CNC machining has developed and changed an entire range of modern industries due to its efficiency, precision, and versatility. It is without a doubt one of the most important features always driving innovation in manufacturing. As the years progress, so does technology, and this is what is transforming the CNC industry for smarter production processes that result in lower costs and advance developments. In this article, we look at the future of CNC machining and what disruptive innovations are moving the industry forward. We also explain how these innovations can be applied by businesses to maintain a leading edge in a competitive marketplace. From automation and AI integration to customization and sustainability, explore emerging forces shaping the next generation of manufacturing.

How is automation changing the future of CNC machining?

With automation, CNC machining receives marking efficiency, precision, and productivity. These automated systems minimize human involvement, allowing machines to self-run at peak efficacy with negligible error. Technologies such as robotic arms and sophisticated computing systems have been integrated, optimizing production workflows, and reducing completion time and costs. In addition, automation aids in maintaining uniformity in manufacturing, achieving quality results in bulk production. This shift allows industries to concentrate on new developments while still adapting in a quickly transforming world to sustain market leadership.

Improvements of Laser Technology on CNC Machines

Precision and speed have become synonymous with modern CNC machines since laser technology was introduced. Progresses made in lasers positively impact activities such as cutting, engraving, and marking by enabling quick execution while preserving precision. To illustrate, fiber lasers have recently become a preferred choice due to their longevity, ease of servicing, and ability to work on many materials, including metals, plastics, and ceramics.

As captured in the industry reports, the worldwide laser cutting machine industry is estimated to reach $6.72 billion by 2026, exhibiting a compound annual growth rate (CAGR) of 8.3%. Some of the reasons for this increase are the expansion of the aerospace, automotive, and electronics sectors because laser speed and precision enhance production schedules while minimizing material waste. In addition, manufacturers can now achieve better results in a wide range of applications due to advances in power modulation and beam quality.

Also, automation and artificial intelligence have revolutionized the capability of CNC machines through the integration of laser systems. Features such as real-time monitoring and adaptive controls contribute to optimal operational efficiency and minimal downtimes. These advancements intercept the growing importance of laser technology as a key tool in increasing productivity within industrial processes.

Progress in Engineering Industries 4.0 and Processes of CNC Machining

The latest industrial innovations ‘Industry 4.0’ is cutting-edge and transforming CNC machining by incorporating heightened levels of automation, interconnectivity, and intelligence into the workflows of manufacturing. The Internet of Things (IoT) interfaces with artificial intelligence (AI) and cloud computing to make CNC machines smarter and much more efficient. A good example would be IoT-enabled sensors that can provide condition monitoring on machines while wear and tear, temperature, and vibration can also be monitored. Reports suggest that using predictive maintenance tools can optimize unplanned downtime by 50% and extend equipment lifespan simultaneously.

Production planning is simplified by AI-powered algorithms, which autonomously optimize tool paths, augment precision, and minimize production time. Research conducted in the manufacturing industry states that implementing Industry 4.0 technologies could enhance overall equipment effectiveness (OEE) by almost a 30% directly benefiting productivity ratios. The need of the hour is now met as cloud-based platforms allow data to be shared across departmental boundaries without any precursors or limitations creating an adaptable and flexible manufacturing system.

These advancements are a step further towards sustainability in the cutting and machining processes. Smart CNC systems control tool wear and cut sith accuracy, thus reducing the waste material. Research has shown that firms adopting newer advanced CNC frameworks in the context of Industry 4.0 have claimed material cost saving of nearly 20%. This change not only enhances the operational margin of the company, but also furthers the underlying sustainability initiatives of the economics.

Constant and incremental changes introduced in these areas are aiming to make CNC machining more adaptive, efficient, and proactive, reflecting the quintessential features of the Industry 4.0 revolution.

Automation in the CNC world, does this mean that human operators will be completely replaced?

The sharp increase in automation development in the CNC sector does not suggest that human operators will be eliminated in the near future. Rather, the focus will shift to human roles due to the new implementations of automation and artificial intelligence (AI). It has been stated that around 60 percent of the procedures involved in CNC are automatable. Most of these tasks happen to be repetitive in nature, for example, part loading, unloading and quality checks. In contrast, system programming, toolpath setting, and troubleshooting actions still require human skills and judgment to perform the actions.

Moreover, research indicates that best performance outcomes are achieved when combining automation with trained personnel. For example, one study conducted in 2023 showed that workplaces which incorporated cobots alongside trained CNC machinists experienced 25% greater productivity as opposed to manual-only workflows. Humans are essential for supervising operations of the sophisticated systems for quality control and safety standards. Thus, it can be concluded that the effectiveness of automation will always require humans to supervise and optimize CNC processes.

What innovations in CNC machining are shaping the future?

- Advanced Automation: Incorporating artificial intelligence (AI) and machine learning is leading to smarter CNC systems, which self-optimize. These technologies also increase uptime and precision.

- Additive Manufacturing Integration: The amalgamation of CNC machining processes with 3D printing gives way to hybrid manufacturing, which enhances design freedom and accelerates prototyping.

- Improved Tooling Materials: The use of stronger, more durable cutting tools like carbide composites increases operational efficiency and tool longevity.

- Real-Time Monitoring: Part and machine performance evaluation IoT sensors provide in real time enhance consistency while minimizing waste.

- Sustainable Manufacturing: New methods of machining strive to be more efficient with material and energy use, improving environmental and economic concerns.

The Influence of IoT on CNC Manufacturing Efficiency

The adoption of IoT in CNC manufacturing has revolutionized the monitoring and control of processes. A tangible example would be the seamless integration of IoT devices wherein sensors collect data from the CNC machines and enable maintenance to be scheduled based on predicted needs. With this integration, studies show that CNC machine downtime can be cut by 30%. Furthermore, IoT systems permit the automation of intricate workflows which reduce production cycle times by as much as 20%.

IoT analytics platforms enable deeper insights into machinery and energy consumption, giving manufacturers the ability to make informed decisions. Some studies suggest that IoT enabled systems provide smarter energy management which can result in an energy consumption drop of 10 to 15 percent on average, and greatly improving operational cost. In addition, quality monitoring done remotely through IoT ensures global operations maintain the same quality standards while reducing logistical burdens. The intersection of these technologies leads to a more flexible and economical manufacturing environment.

Use of Artificial Intelligence in CNC Machining Technology

AI technology is transforming CNC Machining by improving operational efficiency, accuracy, and flexibility of the manufacturing processes. Traditionally, a CNC system would require a dedicated operator stationed beside the machine to oversee operations. With AI advancements, one main application is predictive maintenance. AI employs machine learning techniques to forecast equipment breakdowns, and in doing so, minimizes downtime. As predictive maintenance continues to evolve, it has the potential to enhance machinery reliability and reduce operational costs significantly by decreasing unplanned downtime by up to 30 percent and extending the life expectancy of the machines.

Process optimization and increasing productivity are two areas receiving attention from AI. AI and analytics can adjust parameters like spindle speed, tool wear, and cutting depth in real-time. The improvement in product quality and reduction of materials used significantly benefits the business. Research suggests that productivity in machining processes could be increased by 20-25% with this approach.

Aspects of CNC machining are also being transformed by AI with design augmentations. AI significantly reduces the prototyping and development timelines by aiding in formulating optimized component designs. This is done through generative design algorithms that reduce the amount of material needed whilst maintaining the required structural strength. It aids in sustainability initiatives as well too.

In addition to this, AI plays a significant part in quality control via machine vision. Defects on the surface of machined workpieces and deviations from nominal geometric features of CAD models can be automatically evaluated by CNC systems with the use of high-speed imaging with sophisticated pattern recognition techniques. Bearing the high standards of quality and lesser manual inspections done saves costs because there is less time wasted due to the inspections being prone to errors.

These capabilities mark the advancing levels of precision, efficiency, and sustainability the industry of CNC machining are attaining with AI incorporate. The ever-growing requests and sophisticated design issues are easily managed with these solutions.

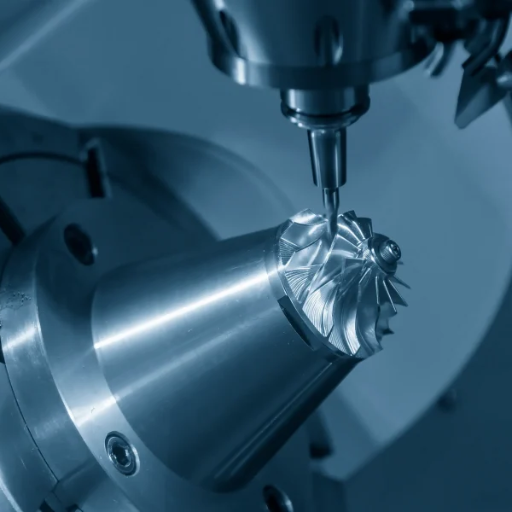

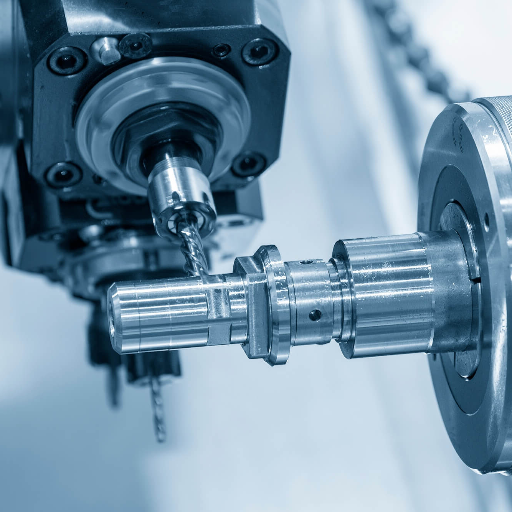

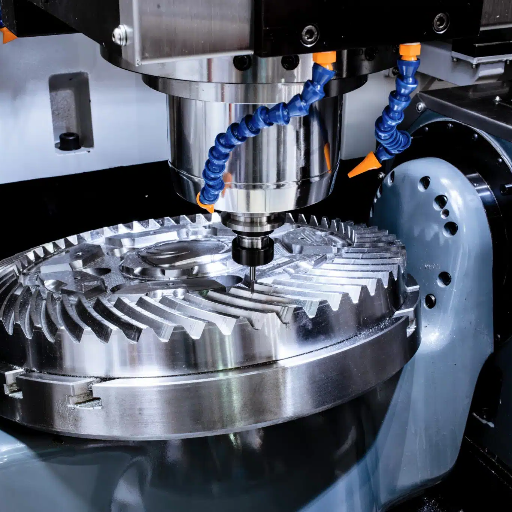

Advanced technologies are playing a major role on the Precison of CNC milling

Different technologies have worked toward development of CNC milling for accuracy and efficiency. A great example is the innovation of 5-axis CNC machines, which lets tools move and work within multiple planes simultaneously. This feature alone diminishes the amount of machine setups needed, improving speed by 25%, in addition geometic entailments increase for complicated designs.

Additional advancement includes the use of high speed precise cutting systems, which optimize cutting path and cooling methods. These systems offer as much as 50% improvement in material removal rate which helps complete projects faster. Addition of intelligent sensors to tools allows for real monitoring during machining processes. Tools can now identify wear and respond to vibration patterns instantly, reducing downtimes and helping improve product quality by identifying defects early.

The recent ‘material science’ advancements have played a central role in improving the precision of some tools. For instance, advanced alloys and composites crafted for specific purposes guarantee the cutting tools sustain their cutting action at the required level through enduring wear. As research suggests, utilizing carbide or PCD (polycrystalline diamond) tools increases the tolerances of the end product by 30% over what is achievable without these tools.

The combination of these tools and AI with what was previously available is transforming how far CNC milling could reach. Seamless integration of high-end components, sophisticated algorithms, and AI-based controls enables the realization of a self-sustaining manufactural environment prepared to adapt to the advanced complexities of contemporary operational robotics systems.

Is additive manufacturing replacing traditional CNC machining?

Although additive manufacturing assists in creating intricate designs and helps minimize material waste, it hasn’t replaced CNC machining. Manufacturing industries such as Aerospace, Automotive, and Medical Devices still heavily rely on CNC machining for durable, high-precision, and scalable components. Instead of using CNC machining, additive manufacturing mostly works in conjunction with it, where both processes are used to enhance the production workflow.

New Developments In Integrating 3D Printing With CNC Machining

The combination of 3D printing with CNC machining has brought a new wave of creativity and efficiency in manufacturing. Also, as per the report, global 3D printing revenues are predicted to hit $76.17 B by 2030, increasing at an extraordinary pace of 22.3 per cent annually during the period of 2023-2030. Additionally, the sharp accuracy associated with CNC machining remains crucial for the production of precision parts in the spaces and medical device sectors.

Industries are leveraging hybrid systems that combine both additive and subtractive methods to enhance production timelines while minimizing material waste. An example of this would be in the aerospace sector, where intricate structures are 3D printed and then further refined through CNC machining, allowing the bounding geometry to be cut to precise tolerances. In some applications, these collaborative techniques have given a 50% reduction in lead times which unlocks significant savings and increased productivity.

Moreover, the development of hybrid production is further bolstered by advancements in materials for 3D printing. For example, high-performance metals such as titanium and aluminum which serve as CNC machining materials can now be programmed to be used with additive manufacturing, facilitating workflows between both technologies. This ability not only boosts the range of designs that can be manufactured, but also empowers producers to meet the rising market and regulatory demand for lightweight and durable components that are more environmentally friendly.

Benefits of Merging CNC Machining with Additive Manufacturing

As industrial processes become more effective and environmentally friendly, the combination of additive manufacturing with CNC machining offers numerous benefits. Recent studies indicate that hybrid manufacturing allows for a material waste reduction of up to 90 percent when compared to traditional subtractive-only approaches. This is advantageous when working with costly titanium or nickel alloys because it lowers production costs. Furthermore, the ability to achieve near-net shape parts via additive processes increases the efficiency of time saving CNC machining.

Additive manufacturing enhances the design complexity and functionality of a component. In addition to these advantages, CNC machining on its own would find it impossible or extremely difficult to perform many processes like creating complex internal cooling channels. Most importantly, these technologies combined ensure that both the precision and strength of the component is maintained with tolerances reaching up to ±0.001 inches.

One of the best hybrid manufacturing use cases is in the aerospace and medical industries. Industry studies show that the use of hybrid production aids aerospace manufacturers in achieving up to a 50% weight reduction of components like brackets and supports, improving fuel consumption and lowering emissions. Likewise, the medical field has also benefited as the accelerated production with hybrid processes of customized implants enables more tailored options which improves patient care.

The combination of these two technologies also aids in promoting environmental stewardship. When initial models are created using additive manufacturing, coupled with CNC finishing, such companies enjoy lower carbon footprints as a result of less fuel-consuming hybrid manufacturing processes. This makes these blend technologies useful for companies looking to improve their sustainability metrics without compromising on quality.

The Timeless Importance of Traditional CNC Processes

3D printing is evolving rapidly, yet CNC (Computer Numerical Control) machining still plays an integral role in contemporary manufacturing. As with most things in life, 3D printing has its advantages and disadvantages; however, it is far more flexible and saves on materials compared to it’s stronger, but harder to scale counterpart. Everything needs a balance and for CNC machining, that is the aerospace, automotive, and medical device industries that require extremely tight tolerances, superior quality, and high precision surfaces.

According to new information, the demand for precision manufacturing will drive a surge of approximately 6% in the global CNC machine market between 2023 and 2028 (CAGR) in comparison to additive manufacturing which is expected to grow at a marginally higher pace while mainly having a focus on prototyping and other niche applications. With everything, there are examples, and in this case, CNC machines are vital in operations involving titanium or even hardened steel, where the consistent structural integrity provided by additive manufacturing could be questionable.

Moreover, hybrid manufacturing, which integrates the material efficiency of 3D printing and the precision of CNC machining, is promising but does not entirely supplant CNC processes. Rather, studies indicate that CNC will continue to be critical for the finishing steps of hybrid workflows. This interplay allows traditional machining processes to keep pace with additive manufacturing and ensures these techniques are not discarded, which is more supportive in complementing advanced production systems in the future.

What are the latest trends in sustainable CNC manufacturing?

- Material Utilization: CNC manufacturing now focuses on optimizing material use and minimizing waste by applying efficient cutting methods alongside software that creates optimized designs.

- Energy Use: Newer models of CNC machines incorporate features such as automatic standby mode and lower overall system power to make them more energy efficient.

- Use of Recyclable Materials: The increase in recyclable and biodegradable material utilization in the CNC processes helps create a sustainable circulation with the economy.

- Innovations In Coolants and Lubricants: The use of eco-friendly coolants and lubricants has decreased the waste of harmful chemicals while sustaining the performance of the machines.

- Integration of Hybrid Systems: The combination of additive manufacturing with CNC enables the diversification of sustainable production while improving energy and material efficiencies.

Developments In Sustainable Practices In CNC Machining

In modern times, there have been more efforts to incorporate technology-focused initiatives to strengthen sustainable approaches, one of which CNC machining evolving its practices. Incorporating energy-efficient machines is one of these improvements. It is no secret that modern CNC machines are built to endure tasks without the use of excess energy. Studies suggest that the addition of variable-speed drives paired with intelligent energy monitoring systems can yield a 20-30% decrease in energy used, increasing costs and environmental benefits at the same time.

In sustainable practices, the reduction of material waste still remains one of the primary focuses in CNC operations. Manufacturers are able to significantly reduce material scrap with the use of more advanced software for simulation and precision modeling. Studies show that waste reduction due to optimized cutting paths with real-time error rectification is possible by nearly 40% in some industries, particularly in aerospace and automotive which utilize high-value materials.

The implementation of closed-loop systems for coolant recycling is another impactful development. As industry sources report, nearly 90% of water-based coolants used in CNC machining can be filtered and recycled, reducing resource expenditure as well as costs associated with hazardous waste removal. These systems are ecologically beneficial, but also improve operational efficiency by providing reliable control of the coolant’s properties over time.

Finally, the adoption of Industry 4.0 and IoT has led to smarter and more sustainable manufacturing processes in CNC machining. Energy consumption and machine health along with maintenance needs are monitored with the use of sensors and data analytics which optimize workflows, prolonging the machine’s lifespan. For example, technologies focused on predictive maintenance can cut equipment downtime by as much as 50%. This is vital for productivity while resource consumption is diminishing.

Section Title: Applicable Methods of Energy Saving in Modern CNC Machines

Innovative technologies and proficient energy-efficient designs greatly improve energy efficiency in CNC manufacturing processes. One effective method is the adaptation of variable frequency drives (VFDs) which regulates the consumption of electrical energy within CNC machines by modifying electromagnetic motor drive speed and motor torque to match the work needed. Studies indicate that VFDs have the potential to reduce energy consumption by as much as 30%, especially during energy-demanding functions.

Power saving through the application of high speed CNC machines has also been of great importance. Besides, their material removal requirements also power the CNC machines less in comparison to other types of CNC machines. The amount of total electricity used is lower because less time is generally needed to remove the materials. Studies prove that depending on the material and job complexity, 20-50% reduction in cycle time is possible.

Capturing waste energy has become an indispensable task for modern CNC systems. Wasted energy is captured by Heat recovery system, and as well as Regenerative braking for auxiliary processes. This practice enables reallocation of low-valued energy to valuable processes within manufacturing. Reported energy savings for some manufacturers using these systems was claimed up to standard 15% energy efficiency increase.

In addition, energy consumption has been identified to be less while using lightweight components and structures in the design of a CNC machine. There is a direct relationship between the the moving mass of the components of the machine and the energy consumed to operate the machine. With a combination of optimization real time software, the operations are managed in a precise way while maximally reducing the energy used.

Implementation of the new strategies and other advanced technologies within contemporary CNC manufacturing boosts sustainability while simultaneously lowering the operational costs. This reflects the responsibility of productivity with the environment.

CNC technology reduces waste material and waste processes at a business.

By reducing control of operations during the manufacturing process, countless businesses around the globe have reduced meticulous material waste through CNC (Computer Numerical Control) technology. Research and Markets reported that the waste of materials through machining using CNC is 30% lower than the traditional ways. This is due to the optimized materials because the cutting of the materials is done accurately. Well designed software can be integrated into the CNC system, which can simulate processes enabling the detection and rectification of inefficiencies before the production commences.

Also, CNC machines allow sustainable materials to be used since composites, bioplastics, and recycled materials can be machined without excessive waste. Surplus material is minimized during the machining of complex shapes, which is done with great precision on a CNC. A report states that 3-axis and 5-axis systems have cut waste for part creation to a greater extent since intricate pieces can be made without unnecessary material being sculpted away.

Real-time monitoring of the process improves material productivity even more, with sensors and automated feedback adjusting the machining close to the actual event to avoid mistakes that would cause discarding the piece. Losing out on raw materials for production is a big challenge in manufacturing, and therefore, the aerospace, automotive, and medical industries reduce these costs significantly while improving sustainability at a macroscale level.

How is the CNC machining industry evolving to meet future demands?

The integration of machine learning, AI, and automation technologies is reshaping the CNC machining business for better accuracy and efficiency. There is a shift in focus towards environment-friendly practices like using recyclable products and energy-efficient machines. Real-time monitoring, predictive maintenance, and minimized delays offered by IoT (Internet of Things) smart factories significantly increase productivity and efficiency. In addition to that, the industry is preparing for future requirements by easing the adaptation of customized, complex designs at quicker production speeds.

Maximizing Productivity and Accuracy with New CNC Technologies

Advanced manufacturing operations management (MOM) software have transformed CNC processes, improving operational efficiency through automation and streamlined workflows. Machine tools now communicate with each other during real-time data exchange, allowing for instantaneous decisions to be made enhancing efficiency. An example would be manufacturers with MOM-incorporated CNC workflows reporting productivity increases of 25% alongside material waste reduction of 30%, which helps minimize costs and waste as well as economic expenses.

Moreover, the use of MOM software improves quality control by implementing automatic supervision systems, which identify production errors. This function prevents the output of defective products and inspection time considerably. With this technology, manufacturers can undertake more complex projects due to integrated functions like scheduling, resource allocation, and performance monitoring, thus fulfilling the requirements of customization along with reduced time frames for production. Advanced CNC machining with the use of MOM software exemplifies the perfect blend of precision engineering and intelligent technology, transforming the manufactured world to unprecedented levels of advancement.

How optimized machining parameters are increasing efficiency and quality

Optimized machining parameters is a modern manufacturing paradigm shift that improves efficiency and product quality simultaneously. Optimizing parameters like cutting speed, feed rate, and depth of cut enhances the material removal rate while upholding precision and the surface condition of the part. Recent research indicates that optimal parameter settings can also decrease the machine’s idle time by nearly 20% and attain tight-controlled repetitive tolerances in the order of a few microns for, achniversal, aerospace, and medical devices manufacturing.

The role of AI and machine learning in advanced simulations and decision-making processes based on data is equally important. As an example, self-learning algorithms monitor the process in real-time and propose the best possible machining conditions. This proactive approach can minimize tool damage and increase the average tool life by 30%. Moreover, the combination of some high-speed machining methods with properly adjusted cooling techniques increase productivity by 40% in the manufacture of intricate parts.

Meeting all these goals makes manufacturing more sustainable in terms of energy and materials while simultaneously addressing the growing need for greater productivity and efficiency. The combination of smart technologies with the ever-evolving industry needs enables eco-optimized work processes with minimal material costs leading to increased productivity, performance, and enhanced sustainability.

How CNC Machining Is Shaping Global Manufacturing

CNC machining will continue to transform global manufacturing industries, and for better reasons than one. As automation and digitization progresses, CNC machining becomes more efficient, precise, and adaptive to changes in production requirements. Analysts have estimated that the CNC market will experience an increase in demand with a compound annual growth rate (CAGR) of 7.2% from 2022 to 2030, attributed to the greater need for customized mass production and high-quality manufacturing.

A major innovation comes from the integration of AI and IoT technologies into CNC systems. Now, Smart CNC Machines can monitor a machine’s performance IoT and self-report metrics in real-time while also using preset learning algorithms for cutting and learning-enabled altering them for optimal efficiency. Predictive maintenance can eliminate unforeseen downtime by up to 20% and extend the lifespan of a machine by 25%.

Also, the development of multi-axis machining is further increasing the flexibility of CNC systems. These enhancements allow manufacturers to achieve proffound geometric complexity in the required workpiece with a significantly smaller number of attempts and greater precision. Such accuracy is critical in the aerospace sector and medical devices manufacturing, where components must fit within tolerances measured in micro meters. It is reported that carrying out work with five-axis CNC machines allows production to be done up to 50% faster without any deviation in quality standards.

In addition, sustainable development is now an important guiding factor for global trends in CNC machining. Efforts to order residue free materials are now more common in newer models of CNC systems because cutting paths are optimized and simulation software are more advanced. More efficient ways to decrease resource utilization are also available through innovations in hybrid manufacturing, which are now more capable of integrating CNC with additive manufacturing. These assist industry purposes to achieve net-zero emissions and to satisfy their consumers who are looking for eco-friendly products.

Investments in automation, material science, and AI technologies sustains CNC machining, which is promising to heighten further the prominence of advanced technologies-responsible manufacturing systems- faster, more intelligent, and environmentally safe processes. Smart production will not only pose new challenges for a massive scale production, but also allow a high level of customization and innovation across the entire spectrum of industries.

Reference sources

- Study: Rapid Process Planning in CNC Machining for Rapid Manufacturing Applications4

- Objective: To develop a tool for automating process planning in CNC machining, enhancing its application in rapid manufacturing.

- Methodology: The study utilized advanced Computer Aided Manufacturing (CAM) tools to create a customized program for process planning. This program integrated with CAD software to automate machining operations, reducing reliance on manual inputs.

- Key Findings:

- The developed tool significantly reduced process planning time by up to 79% compared to conventional methods.

- Automation in CNC machining process planning enhances efficiency and minimizes human error, making it a vital component for future manufacturing systems.

- The study highlighted the potential of CNC machining in rapid prototyping and manufacturing, emphasizing its adaptability and precision.

- Study: Investigating the Differences in Human Behavior Between Conventional Machining and CNC Machining for Future Workforce Development5

- Objective: To analyze the role of human behavior and decision-making in CNC and conventional machining, with implications for future workforce training.

- Methodology: The study employed eye-tracking, video analysis, and interviews to observe machinist behavior during CNC and conventional machining tasks.

- Key Findings:

- CNC machining offers consistent quality and efficiency, making it dominant in modern manufacturing.

- The study emphasized the importance of human expertise in operating CNC machines, even as automation increases.

- Insights from the research can inform the development of training programs and expert systems, ensuring the effective integration of human and machine capabilities in future manufacturing environments.

- Top ATC CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the recent innovations made in CNC machining that indicates it is the future of manufacturing?

A: The CNC innovations that I’ve highlighted including multi-axis or five plus axis machining, hybrid manufacturing systems which include both traditional and additive machining, advanced automation via cobots, AI optimization, the cloud, and digital twins all point towards the future of the manufacturing industry. These innovations from the CNC industry greatly improves accuracy and waste minimization of complex processes, greatly increasing productivity and decreasing the amount of required manpower. It is evident that there is a shift into the use of technologies in industries. Along with the rising capabilities of machine tools and the growing sophistication in computer-aided manufacturing systems, CNC machinery will be progressively crucial to contemporary production settings.

Q: What is the current trend in CNC machining with regards to automation?

A: The most distinguishing trend in CNC machining is advanced automation of processes which includes unmanned machining cells, robotic loading and unloading systems, and lights-out manufacturing. Trends in the industry indicate that manufacturers are progressively adopting automation technologies which utilize AI for adaptive machining where parameters are adjusted automatically. Quality control can be performed by machine vision systems while the manufacturing operations management software integrates the machines into the wider enterprise systems. This is further augmented with AI which pushes the machine-learning frontier. Such level of automation goes beyond just reducing labor needs, providing sustained precision, constant operation, and agility in meeting demand shifts, which fundamentally transforms the CNC landscape.

Q: What Is The Role Of Artificial Intelligence In Production CNC Machining?

A: Prediction-driven maintenance, which anticipates equipment breakdowns, contactless parameter modifications, and generative design that creates manually unachievable components are just a few of the ways AI is enabling CNC machining to transform the production frontier. Advanced Artificial Intelligence algorithms are now more than capable of data analysis for machining processes aimed at optimizing cycle time, tool life, and quality consistency. The implantation of machine learning further enables CNC systems to ‘learn’ and perform better based on previously executed processes. We anticipate fully autonomous machining cells capable of planning, executing, and optimizing intricate fabrication processes with only minimal human supervision as these technologies advance.

Q: What does the future hold for the role of CNC machines in sustainable manufacturing?

A: With regard to sustainable manufacturing, future CNC machines will be further augmented by several key developments. CNC machines will have regenerative drives that capture and reuse energy. Efficient energy designs will capture energy from braking and reuse it. Sophisticated simulation programs will minimize material and energy waste, while energy-efficient designs will optimize toolpaths to reduce waste. Advanced tools will enable precision machining and near-net-shape production, which minimizes the need for material alteration. Also, CNC machines will monitor coolant use, manage energy analytics, and incorporate sustainable materials into the machining processes. To form a CNC lifecycle assessment, sustainability will guide future parameter settings to broad-scope efficient resource management throughout the entire machine lifecycle. The analyzes will detail CNC energy consumption and coolant use alongside sustainable material inputs.

Q: What is the impact of connectivity and IoT on CNC machining evolution?

A: CNC machining evolution is profoundly impacted by connectivity and IoT with the introduction of machine monitoring with real-time performance tracking, predictive maintenance based on operational data analysis, and digital twins which are virtual models of machines used for simulating and optimizing. Manufacturing is taken a step further as programming and monitoring can now be conducted remotely through the cloud. Integrated quality control also self-regulates the machining process by measuring the output during processing to fine-tune the parameters based on actual results. All of these integrate to form smart factories where high level communications between equipment takes place leading to unparalleled coordination, efficiency, and responsiveness in the management of the manufacturing processes.

Q: Which new materials are emerging in the future of CNC machining?

A: Newer composites such as carbon and glass fiber reinforced polymers, superalloys such as Inconel and Hastelloy, engineered ceramics, metal matrix composites, high-entropy alloys, and ultra high performance polymers like PEEK and PEI are changing the industry vertically and horizontally and are the forerunners of the future in CNC machining. The industry does require more attempts and accuracy to achieve desirable results, but the advancements in machining technology, tool design, and methods of applying cooling make the challenge much easier. These particular materials, among others, exceed expectations when it comes to mechanical, thermal, and other physical attributes as well as further requiring advanced methods of CNC machining. The evolution of CNC machining even more continues to await the evolution of material sciences.

Q: What is the Additive Manufacturing’s impact on CNC machining?

A: Additive manufacturing is not replacing traditional CNC machining but is integrating it through hybrid systems that employ both technologies in a single system. These systems use 3D printing to make complex geometries and internal features, while CNC machining is used to achieve precision surfaces and tight tolerances. The CNC processes are preceded with parts being printed to near-net shape. Moreover, additive processes are helping to manufacture custom tooling and fixturing for the CNC processes. This is now a cradle-to-grave ecosystem where both technologies build upon each other’s strengths, providing incredible flexibility in design and extreme precision at the same time—this is defining the future of manufacturing as we know it.

Q: What economic factors are shaping the future of CNC machining in global manufacturing?

A: A number of critical economic drivers are reshaping the future of global CNC machining, including reshoring trends, on-demand manufacturing, automation, and distributed manufacturing networks. These new developments help alleviate problems such as labor shortages, wage inflation, and supply chain disruptions. The drive for mass customization results in investments in flexible CNC systems with rapid changeover capabilities, while sustainability mandates influence capital expenditures. Furthermore, the CNC technology democratization trend enables shrinking users’ businesses to contest on the global stage, and significantly more affordable and easier to use CNC systems are making the technology accessible to smaller manufacturers. All these economic forces will continue to advance the recently developed flexible and efficient CNC technologies.

- Understanding the Difference Between CNC and VMC Milling Machines: Complete Comparison Guide

- Laser Marking vs. Laser Engraving vs. Etching: Differences Explained

- Fiber vs. CO2 vs. UV: Which Laser Engraver is Right for You?

- Pulsed vs Continuous Wave Lasers: What’s the Difference?

- Color Laser Engraving: Everything You Need to Know About Laser Engraving Work

- The Ultimate Guide to Laser Cleaning: How This Revolutionary Rust Removal Technology Works

- Master the Art of Tree Trimming: Essential Pruning Tools and Techniques

- Maximum CNC Router Cutting Thickness: What Thickness Can Your CNC Router Cut Through Wood?