There are many methods for surface cleaning, and laser cleaning technology seems to be the newest on the block while replacing a lot of older, less environmentally friendly options. This new technology utilizes lasers for cleaning, allowing various materials to be stripped or cleaned of contaminants, rust, and other coatings with precision and a minimal loss of materials. This brings us to the question, “How does this process work?” In this blog, we will tackle the question of how laser cleaning works and explore its mechanics, advantages, and additional uses spanning multiple industries ranging from manufacturing to tech. Industries and professionals looking to understand better how technology is changing sustainability and precision standards are encouraged to keep reading.

What is the Laser Cleaning Process?

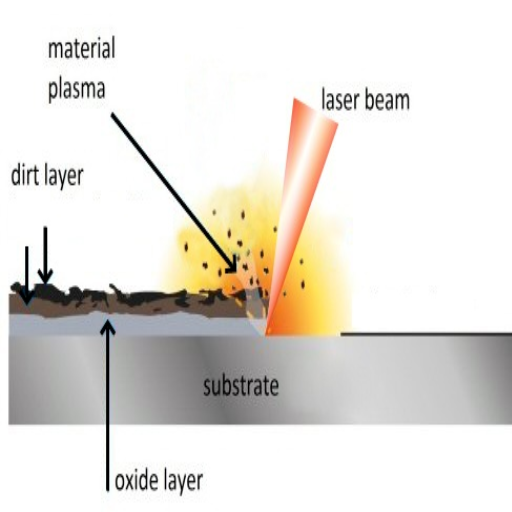

Contaminants such as rust, paint, or other debris threaten the appearance and performance of tools and appliances and thus prompt the need for their eradication. Luckily, some methods can tackle this cleaning without damaging the tools themselves. With lasers, it is possible to remove several contaminants with laser cleaning. As the name implies, a laser beam is used extensively. The first step is the directed application of the laser onto the artwork microtome surface, where the beam focuses on the exact portion of interest and heats the specific layer of material present. Subsequently, the layer is vaporized and removed together with all the contaminations posed. As mentioned earlier, portions of the tools can be evaporated without damaging the underlying surface, which is called vaporizing. Based on the characteristics of the method, we can ascertain that this was an eco-friendly approach. There were also no harsh cleaning chemicals that might skin the already pristine nature of the environment.

Understanding the Laser Cleaning Method

The laser cleaning system has developed as one of the most effective and reliable methods of cleaning tasks throughout diverse industries. Modern laser systems can achieve astonishing precision by optimizing the wavelength for specific contaminants so that the base material is untouched. One case is the widely used pulsed fiber lasers, which have short bursts of energy capable of removing particles, even microscopic ones, without causing thermal damage to the surface.

These systems have remarkable energy efficiency as an advantage. Modern laser cleaning setups designed for small-scale applications clean at an average rate of 20 to 100 watts, while industrial-grade cleaning systems use several kilowatts. Studies further indicate that laser cleaning can reduce time spent on maintenance by 70% compared to traditional techniques such as sandblasting or chemical cleaning. Such a reduction in operational downtime is highly beneficial.

The absence of chemical solvents in laser cleaning makes the process more sustainable by reducing hazardous waste materials. This invention goes hand-in-hand with efforts made by various industries to reduce ecological footprints, particularly within aerospace, automotive, and cultural heritage restoration. For example, turbine blades in aerospace can be cleaned with lasers for precision, extending their lifespan while observing strict environmental regulations.

Finally, as technology advances, automated laser cleaning systems and AI-powered diagnostics are increasing operational efficiency. Such systems enhance safety and reliability by adjusting laser parameters based on surface type in real time. Because of laser cleaning’s potential for precision, efficiency, and sustainability, it is a revolutionary tool for modern industrial and environmental applications.

The Role of Laser Beam in Cleaning

The development of laser technologies has made cleaning easier across various sectors because it is clean, effective, and precise. By focusing light energy on a specific area, contaminants, rust, paint, or additional unwanted layers can be removed using “ablation.” This non-invasive approach does very little harm to the substrate, making it ideal for fragile machinery, ancient relics, and sensitive electronics.

One of the benefits of using lasers for cleaning is that they do not require hazardous chemicals, which are commonplace in traditional cleaning methods. Emerging research suggests that this technology reduces harmful waste by 90 percent, significantly reducing the environmental impact and disposal expenses. Besides that, different materials can be exposed to lasers set at specific conditions to yield the desired results. For example, the power can be adjusted, wherein fine-detail cleaning may require only a few watts, and industrial-grade tasks may go as high as several kilowatts – a level of versatility unlike any other.

Laser cleaning has excellent applications in the automotive, aerospace, and cultural preservation industries. Studies show that automotive plants that implemented laser systems improved their cleaning efficiency by 65% compared to traditional chemical cleaning. In heritage conservation, specialists can restore complex works with the utmost precision while ensuring they maintain their structural authenticity and originality.

The automation and scalability of laser cleaning make it even more attractive. Cleaning can now be performed efficiently with the utmost precision, and robotic laser systems decrease manual handling, increasing safety within the working environment. New developments in AI mean the cleaning laser parameters can be changed in real time according to the analysis of the surface being treated, giving accuracy that older cleaning methods don’t offer. These features make laser cleaning one of the most innovative and environmentally friendly cleaning approaches.

How Laser Energy Affects Cleaning Efficiency

Different factors, including the laser’s energy, impact the operation’s effectiveness and efficiency. Energy density, wavelength, and pulse duration all affect the cleaning capability of the laser to remove contaminants cleanly. Additionally, the underlying surface should not be negatively impacted, which is vital. Regarding industrial usage, the need for speed and precision means energy density needs to be higher. Lasers with 1064 nm (near-infrared) wavelengths work well with metal, while ultrasound lasers aid nonmetals.

A recent study has focused on cleaning efficiency. Pulsed lasers exceed 90% cleaning efficiency when the goal is to remove rust or strip paint (when optimally configured). Research done with laser fluency set at 10-20 J/cm squared seems to offer the best cleaning results while causing minor substrate damage. The advancement of fiber laser technology has further decreased the power consumption of modern systems by 30%, significantly lowering costs and mitigating the environmental impact.

Industries can strategically adjust the laser parameters to tackle specific materials and contaminants precisely, thus demonstrating the effectiveness and adaptability of laser cleaning for different sectors.

What are the Types of Laser Cleaning Systems?

Every laser cleaning system is made to solve specific issues and meet particular needs:

- Low-Power Laser Cleaning Systems

It is best suited for delicate cleaning needs. It is commonly used to remove rust, paint, or dirt from sensitive materials.

- High-Power Laser Cleaning Systems

It works best with severe applications. It is commonly used to clean thick layers of rust off industrial equipment or massive surfaces.

- Pulsed Laser Cleaning Systems

Pulsed lasers deliver short and powerful bursts of energy, making them ideal for cleaning sensitive surfaces that cannot endure too much heat.

- Continuous Wave (CW) Laser Cleaning Systems

Most ideal for large-scale tasks where the consistency and constant emission of the laser beam is required.

Each type of system is designed to provide the best possible efficiency during cleaning while attempting to cause no degradation to the material being cleaned.

Differences Between Fiber Laser and Other Systems

- Energy Efficiency

Fiber laser systems are remarkably more energy efficient than other types of lasers. With them, up to 75%- 90% of the electrical energy consumed is transformed into laser light, while traditional CO2 lasers only convert around 10%- 20%. This increases the amount of energy waste and the operational costs.

- Beam Quality

The superior beam quality provided by fiber lasers’ smaller diameter makes precision cleaning applications easier. Other systems, like diode-pumped or CO2 lasers, tend to have larger beam sizes, which might result in less precise outcomes.

- Compact Design

Using optical fibers to transmit beams makes it possible to design lightweight and compact fiber lasers, allowing easier integration into portable cleaning systems. On the other hand, CO2 lasers tend to be bulky because of the external mirrors and maintenance-intensive components that need to be incorporated.

- Longevity and Durability

Fiber lasers’ operational lifespan is longer than that of solid-state lasers and COB systems. This is mainly because of their robust design, which can withstand over 50,000 hours of continuous use. The other lasers incur more costs over time, as they are entirely dependent on maintenance and component replacements.

- Versatility of Materials

A fiber laser performs well on metals like steel, aluminum, and titanium and nonmetals like glass and ceramics. Other systems would struggle to operate efficiently on such a wide variety of materials.

- Cooling Requirements

Fiber lasers typically utilize air cooling instead of water-based systems. This is an advantage because it simplifies the setup, reduces cooling expenses, and improves the overall energy efficiency of the fiber lasers.

- Stability in Operations

Fiber lasers show superb precision in dealing with external environmental elements like temperature changes, vibrations, and other factors. This allows stable operations under varying working conditions compared to traditional systems that are more sensitive to these factors.

- More Significant Cost Savings in the Long Run

Fiber lasers are more economical than other systems despite their high initial cost because of their reduced maintenance, increased energy efficiency, and longevity.

Among other solutions, fiber-based laser systems are at a clear advantage because they surpass the performance, precision, and practicality alternatives across various industrial or cleaning applications.

Overview of Industrial Applications of Laser Cleaning

The precision and versatility of laser cleaning make it an efficient industrial solution for a wide range of problems. The non-contact, eco-friendly method ensures accurate material removal without damaging the underlying surface, making it suitable for the aerospace industry, automotive, manufacturing, energy, and many more.

- Aerospace industry

Surface preparation and painting require decontamination and cleaning in the aerospace sector. Cleaning superalloys like aluminum or titanium beams with lasers helps preserve their structural integrity. Moreover, oxidation, rust, and other residues from highly sensitive parts are removed to provide better adhesion in performance.

- Automotive industry

Mold cleansing, welding preparation, and paint removal are some areas where lasers serve the car industry. Lasers clean molds used for making tires, significantly increasing their life span. Research also confirms that laser cleaning enhances welding quality by eliminating unwanted rough edges, making the welds more durable. It also helps minimize the waste produced by traditional methods like sandblasting.

- Restoration of Historical Artifacts

Laser cleaning is beneficial in cleaning historical artifacts and monuments. Lasers make removing dirt, corrosion, and pollutants easy without harming the surface. The technology has made it possible to recover many archaeological finds and ancient sculptures that would otherwise be lost to future generations.

- Energy Sector

Laser cleaning is heavily used in energy maintenance and repair work. Its applications range from cleaning turbine parts in power plants to surface preparation for repairs on pipelines and wind turbines. It even aids in the Eco-Friendly production of energy in other ways. Some reports show that this technique leads to lesser downtime and more excellent operational dependability in the adopting industries.

- Cost and Eco-friendly Features

Laser cleaning stands out due to its environmentally friendly nature. Unlike older methods that use chemical solvents or abrasives, lasers do not produce as much waste. They also lower emissions and disposal costs, helping almost any sustainability goal. Companies have also stated that they save costs in the long run due to highly reduced maintenance, lesser operational downtime, and the long lifespan of advanced laser systems.

With its growing use, laser cleaning is setting new precision, efficiency, and sustainability standards for various industry tools and uses.

Choosing the Right Laser Machine for Your Needs

When considering purchasing a laser machine, paying adequate attention to factors such as application specifics, materials to be worked on, and results to be achieved is recommended. Each use case and industry has predefined straining features. Therefore, knowing the primary specifications of the devices is a prerequisite, considering the industry’s use.

1. A Classification of The Devices

Laser machines include devices such as Fiber lasers, CO2 lasers, and UV lasers, which are specialized in specific applications. Fiber lasers have proven to be the most efficient devices for metal cleaning, welding,g, and cutting, and they remain the best in terms of power and precision. CO2 lasers are popular with non-metal constituents like wood, acrylic, and leather, while UV Lasers shine through their lower wavelength on sensitive work like marking on glass or plastics.

2. Machine Power vs. Required Cutting Speed

It is safe to assert that the power level touching a device dictates its efficiency and agility. Higher power machines(1000W – 6000W or even more) are more appropriate if deep cuts, and high speed cleaning is approved, such are the requirements for most industrial applications. Otherwise, lower-power devices are more than enough for marking or engraving tasks.

3. Cost Efficiency and Maintenance

Evaluate energy efficiency and maintenance costs before making a decision. As an example, fiber lasers are said to outlive other types in maintenance needs and life expectancy, boasting up to 100,000 hours of operation. It is more costly to invest in fiber lasers initially, but they bear more savings in operational costs.

4. Precision and Software Integration

Enhancements in modern laser machines include the addition of sophisticated software for ease of use and precision. CAD/CAM integration, real-time visibility, and setting adjustments allow for flexibility and excellent accuracy for intricate and high-volume work.

5. Industry-Specific Data

For instance, in the automotive industry, fiber laser machines have shown an increase of up to 40% in production efficiency over traditional cleaning and welding methods. Also, textile CO2 lasers have shown a material waste reduction of approximately 30%, contributing to environmental sustainability.

If these factors are considered, businesses and individuals can purchase laser machines that serve their immediate needs and consider long-term operational and maintenance sustainability.

What are the Advantages and Disadvantages of Laser Cleaning?

- Pros of Laser Cleaners

Maintains Environment: No chemicals are used in laser cleaning, making it more eco-friendly as no hazardous waste is generated.

Target-Specific Cleaning: Unlike other cleaning methods, laser cleaning does not damage the internal structures of the material while cleaning.

Affordable: Cost saving due to removal of cleaning solvents and abrasives.

Non-Invasive Cleaning: There is no damage to equipment or surfaces; therefore, no maintenance is done.

Multi-Purpose Applicability: It works on stone, metals, and specific polymers.

- Cons of Laser Cleaning

Requires Significant Capital: The cost of laser cleaning equipment can be too high for small businesses.

Time-Consuming over Large Surfaces: Large areas require more cleaning time than traditional cleaning methods.

Mandatory Operator Training: Equipment manipulators must be trained on efficient and safe procedures.

Not ideal for heat-sensitive or fragile materials: Other forms of cleaning delicate surfaces that cannot withstand high temperatures are preferable.

Benefits of Using a Laser Cleaner

- Eco-Friendly Application: Laser cleaning does not employ solvents or chemicals, making it a dry process that avoids using pollutants. Studies show it can reduce hazardous waste production by 80% compared to other methods.

- Precision Cleaning: Laser cleaners offer unmatched precision, which allows for cleaning at a focus without damaging the base. This is significant for cleaning delicate and intricate components.

- Minimal Maintenance: Compared to other methods of cleaning, this method uses fewer consumable parts and does not require frequent replacements, leading to lower maintenance costs.

- Cost Efficiency in the Long Run: The initial investment may be high, but laser cleaning reduces recurring expenses such as chemical purchases, disposal fees, and labor, leading to increases in revenue in the long term.

- Non-Contact Process: As the laser beam does not come into contact with the material, there is no risk of surface wearing or abrasion, ensuring the material’s integrity.

- Adaptable to Various Applications: Laser cleaning is highly adaptive and can clean materials such as metals, stonework, and even gentle historical artifacts.

- Improved Workplace Safety: No dangerous chemicals are introduced, significantly improving air quality and reducing the danger required in cleaning methods, making it a better workplace.

- Speed and Precision Uses: Lasers can be time-saving for targeted cleaning tasks, even though they take longer in wider areas.

- Increased Lifespan of Equipment: Maintaining machinery and tools through non-abrasive methods, such as laser cleaning, increases their longevity.

Meticulous Contaminant Removal: Studies show that laser cleaning enhances the cleaning efficacy of critical applications by achieving a 99.9% precision in contaminant removal.

Potential Drawbacks of Laser Cleaning Technology

Expensive High-End Cleaning Devices: An obvious disadvantage of laser cleaning technology is the high investment required. Cleaning systems using laser technology differ in cost, and advanced ones can cost well over $100,000. With this type of pricing, integrating this technology becomes impossible for small and medium-sized enterprises.

Limitations Relating to the Materials Being Used: Laser cleaning can be helpful with a wide variety of materials; however, this method might not be relevant to some surfaces. For example, highly transparent and highly reflective materials might be cumbersome because they require Special lasers or particular settings, which make the entire process more complex and costly.

Cost of Running the Equipment: Operating a powerful laser system comes at a price, literally. For some industrial systems that operate at higher power levels, significant amounts of electricity may be required, increasing operational costs, especially when energy is expensive.

Staff Training: Unsurprisingly, a laser cleaning system has to be operated by someone with a particular skill set, which comes with costs associated with proper utilization. This could lead to ineffective cleaning and possibly substrate damage. In these scenarios, organizations have to deal with the challenge of spending more time and money training their staff on these pieces of equipment.

Safety Warnings: Although using lasers in cleaning reduces the need for dangerous chemicals, some risk factors related to using lasers still exist. If proper safety precautions are not taken, severe burns, eye injuries, and other traumas can result. Adding safety measures like protective shields or glasses may also increase cost and complexity.

For some cleaning, Laser Oh My May Be Slow: When cleaning large surface areas, laser cleaning is oftentimes slower than other abrasive methods, such as sandblasting. Because of its precision, some industries may find the time it takes to treat large spaces less practical.

These factors show that although laser cleaning technology has boundless benefits, one must carefully assess these inadequacies before implementing it commercially or industrially.

How Does Laser Cleaning Work Compared to Traditional Methods?

Cleaning with a laser involves focusing a laser beam on a surface to remove rust, paint, and other residue while protecting the underlying material. Unlike traditional methods such as sandblasting or chemical cleaning, which utilize abrasives or strong chemicals, laser cleaning is a non-contact process that employs energy to eradicate unwanted materials by vaporization. This method is more eco-friendly, safer for the users, and does less damage to sensitive surfaces. Laser cleaning is far more precise and controlled than traditional methods and tends to create large amounts of waste.

Efficiency of Laser Cleaning Versus Chemical Cleaning

Laser cleaning is preferred across many industries due to its accuracy and efficient energy use. It is also much better than chemical cleaning, which relies on dangerous solvents that often need strict safeguarding procedures and generate chemical waste that has to be disposed of. With lasers, no materials are physically used, which results in almost zero environmental damage, lower operational costs, and reduced impact on nature over time.

For further comparison, chemical cleaning requires multiple solvents, which can take hours to apply and remove, but targeting a specific area with a laser results in achieving the same goal in a fraction of the time. For instance, industrial testing demonstrates that laser systems can clean surfaces 3 times quicker than manual chemical scrubbing. Moreover, laser cleaning does not require any post-treatment since there are no hazardous remnants or waste—known as drags—with chemicals.

Several industries now employ laser cleaning to help reduce pollutants and ease the disposal of toxic chemicals, as it is far less harmful to the environment. Laser cleaning systems have been reported to last for thousands of hours instead of recurring expenses to buy and dispose of chemicals, demonstrating efficiency and value. These factors highlight the increased use of laser cleaning in aerospace, automotive, and heritage preservation industries.

What are Common Cleaning Applications for Laser Technology?

Considered to be one of the most effective answers to cleaning in a variety of industries due to its efficiency, precision, and effectiveness, laser technology has the following precision applications:

- Maintenance Industrial Equipment: Cleansing machines and tools of rust, grease, and other dirt and cleaning materials.

- Aerospace: Cleaning of intricate parts while safeguarding the underlying materials.

- Automotive: Cleansing paint, welding remnants, and cleansing surfaces to be coated.

- Cultural Heritage: Restoring dirt and corrosion-covered historical artifacts, sculptures, or monuments, in addition to the old paint layers, which are easy to remove.

- Electronics: Considered a critical component, circuit boards, and crane arms are cleaned with utmost precision.

The different fields in the above information express the dexterity achieved with laser cleaning and its reliability in achieving impeccable results.

Applications in Metal Surface Cleaning

These days, laser cleaning has emerged as one of the most effective methods for cleaning and pre-treating metals. Its use is quite extensive and includes:

Laser Cleaning of Rust: It is well known that rust damages sensitive metals. Unlike traditional techniques, rust laser cleaning is very effective and does not harm the metal underneath. Studies have shown that rust laser cleaning can reduce rust thickness by up to 95 percent with minimal effort.

Laser Cleaning of Oxide Layers: As mentioned previously, there are several industries in the contemporary world where laser cleanliness is essential. For example, aerospace, automotive, and medical. In the above mentioned industries, they rely heavily on precision manufacturing, therefore erosion of fine details caused by materials such as rust, dirty oxide layers, or oil must be eliminated. Laser-cleaning oxide layers allow accuracy and constancy on surfaces that need to be cleaned before processes like coating or welding are carried out.

Cleaning Before Welding and Cleaning After Welding: Before welding, laser cleaning can prepare the metal surface by eliminating contaminants like grease and rust. This improves the weld’s aesthetic appeal and strength. Further, it helps remove residues such as oxides and discoloration that occur post-welding.

Removal of Paint: Old coats of paint on metal structures must be refurbished or removed for re-coating. Laser cleaning is a sophisticated, eco-friendly alternative to removing paint while avoiding generating harmful waste.

Preparation for Adhesive Bonding: In the preparation stages of aerospace and other electronics that require bonded adhesive, laser cleanliness is heavily used to prepare metal surfaces by removing contaminations, which guarantees strong, secure bonds.

Surface Texturing for Enhanced Adhesion: Various lasers can be used for laser cleaning and surface texturing, improving the adhesion strength of treatments or coatings, which increases their functionality and durability.

These tools and techniques are new and innovative while green, demonstrating high effectiveness in maintaining or preparing metal surfaces with the least damage and waste.

Reference Sources

1. Cleaning up the World’s Oceans with Underwater Laser Imaging1

- Key Findings: This study explores the use of laser imaging for detecting underwater garbage. It highlights the limitations of traditional methods like sonar and cameras, emphasizing that lasers can penetrate deeper and provide more explicit images in turbid water. The research also identifies factors affecting image quality, such as depth, turbidity, and object material. Deconvolution techniques were found to improve image clarity significantly.

- Methodology: Experiments were conducted in a controlled lab setting using a green laser and various objects submerged in water. The study tested different polarizations, depths, and turbidity levels, applying image processing techniques like guided filtering and deconvolution to enhance image quality.

2. An Overview Study on Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry2

- Key Findings: This paper provides a comprehensive overview of laser applications in manufacturing, including cleaning, cutting, and engraving. It emphasizes the precision and efficiency of laser technology in handling complex tasks, such as cutting metal sheets and engraving intricate designs. The study also discusses the role of lasers in Industry 4.0, highlighting their adaptability and high-speed processing capabilities.

- Methodology: The paper reviews existing literature and case studies on laser applications, focusing on their principles, operational modes (continuous and pulsed), and specific uses in mechanical engineering.

3.. Top Handheld Laser Cleaning Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a laser cleaning machine, and how does it work?

A: A laser cleaning machine utilizes a focused laser beam to remove contaminants from surfaces through a process known as laser ablation. The high-energy laser pulse interacts with the material, breaking down dirt, rust, and other unwanted substances without damaging the underlying surface.

Q: What are the advantages of laser cleaning over traditional cleaning methods?

A: Laser cleaning’s advantages include efficient cleaning with minimal waste, reduced chemical usage, and the ability to target specific areas without affecting surrounding materials. Laser cleaning is also a dry cleaning technique, meaning no water or solvents are required.

Q: What types of laser cleaning machines are available?

A: There are several laser cleaning machines, including fiber laser cleaning systems, pulsed laser beam machines, and high-energy laser units. Each type is designed for specific applications and offers unique benefits depending on the cleaning task.

Q: How does the laser process work in cleaning applications?

A: The laser process involves directing a beam of light with a specific wavelength at the contaminated surface. The incident laser beam generates a cleaning effect by producing a shock wave that detaches the contaminants through thermal and mechanical interactions, effectively cleaning the surface.

Q: What are some typical applications of laser cleaning?

A: Laser cleaning applications include rust removal, paint stripping, surface preparation for welding or bonding, and industrial machinery cleaning. It is also used for delicate processes such as laser marking and artistic applications.

Q: How do I choose a suitable laser for my cleaning needs?

A: When choosing a laser, consider factors such as the type of contamination, the material being cleaned, and the required cleaning speed. Evaluating the laser power, intensity, and wavelength can help determine your specific application’s most effective laser cleaning solutions.

Q: Is laser cleaning a safe method for industrial cleaning?

A: Yes, when proper laser safety protocols are followed, laser cleaning is considered safe for industrial cleaning. Operators should wear protective eyewear and ensure the work area is adequately secured to prevent unintended exposure to laser radiation.

Q: Can laser cleaning be used for both metal and non-metal surfaces?

A: Laser cleaning can be used on metal and non-metal surfaces. However, the effectiveness may vary depending on the material’s properties and the cleaning technique employed, such as laser rust removal on steel or cleaning of plastics.

Q: How does laser cleaning improve cleaning efficiency?

A: Laser cleaning improves cleaning efficiency by providing a non-contact cleaning method that minimizes the risk of surface damage while achieving thorough removal of contaminants. This leads to faster cleaning times and reduced labor costs compared to traditional methods like steam cleaning.