Cutting alumina ceramic is a process that requires precision, skill, and using proper tools to guarantee the best outcome. Alumina, with its remarkable hardness, durability, and wear resistance, is a critical material for various industries like electronics and manufacturing, etc. However, without the right approach, processing this tough ceramic is going to be difficult. The present guide is ready to share with the professionals and the enthusiasts all they need to know about cutting alumina with precision and efficiency. The paper will take you from understanding its peculiar properties to discovering the most effective methods and the right tools, thus giving you the expertise to perform this quite demanding task confidently. The insights are going to be beneficial whether you are an expert in ceramic processing or a novice looking for help, thus making the whole cutting alumina process less scary and more precise.

Understanding Alumina

What is Alumina? Properties and Types

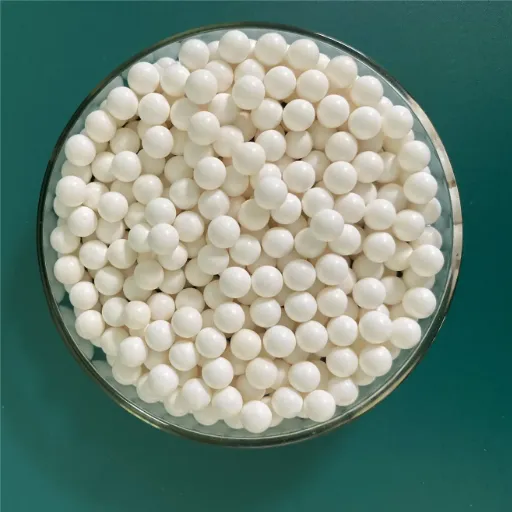

Alumina or aluminum oxide (Al₂O₃) is a highly adaptable ceramic material and main element in different fields. It comes from bauxite ore through the Bayer process and is very hard, has a high melting point and is stable chemically. Alumina is completely used in production processes like manufacture of refractory materials, electronic parts and tools for cutting.

Alumina has different types that are specially made for certain applications. Alpha-alumina is the most common among them, being very crystalline and utilized in abrasives and ceramics; on the other hand, gamma-alumina is less crystalline, having a porous structure which makes it appropriate for catalytic and absorption applications. The combination of these two forms plus the properties of excellent thermal conductivity and wear resistance all contribute to making alumina essential in various industries from aerospace to medical technology.

Common Uses of Alumina in Industries

Alumina or aluminum oxide is widely used to their superior properties in all industries. Nevertheless, alumina has one of the biggest markets in the ceramics manufacturing which is mostly due to its high melting point and hardness that also make it ideal wear-resistant tools and components. In chemical industries, alumina has also been playing an important role as a catalyst or catalyst support, especially in the processes of refining oil, producing fertilizers, and the like. The medical industry is another one benefiting from alumina’s property of being biocompatible by using it for implants and prostheses. Furthermore, due to the fact that alumina has not only good electrical insulation properties but also thermal conductivity, it is being highly employed in the making of electronic substrates and insulators. The continuous growth of the technology sector and market demands has put alumina on the list of materials that can be used Besides the present sectors like renewable energy systems and advanced composites, thus making it a key material for the innovation-driven industries.

Challenges in Cutting Alumina Ceramic

Key Challenge: Cutting alumina ceramic is very hard because of its extreme properties of hardness, brittleness and conductivity combined. Alumina being of approximately 9 on the Mohs hardness scale, it is almost of the same hardness as diamond which leads traditional cutting tools and techniques to be ineffective and also to wear proactively at the same time. The situation is made worse by the brittle nature of the material, as even the slightest of the wrong movements or too much force used can cause either micro-cracks or sudden failure that ruins the material’s strength. What also contributes to this difficulty is that an alumina’s good thermal conductivity can make the heat that is produced during the machining process accumulate leading to degradation of the tool and damage to the surface.

In order to get rid of these issues, the most modern approaches such as laser cutting, water jet cutting, and diamond or cubic boron nitride (CBN) tools are widely used nowadays. But even with these methods, it is still necessary to have an accurate control of cutting speed, pressure, and cooling factors to achieve clean cuts without any defects. Moreover, the development of hybrid machining processes has also made it possible to combine the cutting of alumina ceramics with machining. This is done to find the right mix of efficiency, precision, and cost effectiveness; thus, guaranteeing the best performance for both the manufacturers and the users.

Tools and Techniques for Cutting Alumina

Diamond Saw Blades: Advantages and Best Practices

Utilizing diamond saw blades is unavoidable when it comes to cutting alumina ceramics, this is because of their extreme hardness and robustness. These blades’ major merit is that they dissolve in making sharp and clean cuts, quieting the chipping or cracking risk in the material to a great extent. Diamonded edges do not just mean free-cutting performance, but they are also perfectly capable of demanding ceramics; they do not need to be replaced very often. Besides, the capability of high-speed operation goes hand in hand with the efficiency and further cuts the processing time.

Best Practices for Diamond Saw Blades:

- Select a blade with the right size, grit, and bond strength that will marry the hardness of alumina

- Use coolant to manage heat generation and prolong blade life

- Maintain proper feed rate and pressure to prevent material damage

- Perform regular cleaning and blade wear inspections

- Monitor working conditions such as spindle speed and axial runout

The latest search trends and data reveal that one of the most popular questions users ask is how to get the longest life out of diamond saw blades? The pros in the field state that besides employing the correct techniques, they should also make proper monitoring of the conditions that the blade is working under, such as spindle speed and axial runout, and thus they will be able to reduce the strain that is put on the blade to the bare minimum. These practices are, of course, in line with the technological advancements in the industry and also warrant the output of the best quality when machining alumina ceramics.

Abrasive Waterjet Cutting: How It Works

The abrasive waterjet cutting is a highly accurate and adaptable machining process that utilizes the forced combination of a high-pressure jet of water mixed with particles of abrasive for slicing through different sorts of materials. This method involves pushing the water through a tiny opening with astonishing pressures that quite often go beyond 60,000 PSI and then it gets mixed with the abrasives like garnet. The output is a cutting stream that is tightly packed enough to saw through everything from metals to ceramics and glass, and that is done without the creation of heat-affected zones (that would wreck the material’s qualities).

Many customers mainly ask about the advantages of waterjet cutting over traditional methods from the latest data that is manufactured by the search trends. One important characteristic of the waterjet process is that it handles very complex geometries, and it the best cutting with the lowest wear. Moreover, the fact that it is cold cutting avoids distortion due to heat which, in turn, makes it applicable to the most delicate and difficult to process materials. Through this process, factories can ensure accuracy and speed of production while at the same time lowering waste and the necessity of additional processing.

Laser Cutting: Applications and Limitations

Laser cutting is an extensively adopted manufacturing process that is popular among industries like automotive, aerospace, electronics and medical devices, among others; it is known for its accuracy and versatility in such fields. The principle is to produce very high energy laser light that is then focused through optics, with specialist software controlling the movement of both the laser and the plate. In this way, laser cutting creates complicated designs and at the same time, ensures that the cutting burr and massive unproductive waste of raw materials are minimal.

| Advantages | Limitations |

|---|---|

| High precision and accuracy | Substantial initial investment and maintenance costs |

| Minimal cutting burr and material waste | Ineffective on highly reflective materials |

| Creates complicated designs easily | May generate toxic fumes with certain materials (e.g., PVC) |

| Versatile across multiple industries | Requires careful material selection |

To sum it up, even though laser cutting is very precise and adaptable, knowing its limitations helps applying the method rightly for the desired results.

Key Considerations Before Cutting Alumina

Comprehending Alumina Grades

Alumina or aluminum oxide is there in different grades purposely made for various industrial and manufacturing applications. The primary grades are smelter-grade alumina (SGA) and calcined alumina. SGA is the main source for aluminum metal production and its very polished and smooth character during the electrolytic process (Hall-Héroult) is pure. In comparison to SGA which is the lowest grade of alumina there is calcined alumina which is the highest grade of alumina that is so pure that it can be used for the most demanding applications such as ceramics or refractory materials that require the hardest materials and the highest thermal stability.

Purity requirements, grain size, and end-use industry needs are the main factors that determine the grade of alumina. An example of this is the electronics industry that usually seeks the highest purity grades for insulation and wear resistance while the industrial applications might select the grade specifically based on the parameters of thermal conductivity and mechanical strength. Being aware of these variations translates into superior performance and cost savings in the selection of materials.

Alumina Plate Thickness and Dimensions

The thickness and dimensions of an alumina plate are crucial features affecting its applicability in different industries. As per the recent updates, the most common thicknesses are the ones which vary from below 1 mm to above 10 mm, whereas the specific requirements of the industry are the decisive factors. The electronics industry prefers the light-weight alumina plates which are known for their excellent thermal insulation and resistance properties. Thicker plates, however, are mainly used in applications like industrial machinery or construction where the advantages of durability and mechanical strength are paramount. In addition, there are custom sizes available to fit the particular operational requirements thus the material gets perfectly matched with the design and performance specifications. Hence, the manufacturers have the chance to enhance the functionality without the need to sacrifice the efficiency.

Health and Safety Practices and Personal Protective Equipment

Safety First: The use of safety measures when dealing with metal plates or heavy materials is of utmost importance to avoid accidents and secure the health of workers.

Required PPE:

- Gloves

- Safety goggles

- Steel-toed boots

- High-visibility clothing

- Fire-resistant apron (for welding/cutting)

- Welding helmet (for welding/cutting)

- Respirator (for welding/cutting)

On top of that, the latest safety procedures should be followed every bit as scrupulously. To mention a few, the procedures consist of regular inspection of the equipment, right handling and storage of the materials, and workstations being maintained free of any unnecessary clutter. The latest guidelines of occupational safety urge that the use of automated lifting devices such as hoists and forklifts to eliminate the risk of strain or injury from the workers’ manual lifting is strongly recommended. In addition, the continuous safety training and the review of emergency procedures foster an environment of vigilance and preparedness among the workers, which in turn, greatly diminishes the incidence of hazards in the workplace.

Step-by-Step Guide to Cutting Alumina

Step 1: Selecting the Right Tool

The time of alumina cutting has it that the right tool selection is of paramount importance to get accurate parts and at the same time reduce the amount of material wasted. As per the most recent information from ‘s search engine, diamond-tipped-edge tools or diamond-coated blades are the most preferred ones for cutting hard ceramics like alumina, owing to their durability and effectiveness. Use the parameters of your project in decision making, such as alumina thickness, and finishing requirements to judge whether a wet or dry cutting machine is the right one for you. Provide yourself with the best quality, and you will have smooth cuts and also the risk of cracking or chipping the material reduced.

Step 2: Preparing the Alumina Material

The proper preparation of the alumina material is a very important step in cutting or shaping it obtaining results of high precision and efficiency. Firstly, the alumina surface should be well cleaned to ensure that all dust, grease, and/or debris that could negatively influence the tool’s performance or precision of the cuts are removed. The best method of cleaning is using isopropyl alcohol together with a lint-free cloth. Then, inspect the material for any cracks or other imperfections that are not visible to the naked eye since these could worsen the damage during processing. Drawing the line accurately is very important so one can either use a fine-tip marker or a laser guide and make sure proper alignment while marking. Last but not least, fix the alumina in position with clamps or a stable vise so that it doesn’t move, vibrations are reduced and cutting becomes cleaner. By following these steps, you will very much increase your project result.

Step 3: Setting Up the Cutting Equipment

To cut with accuracy and efficacy, the cutting machines have to be set up properly. First, the right cutting tool has to be picked depending on the material, for example, a diamond-tipped blade for alumina, as they are extremely tough and can withstand the hardness of the material. Next, to eliminate blurring or wobbling, make sure that the cutter is tightly mounted and that its position in the device is precise. The machine’s speed should be set according to the manufacturer’s recommendation, usually low speeds are the preferred ones as they lower the heat that may eventually lead to cracking or weakening of the alumina. Also, during the process, a cooling system has to be established or water has to be used to keep the cutting area cool; this will not only avoid overheating but also the tool will be able to last longer. Check that all safety devices such as blade guards and emergency stops are functioning and in their respective locations before proceeding. Properly done equipment setup will prevent potential problems from arising thus ensuring continuous and safe cutting operations.

Step 4: Executing the Cut with Precision

The cutting process begins by positioning the tool on the designated alumina cutting line to adhere to the required accuracy. The procedure is to be initiated at a constant and regulated pace, while the application of a strong force that could fracture the material should be avoided. The cutting operation is to be monitored in such a way that the tool’s rotation speed is kept uniform, and the coolant system is seen to be working properly. Cutting with precision entails being patient; hurrying or straying can ruin the workpiece’s integrity.

Pro Tip: Diamond-coated tools come first in the list for cutting tasks that involve alumina, according to ‘s search engine, based on their extraordinary hardness and durability. Besides, employing efficient cooling techniques not only averts the risk of overheating but also produces the cleanest, most accurate cuts. Frequent checking for the new safety standards and best practices will keep you informed and help you to reach the best results.

Step 5: Post-Cut Finishing and Inspection

To the view of the search engine of ‘s, the surface quality and the overall precision of post-cut finishing should be the two main care areas in the case of the desired outcomes. A suggestion for getting smooth finishes on alumina which is a tough material aside from being very hard is the use of advanced polishing methods like abrasive blasting or ultrasonic cleaning. High-precision tools like coordinate measuring machines (CMMs) or laser scanners should be used in the inspection process to detect irregularities or inconsistencies. These data-backed practices adoption ensures not only superior results but also higher product reliability.

Common Mistakes to Avoid

❌ Using the Wrong Cutting Tool

Incorrectly selecting cutting tools is one of the main problems that manufacturers face, leading to poor cutting quality, increased wear and perhaps even damage to the workpiece. It is imperative to select the proper cutting tool based on both the material and the cutting type, Trees. For example, a less challenging material like aluminum will need its special coating to be applied to prevent any thickening of the product, while a more demanding metal, i.e., stainless steel, will call for the use of carbide or diamond-tipped tools and the like for effective machining. Serious research, intensive checking of the newest cutting tools, and technology can facilitate a tremendous improvement in the quality of work and speed. Use the somewhat new resources or the manufacturers’ recommendations to meticulously select the appropriate tool for the desired job.

❌ Applying Excessive Force

Over-exerting force as part of machining may result in a worser final product, and it even might lead to much quicker tool wear and damage to the machine as well. Heating up the area with excessive force, making changes in the shape, and in some cases, the equipment failure can occur right there and then during the operation. Based on ‘s search engine, which cites industry data and analyses, it is inferred that oneof the most important factors in maintaining tool life is the use of the right cutting force, so, that the precision stays unaltered. The recommendation is to closely observe feed rates, cutting speeds, and the condition of the tools while being in line with the instructions given by the manufacturer. Modern sensors, along with force detection systems, can further assist at the stage of controlling and even lessening the force applied thus resulting in very consistent and reliable outcomes.

❌ Ignoring Safety Protocols

Machining safety measures not only keep the operator safe but also protect the machine and workpieces involved by ignoring safety protocols. Data from ‘s search engine, industry trend reports, and machine usage accidents point to the need to answer the question, “What hazards accrue when the safety measures are neglected”? The list of the most usually related and frequent problems includes accident-prone places, machine failures, and low quality results. The right thing to do always is to comply with the safety protocols and wear safety clothing, use the machines and equipment according to the guidelines, and have the equipment serviced regularly. Those are not just the safety rules, but they are also the steps to avoid unnecessary downtime caused by mistakes or occasional machine breakdowns as they lead to the overall increase in productivity.

Frequently Asked Questions (FAQ)

❓ What are the most effective ways to cut alumina?

The specific needs of the application usually determine the cutting methods of alumina. Among the most well-known traditional methods are diamond blades and wheels, which can be really hard but are still used on alumina ceramics. Regarding the more complex designs, water-jet cutting is a great option since it is incredibly gentle with the material and does not add thermal stress. Besides, there is also the high-temperature plasma cutting which, however, requires more expertise. The selected method will be the one that best suits the desired precision and finish as they all have their pros and cons.

❓ Can a CO2 laser be applied to cut alumina ceramic?

A CO2 laser is capable of cutting alumina ceramic, but there are important factors that need to be considered. Laser cutting is a productive method for the solid formation of the complex shapes and intricate designs owing to the fact that it is very accurate. However, when talking about the high melting point of alumina (Al2O3), coming up with the best settings to match this condition is often taken for granted. A proper cooling system during cutting is of utmost importance in order to release any thermal stress and prevent cracks. So, the CO2 laser cutting process of alumina can be termed as a complex one; it requires skilled professionals for the successful going on of the same.

❓ What is the most suitable cutter for producing alumina ceramic plates?

For making the plates of alumina ceramics diamond-tipped tools are considered the best most of the time; this is because such machines are specifically designed to handle similar hardness and brittleness materials easily. Cutting with a straight-edge can create very clear lines, which is a great advantage if you are dealing with precision. A heavyweight tile saw that has a diamond blade may be required for large jobs or thick slabs. Furthermore, a wet cutting technique is likely to be widespread enough to consist of dust suppression and cooling to a minimum thermal stress during the cutting process. To sum up, the cutter selection is greatly influenced by the specific thickness and size of the alumina ceramic to be cut.

❓ How does thermally treated alumina ceramic affect the cutting process?

When it comes to cutting ceramic plates that are made of alumina, generally the diamond-tipped tools are found to be the best; these specially-made machines can manage the similar hardness and brittleness very well. While a straight-edge cutter can create sharp lines, this is a great benefit when accuracy is a requirement. A heavy duty tile saw with a diamond blade would be required for larger jobs or thicker slabs. Also, a wet cutting method would likely be broad enough to consist of dust suppression and to reduce the possible thermal stress on the cutting tool during the procedure. To sum up, the choice of the cutter is greatly influenced by the specific thickness and dimensions of the alumina ceramic being cut.

❓ What is the most efficient method to cut alumina so as to have a smooth ceramic surface?

The selection of the cutting technique is the main factor in achieving a smooth ceramic surface when cutting alumina. The combination of a diamond blade or wheel and a wet cutting method will fine finish the ceramic. Plus, using finer grit abrasives to polish the edges after the initial cutting will get rid of any roughness and enhance the overall look of the surface. Besides, it is a good practice to cut alumina slowly and under control to reduce the extent of chipping and to keep the ceramic surface unblemished. The factors of proper handling and technique are what make the difference between smooth and rough alumina ceramic surfaces.

Reference Sources

- Deep and High Precision Cutting of Alumina Ceramics by Picosecond Laser

This paper discusses laser cutting technology for machining brittle materials like alumina ceramics.

Read more here - Machining Refractory Ceramics with Abrasive

This study investigates the material removal process of refractory ceramics, including alumina, using abrasive water jets.

Read more here - Alumina-Based Cutting Tools—A Review of Recent Progress

This review provides insights into advances in alumina ceramic materials used as cutting tools.

Read more here

- weld titanium: Techniques and Best Practices for Titanium Welds

- Harnessing the full potential of technology Fiber Laser: A Step by Step Guide

- Laser Marking vs. Engraving vs. Etching: Understanding the Key Differences and Applications

- Does Alloy Steel Rust? Understanding Corrosion Resistance in Alloy Stee