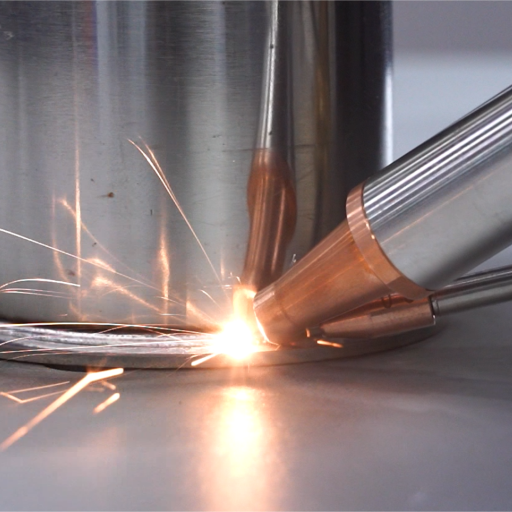

Laser welding has indisputably become one of the most transformational advancements in engineering – with unrivaled accuracy, efficiency, and flexibility, it has revolutionized the manufacturing and metalworking sector. Among the latest innovations, handheld laser welders are contended as one of the most portable and efficient options for professionals with diverse welding requirements. However, one common question remains—what is the maximum thickness a handheld laser welder can weld? This post outlines the workings of these powerful machines, detailing the machines functions, their defining performance factors, and their use in real life. This guide is meant for both – the seasoned welders and the novices looking to understand the breadth and limitations of laser technology.

What is the Maximum Thickness a Handheld Laser Welder Can Achieve?

The highest thickness attainable by handheld laser welders is contingent on the material being welded as well as the power of the laser. Generally speaking, most metals can be laser welded up to 6mm in a single pass with a handheld laser welder. It is possible to achieve greater thicknesses with additional passes, but this is also dependent on the welder’s power settings and joint design, among other factors. Always observe manufacturer recommendations for reliable parameters.

Factors Influencing Weld Thickness

The output power of the welder’s laser is with no doubt the most critical element that determines the achievable thickness with a laser welder. As an example, a 1000W handheld fiber laser welder can easily wield stainless or carbon steel of roughly 4mm thickness in a single pass. However, this value is far lower than what can be achieved if a handheld welder with 1500W or even 2000W is applied, as this power can now cut thicker materials, sometimes up to 6mm, in a single pass with proper settings.Another salient factor affecting welding is the material to be welded. For example, high thermal conductivity metals like copper and aluminum, require more laser power than steel with the same thickness. Furthermore, joint type contributes since lap and butt joints have varying penetration capability within material stacks.

The strap seam weld form also interlinks with the distance of the laser. Extensive distances, for instance, are likely to consume less energy hence shallow parts while close quarters take a great deal of energy penetrating the material. Also, sweat fractures along the axis or misalignment form a secondary defect, exaggerating chances of cut back or non-fusion with the primary contours.

Finally, the quality and focus of the beam affect laser welding. Correct placement and focus aid the proper application of energy as it extracts heat through the weld seam to increase temperature and concentration on both sides resulting to cost effectiveness and reliability. So here, the operators have a variety of parameters to change to adapt the laser welder for various material thicknesses.

Impact of Laser Power on Welding Speed

Laser power and welding speed, and other parameters defined in the procedure of work, are the main factors of the welding quality and efficiency met during a welding operation. Higher laser power applies to thicker materials because it can increase penetration depth. For example, it is well known that the laser power of 1,000 watts allows a weld depth of 3–4 mm in stainless steel. Other steels can achieve even higher values (about 1500 watts allows more than 4mm). However, too much power can also be detrimental, causing overheating as well as imperfections like porosity and burn-through.

Faster speeds are favorable in sections as they reduce heat input and prevents warping, but with thin materials the quality of the fusion may suffers. Research indicates that an optimum welding speed is between 2 to 3 m/min for the desired productivity while preserving the integrity of the material. With the right combination of power and speed, operators can achieve optimal results while reducing defects, sustaining the precision and repeatability of handheld laser welding in multiple industries.

Fiber Laser vs. Traditional Welding Methods

In my opinion, fiber laser welding has more benefits than other types of welding. It has greater accuracy and faster processing speeds, significantly boosting efficiency for complex or thin materials. Moreover, the reduced heat-affected zone further enhances welds by lessening distortions and improving overall quality. While traditional welding techniques are more adaptable, they usually have problems with consistency and require a greater number of treatment post-weld. Traditional methods can be more appropriate, though, in some situations like working with thicker materials or where the price of equipment is a primary consideration. In the end, the decision between the two types of welding boils down to the needs of the particular project.

Can Handheld Laser Welding Machines Weld Stainless Steel?

Stainless steel can be welded with the use of handheld laser welding machines. They offer clean and durable results with high precision, and welds of supreme quality are ensured with low distortion, making them perfect for complex tasks.

Welding Stainless Steel with Laser Welders

Handheld laser welders are known for their high efficiency in executing precise welds onto stainless steel. The use of welders with lasers aids to avoid deformation caused by traditional welders as the energy used is focused on specific areas. The orthogonal geometry of laser welders results in the difficult stainless steel parts being welded with corrosive joints and superlative finishes. As a result of the structure of handheld laser welders, users are able to easily complete complicated stainless steel welds, which is of great importance for the automotive and aerospace industries, as well as manufacturing.

Impact of Heat Input and Weld Penetration

Every weld has a set level of quality defined by the input and the heat required to perform it. Consistency and control of the auto-heat is said to aid in achieving strong joints through deep penetration and orthogonal geometry. For stainless steel structure, the optimal range of auto-heat provided is between 10-20k J/in, as it is able to distort penetrations with a view of achieving minima whilst retaining penetrations. When the input levels provided to the weld are at the boundless level beyond the optimal range, causes deformation effects such as expansion or severe erosion.

Handheld laser welding tools have a remarkable control of the amount of heat supplied. Industry reports indicate that newer models of lasers are able to real-time change energy output to the specific demands of the material being used. For example, some reports show that laser welders boast greater than 80% efficiciency in stainless steel cutting with penetration depths of 10 mm. These developments greatly lessen the chances of numerous defects such as pores or cracks, achieving the smoothest finish for demanding applications.

These special techniques for heat supply control also allow for an optimal balance between penetration and input, leading to weld of unparalleled quality at minimal costs.

Tips for Obtaining Quality Welds on Steel Plates

Attention must be paid to some precise requirements to guarantee a good weld on steel plates. First, effective surface preparation is essential. The plate must be cleaned as it should not contain rust, oil, or any other form of dirt. Weld clean surfaces. Second, the correct welding method must be chosen: MIG, TIG or stick welding. The welding method should correlate with the thickness of the plate and the intended application to achieve strong and durable Welds. Stick welding capable of providing accurate penetration bends will fill in gaps without the risk of undercuts, portraying defects such as porosity or undercutting. Accuracy along the parameters of heat distance and filler material also aids in quality welding. For best results, the filler materials should be made of the same steel composition to ensure structural integrity and compatibility. Finally, post-weld inspections and testing done should help determine any flaws required, aiding in validation of rigid standards have been met. Following these basics will aid in building dependable structures easily.

What are the Best Practices for Using a Handheld Laser Welder?

- Wear Proper Safety Equipment – For protection while Lap Joint Laser Welding, gloves, specialized welding eye wear and laser welding gowns should always be used.

- Maintain a Steady Hand – Accurate and uniform welds will be achieved by holding the welding instrument at the specified position and angle.

- Prepare the Work Surface – For clean welds, the components surfaces intended to be joined must be devoid of any contaminants.

- Adjust Settings Appropriately – Calibration of laser power, speed, and focus should be set according to kind and thickness of material being used.

- Practice Controlled Movements – For prevention of excessive heat and uniform bonding along the weld line, the laser welder should be moved in a controlled manner.

Understanding Laser Safety Protocols

To ensure safe use of laser welding tools, laser safety protocols must be enforced in the workplace to control hazards. One of the most important aspects is the type of laser in use since class 4 lasers are the most dangerous. They can cause skin damage, eye injuries and other health risks when not properly used. Security goggles that are designed for the field of energy of the laser must be worn to protect eyes from danger posed by unintentional incident beams or scattered beams.

Fume emissions during welding operations make proper ventilation in workspaces essential. In a 2023 study of laser processing environments, it was noted that poorly maintained fume extraction systems could contribute to respiratory illnesses as well as higher concentrations of dangerous particulates in the enclosed spaces. These systems are best managed with the installation of HEPA filtration units.

Practices by operators must also include following the set boundaries for tool rotation and rate changes considering the nature of the materials. For instance, recent industrial testing indicates that excessive application of laser power to thin materials results in warping whereas insufficient power leads to substandard bonding Quality. Applying these measures not only guarantees precision in welds, but enhances safety for operators.

Optimizing Weld Speed and Laser Power

Achieving successful results with laser welding requires harmonization between weld speed and laser power. Maintaining the integrity of the weld while also optimizing productivity is possible if laser power is held constant and weld speed is increased. For example, it has been documented in industry reports that for most thin metal applications, weld speeds of 100-300 mm/s, with laser power of 1-3 kW, is adequate. However, if parameters are pushed above these indicators, other issues such as undercutting or incomplete fusion may take place.

Real time monitoring of weld penetration and depth of weld heat allow operators to make changes as needed with the aid of advanced monitoring systems. New options in laser systems, like the adaptive power control feature, makes sure that there is sufficient power to cater for modifications into material’s thickness as the welding process is going on. This action improves efficiency and minimizes error susceptibility.

Minimal machine downtime and optimum material utilization in manufacturing can now be achieved through these strategies. This shows the essence of adjusting calibrations for control variables; both laser power, speed, and specific materials to achieve desired reliability and performance simultaneously.

Maintaining the Functionality of Laser Weld Machines

To ensure maximum longevity and performance of laser weld machines, onderhoud (Dutch for maintenance) procedures should focus on the proper care of its components. For example, damage to the lenses or mirrors in the optics leads to energy loss sufficient enough to merit a dip in proficiency due to overheating. Industry standards state that detailed cleaning routines are necessary for highly stressed locations every one to two weeks.

Forward-looking maintenance procedures that replace items such as gas lenses and protective nozzles should be set on a timeline. Research has identified that consumables that have become too worn out can adversely impact beam alignment, creating further issues down the line. Flawed beam alignment is one example of how difficult and expensive issues can arise from poor weld penetration.

Make it a habit to regularly monitor the cooling system in your laser weld machine. The optical components and laser source face severe threats when it comes to excess overheating. Data stresses that the equipment’s lifetime can be enhanced by 30% when the cooling system functions effectively.

Lastly, shifting their attention to lines of business. Full features usually come with services. Do not omit killing useless orders. Ensured accuracy of billing. Software and firmware are a set sequence of changes that need to be made to the computer. Restricting access to systems is a security feature. Updating the system provides new functionality and improves your PC. Keeping track of activities made in a device or software is essential for diagnosing a malfunction.

What are the Key Differences Between Laser Welding and Traditional Argon Arc Welding?

The main distinctions between laser welding and traditional argon arc welding are their accuracy, pac, and heat input. During a laser welding process, a focused laser beam is employed to join components, which results in a delicate weld with very low heat affected zones. This makes laser welding perfect for small or fragile components. Argon arc welding, however, depends on an electric arc which produces higher heat and is suited to larger applications due to the need for deeper weld penetration. Additionally, laser welding usually has faster processing times and higher automation compatibility; argon arc welding is cheaper and easier to do manually in most cases.

Comparing Welding Methods and Weld Quality

| Laser Welding | High precision, low heat-affected zone | Extremely precise and clean welds | High initial cost, efficient for automation | Ideal for small, delicate components and industries like aerospace and medical manufacturing |

| Argon Arc Welding | Higher heat generation | Moderate precision | Lower initial cost, widely accessible | Suitable for larger, thicker materials such as structural and automotive components |

The Limitations of Welding Thickness

It is clear that different strategies or methods for welding have varying thickness limitations, and this is directly influenced by the welding method and materials employed. For example, laser welding is usually effective for up to 10 mm in thickness, providing precision. However, for thicker materials, multiple passes or other secondary joining techniques may be needed for proper joining. Argon arc welding, however, is most effective on materials 1.6 mm to 25 mm in thickness. This method is particularly suited for thicker materials because of its greater heat input and high degree of flexibility.

Innovative developments have weakened the constraints of conventional techniques. Hybrid welding, which uses a combination of laser and arc welding, is one example that has great promise for larger thicknesses, often above 25 mm, while maintaining weld integrity and efficiency. Also, the automation of processes has contributed to reliable consistent welds in industrial applications, as emphasized in some studies citing a significant drop in defects and enhanced production rates.

It’s important to look at material properties like heat conductivity and melting point when solving problems related to thickness limitations. For instance, aluminum can pose challenges regarding thermal conduction through laser welding on thicker sections; more so than steels which are more interchangeable across different techniques. Regardless of how thin or thick the material is, weld parameter selection and joint design have to be done with precision in order to yield optimum results.

Cost and Efficiency: Laser Welding Machinez vs. Traditional Welding

As efficiency and cost come to the forefront in questions of traditional versus laser welding, differences in cost efficiency become clearly distinguishable across diverse sectors for advanced laser welding systems. Initial setup costs are lower for TIG and MIG (Tungsten Inert Gas and Metal Inert Gas, respectively) welding. Their equipment is in abundance, and operators don’t need extensive training. Still, traditional welding often ends up being very exacting, especially when it comes to time or volume and requires finely tuned control. This is especially expensive in the long run.

Unlike other methods, laser systems require a lot of maintenance. With skilled operators, however, cost-benefit affordable for industry adopting these systems. Even with these disadvantages, laser welding is great for modern automated manufacturing lines due to it’s low processing minutes post automation and excellent precision.

Cost-effectivity, however, shines with these methods in high-production environments due being economically helpful laser systems unexpectedly were with initial costs. Compared to traditional methods, laser welding machines do put insane numbers in productivity, achieving upwards of ten meters per minute. Along with awe inspirational speeds, contributions to cost fully achieves in precision reducing waste. Defect needs like rework and reduction needs, however, would be minimized as well aiding in added savings. Figure from 2023 study shows that, to the surprise of many, these systems aided industries boasting of up to thirty percent savings when using laser systems for construction.

Welding work best under automation settings enhanced efficiencies, allowing post-process processing needing to be reduced, increasing optimum results. It must be stressed, though, that investment will also be needed dealing deft with required skill spending while maintaining cost decision balance evaluating, while also bringing in higher costs for maintaining systems. Overall, striking balance to include cost w61ith these advanced expense strengths will propel industry.

Reference sources

- “On the Weldability of Thick P355NL1 Pressure Vessel Steel Plates Using Laser Welding” (2021)1:

- Key Findings: Laser welding was successfully applied to 10 mm thick pressure vessel steel plates. The study highlighted the mechanical properties, including tensile strength and fatigue resistance, which were comparable to traditional methods. The research emphasized the importance of controlling residual stresses and microstructural changes to prevent crack initiation.

- Methodology: Double-sided square butt welds were performed using a high-power laser. Mechanical tests (tensile, impact, and fatigue) and microstructural analyses (X-ray and neutron diffraction) were conducted to evaluate weld quality.

- “The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel” (2021)2:

- Key Findings: Hybrid Laser Arc Welding (HLAW) achieved full penetration in 15 mm thick naval steel T-joints. Optimal parameters included a laser power of 12.5 kW and a welding speed of 1.6 m/min. The study also identified microstructural zones with varying hardness and toughness.

- Methodology: Single-sided welding was performed on EH36 steel plates. Advanced characterization techniques, including optical microscopy, SEM, and XRD, were used to analyze microstructure and mechanical properties.

- “Applying Optical Coherence Tomography for Weld Depth Monitoring in Remote Laser Welding” (2021)4:

- Key Findings: This study focused on monitoring weld penetration depth in thin materials (e.g., 450 μm aluminum and 300 μm copper foils) using Optical Coherence Tomography (OCT). It demonstrated improved accuracy in depth measurement by stabilizing the keyhole during welding.

- Methodology: A novel adjustable ring mode laser was used, and OCT technology was integrated for real-time monitoring. The study emphasized the importance of precise alignment for accurate depth measurement.

Frequently Asked Questions (FAQs)

Q: What is the maximum thickness a hand-held laser welder can weld?

A: The maximum thickness a hand-held laser welder can weld depends on the power of the fiber laser welding machine. For instance, a 1500w laser can weld up to 4mm thick materials, while a 2000w laser can weld 6mm thick materials.

Q: How does hand-held laser welding work?

A: As the name suggests, hand-held laser welding refers to the hands-on use of lasers to weld. A hand-held laser welding machine uses a highly concentrated laser beam to melt the desired material and produce a weld pool that is precise enough to allow speedy welding without losing structural integrity. This method is effective regardless of the type of material being dealt with—aluminum, stainless steel, or any other—for they all respond well to fast welding techniques.

Q: What are the advantages of using a hand-held laser welding machine?

A: With hand-held laser welding, the speed of welding thin materials is quite remarkable. Aside from welding that requires extreme detail and high precision, the distortion caused by the laser is very minimal. Advanced laser machines are built to deliver accurate and consistent welds, even on challenging seams, thus making the joints of the welded materials incredibly strong.

Q: Are there any disadvantages of handheld laser welding?

A: Apart from the high price of the device, the term “disregardably simple” perfect is not applicable when referring to the hand-held laser welder, as the handheld laser welding machine needs a quite skilled operator if the best results are to be achieved. Moreover, for highly thick materials, laser welding may not prove to be the most efficient option.

Q: Can hand-held laser welders be used for welding aluminium?

A: Yes, all types of laser welders can weld hands-free operated. They accomplish strong welding with minimal distortion which makes them best suitable for this purpose.

Q: What is the difference between laser welding and laser cutting?

A: In laser cutting, a laser tool is used to make a cut through the material while in laser welding, the laser beam is used to join two or more parts by melting them forming a weld pool. Both processes employ a laser machine but use them for different applications.

Q: How does the thickness of the laser welding machine affect welding capabilities?

A: The thickness of materials that a laser welding machine can be set capable of welding is dictate by the power of the machine. A 2000w laser will clearly suite thicker materials while lower power lasers will best fit for thinner materials.

Q: What should you consider when choosing a hand-held laser welding equipment?

A: For hand-held operated ones, the most deciding factors to consider is the brand a laser of the machine being merchaned, the type of material to be welded in concern, and the maximum thickness to be required. The power of the laser cuts along with the type of materials to be welded and require maximal thickness also matters.

Q: Is it possible to do welding without wire, using a hand-held laser welder?

A: That’s correct. A handheld laser welder can achieve welding without the use of wire. This procedure makes use of the energy produced by a laser beam directed to a focal point, which melts and welds the materials, and is usually done for very thin pieces.

Q: What makes hand-held laser welding the most efficient laser for some applications?

A: In industrial settings, when speed, accuracy, and quality welds are required, they tend to prefer handheld lasers. It is also widely applied in domains where very low distortion at the final product is desired.