When it comes to innovative cleaning technologies, few methods are as revolutionary as laser cleaning. Whether it’s restoring delicate historical artifacts, preparing industrial surfaces, or maintaining precision machinery, laser cleaning offers a cutting-edge solution that is both efficient and environmentally friendly. But how does this incredible technology actually work? This blog post will take you on a deep dive into the science and mechanics behind laser cleaning, unraveling why it has become a game-changer across diverse industries. From its ability to remove contaminants with extreme precision to the eco-conscious advantages it brings, you’ll discover what makes laser cleaning a powerhouse of modern technology. Get ready to explore the inner workings of this fascinating process and see why it’s sparking interest worldwide.

What is Laser Cleaning and How Does It Work?

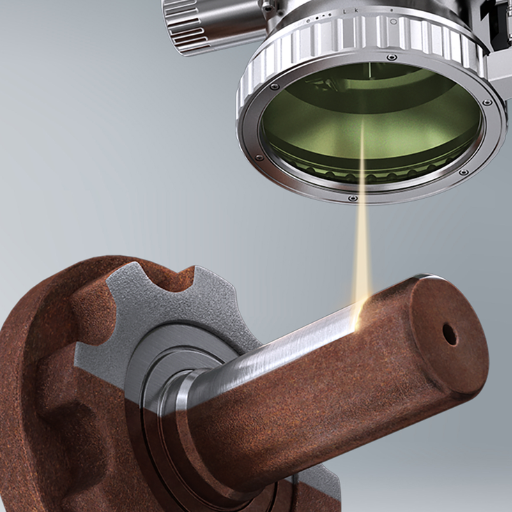

Laser cleaning is a non-contact method of removing unwanted materials such as rust, paint, oil, or other contaminants from surfaces using focused laser beams. It works by directing short pulses of high-intensity laser light onto the surface, which causes the contaminants to absorb the energy, heat up, and either vaporize or detach from the base material without causing damage. This process is precise, efficient, and environmentally friendly, making it an ideal solution for industries like manufacturing, aerospace, and conservation where cleanliness and accuracy are critical.

Understanding the Laser Cleaning Process

Laser cleaning offers a wide range of advantages that make it a revolutionary technology for surface treatment across various industries. Unlike traditional cleaning methods, this process is non-contact and chemical-free, minimizing the risk of damaging delicate surfaces or introducing harmful residues into the environment. The precision of laser cleaning allows operators to target specific areas while leaving the surrounding sections untouched, making it highly effective for intricate or sensitive applications.

One of the most significant benefits is its efficiency. Lasers can remove contaminants such as rust, oil, oxides, or paint layers at remarkable speeds. For instance, industrial-grade laser cleaning systems are capable of processing up to 100 square meters of surface per hour, depending on the material and contamination. Additionally, laser systems can work on diverse materials, including metals, plastics, and even stone, offering exceptional versatility.

Modern laser cleaning systems also integrate advanced features such as real-time monitoring and automation. These technologies enhance productivity, allowing for streamlined operations in manufacturing or restoration projects. For example, some cutting-edge systems include sensors that detect the level of contaminants and adjust the laser intensity accordingly, ensuring optimal cleaning efficiency while conserving energy.

Environmental sustainability is another standout feature of laser cleaning. Traditional methods often rely on abrasive materials or chemical solvents, many of which generate hazardous waste. By contrast, laser cleaning produces minimal byproducts, typically in the form of fine particles that can be collected with specialized filtration systems. This makes it an eco-conscious choice for industries aiming to reduce their environmental footprint.

Role of Laser Beam in Cleaning

The laser beam serves as the core component in laser cleaning, leveraging advanced photonics to deliver unparalleled precision. It operates by emitting high-energy pulses of light that interact with surface contaminants, such as rust, paint, grease, or oxide layers. These contaminants absorb the laser energy, causing them to heat up rapidly and vaporize, or break apart, while preserving the underlying material. This selective process ensures that even delicate surfaces, such as historical artifacts or sensitive industrial components, can be cleaned without risk of damage.

Recent advancements in laser cleaning technology highlight its efficiency across various power levels. For applications that demand delicate touch, such as restoration of cultural heritage, low-power lasers—typically in the range of 20-50 watts—are used to prevent over-cleaning. On the other hand, industrial-scale tasks, like cleaning of heavy machinery or mold removal, often employ lasers boasting higher power levels, ranging from 200 to over 1000 watts, which enable swift removal of stubborn contaminants.

Additionally, data underscores the cost-effectiveness and long-term benefits of laser cleaning. Studies in manufacturing settings have illustrated that laser cleaning systems can reduce maintenance intervals and increase operational efficiency, with some industries reporting up to a 25-30% decrease in cleaning-related downtime. This combination of precision, adaptability, and efficiency demonstrates why laser cleaning is rapidly becoming a preferred solution across diverse sectors.

How Laser Rust Removal is Achieved

Laser rust removal operates through an advanced process involving the interaction of laser beams with the surface material, effectively removing rust, oxides, or contaminants without damaging the underlying substrate. Utilizing a high-powered, pulsed laser, the system emits focused energy beams that heat and vaporize the rust layer. This method capitalizes on the difference in thermal properties between corrosion and the base material, ensuring precise removal.

Modern laser cleaning systems are often equipped with adjustable power settings, allowing for fine-tuned control based on the material type and the corrosion’s thickness. For instance, some industrial lasers can operate at power levels ranging from 20 to 1000 watts, adaptable for cleaning anything from delicate machinery to heavily corroded metal structures. Studies demonstrate that laser cleaning can achieve removal speeds of up to 15 square feet per hour, maintaining consistency and high-quality results across surfaces.

Additionally, laser rust removal is environmentally friendly as it eliminates the need for abrasive chemicals or media blasting, significantly reducing waste and contamination. Many industries, including aerospace, automotive, and shipbuilding, have adopted this technology for its outstanding efficiency, sustainability, and cost-effectiveness.

What are the Different Types of Laser Cleaning Machines?

Each machine is made with a specific need or purpose in mind, resulting in various types of laser cleaning machines, including:

Low-Power Laser Cleaning Machines

These machines excel in removing very thin layers of contaminants while preserving the underlying surface. They are widely used in the electronics sector and restoration works as such repainting details on old relics.

Medium-Power Laser Cleaning Machines

These machines have greater versatility compared to the low power ones, with an ability to tackle general industrial cleaning tasks like removal of coatings and moderate levels of oxidation on metals and other materials.

High-Power Laser Cleaning Machines

Best suited to heavy duty uses, high power machines work well when cleaning thick layers of oxidation and paint and other large systems structures, making them ideal in industrial setting.

Portable Laser Cleaning Machines

These machines are best when a person needs a light and compact cleaning device that can be transported around easily, allowing for easily cleaning of tight spaces.

Exploring Fiber Laser Technology

Fiber laser technology has revolutionized cleaning, cutting, and marking processes across various industries due to its efficiency, precision, and reliability. Unlike traditional lasers, fiber lasers use an optical fiber doped with rare-earth elements such as erbium, ytterbium, or neodymium to amplify light. This method allows for a more compact design, higher energy efficiency, and longer operational lifespan.

- Precision and Versatility

One of the standout features of fiber lasers is their ability to focus energy with high precision, making them ideal for intricate tasks such as micro-machining or surface texturing. They produce a small spot size and high beam quality, which is invaluable in industries requiring meticulous detail, such as electronics manufacturing or medical device production.

- High Energy Efficiency

Fiber lasers have an energy conversion efficiency of up to 30-40%, significantly higher than their CO2 or solid-state counterparts. This not only reduces operational costs but also minimizes environmental impact, aligning with modern sustainability goals in manufacturing and industrial sectors.

- Low Maintenance Requirements

Due to their solid-state construction and lack of moving parts, fiber lasers require minimal maintenance compared to older technologies. Their durability ensures consistent performance over thousands of operational hours, translating to reduced downtime and increased productivity for industries like automotive and aerospace.

- Application in Laser Cleaning

Fiber lasers have become a preferred solution for industrial cleaning due to their ability to remove contaminants like rust, grease, and residual coatings without damaging the underlying material. For example, studies report that fiber laser cleaning systems can achieve cleaning rates of up to 15m² per hour, offering unparalleled efficiency and accuracy in large-scale operations.

- Market Trends and Growth

According to recent data, the global fiber laser market is expected to reach USD 5.6 billion by 2032, growing at a compound annual growth rate (CAGR) of 11.5% from 2023 to 2032. This growth is fueled by increasing demand across sectors like automotive, electronics, and renewable energy, showcasing fiber laser technology’s pivotal role in modern industrial applications.

Fiber laser technology continues to prove its value in enhancing industrial processes, offering superior performance alongside reduced energy consumption and operating costs. It remains a dynamic and integral component in advancing technology-driven industries worldwide.

Comparing Pulsed Laser and Continuous Wave

When considering pulsed lasers and continuous-wave (CW) lasers, it is important to note their operational features, benefits as well as their use in industry.

Energy from a pulsed laser is released in the form of short bursts or pulses. This burst of energy can last from nanoseconds to femtoseconds based on the application and design. Precision tasks, such as engraving and micromachining as well as some surgical procedures, are often carried out using polsed lasers. Since the duration of intense peak power is very short, greater efficacy is attained when used for intricate and delicate opsitting of surrounding materials. For instance, femalesct lasers are popularly utilized across various industries for the processing of brittle materials like glass to provide fine and damage free cuts.

CW lasers work by delivering a laser beam continuously without any interruptions. This may be advantageous for scenarios or tasks which require energy to be delivered for longer durations. For example, welding, cutting, and drilling are some examples which make use of CW lasers. With use in the automotive industry, CW lasers allow for effective and accurate cutting of metals and materials while adding efficiency. CW lasers are usually favorable for thicker materials, where they can be used for metal welding. Continuous energy can be relied on for deep penetration during metal cutting.

Choosing the Right Cleaning Machine for Your Needs

Selecting the right cleaning machine requires considering your specific requirements and the type of cleaning tasks you aim to perform. Begin by assessing the materials or surfaces you need to clean—are they delicate, heavily soiled, or industrial-grade? For light cleaning tasks on sensitive surfaces, ultrasonic cleaners are highly effective. If you face tough industrial grime, high-pressure washers or abrasive blasting machines may be more suitable. Additionally, evaluate the size and scale of your operations; compact units work best for small-scale tasks, while larger systems are ideal for industrial use. Lastly, consider energy efficiency, ease of operation, and maintenance to ensure long-term usability and cost-effectiveness.

How is Laser Cleaning Used in Industrial Applications?

Laser cleaning is widely used in industrial applications for its precision, efficiency, and eco-friendliness. It is primarily employed to remove rust, paint, grease, or other contaminants from surfaces without causing damage to the underlying material. This method is non-abrasive, making it ideal for delicate substrates like metals and composites. Additionally, laser cleaning is valued for its ability to clean intricate and hard-to-reach spaces, offering superior results compared to traditional methods. Its applications span industries such as aerospace, automotive, and manufacturing, where surface preparation and restoration are critical to maintaining quality and performance.

Applications in Metal Surface Preparation

Laser cleaning has revolutionized metal surface preparation processes, offering unparalleled precision and efficiency. This cutting-edge method is widely employed for applications such as rust removal, paint stripping, oxide layer elimination, and pre-treatment for welding or coating. Unlike abrasive or chemical cleaning techniques, laser systems ensure the surface integrity of metals is maintained, even for sensitive materials like aluminum and titanium.

A significant advantage of laser cleaning in this field is its exceptional environmental compliance. It eliminates the need for hazardous chemicals, reducing waste production and ensuring worker safety. For instance, in the automotive industry, laser cleaning can prepare car bodies for coatings, resulting in remarkably uniform adhesion and improvement in product durability. Studies show that laser-cleaned metallic surfaces experience up to a 60% enhancement in coating lifespan compared to conventionally prepared surfaces.

Industries also benefit from the scalability of laser cleaning systems. Small-scale portable devices are fitting for localized cleaning tasks, while high-power setups cater to large-scale industrial operations, such as cleaning turbine blades or refurbishing ship hulls. This versatility has made laser cleaning a preferred solution for companies aiming to adopt sustainable, high-precision standards in surface preparation. The integration of advanced technologies, including AI-based process optimization, further increases the consistency and efficiency of laser cleaning processes in metal applications.

Using Laser Technology for Ablation

Laser ablation has emerged as a cutting-edge technique for precise material removal across a diverse range of industries. This method operates by focusing high-intensity laser beams on a specific material surface, causing the rapid evaporation or sublimation of the targeted layer without affecting surrounding areas. Modern advancements in laser systems have fine-tuned the process, ensuring unparalleled accuracy and efficiency in delicate applications such as removing coatings, thin films, or contaminants.

According to recent studies, pulsed laser ablation is particularly effective in industries like aerospace and electronics, where precision is paramount. For instance, nanosecond lasers can achieve energy densities ranging between 1–10 J/cm², ensuring exceptional control over material removal down to the micrometer scale. Additionally, femtosecond lasers, with their ultra-short pulse durations, have demonstrated remarkable applications in creating nano-structured surfaces and ensuring minimal thermal damage to sensitive substrates.

Furthermore, laser ablation is increasingly applied in environmental science and biomedicine. For example, the technique has been used for isotope analysis in geological samples, enabling researchers to better understand earth processes and climate changes. Regarding health sciences, lasers have shown promise in minimally invasive surgeries and tissue removal, offering a cleaner, more controlled alternative to traditional methods. This expansion into diverse fields highlights the versatility and future potential of laser ablation when paired with advances in laser technology and automated systems.

Role in Weld Seam Cleaning

Laser ablation has become a groundbreaking method for weld seam cleaning, offering a high-precision, eco-friendly alternative to traditional mechanical and chemical processes. By utilizing laser beams to remove contaminants, oxides, and residues from the surface of weld seams, this technology ensures a cleaner and stronger bond, which is critical in industries like automotive, aerospace, and construction.

One of the key advantages of laser cleaning in weld preparation is its ability to achieve exceptional accuracy in removing unwanted materials without damaging the underlying metal. Studies show that laser cleaning can reduce surface roughness and improve the quality of weld joints by eliminating impurities that might otherwise compromise structural integrity. Additionally, laser cleaning systems can process intricate and hard-to-reach areas efficiently, making them highly adaptable for complex designs.

Furthermore, laser ablation proves to be an environmentally conscious solution. Unlike abrasive or chemical cleaning methods, it doesn’t generate hazardous waste or require consumables such as solvents. Data suggests that laser cleaning can lower operational costs by up to 30% in some industrial applications by minimizing waste disposal and supply expenses. It also significantly reduces downtime compared to conventional methods, allowing manufacturers to streamline production workflows.

Modern laser systems are equipped with advanced automation and remote control capabilities, enabling consistent and reproducible cleaning quality while enhancing worker safety by reducing exposure to harmful substances. These innovations have cemented laser weld seam cleaning as a reliable and efficient choice for high-demand engineering applications.

What are the Advantages of Laser Cleaning?

Due to its numerous advantages in various sectors, laser cleaning remains one of the optimal solutions in contemporary industrial and engineering applications:

Versatility: Laser cleaning can remove a variety of contaminants including rust, paint, grease, and other coatings from many surfaces.

Cost-Effective: It provides long-term financial benefits due to low maintenance, reduced consumable requirements, and operational costs.

Precise and Controlled: This form of cleaning offers high accuracy in the removal of contaminants without underlying surface damage.

Enhanced Safety: Automated controls during the process greatly reduces worker exposure to hazardous cleaning substances resulting in an overall safer work environment.

Eco-Friendly Process: Its sustainable practices further reduce environmental impact by removing the need for abrasive materials and chemicals.

Non-Contact Technique: No mechanical contact means there is no abrasion or friction, ensuring the to-be cleansed surface will not suffer from wear.

These benefits combined establish the effectiveness of laser cleaning as a superior and safer industrial cleaning process compared to traditional methods.

How Laser Cleaning is Environmentally Friendly

Laser cleaning is environmentally friendly because it eliminates the need for harsh chemical solvents and reduces waste generation. By using focused laser beams to remove contaminants, it minimizes pollution and energy consumption compared to traditional cleaning methods. I see it as a sustainable solution that aligns with modern environmental goals, promoting both efficiency and ecological responsibility.

Benefits of Non-Contact Cleaning Method

I find the non-contact cleaning method incredibly beneficial due to its precision and efficiency. By avoiding physical contact, it prevents wear and tear on delicate surfaces, ensuring the integrity of the material being treated. Plus, it reduces the risk of damage caused by friction or abrasion, making it ideal for sensitive applications. This approach also keeps the process cleaner and safer, as there’s no need for harsh chemicals or excessive maintenance.

Efficiency Compared to Traditional Cleaning Methods

When comparing this innovative cleaning method to traditional approaches, I find it significantly more efficient. Traditional methods often rely on manual scrubbing or the use of harsh chemicals, both of which can be time-consuming and labor-intensive. In contrast, this method streamlines the process, delivering precise and consistent results with minimal effort. It saves time, reduces resource consumption, and eliminates the downsides associated with conventional techniques, making it a clear choice for efficiency.

Are There Any Limitations or Disadvantages of Laser Cleaning Technology?

While laser cleaning offers numerous advantages, it does have some limitations. The initial investment cost for laser cleaning equipment can be significantly higher compared to traditional methods, which might not be ideal for small-scale applications. Additionally, the process can be slower when dealing with large surfaces or heavily soiled materials, requiring more time to achieve desired results. Furthermore, improper use of the technology or incorrect settings can potentially damage delicate surfaces. Despite these drawbacks, the long-term benefits often outweigh the limitations for many industries.

Understanding the Ablation Threshold

The ablation threshold refers to the minimum energy density required to remove material from a surface through processes such as laser ablation. It is a critical parameter in laser-based technologies and determines the efficiency and precision of material removal. Measured in terms of energy per unit area (e.g., J/cm²), the ablation threshold varies depending on factors like the material’s physical and chemical properties, as well as the wavelength and pulse duration of the laser.

For instance, metals typically have higher ablation thresholds compared to polymers due to their thermal conductivity and lower optical absorption in certain wavelength ranges. Modern studies indicate that materials like aluminum have an ablation threshold of approximately 2-6 J/cm², while materials like silicon require thresholds around 0.1-0.3 J/cm², depending on the laser parameters used.

A key aspect of understanding the ablation threshold is its role in achieving optimal efficiency without causing unintended damage. Exceeding the threshold may result in excessive heating, leading to distortion or microstructural changes. Conversely, operating below the threshold may result in insufficient material removal. Advancements in ultra-short pulse lasers and precise calibration techniques allow for a highly controlled approach to managing ablation thresholds, particularly in industries like microelectronics, aerospace, and medical device manufacturing.

Careful consideration of these parameters ensures minimal energy wastage while achieving precise ablation, making it possible to meet the demands of even the most sensitive applications.

Challenges in Paint Removal and Coating

Paint removal and coating processes face numerous challenges, particularly as industries push for greater efficiency, safety, and environmental sustainability. One significant issue lies in the production of hazardous waste. Traditional paint removal methods, such as chemical strippers, often rely on highly toxic substances like methylene chloride, which pose serious health risks to workers and generate substantial environmental impact.

Additionally, achieving consistent coating thickness and adhesion remains a critical challenge. Variations in surface preparation or paint application can lead to defects such as uneven coverage, cracking, or peeling, compromising the durability and appearance of the end product. Such defects are particularly problematic in industries like aerospace and automotive manufacturing, where precise performance standards are vital.

The rise in regulatory requirements to reduce volatile organic compounds (VOCs) has also forced industries to adopt more eco-friendly coating formulations. While this shift is a positive step for environmental stewardship, it necessitates the development of advanced removal and application technologies to accommodate new material properties. For example, water-based and low-VOC coatings often require special handling conditions, further complicating the processes.

Finally, economic considerations, such as material costs and operational efficiency, remain key concerns. Introducing advanced technologies, like laser paint removal or robotic coating systems, may address many of these challenges while reducing waste, improving precision, and ensuring compliance with stringent standards. However, the high initial investment for implementing these systems can hinder widespread adoption, especially among smaller enterprises.

Innovations in this field continue to evolve, offering promising solutions to balance efficiency, safety, and sustainability in paint removal and coating technologies.

Considerations for Surface Area and Substrate

When selecting appropriate paint removal and coating technologies, understanding the relationship between surface area and substrate material is crucial. Larger surface areas often demand solutions that balance efficiency and cost-effectiveness. For instance, laser ablation and ultrasonic cleaning are excellent choices for intricate surfaces or those with hard-to-reach areas, as they provide precision without causing damage. However, these methods may require significant initial investments, making them more suited for critical applications such as aerospace or medical device manufacturing.

The substrate material further influences the choice of technology due to factors like material sensitivity, thermal tolerance, or chemical compatibility. For example, softer metals like aluminum are highly susceptible to damage from abrasive techniques, necessitating gentler solutions like eco-friendly chemical stripping agents or low-intensity laser cleaning. Conversely, substrates like stainless steel may withstand more aggressive techniques like sandblasting.

Current advancements highlight the importance of customizing processes based on specific material needs. Some coatings now incorporate smart polymers or nanocoatings that can be removed selectively by applying particular wavelengths of UV light, thus ensuring minimal interference with the underlying surface. Data shows that such innovations reduce material wastage by up to 25%, while also cutting processing time by nearly 15% compared to traditional methods. This emphasis on precision and sustainability aligns with global industry efforts to improve both environmental and economic outcomes.

Reference Sources

-

Design of Laser Clear Machine with Visual System1:

- Focus: This study explores the integration of motion control, visual algorithms, and pulsed laser cleaning technology in a laser cleaning machine (LCM).

- Key Findings: The LCM uses high-frequency, high-energy pulsed lasers to remove surface contaminants like rust and coatings without damaging the substrate. The system incorporates a vision module for precise targeting and a motion control module for efficient cleaning.

- Methodology: The research combines hardware (laser, vision, and motion control modules) with software (image processing and motion algorithms) to develop a prototype machine for industrial cleaning applications.

-

The Samuel F. B. Morse Statue in Central Park: Toward a Sustainable Regime of Science-Based Monuments Conservation2:

- Focus: This study examines the use of laser cleaning for the conservation of bronze sculptures, specifically the Samuel F. B. Morse statue.

- Key Findings: Laser cleaning effectively removes corrosion and degraded coatings through photomechanical, photothermal, and photochemical reactions. The process is precise, environmentally friendly, and minimizes damage to the substrate.

- Methodology: The research employs scientific analyses like X-ray fluorescence, scanning electron microscopy, and gas chromatography to monitor and optimize the cleaning process.

-

An Overview Study on Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry3:

- Focus: This paper provides an overview of laser technology applications, including cleaning, in the mechanical and manufacturing industries.

- Key Findings: Laser cleaning is highlighted for its precision, efficiency, and ability to handle complex surfaces. It uses high-energy beams to remove contaminants without physical contact, making it ideal for delicate and high-value components.

- Methodology: The study reviews the principles of laser operation and its applications, emphasizing the advantages of laser cleaning in industrial settings.

- Top Handheld Laser Cleaning Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: How does laser cleaning work?

A: Laser cleaning involves using a laser machine to emit laser pulses that remove contaminants from surfaces. This process is often referred to as laser processing and allows for precise and selective removal of unwanted materials without damaging the underlying substrate.

Q: What are the main applications of laser cleaning?

A: Laser cleaning is used in various cleaning applications, including industrial laser cleaning, surface cleaning, and maintenance of historical artifacts. It is also applied in the automotive and aerospace industries, and for restoring artwork, among other uses.

Q: What are the advantages and disadvantages of laser cleaning compared to traditional methods?

A: The advantages of laser cleaning include its non-abrasive nature, precision, and minimal waste production. However, disadvantages may include the initial cost of the laser cleaning system and the need for specialized training to ensure laser safety.

Q: How do laser cleaning systems differ from other laser machines?

A: Laser cleaning systems are specifically designed for surface cleaning and rely on high-energy laser pulses to remove contaminants. Other laser machines might be used for laser marking or cutting, which involve different laser processing techniques.

Q: What are the benefits of using a laser cleaner for industrial applications?

A: Industrial laser cleaning provides benefits such as reduced downtime, enhanced precision in cleaning applications, and the ability to clean without chemicals. This makes it environmentally friendly and cost-effective over time.

Q: Can laser cleaning be applied to all types of surfaces?

A: Laser cleaning is versatile and can be applied to a wide range of surfaces, including metals, stone, and glass. However, the suitability depends on the material’s ability to withstand the laser power without damage.

Q: What type of laser is commonly used in laser cleaning solutions?

A: Pulsed laser beams are commonly used in laser cleaning solutions due to their ability to provide controlled energy bursts for effective cleaning. Continuous lasers are less frequently used because they can generate too much heat, potentially damaging sensitive surfaces.

Q: Are there any safety concerns when using a laser for cleaning applications?

A: Yes, laser safety is paramount when using a laser cleaner. Proper safety measures, including protective eyewear and training, are essential to prevent accidents and ensure safe operation of the laser cleaning system.

Q: How does laser cleaning improve surface preparation for subsequent processing applications?

A: Laser cleaning ensures surfaces are free from contaminants, which enhances adhesion and quality in subsequent processing applications, such as coating or welding. This leads to better performance and longevity of the finished product.