Lasers have changed the relationship we have with technology, as they serve as one of the most important modern inventions. They serve a critical role in revolutionary technology such as modern medicine, high-speed communications, and precision manufacturing,” For what reason are these perfectly aligned light beams so adaptable and versatile? This blog will discover the very intriguing science of lasers, identifying the many industries they are shaping as well as revolutionizing our daily lives. No matter whether you are an industry professional, technology aficionado, or just curious about the sparks of innovation, this laser technology excursion will surely fascinate and educate.

What are the Laser Applications in Medical Fields?

Medical lasers have transformed the construction of a new patient-specific treatment by providing opportunities for accurate and less difficult treatments. Currently, they are widely used in surgical procedures, including tumor excisions and surgical repairs of tissues, where they focus on specific intended portions of body without damaging other adjoing tissues. They are also indispensable instruments in the field of dermatology for managing the skin disorders scars, wrinkles, hirsutism and others skin. Moreover, their use in ophthalmology for vision corrections like LASIK and other eye surgeries, including cataracts or glaucoma surgery, is remarkable. This shows the immense benefit and precision in using laser technology towards better healthcare services.

How is Laser Technology Used in Surgery?

Laser technology is extremely important in surgical procedures in this modern world because precision and control along with Laser techniques makes surgery less invasive. It is possible for surgeons to cut as well as remove unhealthy tissue with the use of advanced laser instruments while not damaging the tissue parts which are healthy which subsequently, decreases the risks and complications of surgeries, enhancing the recovery time for the patients. For instance, in general and oncological surgeries, lasers are effective in excising (removing) tumors along with any surrounding soft tissues which may be necessary, and less unwanted healthy tissue, spare great healthy tissue. With this, the aim of preventing excessive destruction of adjacent healthy tissues can also be balanced without compromising precision. This is particularly important in delicate surgical procedures like brain and spinal cord surgery. Also, laser technology has a big place in the field of cosmetics and reconstructive surgery for accuracy. The use of laser instruments improves accuracy, reduces the amount of bleeding and the periods of healing are also significantly smaller which makes such methods of surgery absolutely essential in assisting advancements in surgical procedures.

What are the Effects of Laser in Dermatology?

Based on my clinical experience lasers are performing a very useful function in dermatology by enabling non-invasive and highly focused interventions. Lasers can be used to reduce skin scars, wrinkles, and pigmentation. They are also used for hair removal and for the removal of vascular lesions. Lasers have the benefit of precision, which means that a specific problem area can be treated without extensive damage to the skin around it. Moreover, laser treatments frequently result in an increase in collagen production and therefore, after some time the skin gets smoother and rejuvenated. In summary, lasers are a safe, effective, and dependable means of improving the condition and health of the skin.

How Do Medical Lasers Aid in Eye Treatments?

In ophthalmology, the advent of medical lasers has marked a distinct change in how various conditions of the eye are treated by providing more accurate and less invasive techniques. For example, lasers are widely used in correcting refractive errors in the eyes such as in LASIK done for corneal reshaping so patients do not have to rely on spectacles or contact lenses. Studies report that LASIK has a success rate of 96% where patients achieve 20/20 vision or better.

Diabetic retinopathy and glaucoma are some of the age-associated illnesses of the eyes which can also be treated with lasers. In glaucoma, the eye pressure is lowered with the help of fluid drainage through the laser-operated eye’s natural pathways with laser trabeculoplasty. It has been demonstrated in studies that this method has managed to lower the pressure in numerous cases by 20-25% and above. In the case of diabetic retinopathy, vision is protected by the internal sealing of blood vessels in the retina and preventing further bleeding by laser photocoagulation. The increase in patients with diabetic retinopathy who improve with the laser treatment is over 70%.

Also, ocular femtosecond lasers are now commonly used in cataract surgery to break up and remove clouded lenses which are later replaced with artificial ones. This technology improves the precision of the treatment and speed of recovery relative to other methods. The use of medical lasers is contributing to advancements in the safety and effectiveness of eye care procedures and is improving the treatment results and the quality of life for many patients around the globe.

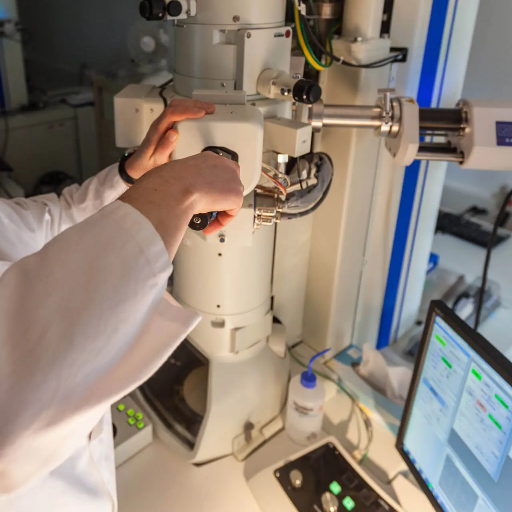

How is Laser Spectroscopy Transforming Research?

Laser spectroscopy is revolutionizing research with the ability to analyze materials on a molecular and atomic scale. It provides more accurate data of matter’s chemical composition, structure, and dynamics. For this reason, it has applications in environmental science, medicine, and materials engineering. It is also non-invasive, maintaining the samples’ integrity, which enhances experimental capabilities.

Major Uses of Laser Spectroscopy in Chemistry

One crucial use of laser spectroscopy in chemistry is in the monitoring of the environment. This includes detection and measurement of trace gases and pollutants within the atmosphere. Cavity ring-down spectroscopy CRDS techniques can assess climate change by using parts-per-billion levels to identify greenhouse gases such as CH₄ and CO₂.

Biomedical research and diagnostics is another critical area. Laser induced-fluorescence (LIF) spectroscopy enables the earliest detection possible for medical conditions through fluid biomarker analysis. For instance, specific proteins or metabolites might trace forward for cancer or diabetes.

Moreover, within the field of materials science, laser spectroscopy enables a wide-ranging comprehension of the properties of various materials on an atomic level. In particular, Raman spectroscopy is well known for determining the structural features of nanomaterials which supports the design of new and more efficient catalysts and semiconductors. Additionally, time-resolved spectroscopy allows researchers to gain insight into the chemical processes and obtain the reaction kinetics during the course of the reaction.

The unmatched accuracy and flexibility which laser spectroscopy offers, together with new developments, continue to transform and advance the fields of chemistry and environmental protection, health care, and materials innovation. One such example is the application of AI algorithms to data interpretation, which is fast decelerating the pace of complex data set analysis and improving efficiency in research timelines.

What Is the Role of Laser Beams in the Analysis of Materials?

Due to the variety of applications covered, laser beams represent an important tool in material analysis because of their accuracy and flexibility. Material characterization using lasers such as Laser Induced Breakdown Spectroscopy (LIBS), or Raman Spectroscopy, employ focused laser beams to provide material composition on a chemical and structural level. For example, in LIBS, high energy laser pulses are used to vaporize a small volume of the sample into a plasma that radiates light. The light generated can be analyzed for its elemental nature and the material identified with a high degree of precision.

The latest innovations have integrated lasers into the industrial sector for non-destructive testing (NDT) procedures. These methods enable manufacturers to detect material flaws or perform quality checks without causing any destruction to the product. A good example is fiber lasers, which are now widely accepted because of their high beam quality and energy efficiency. They enable the industry’s most precise measurements, even for micro-scales, on the most complex or fragile materials.

Results from the 2023 study on materials indicates that the use of ultrafast lasers with femtosecond pulse duration results in approximately 30% faster analysis compared to older methods while significantly reducing thermal damage to the delicate samples. These developments exemplify the ever-increasing importance of laser technology in understanding the material’s properties for advancements in aerospace, biomedical engineering, and renewable energy wonders.

What Role Does Laser Technology Play in Environmental Monitoring?

In modern ecology, monitoring the state of the environment and its components is a priority. This is precisely why lasers are used in ecology. In monitoring the environment PE lasers LIDAR systems can measure pollutant aerosols, gases, and even greenhouse emissions. Lidar LIDAR based systems have proven LIDAR capable of measuring the concentration of particulates PM2.5 in large cities which aids in monitoring and improving air quality. Moreover, laser gas analyzers of CH4 and CO2 configured to operate in real-time enable scientists to monitor emissions which reduces climate change’s impact.

Adjusting laser gas analyzers to measure real time data helps scientists better deal with climate change. In addition, LIBS is extensively used in soils and waters to assess their quality for LIBS is complete without soil contamination testing. Lead is assessed for its various industrial applications using LIBS in high accuracy soils devoid of any anthropogenic contamination. Pb content in soils can now be determined with better than 95% accurate levels. These are important steps towards solving environmental issues and integrating environmental technologies across borders.

What are the Military Applications of Lasers?

Lasers are of great importance in military technology because they have a wide range of application. They are observed in the form of high-powered lasers making use of auxiliary navigation and target acquiring systems amplifying operational efficiency. High-energy lasers also propel modern communication systems with their ability to send protected documents containing high volume information and data. Wielded by advanced fighting technologies, they defend openly against systems of threats like drones and missiles. The concentration of energy on targets makes lasers invaluable within the context of military technology.

How are Laser Weapons Utilized in Defense?

Laser weapons or directed energy weapons (DEWs) are growing popular defensive technologies as part of military strategies owing to their unparalleled performance, rapid firing rates, and low operational costs. Various uses of this technology exist, among which falls under counter-drone operations. Recent intelligence indicates that lasers can neutralize unpermitted or malign drones effectively. Systems like the US Navy’s Laser Weapon System (LaWS) are demonstrating successful destruction of unmanned aerial targets. These systems work with laser-like precision and greatly reduce collateral damage.

Another important function includes their application in missile defense systems. Lasers allow for missiles to be intercepted and destroyed mid-flight, providing an extremely fast and potentially boundless response capability as long as energy resources are available. For example, advanced test systems such as the High Energy Laser Weapon System (HELWS) have demonstrated their effectiveness in tracking and destroying missile targets during their flight, providing defense assistance with reliable, low cost-per-shot operations.

Information gathered from global defense studies suggests that the effectiveness of laser weapons makes them useful as well for aimed shooting and range-finding. With precision aim, a system can focus energy to disrupt/destroy the enemy equipment’s sensor and electrical systems without collateral damage. Furthermore, better fiber optics and solid-state lasers have increased the power output to a scale-fitting smaller tactical operations to join larger military engagements.

These abilities highlight the importance of laser weapon technology in the modern strategy of military defense, integrating old and new technologies to sophisticated challenges swiftly.

The Importance of Laser Sights in Today’s Warfare

Laser sights have proven to be important when precise accuracy is required in any military operation. A soldier can target threats easily by aiming at a particular point using fixed light beams, which is very useful for low visibility scenarios like nighttime or covered locations. With this technology, the time spent trying to aim at targets is minimized, improving response times in critical situations. Moreover, laser sights can be used on different types of weapons from rifles to handguns, and can be used in any combat situation. They enhance operational efficiency and reduce unwanted collateral damage. In short, attempts to achieve greater efficiency in modern day warfare has lead to the development of laser sights and has improved the efficacy of armed forces.

In What Ways Do Lasers Improve Missile Guidance Systems?

Lasers improve the precision and capability of modern guidance missile systems. Laser guidance systems can allow missiles to lock on with great accuracy to fixed point by directing focused light beams to the point of interest. Target designation systems are used to light the target and create a box which the sensor mounted on the missile can easily follow and trace.

One of the primary benefits is that laser-guided missiles claim a hit accuracy of 90%, which is better than any unguided system. Military data brag about the wonders of these systems regarding collateral damages; they permit precision bombardments in heavily congested battle situations. Plus, advancements in laser technology have made performance on fog or rain enhanced conditions stronger because the lasers are much more stable and powerful.

In addition, with the introduction of AI and ML, laser-guided systems are becoming more flexible and smarter. These improvements enhance the algorithm’s ability to track a selected target and anticipate its movements, even if the target is moving or blocked from view. Research indicates that the most current laser-guided systems have the ability to mid-course adjust trajectory calculations, which minimizes the mistake offset caused by unexpected environmental parameters(“the surroundings”) or movement of the designated target. Adapting these changes will make sure that these innovations will keep making sophisticated arms like laser-guided missile systems a prized jewel in any military arsenal for their strategic flexibility.

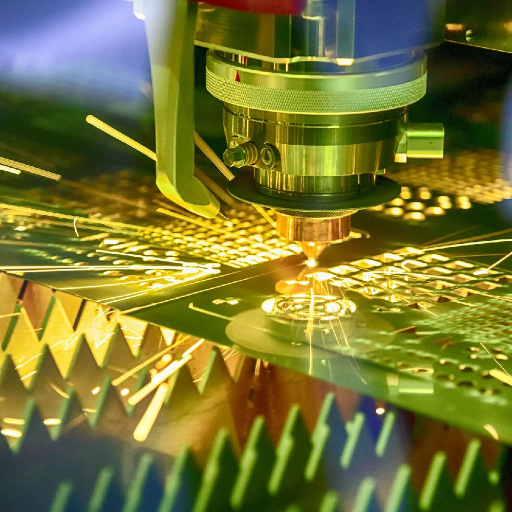

How Do Lasers Impact Manufacturing Industries?

Lasers are used in different areas of industries for their cutting, welding, engraving, and even 3D printing functions. The precision with which they operate at is unparalleled and extremely useful for manufacturers looking to achieve consistency. The incorporation of lasers within industrial functions has resulted in a lower material wastage, reaped the benefits of automation, and even reduced the overall cost of production. They have a wide array of applications and their adaptability is a very important asset for modern manufacturing.

What are the Benefits of Laser Cutting in Manufacturing?

Manufacturers have benefitted greatly from laser cutting and the introduction of their innovative technology. Laser cutting as the name suggests has its main advantage to be precision, it enables manufacturers to accurately reproduce patterns and shapes within strict tolerances resulting in very little fault. It is also non-contact meaning that there is no physical interaction so the materials will not undergo deformation which is a plus for those sensitive materials. Time is of the utmost importance and laser cutters have shown to be extremely efficient and reliable, time is not the only thing that is reduced as material waste is also lowered. It can easily remove sections of material without causing damage. The different fields of services lasers can be utilized ranges from metals, plastics, and composites – making it an essential apparatus for numerous industries.

What is the Importance of Laser Marking in Product Identification?

Product identification is one of the core capabilities of laser marking since it provides a lasting, accurate, and trustworthy mark on almost any material. This process remains implemented in virtually every sector that deals with automotive parts, aerospace, electronics, medical equipment, as well as consumer products. Markings may consist of not only product information such as serial numbers, but also barcodes, QR codes, logos, and many other markings as per requirements of monitoring and control systems.

The laser marking process is widely accepted due to its accuracy and long-lasting results. As an illustration, industry reports indicate that laser marked codes can achieve over 95% scan rate which means that the codes can easily be scanned in very tough environments. Marks made using this technology stand up against excessive abrasion, fading, and even corrosion. When the wear and tear resistance products are subjected to extreme temperatures or even chemicals, laser marking helps prepare such products.

Also, a variety of marking methods such as annealing, engraving, and scribing can also be done with laser marking. A good example is in the electronics industry where fiber lasers are known for detailing markings on circuit boards because of their precision and non-damaging nature to the nearby materials. Fast marking speed which can reach thousands of components per hour depending on the system, material and set parameters, is another major advantage manufacturers enjoy with laser marking systems.

Advancing technology has enabled the integration of lasers with automated production lines, where they are controlled via software to further improve precision and repetition. Because of such innovations, laser marking has become an essential feature in contemporary manufacturing that strives for optimal traceability, customization, and quality control.

What Role Does Laser Welding Play in Automotive Production?

Laser welding is one of the most important technologies in automotive production because it accurately, effectively, and reliably connects different parts. This technology is specially designed to construct strong, ultra-lightweight systems, which optimize vehicle performance and fuel economy. As reported in the latest industry research, laser welding systems can reach remarkable weld speeds of 100 inches per minute, depending on the application as well as the material used. With this capability, mass production becomes effortless. Reduced cycle times, even at weld speed, improve efficiency without risk to quality.

Moreover, the laser welding’s adaptability for joining metals, alloys, or composite materials is proven useful for the automotive sector. For instance, aluminum and high-strength steels which are frequently found in modern day vehicles, can be easily welded with custom laser settings. The evolution of laser welding in automated production systems is further improved by real-time control systems that guarantee excellent standard assurance and reduction in quality errors. These technological innovations sustain the electric vehicle (EV) market, which needs light weight and dependable assemblies for battery packs. Laser welding is fundamental to augmenting automotive manufacturing because it adeptly fulfills tough requirements and adjusts to shifts in design needs.

What is the Significance of Photonics in Laser Development?

As the guiding principle in the creation, manipulation and controlling of light, photonics is very important in the development of lasers. With lasers achieving greater precision and efficiency due to photonics, lasers can now be tailored to specific uses and requirements. The technology is advancing a range of industries, including manufacturing, medicine, telecommunications, and research, which in turn enhances the capability and flexibility of modern-day lasers.

What effect does photonics have on laser systems?

Photonics contributes exceptionally towards the improvement of laser systems by facilitating the control over the propagation, coherence, and intensity of light. Such sophisticated control is necessary to maximize efficiency when utilizing lasers in various fields and industries. Take micromachining for example. With photonic powered ultrafast lasers, some can operate at pulse durations of femtoseconds (10^-15 seconds) which makes for precise material removal accompanied with low levels of thermal damage. This especially benefits the electronics industry where components such as PCBs (Printed Circuit Boards) are made with complex designs that need sub-micron precision.

The productivity improvements made from new photon technologies have been documented in the latest research. As reported by the industry, the incorporation of photonic technologies has improved the energy efficiency of fiber lasers by about 35-40%, significantly lowering the operational energy expenditures. Moreover, these systems allow for adaptive beam shaping, which permits the modification of laser beams for various uses including cutting, welding, and even 3D printing. This versatility is enhanced by the development of diode pumped solid-state (DPSS) lasers which, in addition to these capabilities, extend operational lifetimes and provide better thermal management.

Laser systems, especially in high-power ranges, have been noted as further supported by photonics advancements. For instance, lasers for industrial metal cutting have power capabilities of over 10 kW with maintained beam quality due to the photonic design. Such system scalability guarantees economic viability and flexibility for laser systems in other supporting technologies like quantum computers and advanced lithography systems.

Integrating photonics into laser technologies enhances their efficiency, precision, and adaptability, allowing users to fulfill the needs of modern technological applications.

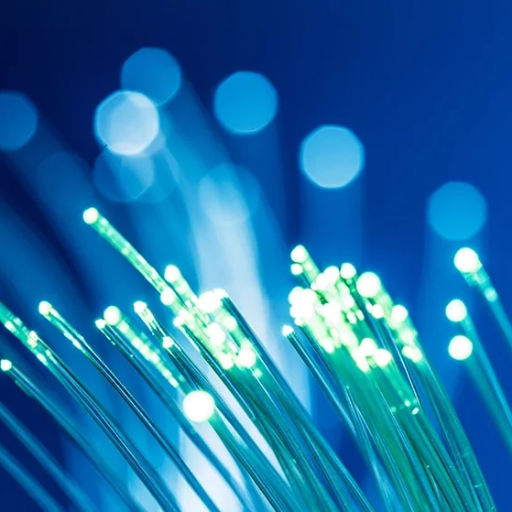

How Laser Technology Advance The Field Of Optics

The incorporation of laser technology into optics has enabled substantial progress in precision, speed, and scalability. The most promising growth area is now in femtosecond laser optics, which use ultra-fast bursts of laser energy to process materials, owing to its precision in executing steps clinically clean, wide, and deep. Research indicates fabrication and photonics-based devices are indeed possible because femtosecond lasers are capable of constructing features at a nanometer scale.

Another important area of progress is adaptive optics, commonly associated with modern laser technologies aimed at correcting distortions in the atmosphere for use in such applications as satellite and astronomical imaging. Observatories that apply adaptive optics achieve image resolution improvement of 20 times over the traditional techniques Optical with the use of higher order modes; however, conventional techniques are capped at 1 to 5 times over.

Moreover, the use of high-power lasers is pushing the limits of optical data transmission by increasing the speed at which multiple signals are sent and received throughout a single optical fiber using wavelength-division multiplexing (WDM). As a result, data is transferred at rates above 10 terabits per second (Tbps), which is important for the growing global population’s need for fast and reliable internet service.

The incorporation of lasers into some spectroscopic methods has greatly advanced environmental surveillance as well as medical diagnostics. As an example, laser-induced breakdown spectroscopy (LIBS) has emerged as an important technique for analysis because it can detect trace elements with detection limits in the parts-per-billion (ppb) range, which is important for airway quality measurements and in metallurgical assessment.

At the same time, the cooperation between laser and optics technologies is developing a world that is more accurate, quicker, and able to solve difficult scientific and industrial problems in the near future.

In What Manner Do Optical Parts Improve the Application of Lasers?

Optical parts are fundamental in enhancing the performance of lasers in a particular area of industry or science. Specially designed lenses, mirrors, and beam splitters are needed for the proper manipulative guidance of the laser beams. For example, beams from lasers are of low intensity and high divergence, but the use of high-quality focusing lenses drastically increases beam intensity and precision which is especially critical in operations like material cutting and engraving. In the same way, dielectric mirrors with highly reflective coatings perform beam steering with no energy losses.

Recent research indicates that the development of optical coatings has increased the damage threshold limits for components, enabling higher laser intensities without compromising system integrity. For instance, the ultrafast lasers employed in micromachining are now capable of producing features smaller than 1 µm and achieving processing speeds of hundreds of mm/s due to more advanced optics. Furthermore, the incorporation of adaptive optics systems has enhanced beam shaping and broadened the application range of lasers for sophisticated tasks such as 3D imaging and construction at microscopic scales. Such development demonstrates the growing impact of optical components innovations on the evolution of laser systems in many fields.

Reference sources

Frequently Asked Questions (FAQs)

Q: What are some of the most prevalent medical uses of lasers?

A: Lasers are very helpful in medicine for use in eye operations, getting rid of hair with a laser, and laser procedures in dentistry. They make surgeries and other medical processes easier and faster, resulting in shorter recovery periods and more favorable results.

Q: What is the role of laser light in the processing of materials with a laser?

A: In the processing of materials with a laser, laser light is employed for cutting, engraving, or modifying the surface of materials. The concentration of energy in the laser beam is great enough to permit clean and accurate cutting or engraving which is useful in more complex tasks.

Q: What precautions should be taken when using lasers for medical purposes?

A: Laser safety is critical with regards to medical use, as injury can occur to the skin and breach eyes. Steps must be taken to protect lasers and the use of lasers must be accompanied with proper equipment as well as the use of controlled environments.

Q: What kinds of lasers are utilized in surgical medicine?

A: Different kinds of lasers are employed in surgical medicine which include: diode lasers which are used in hair removal, CO2 lasers which do skin resurfacing, and Nd:YAG lasers which are used in treatment of vascular lesions.

Q: In what ways can lasers assist in manufacturing processes?

A: Lasers are utilized in manufacturing for material cutting, welding, and marking. The accuracy accompanying laser processing improves the quality and productivity of production lines, which adds efficiency to manufacturing processes.

Q: What is the importance of laser cooling in scientific investigation?

A: In scientific research, laser cooling refers to the method employed to lower the temperature of atoms or molecules. It is important for experiments that need very low temperatures, for instance, those involving quantum mechanics.

Q: What are the advantages of laser microscopy in biological research?

A: Laser microscopy enables the imaging of biological samples at the cellular and subtissular levels which makes it possible to analyze more complex structures. This technique enhances appreciation for more intricate processes in biology.

Q: What is the significance of laser deposition in different fields of industries?

A: It is also referred to as laser cladding. Laser deposition is employed in the addition of materials to surfaces with high accuracy of the work done. It is helpful in the repair and improvement of parts. This method extends the lifespan of components and minimizes material waste in industrial work.

Q: What changes have been made in the design of laser systems over the years?

A: The overall design of laser systems has enriched the compactness, efficiency, and power of the laser systems. New types of laser components, especially laser diodes, have increased their effectiveness and broadened their scope of applications.

Q: What are the applications of laser technology in the military?

A: With regard to military purposes, laser technology is being used for aiming, distance measuring, and sending messages. To refine telescopic views and offset distortions caused by the atmosphere, laser guide stars are used to enhance the accuracy of the telescope observations.