Every CNC hobbyist–whether into woodworking, metal engraving, or design creation–knows how important the rigidity of a CNC router is in achieving precision and durability. Given the virtually limitless options available in the market, choosing the ideal machine that captures performance, pricing, and reliability seems like an impossible task. This guide will walk you through the process and will help you identify considerations and features that you must know. Rest assured, by the end of it, you will feel confident enough to choose a cnc router that fits your requirements and improves your work on every level.

What factors should I consider before buying a CNC router?

- Material Compatibility: Check if the router is compatible with the materials you work on (i.e. wood, metal, or plastic).

- Work Area Size: Select a machine whose work area suits the size of your projects.

- Precision and Accuracy: Select a router that is suitable for the level of detail you have in your designs.

- Build Quality: Choose a machine that is solid and can take the rigors of constant use.

- Software Compatibility: Check if the router will work with design software you know or intend to learn.

- Budget: Consider the price and weigh it against other factors such as quality, dependability, and the features that are most appealing to you.

- Support and Warranty: Choose a unit that has customer support that can be reached easily and has a good warranty.

Factors Impacting CNC Performance and Precision

While buying a CNC router, one must pay attention to the factors determining performance and precision. The spindle speed and power of the motor are among the most important. Smooth cuts in wood, acrylic, and aluminum come from higher spindle speeds (RPM). For example, many CNC routers professionals use are set to 20,000-30,000RPM to provide the best results for detailed work.

Also of great importance is the repeatability and accuracy of a given machine. Modern CNC routers can achieve tolerances of approximately ±0.001 inches, which is good enough for engraving and making parts for mechanical assemblies. This precision guarantees the same level of quality throughout several production cycles.

Also, compatibility of materials is regarded as an important aspect of performance. Heavy duty CNC routers can cut and shape harder materials such as steel or composites with accuracy and speed. Industrial machines are frequently built with heavy-duty reinforced frames and advanced cooling systems capable of withstanding extended periods of operation without overheating.

Also, the introduction of automated tool changers and control devices that require little to no monitoring makes other work easier and reduces idle time. The rest of the market data on the new models of CNC routers shows that machine tools with automated control devices boost productivity by more than 25% relative to standard models.

Finally, do not ignore software integration. A number of the leading CNC companies have bundled their products with a complete software suite that includes simulation functions that enhance the optimization of the path and time calculations for a run. Such integration reduces risk, increases efficiency, and most importantly, shortens production times.

These details allow for proper selection of a CNC router, in turn meeting specific project needs and increasing operational efficiency.

Important Considerations While Budgeting for a CNC Machine for the First Time

Finding the right balance between cost, functionality, and long-term ROI is critical while budgeting for your first CNC machine. The starting price for a CNC router, for example, is around $2,000. Entry level models can exceed $50,000 for more professional equipment. As with any machine, cost is affected by additional factors such as size, quality of construction, spindle power, and other software compatibilities and features like automated tool changers.

Alongside maintenance, your budget should also take long term recurring expenses into consideration. A dust collection system costs a few hundred while a work holding fixture can run into the thousands. On top of these, additional expenses is also incurred in the form of peripherals such as cooling units.

If your budget allows for it, try to find models with energy efficient parts. Some systems have started utilizing energy-efficiency spindle motors and standby modes, which can cut power to the entire system by 30% while still enabling the machine to start within seconds. In addition to saving on operational expenses, these savings can be compounded over time. Ensure to vet the warranties offered by various manufacturers as well, several provide parts and labor packages for 1-3 years which greatly increases the financial predictability of servicing one’s machine.

For those without a significant upfront budget, leasing or financing options can be appealing to businesses and individuals. Most providers now offer flexible financing plans, with interest rates between 3% and 10%, depending on the credit score and term length. Paying in installments might be a viable option, though careful calculations should always be made first, ensuring production goals can still be met and finances won’t take a hit.

Considering the estimated expenses with possible long-term savings will greatly improve the investment decision process when purchasing the first CNC machine.

The Impact of Laser Power on Marking Efficiency and Speed

While choosing a CNC laser engraving machine, knowing the importance of laser power with regards to marking speed and efficiency is important. Laser power, which is measured in watts, determines how deep and clear an engraving will be. For example, 80W and 100W systems are able to engrave metals and other harder materials much quicker than a 20W machine, which is better suited for plastic and wood.

Increased laser power can improve precision and speed simultaneously, making it a very important factor for industrial workloads. This added benefit, however, comes at the cost of greater energy consumption. One study indicates that lasers running on 100W consume approximately 2.5 times more to operate than 20W lasers, heightening energy expenditure depending on how long the laser is in use.

Ultimately, the decision lies with the type of material you are working with, the level of production, and how much energy you wish to conserve. Finding the right balance ensures that resources are not wasted, and the CNC machine is more cost effective for the business in the longer term.

How do different types of CNC routers compare for various applications?

- Woodworking Routers – engraves and gouges wood which makes them suitable for furniture production, cabinet making and decorative carving work.

- Metalworking Routers – have greater toughness and accuracy than the woodworking class of routers and work on softer metals like aluminum, steel and other alloys in industrial and engineering works.

- Plastics and Composites Routers – specifically designed to cut and shape acrylics, composites, plastics and other materials, thus used for signage and light structural components.

- Multi-Purpose Routers – operate on many types of materials, which give them great versatility, but may not have the level of precision single-purpose machines offer.

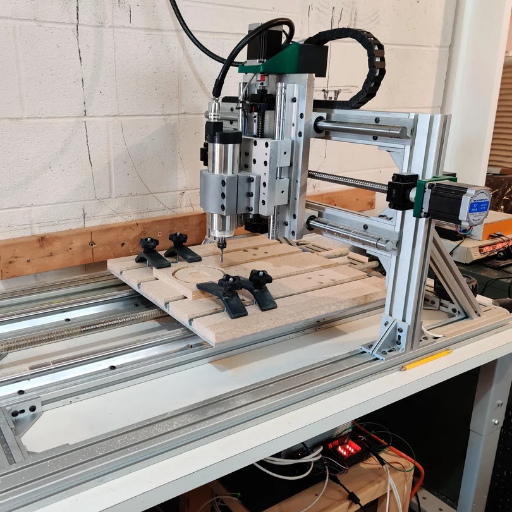

Desktop CNC Routers vs. Full-Size CNC Machines for Hobbyists

As for the choice between a desktop CNC router and a full-sized CNC machine, hobbyists should take into account the working area, the dimensions of the materials to be used, the required level of accuracy, and the available budget. For small scale projects, hobbyists can do engraving, cutting or crafting wood, acrylic, and soft metals with a desktop CNC router and store them in a compact space since the working area is 12×12 inches or 24×36 inches.On the other hand, full-size CNC machines provide greater versatility and power for substantial or more intricate materials detailing. These machines can easily handle wood, aluminum, and composites on a large scale. Professional-grade work, which is advanced project level, can be achieved with full-size CNC machines with working areas greater than 4×8 ft and higher spindle power ratings.

Also, recent advancements in technology introduce new differences in the precision and efficiency of full sized machined and desktop. The lesser powered spindles which are standard in desktop machines have max speeds of 10,000 to 24,000 RPM, while full-size machines boast a higher range with the ability to lower speed for cleaner cuts on tougher materials. Also, newer models of CNC machines are being designed incorporating features like ATC (automatic tool changer) that improve workflow efficiently. These features can be beneficial for hobbyists and entrepreneurs looking to scale their operations, hence justifying the investment in a full featured machine.

In the end, whichever option a user goes for is determined by the scope and goals of the project. Desktop routers are easier to obtain and start working with, while full-sized CNC machines offer long-term flexibility

3-Axis vs 5-Axis CNC Machines: Which one caters to your routing preferences?

Choosing between a 3-axis and 5-axis CNC machine requires consideration of specific criteria such as budget, material, and complexity of the project at hand. A 3-axis CNC machine works on three linear axes; best for simple geometrical operations such as cutting, milling, and drilling flat surfaces. These machines are affordable, and commonly found in the woodworking, sign making, and prototyping industries.

In comparison, 5-axis CNC machines have an added two rotational axes allowing more flexibility and precision. These machines are best used in the aerospace, automotive, and medical device industries for intricate designs requiring complex contours and details in 3D. A notable example is the production of turbine blades and prosthetic implants which can be done on a 5-axis machine without manual repositioning, improving efficiency and accuracy.

Based on recent information, the 5-axis CNC machine market is anticipated to expand considerably in the following years, owing to the growing need for precision engineering. Further, the return on investment for advanced applications due justify their higher upfront cost owing to increased efficiency and the ability to eliminate multiple steps in the manufacturing process. However, users should thoroughly evaluate their needs before making a decision, as production requirements will dictate cost and the final quality the work.

Entry-level vs. Professional-grade CNC Routing Systems

While comparing entry-level and professional-grade CNC routing systems, there are a number of considerations such as functionalities, pricing, and the projects they are intended for. Generally, entry-level machines are targeted towards hobbyists and provide lower costs as well as a more intuitive interface. These machines are specifically designed to perform basic operations and use softer materials like wood, plastic, and some lightweight metals. They are suitable for prototyping and light production work; however, they tend to be slower, less precise, and more fragile in terms of suppling enduring durability.

The other category includes industrial-grade CNC machines. These have far greater accuracy, power, and efficiency compared to professional CNC machines. These systems can work on tougher materials like steel and titanium and they can maintain strict tolerances in even the most challenging fabrication conditions. According to the global CNC market report for 2023, high performance CNC systems, fully automated and equipped with up-to-date software, are reported to increase production rates by 30%. Though these machines require a larger investment upfront, they pay for themselves in the long run with reduced operational costs, lowered error rates, and increased production output.

In addition, new features such as multi-axis machining, touch-screen interfaces, and real-time diagnostic capabilities have been added to entry-level CNC machines, narrowing the gap in capabilities between these and professional machines. With this in mind, professional systems may increase productivity while reducing ergonomic strain during long work shifts, but users must carefully assess their specific budget and operational requirements before making a purchasing decision.

What technical specifications matter most when choosing a CNC machine?

- Machine Size and Work Area – Ensure the machine’s dimensions and cutting area are suitable for the size of the materials and projects you plan to work on.

- Accuracy and Precision – Ensure the machine can meet your expectations for tolerance levels in order to maintain repeatability and consistent high-quality outcomes.

- Software Competibility – Ensure the CNC device works with simple and well supported software to ensure effortless functionality and easy implementation of designs.

- Check that the CNF device interacts with widely accepted software to enhance functionality and design application.

- Material Compatibility – Ensure the machine can process materials like wood, metal and plastic with.

- Examine the materials used to construct the machine in a bid to ascertain the CNC’s long term reliability.

Power and speed of spindle for different materials

Setting the CNC machine’s spindle speed and power also influences performance in machining various materials. Setting these parameters increases the accuracy and quality of output, as well as extending the service life of tools.

Steel and aluminum, for example, require greater cutting power to drive the spindle when compared to softer materials, since their density and hardness is greater. Aluminum, for example, may need to have its spindle set at 8000 – 12000 RPM whilst steel is effective for sub 3000 RPM with higher torque. Prolonged operations may require specific cooling, such as liquid or mist coolants to avoid overheating.

Plastics and wood materials, however, are the opposite and run their best at higher spindle speeds and lower power. Plywood and pine can be worked with at spindle speeds of 12000 – 18000 RPM. Also, compared to other polymers, plastics are more difficult to work with due to a lower melting point though calibrated, thus they perform best at 10000 – 15000 RPM.

Composite materials like fiberglass and carbon fiber perform best at medium spindle speeds of 8000 – 10000 RPM. However, heavy duty and dust extraction tools are required to deal with the abrasive performance and material.

The tailored spindle speed and power settings are aligned with the material properties and the particular tool used alongside the model of the CNC machine. Reference charts from the tooling manufacturers can be extremely helpful for parameter determination considering some specific machining requirements.

Importance of Stepping Motors on Precision

Stepper motors are fundamental components in CNC routers as they affect the precision of work performed on the machine. Each step of these motors controls a discrete portion of motion, hence a great deal of control. In contrast to DC motors, stepper motors partition a single full revolution into a specific number of steps, typically between 200 and 400. Because of the high number of steps provided, the positioning control, and therefore the routing precision, is exceptional.

Recently, hybrid designs of stepper motors, which integrate the characteristics of both variable reluctance and permanent magnet motors, have come to advance. These innovations improve Vibration and torque instability crucial for error minimization during high-speed operations. Hybrid stepper motors are capable of achieving a positioning accuracy of up to ±0.09° which is well suited for high precision machining tasks.

Moreover, the use of stepper motors together with microstepping drivers can further improve their performance. Dividing steps through microstepping enhances smoothness while reducing resonance. For example, a 16-microstep driver would allow a standard motor with 1.8° step angles to perform steps as small as 0.1125° which assists in delicate routing tasks. Motors are valuable in creating intricate pieces for aerospace and intricate jeweled designs and manufactured usually in the jewelry industry.

Operators will have better machine performance, enhanced precision, and greater efficiency with herculean workflows when deploying new technologies with accurate calibration of stepper motors and drivers.

Impact of Advanced Machine Rigidity on the Precision of CNC Routing

The frame rigidity and construction of a CNC machine have a major impact on its overall precision and performance. A strong, high quality machine frame of the CNC reduces the vibration during the operation hence, aiding even the most delicate cuts. Due to their deflection resistance under load, durable materials such as cast iron or welded steel are commonly used.

Research demonstrates that a stiff CNC frame is capable of lowering machining mistakes by 30% in high speed operations due to the presence of vibrations. Furthermore, modern CNC machines also have sophisticated design features like reinforced gantries and optimized mass distribution that improve the structural integrity of the machine. Take for instance, machines with dual driven gantry. They tend to be more precise during repetitive manufacturing tasks due to better stability while executing heavy-duty cutting.

Another important consideration is thermal stability. The construction of used frames from CNC machines should employ thermally stable materials to avoid distortion from heat accumulation during extended operation. Engineering tests indicate the absence of proper thermal resistance on the frame can lead to accuracy deviations of 0.02 mm due to expansion and contraction of frame components resulting from shift in temperature. Hence, there is a need for machine frame components to be externally treated with heat as well as cooling systems integrated with the machine to sustain precision.

The precision requirements in industries like aerospace, automotive, and electronics manufacturing are now achieved with unmatched accuracy and performance thanks to the combination of advanced materials, innovative designs, and cutting-edge technologies in modern CNC machines.

Which materials can different CNC routers effectively process?

- Wood: Virtually all CNC routers will manage cutting and carving of different kinds of wood like softwood, hardwood, plywood, and MDF with great efficiency.

- Plastics: A variety of plastics can be shaped and engraved on a CNC router with great accuracy, including acrylic, PVC, polycarbonate, and HDPE.

- Metals: Aluminum, brass, and copper can be processed on specific CNC routers with more robust components. More advanced machines may also be able to work with steel.

- Composites: This category includes materials such as carbon fiber or fiberglass which can be processed if the router is sufficiently durable and has the right tooling.

CNC Routers For Wood Working, MDF And Plywood Projects

CNC routers are vital in woodworking, since they automate cutting, carving and engraving wood. Their precision and control are extremely useful for detailed work, especially with MDF and plywood.

Spindle power, cutting speed, and tooling options take priority while picking a CNC router for woodworking projects. For example, a router with a spindle power of 3-5 kW is most efficient for working on hardwood and other dense materials. Softer woods and detailing work can be done with lower power spindles. Modern CNC routers also feature vacuum beds that secure the material and dust extractors to enhance the cleanliness of the work environment.

It is important to note that for woodworking projects, the feed rate is usually 100 to 500 inches per minute (ipm), depending on the material’s density and how fine the work is. In addition, grooves in plywood and MDF blend more efficiently with carbide tools, as those tools retain their dull edges and detrition resistance over time.

Seamless interchangeability between different operations with nesting software significantly changes productivity for fabrication work, which calls for enhanced material efficiency. As a result, CNNC routers become vitally useful in custom furniture making, cabinetry, and decorative woodworking as they improve precision.

Machining Plastic and Composite Materials

Styrofoam, wood, and aluminum are materials that can be worked on using routers. CNC routers focus on such materials by integrating the required features including power and precision. With regard to plastics such as acrylic as well as polycarbonate metals, speed control is critical with the spindle so as to not over heat or distort the material. Composite materials such as carbon fiber and fiberglass often require specialized tooling with reinforced sharp and durable coatings.”

Recent advancements in CNC technology have allowed for higher levels of accuracy and efficiency in routing plastic and composite materials. For example, high-speed spindles combined with vacuum hold-down systems ensure that materials remain stable during intricate cuts. Data shows that CNC routers boasting speeds of up to 24,000 RPM can drastically improve production rates while preserving the integrity of materials. Moreover, work environments are particularly important when it comes to controlling harmful materials produced by power-operated machinery such as routers because fiberglass turns into fine particulates that are hazardous.

Statistical insights reveal that CNC routers industries such as aerospace, automotive, and signage production have plastic and composite processing, have experienced a 30 percent optimization features. These systems enable economic operators to achieve consistent results from complex geometries which impact output quality positively, whilst lowering material waste.

Considerations for Selecting the Right CNC Router for Metal and Aluminum Cutting

When choosing a CNC router, it is critical to focus on other equally important aspects such as precision, economies of time, cost, and efficiency for metal and aluminum. Current models of CNC routers come with rigid machine frames and powerful spindle motors capable of operating under the greater forces needed to cut dense materials such as aluminum. According to recent research, routers with high-speed spindles operating at 18,000 to 24,000 RPM are most effective for cutting aluminum with minimal burring or excessive tool wear.

The first thing to analyze is the type of tooling employed. Cutting tools applied with titanium nitride (TiN) or diamond like carbon (DLC) coatings outperform uncoated tools with respect to thermal fatigue and cut quality when cutting metals. The cut itself, especially mist coolants and air blasts, also avoid excessive chip and heat buildup, leading to smoother operation.

Equally important, robust CNC software assists in the optimization of tool cutting path sequences. Newer software implementations offer adaptive clearing strategies that, according to some recent studies in the field, can enhance machining processes by as much as 40%. These algorithms modify feed and cut depth parameters in real-time, which results in decreased cycle times and improved surface finish quality.

Finally, some hybrid CNC routers with recently added features for simultaneous milling and engraving have broad application for shops that deal with a variety of assignments. These systems are capable of material interchange with ease during engraving and deep cutting and hold high precision, which is particularly advantageous for companies that serve the aerospace, architectural, and manufacturing industries.

What software considerations should influence my CNC router purchase?

- Compatibility: Confirm that the software will work with your model of CNC router and operating system. Verify support for basic file formats such as DXF, STL, or G-code to enhance workflow efficiency.

- Ease of Use: In case of limited technical expertise within your organization, consider using easy to navigate software that is more accessible for less experienced team members.

- Features: Determine what project entails to identify any required features such as 2D design, 3D modeling, nesting, or simulation to test them prior to production.

- Support and Updates: Considerable vendors offer software with regular software updates, technical support, and comprehensive instructional documentations or guides.

- Cost vs. Value: Evaluate the relationship of the cost and available features, picking a solution that meets operational needs for activities required to complete them without unnecessary expenditure.

Importance of Software Compatibility in CAD/CAM Systems

When choosing a CAD/CAM design software, it is essential to check for compatibility with other systems in order to maximize efficiency and ensure streamlined operations. The level of compatibility will determine the communication capabilities of the software with CNC machines, 3D printers, or laser cutters as they work to execute the design being processed. Take, for example, many software products today, like AutoCAD or SolidWorks, using common machine languages such as G-code designed for multiple machine tools, hence multiple software units can use it without modification.

Stylistic consideration set customization and post-processor settings are instrumental to the machine’s compatibility. A post-processor transforms designs into machine-specific commands, which are aligned to the machine’s capabilities. For instance, a CNC milling machine might have very specific requirements for the definition of toolpaths and cutting parameters; thus, the CAD/CAM system must be set up correctly to mitigate machining mistakes or inefficiencies in the workflows that could be created.

Research indicates that companies that operate with aligned software and machines achieve up to a thirty percent decrease in production time, as well as a lower incidence of errors related to miscommunication. The increasing adoption of CAD/CAM solutions hosted on the cloud has also augmented compatibility. The cloud allows access to the platform from different operating systems, thus providing limitless possibilities ensuring the cutting edge of technologies are adopted improving real-time collaboration and agility.

Ultimately, productive environments where precision, timeliness, and automation are imperative, software selection criteria based on broad compatibility improves operational workflows.

The Use of CNC Router Machines with Different Controller Systems

The use of modern CNC router machines requires intelligent controller systems that can adapt to newer technological developments. Modern controllers are built to interact with various software packages and interfaces to improve user experience. Touch screen interfaces, preset buttons, and responsive lags are some of the features more sophisticated systems offer, aiding neophytes to operate CNC routers efficiently.

New feed systems also offer new possibilities for CNC controllers such as the intelligent modification of toolpath sequences and adaptive feed rate. With the right control systems, a 30% saving in production time and higher precision in complex geometric shapes is achievable with intelligent controllers. The intelligent predictive algorithms within the machines determine the optimal routing on the CNC controllers and recalibrate automatically.

Moreover, the setting of wireless control also makes the machine easier to manage remotely by operators through mobile applications and cloud services. This provides mobility in highly automated production lines and rapid changes while keeping delays to a minimum. Through these controller systems, productivity and quality are enhanced for a myriad of industrial processes.

Reference sources

- Study: Proposal of a Process of Mass Customization of Kitchen Cabinetry1

- Objective: To integrate Building Information Modeling (BIM) with CNC router operations for mass customization in small and medium enterprises (SMEs).

- Methodology: The study employed action research to develop a BIM-based workflow for designing and fabricating custom kitchen components. It utilized a BIESSE Rover CNC router for production.

- Key Findings:

- BIM integration streamlined the CNC router setup and programming process.

- The study emphasized the importance of aligning customer preferences with CNC router capabilities.

- It highlighted the need for staff training and process reconfiguration to maximize CNC router efficiency.

- Study: CNC Router Selection for SMEs in Woodwork Manufacturing Using Hesitant Fuzzy AHP Method3

- Objective: To propose a systematic decision-making model for selecting CNC routers in woodwork manufacturing SMEs.

- Methodology: The study used the Hesitant Fuzzy Analytic Hierarchy Process (HFAHP) to evaluate CNC router options based on technical, personnel, economic, and vendor criteria.

- Key Findings:

- Technical aspects were identified as the most critical factor in CNC router selection, even for budget-conscious SMEs.

- The model provided a structured approach to prioritize criteria and select the best CNC router.

- A case study demonstrated the model’s applicability, helping SMEs make informed investment decisions.

- Top 3D CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What factors should I consider when choosing a CNC router?

A: Your materials, workpiece size, work specifications, and budget should all determine which option you go with. These considerations can lead you to the most cost-efficient and best-performing option available.

Q: How important is the quality of the spindle in a CNC router?

A: The spindle quality of a CNC router significantly affects its bolt-on alterations, thus impacting the performance and efficiency of the machine. In addition, high-grade spindles guarantee a favorable output in surface quality of the workpiece and productivity of the router, sustaining proper equipment maintenance.

Q: What is the role of CAD in using a CNC router?

A: CAD allows the user to develop and elaborate specialized plans that CNC routers can implement. This optimizes the njob, increasing both productivity and the quality of the results.

Q: Should I buy a new or used CNC router?

A: The option to purchase a second-hand device may benefit small companies or beginners due to the lower price. Make sure that the machine is functioning properly along with meeting your requirements. A buyer’s guide can help ascertain whether a used option would work best for you.

Q: Feeds and Speeds effect the performance of CNC Router, how?

A: The feeds and speeds settings must be appropriately selected in order to maximize the CNC router’s operation. With correctly calibrated parameters, efficiency as well as accuracy will increase, machine wear would be less, and process results will be superior.

Q: What is the role of computer numerically controlled mechanism in CNC routers?

A: Computer numerical control (CNC) cuts governs the movements of the router with high precision. It helps to perform complicated works by the router to a greater extent of accuracy and precision which is important for bulk production and detailed work.

Q: What Aspects should I keep in mind concerning the router bit while purchasing a router?

A: When working on various materials, the right router bit must be secured to perform the tasks. Be sure to determine the kind and dimension of the bits relative to the materials you intend to work on. You may refer to a buyer’s guide to find the best bit suitable for you.

Q: What is the cost implication of selecting a CNC router based on features, quality, and capabilities?

A: More often than not, the cost of the machine changes drastically depending on the attributes, quality and capabilities offered on the machine. For best value and effectiveness, make sure to balance your projects’ prioritizations and requirements with your spending.

Q: What is the significance of the Z axes in a CNC router’s functionality?

A: Z axes are critical in regulating the upward and downward movements of the router, as far as the height of cutting goes, in the degree of finishing detail, and depth of cut. Its important role is for sculpturing works which demand dynamic forms of cutting and shaping concrete materials.

Q: What are the advantages of CNC routers on small businesses?

A: The efficiency as well as the accuracy of CNC routers can greatly impact the productivity of small scale businesses. The ability to perform complex procedures can lead to less manual work, offering significant improvement in the market position.

- Discover the Versatility of a CO2 Laser: What It Can Cut, Etch, or Mark?

- Unlocking the Secrets of UV Laser Marking Machines: How Does It Work?

- Master the Art of Laser Cutting & Engraving Plastic

- Is a Laser Engraving Machine the Best Investment for Your Business?

- CNC Router vs CNC Mill: Understanding the Key Differences Between These Popular CNC Machines

- Unlocking the Power of Laser Cleaning for Glass Surfaces: Revolutionary Mould Cleaning Technology

- The Ultimate Guide to Laser Cutting Plywood: Mastering the Art of Precision

- The Complete Laser Cutter Buying Guide: Choosing the Best Laser for Your Needs