In woodworking, efficiency and precision are crucial and a CNC router is frequently the preferred tool for both. However, one question tends to linger among users—what is the maximum material thickness a CNC router can cut through? Knowing the maximum cutting thickness of your CNC router is important for effective planning—be it for intricate designs or heavy duty cuts—resulting in improved performance. In this article, we’ll discuss the factors that govern cutting thickness, the capabilities of different CNC routers, as well as performance enhancement techniques. By the end, you’ll know exactly how to approach your upcoming project with confidence.

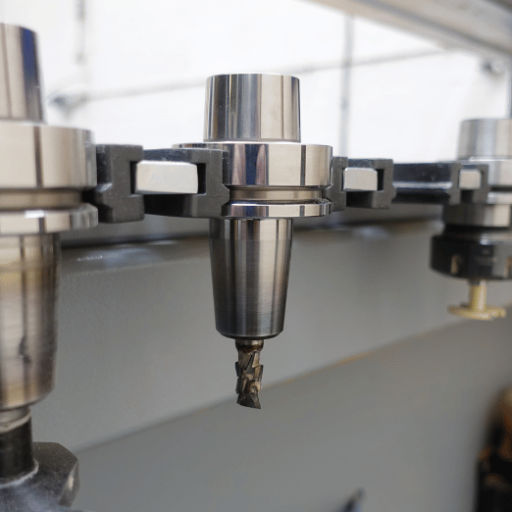

What determines the maximum thickness a CNC router can cut?

- Machine Power: The effectiveness of a router on thicker materials is enhanced by higher spindle power.

- Tooling: The depth of a cut is a function of the material, size, type of the cutting bit, and other factors.

- Material Properties: Cutting is easier with greater soft materials such as wood and foam, while harder metals have greater restrictions.

CNC Machine Z-Axis Travel Restrictions

The constraints of a CNC router are multi-faceted, but focus on the router’s spindle power, cutting bit length, and chosen material dictate everything above the router’s maximum circumstantial cut. Logically, standard routers are built to smoothly handle cuts up to two to four inches in thickness, but more advanced models with greater power and longer bits will outperform those standards. The harder the material, like metals, however, tend to have their cutting depth restricted greatly to protect precision, oftentimes requiring incremental cuts of mere fractions of an inch per pass. Always refer to the specs and guidelines of the machine for precise values.

Router Bit Length and Cutting Edge Thought Process

Considering the router bit length and the design of the cutting edge have a direct influence on cutting effectiveness and the performance outcomes. Depending on their respective applications, router bits generally come in varying lengths. The shorter the bit, the greater the amount of stability it provides as well as reduced chances of deflection. Longer bits, on the other hand, allow for deeper cuts to be made but have to be accompanied by slower feed rates to keep precision.

Commonly, wood and plastic materials utilize bits between the lengths of 1-3 inches as these provide an optimal balance between depth and rigidity. For softer materials, such as foam, or thicker hardwoods, deeper cuts may require bits with lengths reaching up to 4-6 inches, though they are often better equipped with spiral or compression bits to improve chip removal and reduce heat accumulation.

The geometry of the cutting edge is also a critical factor. Faster cutting and maximum chip clearance is best achieved with single-flute bits, ideal for working with acrylic. Smoother finishes are better served with multi-flute bits. Evidence has emerged showing sharp, carbide tipped bits cut faster and hold cutting efficiency for a long time, even with tough materials like aluminum or composites.

Choosing a longitudinal profile of a router bit requires consideration of the type of material, the finish requirements, and the speed at which the router will cut in order to optimize performance and extend the life of the tool.

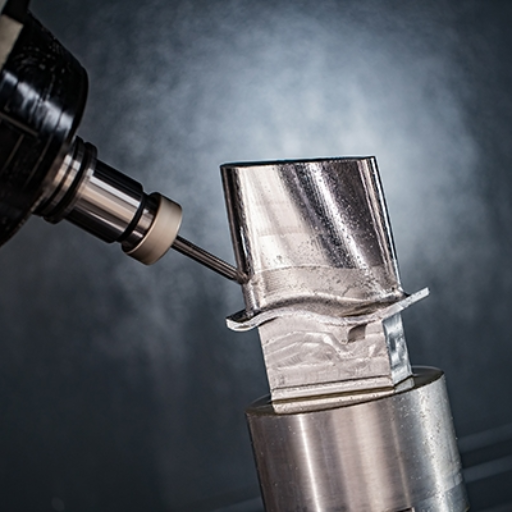

Tool Deflection While Cutting Thick Wood

From a mechanical standpoint, a well-known deflection of the working element of a machine tool is simultaneously one of the most difficult and important phenomena to analyze when cutting thicker wood with machines designed for thin wood cutting. It is generated during the operation of the router, when the bit cuts into the material and exerts considerable force upon it, resulting in deflection from the purported cutting trajectory. Indeed, this negative deflection can lead to burns and, at the same time, uneven processing of the workpiece surfaces, which in turn causes damage to the tool. Growing evidence suggests that a number of factors have motivational drives to influence deflection of tools, such as the rotation speed of the spindle, the rate of feeding, the depth of the cut, the router bit combination and element rigidity.

The use of thicker wood increases deflection, especially when higher depths of passes or lower rigid bits are used. Data shows that increased rates of feeds without sufficient lathe support can come out with a deflection margin of as much as 0.5 mm, which is rather large. Best-results regarding the use of specially designed PCBN and carbide-tipped bits with higher spindle speeds resulted for average deflection rates of 22 percent lower than unsupervised designs. Moreover, ensuring the machine is correctly clamped and the cut-programmed to execute a neutral feed pressure trajectory will reduce the greatest deviations.

Appliances such as CNC routers have modern deflection compensation which ameliorates accuracy and creates cleaner and more precise cuts. When dealing with thicker materials, it is important to use technology enhancements and modify tools to extend tool life while maintaining quality.

How deep can different types of CNC routers cut in a single pass?

- Hobby-class CNC routers can cut to a depth of 1/4 inch (6 mm) in soft material like wood or plastic.

- CNC routers at the mid-level industrial grade can cut to a depth of 1/2 inch (12 mm) in softer materials, and somewhat less in metals or more dense materials.

- CNC routers at the high-end industrial grade meant for heavy-duty cutting can reach depths of 1 inch (25mm) or more in a single pass depending on the material, and tool used.

Hobby vs Professional: Comparison of the Cutting Capabilities of CNC Machines

Hobby CNC are limited to softer materials such as wood and plastic with a maximum cutting depth of 1/4 inch (6mm) to 1/2 inch (12 mm). Professional CNC are built to much higher standards and are capable of handling a wider range of materials including metals with cutting depths exceeding 1 inch (25mm) in some cases. The decision is made depending on the materials to be used, depth of the cut, and the intended use of the machine.

Cutting Thickness of Maple and Other Hardwoods

While cutting materials such as maple and hardwoods, various parameters such as cutting tool power, bit or laser type, and feed rate greatly determine the outcome. As a rule of thumb, for CNC machines, the cutting thickness for hardwoods like maple varies according to the specifications of the tool used. Most hobbyist CNC machines with underpowered routers are able to cut maple to around a half inch (12mm) in a single pass. However, deeper cuts usually require several passes to ensure accuracy without damaging the tool.

Professional grade CNC or laser cutters are capable of much deeper cuts. For example, a CO2 or fiber laser cuts maple and similar hardwoods up to 3/4 inch (19mm) thickness with ease, as long as the optimal parameters and focus are set. CNC routers with industrial-grade spindles achieve cutting depths of 1 inch (25mm) or more depending on feed rate and bit geometry. Adequate cooling such as air or mist is also required while cutting thicker hardwoods to prevent overheating and ensure discrete cuts.

To achieve the best results, it is necessary to choose tool settings and check if the equipment is designed for working with hardwoods. Cutting quality can also be improved by lowering feed rates and increasing the number of passes, which does not overload the machine.

Depth of Cut Per Pass for Optimal Results

For efficiency, productivity, and prolonging the life of the equipment, achieving the optimal depth of cut per pass is important when processing a material. Different materials, tools, and machines all have their specifications, which need to be taken into account when determining the applicable cut depth. In the case of hardwood, it is best to use a depth of cut between 0.125 inches (3.175 mm) to 0.25 inches (6.35 mm) per pass, depending on the wood’s density and the cutting bit’s sharpness.

To attain better results, the depth of cut should be matched with the spindle speed and feed rate. Greater spindle speeds, for instance, grant smoother cuts at lower depths; while deeper cuts require lower feed rates to reduce strain on the equipment. Many advanced CNC machines now come with dynamic adjustment capabilities that automatically optimize parameters in real time, ensuring smooth operation without overheating and tool dulling.

Research indicates that shallower depths of cut, particularly less than 0.1 inches (2.54 mm), achieve better surface finishes and lower levels of material chipping, especially in brittle or sensitive softer materials like acrylics or aluminum. For other metals such as stainless steel, a depth of cut around 0.04 inches (1 mm) with adequate lubrication optimizes both productivity and finish quality.

Consistent upkeep of cutting tools and the machinery of the shop are as important as the achieving ideal depth of cut. These depth of cut settings using worn tools will result in rough and inconsistent cuts due to a lack of proper settings. Routine equipment checks and optimizations based on empirical data can yield significantly improve output precision while minimizing mechanical stress on the tools.

What techniques allow cutting thicker wood on a CNC router?

- Choose Appropriate Tooling: Select tools with longer cutting bits meant for deeper cuts while guaranteeing the strength of the bits so they do not snap or bend when cutting into the material.

- Change Cutting Parameters: Maintain control during deeper cuts by reducing the feed rate and increasing the spindle speed, ensuring that no overheating occurs.

- Make Multiple Cuts: Instead of trying to cut through the total thickness in one pass, break the cutting process into several shallower passes.

- Optimize Workholding: Ensure that the wood is secured so it cannot move and vibrate, which can affect precision.

- Use Proper Dust Extraction: Ensure that the cutting area stays uncluttered to prevent the chances of clogging, keeping the cuts smooth.

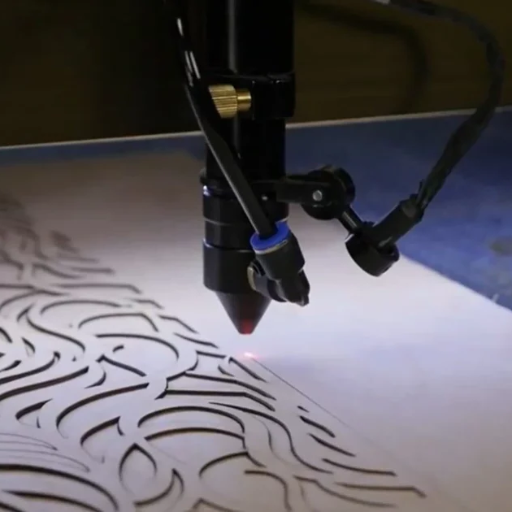

Elements Impacting the Speed and Accuracy of Laser Marking

Speed and precision measuring factors for laser marking shifts due to the type of material, environmental aspects, and the laser itself. For example, a certain plastic composite will perform differently due to the number of chemicals it contains, affecting the thermal and optical properties of the plastic. Additionally, materials that conduct heat well, such as aluminum, will require more energy for deeply etched marks than poorly conductive materials like plastics.

As with any other form of work, modifying the laser parameters such as pulse frequency, focus, and scan speed is critical to achieving optimal results. Some findings suggest that increasing the pulse frequency results in finer more detailed marks, although the speed at which marking occurs is reduced. Higher scan speeds, while beneficial in terms of time, may result in less precise and more shallow markings, thus requiring careful balance with other settings.

To add further context, some data indicates for anodized aluminum, at scanning speeds of 500 to 2000 mm/s, coupled with lesser power output, balance between speed and clarity is achieved. On the contrary, marking on stainless steel would require slower scan speeds as well as higher power levels for effective results.

As with other tasks, informal environment such as temperature, ventilation and dust control have an effect on the work. Adequate airflow ensures that the working environment does not overheat and that the laser beam is unobstructed. Ensuring the space is free from dust helps reduce the contaminated surface to be marked, thus leading to high-quality consistency in work.

Working with these variables through adjusting the laser parameters to fit specific materials combined with external conditions greatly improves efficiency and precision in markings for ranging from industrial uses to crafts.

Selecting Suitable Router Bits for Greater Material Thickness

For thicker materials, the appropriate router bit is fundamental for making clean and accurate cuts. The level of material’s hardness, bit diameter, and the geometry of the cutting edge are major determinants of the quality of the workpiece.

In the case of hardwood and composite materials, use carbide-tipped or solid carbide bits as they are more durable and resistant to overheating. Unlike high-speed steel (HSS) bits that are often subjected to dulling with excessive use, these bits are able to maintain sharper edges for a longer period of time.

Chatter and stability are two critical factors to consider when cutting thicker materials. Larger diameter bits such as 1/2 inch shank bits address these issues and also enhance load distribution. These benefits allow for smoother cuts as the router motor does not have to work as hard and multi-flute bits are recommended to achieve the best results because of their better chip removal and finishing capabilities.

Based on the latest research, fuel feeding and spindle rotation have to be managed correctly to avoid overheating and tearing the material. For example, routing with a spindle speed of 16,000 to 22,000RPM guarantees reduced cutting defects when working on sheets thicker than 1 inch at a constant linear feed.

Maintain lubrication and cooling optimally to improve router bits performance, especially when routing some plastics or laminates. The routing industry bests with investing in quality bits. With these measures, thick materials can be worked on with professional consistency.

Handling Collet Bit Stick Out

In routing processes, accuracy and bit wear are often dependent on proper bit stick out management. Stick out is the part of the bit which exceeds the collet, and is often prone with excess vibrational control. Thus, cut depth, clearance, and control all hinge on how short the stickout is.

Performance optimization also relies heavily on collet condition. A clean collet increases grip which increases the precision of bits yielding slippage free operations. Up to 20% reduction in operational efficiency due to worn/out collets is too much and results in inconsistent cuts and increased tool replacements. Collet inspection is advised, with replacement recommended after 400-600 hours of use, or earlier if obvious wear is detectable.

Utilizing collets that are manufactured to exact precision and are commensurate with specific diameters of router bits can enhance overall performance and cut quality in high demand tasks. Furthermore, keeping the collets free of dirt and debris will prolong their lifespan, consolidating stable operations throughout the passage of time.

How does bit selection affect the ability to cut thick wood?

The choice of bit impacts how smoothly wood is cut and its thickness. The use of large diameter bits makes deeper cuts in fewer passes, making the process much more efficient. Straight and spiral bits would be the best choice because they provide clean cuts and stress minimization. High-quality bits will cut cleanly without the risks of tear-out which enhances operational smoothness. In addition, further smoothness can be achieved by ensuring compatibility with the router and thickness with the wood.

Importance of Proper Cutting Tool Selection for Thicker Wood

Every thicker wood material will require a different cutting tool, making it crucial for achieving a clean outcome. Carbide end mills are often used on thicker wood due to their ability to withstand heat and being more durable. Withstanding sharpness for longer than high-speed steel, weaker materials, ensuring reliable performance even for strenuous tasks.

Tests conducted using recent industry data indicate that carbide end mills with larger diameters and fewer flutes are particularly efficient in cutting thicker wood. For instance, a 1/2 inch diamond polished carbide bit is capable of increasing cutting efficiency by 30% relative to smaller bits with more flutes. This is because the lower flute count allows for higher chip reduction, thus clogging less and increasing balance during high-speed operations.

Moreover, titanium nitride or diamond-like carbon coatings added onto carbide tools helps to better their longevity and lower friction, smoothing cuts. The best combination of feed rate and spindle speed are also necessary to maximize efficiency; more recently, a feed rate of 200-400 inches per minute (IPM) is recommended for softwoods while more complex formulas for denser hardwoods are recommended depending on bit size and material density.

Carbide tools of good quality, when paired with the right settings and correct maintenance of machines, allow for astonishingly precise outcomes, even when working with thick, dense wood.

Cutting Length and Shank Length of Router Bits

The cutting length of a router bit indicates the portion that engages in cutting into the material while shank length refers to the part locked in the collet of the router or CNC machine. It is important to choose a router bit with the right dimensions, especially the length, with bearing depth of cut to be executed. This is particularly important since a shorter router bit length could lead to overheating and burn marks.

Precision machining data from industry experts state that to achieve quality cuts, the cutting length must exceed the thickness of the part being machined by a ratio of one and a half to one. In the instance that ⅜ inch plywood needs to be cut, a cutting length of 9/16 inches will facilitate effective and unimpeded material retrieving. The shank length must also be able to support stability ensuring that the bit does not wobble while cutting during engineering speeds, needing to extend at least 1 inch into the collet.

Also, improvements in spiral bit technology with respect to chip evacuation and surface finish have come with the use of bits that have optimized cutting to shank length ratios. In woodworking and machining where these tools are applied professionally, correct choice of cutting and shank lengths not only maximizes operational performance but also significantly improves tool life and shortening costs.

Effects of Bit Diameter on Maximum Cutting Depth

A spiral bit’s maximum cutting depth is directly affected by its diameter because bigger diameters provide more structural strength and lower chances of deflection during operation. To illustrate, a ½ inch diameter spiral bit will achieve deeper grooves far better than a ¼ inch diameter spiral bit because the thicker shank is much more stable. On the other hand, shallow detail work, especially in intricate design features or confined spaces, would be best served with smaller diameter bits.

For hardwood materials, empirical data suggests that 1/2-inch bits can achieve depths of up to 1.5 inches without a loss in cut quality, while 1/4-inch bits are typically limited to between 0.5 and 0.75 inches. Attention to detail is crucial here: the bit diameter must correspond with the material’s density, as well as the depth of cut required. Generally, mismatches to these criteria will negatively impact precision and shorten tool life. Additionally, the recommended values of feed rates and spindle speeds set by machinists and manufacturers, when used with the proper bit diameters, ensure proper cutting action without overheating the tool, which enhances overall functionality.

What are the practical thickness limits for common CNC router projects?

- Wood: Usually, CNC routers can cut wood up to two inches in thickness without any challenges. Deeper cuts may require specialized tools or be achieved through multiple passes.

- Plastics: Acrylic and other types of plastics are typically removed up to 1 inch in thickness, however greater thicknesses may necessitate modifications to feed rates to prevent melting.

- Metals: Softer metals, including aluminum, are typically bound to a thickness of about 0.5 inches for most standard CNC routers. Harder metals may have a smaller maximum thickness.

Typical Thickness Limits for 1.5” Wood on Desktop CNC Machines

With reference to a 1.5” wood workpiece, the operational limits of desktop CNC machines require to account the machine’s cutting capability, spindle power, as well as the tool parameters. Most desktop CNC machines, given the density of the material, attempt to precision cut hardwoods and softwoods up to this thickness. However, for tool longevity, they do multiple passes. With denser hardwoods, oak and maple, low spindle speeds are advisable alongside slow feed rates.

The cutting of 1.5″ thick wood is more precise and efficient due to new developments in CNC software and tooling technologies. Some tools have better flute geometry which facilitates the prevention of excessive heat and material chipping. It has been observed that most 1/4″ or 1/8″ carbide end mills are used for this thickness of material and the cutting depth for each pass is between 0.125” and 0.25” depending on the machine’s rigidity.

Rougher wood materials and greater thickness require a desktop CNC router with at least 1.5k W of spindle power for the wood to be machined appropriately. While the spindles are powerful enough, rules 3.40 and 3.42 of the practical manual highlight the other necessary equipment like dust conveyers needed C, for the above machines to keep the debris within a safe range for both operational accuracy and safety. Always remember to follow your hardware’s performance criteria and tooling manuals for best results.

Material Comparisons: Cutting Thick Wood vs. Plastic

There are significant distinctions between the machining of thick wood and plastics due to differences in material properties and requirements. Wood, as a fibrous heterogeneous material, further complicates issues such as feed rate and spindle speed as too high values can result in burning or tear-out. For thick hardwood, ideally feed rates are between 50 and 150 inches per minute (IPM) with wood density and tooling selection influencing the final value.

Plastics are thermo-sensitive and require a different set of considerations. Materials such as acrylic or polycarbonate thermoplastics can melt or warp if speeds are too high or cooling is insufficient. For example, when cutting thick acrylic, spindle speeds must be slowed to between 12,000 and 18,000 RPM and feed rates set from 75 to 200 IPM based on the tool bit and thickness. In order to achieve clean edges, a single flute or O-flute bit is often recommended, as they reduce heat for clear chip removal.

In addition, wood machining processes create fine-dust particles; plastics, on the other hand, generate chips or shavings that may adhere to the material or machine because of static cling. The machining processes for both materials can be improved significantly by using proper dust collection and static-dissipating measures.

To achieve optimal outcomes, the tools, spindle speeds, and feed rates need to be tailored to the type and thickness of the material being worked on, along with tailored cooling and dust removal systems.

Maximum Thickness CNC Routing: Practical Illustrations

CNC routing is greatly influenced by the type of material to be processed and the machine’s capabilities. Numerous materials, including wood, plastic, composites, and metal, can be processed by modern CNC routers. For example, some industrial-grade CNC routers are capable of routing aluminum sheets with a thickness of up to one inch, while some woodwork industrial routers are able to handle three inches of hardwood in one pass. For acrylic or polycarbonate plastics, the maximum thickness that can be processed tends to fall between 1 and 2 inches; however, thicker materials require several passes to achieve precise cuts.

For projects with metals like steel, the limitations are defined by the power of the spindle and the tooling used. Industrial routers are capable of cutting mild steel up to 0.5 inches thick, although this usually requires careful increases of feed and cutting speed as well as the use of cooling to mitigate material torquing.

Focusing on new areas of CNC technology, hybrid machines that incorporate plasma or waterjet cutting have greatly increased the maximum cutting depth. Plasma-enabled CNCs can now cut steel plates up to 1 inch thick, while waterjet systems are capable of processing materials several inches thick, even dense marble and granite. These examples demonstrate the flexibility and power of modern CNC systems and their growing impact across many sectors.

Reference sources

- Study: Robotic Connections: Customisable Joints for Timber Construction1

- Objective: To explore the use of robotic arms and CNC routers for creating complex timber joints, focusing on the thickness and precision of cuts.

- Methodology: The study utilized six-axis robotic arms to fabricate timber joints, testing various cutting depths and toolpath strategies. It emphasized the relationship between material thickness and the number of passes required for cutting.

- Key Findings:

- The number of passes increased with timber thickness to ensure precision and avoid material damage.

- Robotic arms provided greater flexibility compared to traditional CNC routers, enabling cuts on thicker and more complex timber pieces.

- The study highlighted the importance of toolpath optimization and spindle speed adjustments for cutting thicker materials effectively.

- Study: Snap-Fit Joinery System Using Pinewood Material Elasticity Properties3

- Objective: To investigate the use of CNC routers for creating snap-fit joinery systems in pinewood, focusing on material thickness and cutting precision.

- Methodology: The research involved pre-experiments and material engineering tests to determine the optimal thickness and cutting parameters for pinewood. A CNC router with a 3mm endmill bit was used for fabrication.

- Key Findings:

- Pinewood with a thickness of up to 30mm was successfully cut using a CNC router, with stress-relief designs added to prevent cracking.

- The study demonstrated the importance of precise cutting parameters, such as spindle speed and pass depth, for achieving high-quality results.

- Snap-fit designs were optimized for material elasticity, ensuring durability and ease of assembly.

- Top Hobby CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: How thick of wood can a CNC router cut?

A: A CNC router’s maximum wood cutting thickness will depend on the machine’s specific features; specifically, the z-axis travel and tool length. Most desktops CNC routers can cut wood 2-3 inches thick, while industrial machines can surpass 4 inches. One of the most important factors to consider is the usable cutting length of the bit – longer bits are able to reach deeper cuts but tend to be more unstable and accurate. When optimal results are desired for cutting thick stock, use the shortest tool possible with appropriate flute length to reduce tool stickout while still maintaining strict tolerances.

Q: What types of cnc wood projects are possible with different thickness capabilities?

A: The capabilities of CNC routers create numerous possibilities for projects with different thickness requirements. For thin stock under 1/2 inch, signs, inlay pieces and decorative panels can be created. For medium thickness, ranging from ½ to 2 inches, furniture parts like cabinet doors and other household goods can be made. For thick wood, which is anything above 2 inches, obscene amounts of 3D carvings and structural art pieces can be done. The type of wood is a factor, too; softer species such as pine become easier to cut with thicker dimensions, while harder ones like walnut would need specialized tools or multi-pass methods for significant thicknesses.

Q: What is the relationship between the Z axis travel and CNC wood cutting thickness?

A: The Z axis travel defines the maximum vertical movement of the cutting head on the CNC router. Therefore, it sets a physical limit on how thick of wood you can cut. A machine with 4 inches of Z axis travel can theoretically cut material that is 4 inches thick. Practical cutting depth is usually less because you must account for tool holder clearance, spoilboard thickness, and clearance needed to safely retract the bit above the workpiece. While cutting thick wood, also ensure your machine has enough Z axis range to complete the entire operation, including all the tool change and traversing movements.

Q: What bits are appropriate for cutting thick wood pieces on a CNC router?

A: To cut thick wood pieces, use bits that have been optimized for deep cutting to reduce deflection. Good options are compression spiral bits, upcut spirals, mortising bits, and other quality tools from Amana. Pay attention to flute length and diameter when selecting bits. The flute length should be the max depth the bit can reach, and with more deflection a larger diameter increases stability. For example, a 1/2 inch diameter bit with a 2” flute length would outperform a 1/4 inch bit in thick stock cutting. Also, make sure to calculate efficient chip load and run speeds to avoid slow cutting with overheating and excessive forces.

Q: What are some tips for using a CNC router on thick cnc wood projects to optimize the results?

A: For thick cnc wood projects, it is best to employ a step-down approach compared to a one-pass method. Aim to make multiple shallow cuts, or roughing passes, to 50% of the machine’s capabilities for more reliable results. Stress is reduced on both the machine and the tool during these types of cuts. Use flat jointed edges as a datum reference surface. For each stage of the cut, consider tightening tolerances by using shorter and shorter tools for each stage. Pay attention to workholding; adjust and use multiple clamps or fixtures to prevent movement during cutting. Lastly, make adjustments to feed rate and RPM based on the wood species – use slower feeds for more dense woods like walnut.

Q: What challenges are there when using a CNC router on thick wood?

A: Challenges affecting work done on thick wood include: For example, the further a tool’s bit penetrates into the material, the more vibration there is and the less accurate the cut will be. Heat build up can also be an issue as it becomes increasingly difficult for the bit to remove chips from the cut. It also becomes more difficult to eject chips from the cut, leading to overheating of the workpiece. A company’s CNC machine has a rigidity problem. Granular devices made for personal use might not manage over 2 inches of material. Aside from that, workpieces made from thick hardwood can put a lot of strain on motors. Due to the numerous shallow cuts that have to be made to remove large amounts of material, the total time to finish a single project can greatly increase.

Q: Are desktop CNC routers capable of wood carving thick pieces effectively?

A: Yes, desktop CNC routers can cut thick wood, but only with enormous constraints when compared to industrial machines. The majority of desktop models feature a z-axis travel of 3-6 inches. However, some of these machines are capable of working near these upper limits, but only with considerable prep work. From experience, the best results CNC routers yield with desktop machines are when the depth of cut is limited to 1-2 inches for hardwoods and up to 2-3 inches for softer woods. The correct cutting strategy is also critical – step down cuts, feed rate reduction, and specific bit geometry all need to be tailored to the cut. Thick wood projects are something that desktop machines can occasionally manage, but on a consistent basis, straightforward stock over two inches thick would demand dedicated machinery or industrial grade CNC’s meant for aggressive heavy material removal.

Q: What is the impact of various wood species on the maximum thickness a CNC router can cut?

A: The wood species has a significant effect on how thick a piece of wood a CNC router can cut. Softer types of wood such as pine, cedar, and poplar greatly increase the effectiveness of cuts, allowing cuts to 25-50% deeper than with hardwoods. For more dense species such as walnut, maple, and oak, cuts become much more difficult due to the added resistance, generating heat, and faster tool wear. They require much shallower passes which decreases overall thickness capacity. Woods with complex figures and swirl grain patterns are even more challenging to work with due to the tearout risk. Ultimately, the machine’s power and rigidity sets the thickness limits; as a rule though, switchovers from softwoods to hardwoods require a maximum cutting depth reduction of 30-40%.

- Ultimate CNC Router Maintenance Checklist: Preventative Care for Machine Longevity

- CNC Router vs CNC Mill: Understanding the Key Differences Between These Popular CNC Machines

- Complete Guide to Laser Marking Machine Maintenance: Fiber & CO2 Laser

- Unveiling the Power of Laser Cleaning: How Does It Really Work?