achieve, broad precision delimiters, and depth of the cost factor.

Q: What laser cleaning equipment safety measures should be taken?

A: Precautions are very important in the operation of laser cleaning equipment. Ensure that the users have undergone appropriate laser safety training, and that they know how to deal with the inherent dangers pertaining to laser radiation. Protective laser shielding eyewear should be worn as per the specific laser source wavelength being used. Implement engineering protective measures such as a class-1 laser enclosure, or other appropriate shields to contain the laser radiations. Emergency stop buttons and interlocking systems should be installed on the workstation laser cleaning. Appropriate workstation ventilation must include fume hoods designed to vent contaminants that have been vaporized. Observe all other relevant safety rules or regulations about the governing control of lasers set in place by the regulating authority. Assign well-defined operational guidelines that include those areas laser cleaning can be performed, and those marked as no entry zones. Be certain that all signs and safety mechanisms are maintained and checked on a constant basis. Never remove protective housings or bypass safety interlock systems. With all the appropriate precautions taken, lasers can be safely integrated industrial processes.

Q: Can laser cleaning damage the surface material during the cleaning process?

A: The benefits of laser cleaning include its functionality to clean without harming the underlying material provided that all parameters and settings are correct. The energy of the laser can be calibrated appropriately to only vaporize the contaminants, leaving the base material intact. This form of cleaning is achieved by fine-tuning the laser’s parameters such as power, pulse duration, and frequency to align with the absorption characteristics of the contaminant and the substrate. Nonetheless, improper settings can lead to some form of thermal damage, which is why training is crucial. Different materials have different thermal thresholds and optical absorption properties, requiring appropriate laser settings. Cleaning is a reserved task done by conservation specialists who first try the scrub on test patches before applying it on the entire surface, especially for fragile surfaces or historical artifacts. When configured correctly, laser cleaning allows cleaning without the risk of scrubbing the surface while removing the unwanted materials.

- The Ultimate Guide to Laser Cutting Plywood: Mastering the Art of Precision

- A Comprehensive Guide to the Most Common Types of Laser Marking

- Unlocking the Potential: How to Use a Laser Marking Machine for Engraving and Etching

- Laser Marking vs. Engraving vs. Etching: Understanding the Key Differences and Applications