UV laser marking machines are revolutionizing the way industries achieve precision and permanence in labeling and engraving. But what exactly makes these machines stand out from traditional marking technologies? Known for their accuracy and versatility, UV lasers offer a non-contact method of inscribing intricate details on a wide variety of materials, from delicate plastics to robust metals, without causing damage or distortion. This article dives deep into the inner workings of UV laser marking machines, unraveling the science behind their operation, their unparalleled advantages, and the reasons they’re becoming a go-to solution across industries. Whether you’re a manufacturer, designer, or simply curious about cutting-edge technology, prepare to uncover the secrets behind one of the most advanced tools driving innovation today.

What is UV Laser Marking and How Does it Differ from Other Methods?

UV laser marking is a process that uses ultraviolet light to create high-precision markings on materials without causing heat damage. Unlike traditional laser marking methods, which rely on heat to etch or engrave, UV laser marking operates at a shorter wavelength (typically 355nm). This shorter wavelength allows for a “cold marking” process, minimizing thermal stress and making it ideal for delicate or heat-sensitive materials like glass, plastics, and certain metals. Its high precision and non-invasive nature set it apart, enabling fine details and smooth finishes that other methods might struggle to achieve.

Understanding the UV Laser Marking Process

UV laser marking relies on advanced photochemical reactions to achieve precise and high-quality marks without introducing significant heat to the material. The process begins with the UV laser emitting light at a short wavelength (typically 355nm), which is absorbed efficiently by a wide range of materials. This absorption creates a photochemical effect that alters the material’s surface, resulting in permanent marks.

One critical advantage of UV lasers is their ability to produce marks as small as a few microns, delivering exceptional clarity even for intricate patterns or tiny text. For example, industries like electronics and medical device manufacturing often utilize UV laser marking to inscribe micro-sized details, such as serial numbers or QR codes, where precision is essential.

Additionally, the process is highly efficient, often achieving marking speeds of up to several meters per second, depending on the material and complexity of the design. Reports indicate that UV laser systems can maintain consistent results over long production runs, reducing waste and increasing throughput for manufacturers.

UV lasers also stand out for their compatibility with an extensive range of materials, from brittle substrates like glass to soft or sensitive plastics. An increasing number of applications can be seen in sectors like aerospace, where the high precision and reliability of UV lasers are critical for marking components without compromising structural integrity. Statistics support the rising demand for UV laser marking, with global market value projected to exceed $10 billion by 2030, driven by innovation in manufacturing and an emphasis on durable, high-precision marking solutions.

Through its ability to deliver exceptional accuracy, speed, and material versatility, UV laser marking continues to position itself as a state-of-the-art technology, indispensable across various industries.

Comparing UV Lasers with Fiber Lasers and CO2 Lasers

UV lasers, fiber lasers, and CO2 lasers each offer distinct advantages and are tailored for specific applications in marking, engraving, and material processing. Understanding their differences helps industries determine the optimal solution for their unique requirements.

1. Wavelength and Precision

UV lasers operate on a shorter wavelength (typically 355 nm) compared to fiber lasers (1,064 nm) and CO2 lasers (10,600 nm). This shorter wavelength enables UV lasers to deliver incredibly high precision with a minimal thermal effect, making them ideal for delicate materials like plastics, glass, ceramics, and semiconductor components. Fiber lasers and CO2 lasers, while effective, generate more heat, limiting their utility on heat-sensitive materials.

2. Speed and Efficiency

Fiber lasers excel in marking metals such as stainless steel, aluminum, and carbon steel, delivering high-speed processing with outstanding durability. They are particularly suited for industries requiring rapid throughput, such as automotive and aerospace manufacturing. CO2 lasers also boast high-speed marking on non-metals like wood, acrylic, leather, and textiles. UV lasers, on the other hand, balance precision and speed, especially for micro-marking and intricate designs.

3. Material Versatility

When versatility is key, fiber lasers dominate with their ability to handle a wide range of metals and some plastics. CO2 lasers are specifically advantageous for organic materials and non-metals, whereas UV lasers shine in applications involving brittle or highly sensitive materials, where heat-induced damage must be avoided.

4. Cost Factors

CO2 lasers generally have the lowest initial investment costs, making them appealing for businesses focused on marking non-metals. Fiber lasers, while more expensive upfront, offer long operational lifespans and low maintenance, yielding cost efficiency over time. UV lasers, given their advanced capabilities, tend to have the highest capital costs; however, they provide unmatched precision, often justifying the investment for industries requiring detailed and permanent markings.

5. Applications Across Industries

- UV Lasers are predominantly used in electronics, medical devices, aerospace, and luxury goods due to their fine detailing and heat-sensitive processing capabilities.

- Fiber Lasers find extensive applications in heavy industries, including automotive, aerospace, and construction, where strength and speed are crucial.

- CO2 Lasers are favored in arts, crafts, and packaging, thriving in engraving and cutting non-metallic materials.

6. Recent Market Insights

The demand for UV laser marking continues to surge, with cutting-edge advancements propelling their adoption in high-precision sectors. Fiber lasers are increasingly popular due to their efficiency in industrial use, while CO2 lasers maintain steady appeal in creative and packaging industries. Industry reports estimate the global laser marking market to grow at a compound annual growth rate (CAGR) of over 7% through 2030, with UV lasers anticipated to see the fastest growth rate due to technological advancements and expanding applications.

Selecting the right laser technology involves analyzing the specific materials, desired precision, and cost constraints. By comparing these technologies’ unique strengths, businesses can make informed choices aligned with their manufacturing objectives.

The Role of Ultraviolet Light in UV Laser Technology

Ultraviolet (UV) light plays a critical role in the functionality and versatility of UV laser technology. Operating at wavelengths typically ranging from 355 nm to 266 nm, UV lasers leverage their shorter wavelengths to achieve remarkable precision and minimal thermal impact. This capability is particularly advantageous for applications requiring micromachining or the processing of delicate materials.

Industries such as electronics, medical device manufacturing, and aerospace benefit significantly from UV lasers. For instance, in semiconductor fabrication, UV lasers are invaluable for tasks like drilling microvias on printed circuit boards (PCBs), where high precision is paramount. A recent market analysis indicated that the UV laser market is projected to grow at an impressive CAGR of approximately 10% by 2030, driven by this expanding demand in high-tech fields.

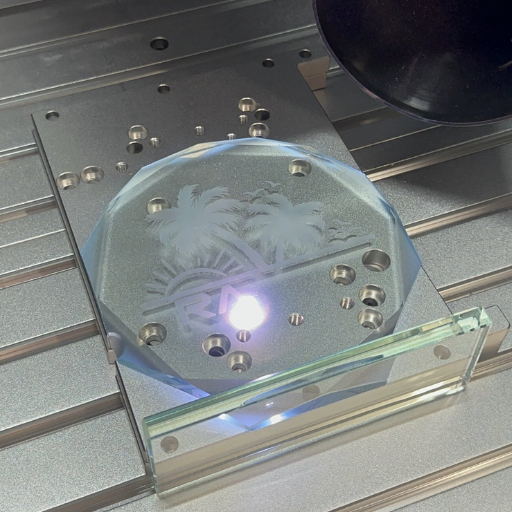

Furthermore, UV light allows for cold processing, which minimizes the risk of heat damage to sensitive materials like polymers, glass, and ceramics. The high photon energy associated with UV light enables direct bond disruption at the molecular level, facilitating cleaner cuts and refined surface finishes. UV laser engraving and marking continue to dominate due to superior contrast and long-lasting results, which are critical for items like medical instruments and optical components.

Advancements in UV laser technology include the development of more compact, efficient, and cost-effective systems. Many devices now combine UV precision with automation, catering to the growing demand for high-throughput production. These innovations underline UV light’s indispensable role in revolutionizing manufacturing across diverse industries.

What are the Advantages of UV Laser Marking?

UV laser marking offers several distinct advantages, making it an excellent choice for various industrial applications:

- High Precision and Detail: UV lasers enable extremely fine marking with minimal heat impact, making them ideal for delicate or sensitive materials.

- Broad Material Compatibility: UV laser marking works effectively on a wide range of materials, including plastics, glass, ceramics, and metals.

- Permanent and Durable Marks: The marks produced by UV lasers are resistant to wear, ensuring longevity and traceability.

- Eco-Friendly Process: Unlike traditional marking methods, UV laser marking is a non-contact and chemical-free process, making it environmentally friendly.

- Versatility in Applications: Industries such as electronics, medical devices, and automotive benefit from UV laser marking due to its precision and adaptability.

These features make UV laser marking a reliable, efficient, and sustainable solution for modern manufacturing needs.

Exploring the Benefits of Cold Marking

Cold marking technology offers an innovative, non-invasive approach to marking and engraving materials, providing a host of advantages for industries with precise and delicate requirements. This process relies on advanced techniques, such as laser marking, that eliminate the need for heat during application. Below is a detailed look at the key benefits of cold marking:

- Material Integrity Preservation: By avoiding the use of heat, cold marking ensures the structural integrity of the material is maintained. This is particularly crucial for sensitive materials such as plastics, polymers, and even biological samples, safeguarding them from warping or thermal damage.

- Improved Marking Precision: Cold marking systems are capable of delivering highly detailed and sharp results, down to micro-level accuracy. For sectors like microelectronics and medical device manufacturing, this level of precision is essential. For example, microchips and surgical tools often require intricate and enduring markings, which cold marking excels at.

- Environmentally Friendly: With no need for consumables like inks or chemicals, and by producing minimal waste, cold marking significantly reduces environmental impact. This contributes to cleaner production processes across industries.

- Durability and Quality of Markings: The markings produced by cold marking methods are resilient to harsh conditions, including extreme temperatures, exposure to chemicals, and wear. These features make it highly suitable for industries such as aerospace and automotive, where parts are subjected to rigorous environments.

- Cost-Efficiency Over Time: While the initial investment in cold marking technology might be higher, the absence of ongoing material costs and reduced maintenance requirements make it a cost-efficient choice in the long term. Manufacturers additionally benefit from minimal downtime caused by tool replacements or consumable sourcing.

Cold marking’s adaptability continues to expand as industries seek sustainable, precise, and reliable marking solutions. It has become an indispensable tool in sectors ranging from aerospace to healthcare, revolutionizing how markings are applied for both functionality and aesthetics.

High-Precision Marking and Engraving Capabilities

Modern cold marking systems are at the forefront of high-precision technology, capable of delivering exceptional accuracy for diverse materials and applications. With tolerances often reaching as fine as ±0.001 inches, these systems ensure unmatched precision, meeting the stringent requirements of industries like electronics, automotive, and aerospace. For instance, laser-based cold marking methods are particularly adept at creating intricate, legible engravings on materials ranging from delicate glass to robust titanium alloys.

The efficiency of these systems is further enhanced by advancements in software integration, which allows for real-time adjustments and seamless customization for unique designs or variable data. Studies highlight that cold marking solutions can achieve surface marking speeds exceeding 1,000 characters per second, significantly reducing processing times without compromising detail or clarity. Additionally, innovations in beam steering technologies and optical systems contribute to greater consistency across even the most complex geometries, ensuring that every mark is of the highest quality.

Beyond precision, these systems are designed to be environmentally friendly. By eliminating the need for consumables like inks or solvents, cold marking reduces waste while maintaining production efficiency, aligning with global sustainability goals. With their unparalleled capabilities and innovative technologies, high-precision cold marking solutions continue to set new standards across manufacturing and industrial sectors.

Why Choose UV Laser Marking for Plastic and Other Materials?

UV laser marking offers unparalleled precision and versatility, making it an excellent choice for a wide variety of materials, including plastics. Leveraging short-wavelength ultraviolet light, this technology ensures minimal thermal distortion by creating markings through a photochemical process rather than heat-based methods. This makes it particularly suitable for delicate or heat-sensitive substrates, such as medical plastics, electronic components, and even glass.

One of the standout benefits of UV laser marking is its ability to create high-contrast, permanent imprints without compromising the surface integrity of the material. Studies show that UV lasers can achieve line widths as small as 10 micrometers, enabling detailed and intricate designs, barcodes, and QR codes. Furthermore, the technology allows seamless marking of materials that are otherwise challenging to work with, such as polycarbonate, ABS, and silicone, addressing a variety of industrial requirements.

From an environmental perspective, UV laser marking eliminates the need for consumables like inks or labels, thereby reducing waste and lowering operational costs. Additionally, it meets global sustainability regulations by avoiding the release of volatile organic compounds (VOCs) into the environment. Reports highlight that industries adopting UV laser marking have seen up to a 30% reduction in production costs tied to consumables and chemical handling.

Industries such as automotive, healthcare, and consumer electronics have embraced UV laser marking, not only for its efficiency but also for its durability. The markings are resistant to wear, UV light, and chemicals, ensuring long-lasting identification even in demanding environments. This makes UV laser marking a superior choice for traceability and branding purposes across a range of sectors.

How to Choose the Right UV Laser Marking Machine?

When choosing the right UV laser marking machine, consider the following key factors:

- Material Compatibility: Ensure the machine can effectively mark the materials you commonly use, such as plastics, glass, or metals. Different machines are optimized for specific materials.

- Marking Requirements: Identify your marking needs—whether you require high precision for small components or deep engraving for permanent markings.

- Production Volume: Choose a machine with a marking speed and capacity that align with your production scale, particularly for high-volume operations.

- Software and Usability: Look for user-friendly software with customizable options to streamline operations and accommodate various marking designs.

- Durability and Maintenance: Opt for a machine known for reliability and minimal maintenance to ensure long-term performance and cost-effectiveness.

- Budget and ROI: Assess your budget while considering the machine’s features, quality, and potential to deliver a good return on investment.

Factors to Consider in a UV Laser Marking System

When selecting a UV laser marking system, it’s essential to evaluate multiple factors to ensure it meets your specific requirements and delivers optimal performance. Here are the key considerations:

- Wavelength and Beam Quality

UV laser systems typically operate at a wavelength of 355 nm, which is ideal for high-precision marking on a variety of materials. Examine the beam quality (measured by M² factor) to ensure fine detail and high resolution in markings, particularly for intricate designs or small components.

- Material Compatibility

Verify that the system is compatible with the materials you work with, such as plastics, glass, ceramics, or metals. UV lasers excel in marking sensitive materials without causing thermal damage due to their cold marking process.

- Marking Speed

Assess the system’s marking speed, which is typically measured in characters per second or area per second. Faster marking speeds lead to higher productivity, but ensure this speed does not compromise the marking quality.

- Marking Quality and Precision

Look for high-quality results with sharp, legible, and durable marks. UV lasers can achieve precision up to micrometer levels, making them suitable for complex geometries or tight tolerances.

- Lifespan of the Laser Source

The longevity of the laser source is crucial for minimizing downtime and maintenance costs. Most UV lasers have a lifespan of 15,000 to 30,000 operational hours, depending on the quality of the source.

- Cooling System

Evaluate whether the laser marking system has an efficient cooling mechanism, such as air or water cooling. Proper cooling prevents overheating, ensuring consistent performance and prolonging the lifespan of the equipment.

- Power Output and Stability

Ensure the UV laser has a stable power output suitable for your marking requirements. Power stability impacts the consistency of mark depth and contrast, which is critical for applications like barcodes or QR codes.

- Control Software and User Interface

Opt for a system with intuitive control software that supports various file formats (e.g., DXF, BMP, PLT) and provides advanced features like variable text, serialization, or CAD integration for enhanced flexibility.

- Safety Features

Since UV lasers operate at a high intensity, ensure the system includes safety measures like enclosures, interlock systems, or exhaust setups to protect operators from UV radiation and fumes.

- Energy Efficiency

Choose a system that balances power efficiency with performance. Energy-efficient UV lasers reduce operational costs and align with sustainability goals.

- Certifications and Compliance

Verify that the system meets relevant industry standards and certifications, such as ISO, CE, or FDA, to ensure operational safety and legal compliance.

- Cost of Ownership

Beyond the upfront cost, consider the total cost of ownership (TCO), which includes maintenance, replacement parts, downtime, and operational expenses.

- Size and Portability

Depending on your workstation or shop floor layout, consider the form factor of the system. Compact and portable designs might suit smaller workspaces, while larger systems may offer higher output capacity.

By reviewing these factors in detail, you can select a UV laser marking system that delivers precision, reliability, and efficiency for your specific application needs.

Understanding Different Types of UV Lasers

UV lasers come in various types, each designed to cater to specific marking and processing needs. The most common types include excimer lasers, diode-pumped solid-state (DPSS) lasers, and fiber lasers. These technologies differ in performance, wavelength ranges, and applications, making it critical to understand their unique characteristics when choosing a system.

- Excimer Lasers

Excimer lasers operate on a short wavelength range, typically between 193 nm and 351 nm. They excel in high-precision applications, such as microelectronics and micromachining, due to their ability to achieve sub-micron accuracy and minimal thermal damage. Their energy pulses are ideal for creating detailed engravings on intricate surfaces.

-

-

- Wavelengths: 193 nm, 248 nm, 308 nm, 351 nm

- Applications: Semiconductor manufacturing, photolithography, and fine material ablation.

- Advantages: High precision, low heat-affected zone, and superior detail resolution.

-

- Diode-Pumped Solid-State (DPSS) Lasers

DPSS lasers offer a balance of performance and cost-efficiency. By leveraging nonlinear crystals, these lasers achieve UV output in wavelengths around 355 nm. They are widely used for marking plastic, glass, and metals with high contrast and durability.

-

-

- Wavelength: ~355 nm

- Applications: Marking medical devices, automotive components, and electronic packaging.

- Advantages: Compact design, reduced maintenance, and versatile material compatibility.

-

- UV Fiber Lasers

UV fiber lasers provide excellent beam quality and are known for their longevity and efficiency. Operating at wavelengths around 355 nm or lower, they are increasingly favored in industrial manufacturing for high-speed marking without compromising quality.

-

-

- Wavelength: ~355 nm

- Applications: Aerospace, automotive, and high-volume industrial marking.

- Advantages: Energy-efficient, long life expectancy, and consistent performance over extended use.

-

Each UV laser type is engineered for specific tasks and industries, making it essential to evaluate your application requirements, such as substrate type, marking speed, and design complexity, before making a decision. By understanding the strengths of these technologies, businesses can implement UV laser systems to improve productivity while maintaining top-notch quality standards.

What are the Applications of UV Laser Marking?

UV laser marking is widely used across various industries due to its precision and versatility. Its primary applications include:

- Electronics: Marking circuit boards, connectors, and other components where high accuracy is essential.

- Medical Devices: Etching unique identifiers or labels on surgical tools, medical instruments, and implants.

- Automotive: Creating durable marks on interior parts, wiring, and sensitive components requiring clear traceability.

- Packaging: Printing expiration dates, batch codes, or logos on materials like plastics or glass.

- Luxury Goods: Engraving logos or intricate designs on cosmetics, jewelry, and watches to enhance branding.

These applications highlight UV laser marking’s ability to deliver high-quality, permanent results on delicate or heat-sensitive materials.

Industries Benefiting from UV Laser Marking Technology

From my experience, UV laser marking technology benefits a wide range of industries by offering unmatched precision and adaptability. Industries such as electronics leverage it for delicate circuit marking, while the automotive sector ensures traceability with permanent engravings. Additionally, consumer goods and luxury markets value its capability to mark intricate designs on diverse materials, enhancing branding and product uniqueness. This versatility makes UV laser marking a vital tool across various fields.

Exploring the Range of Materials Suitable for UV Lasers

When exploring the range of materials suitable for UV lasers, I find that their versatility stands out. UV lasers excel at marking a broad array of materials, including plastics, such as polycarbonate and ABS, as well as metals, ceramics, and glass. Their precision makes them especially effective for delicate or heat-sensitive substrates, as the minimal heat input prevents damage or deformation. From intricate designs on electronic components to detailed markings on luxury items, UV lasers prove adaptable to virtually any industry requiring high-contrast, permanent results.

The Growing Role of UV Laser Markers in Modern Laser Engraving

UV laser markers have become an indispensable tool in modern laser engraving due to their unmatched precision and versatility. Personally, I find their ability to work with a wide range of materials, produce high-contrast marks, and avoid damage to delicate substrates to be game-changing. Whether it’s crafting intricate designs, ensuring traceability on sensitive electronic components, or enhancing the aesthetics of luxury products, UV lasers offer a reliable and efficient solution for meeting today’s diverse engraving needs.

How Does a UV Laser Marking Machine Operate?

UV laser marking machines operate by emitting a high-energy ultraviolet laser beam that interacts with the surface of a material. The UV light alters the material’s properties through photochemical reactions, such as breaking molecular bonds or altering pigments. This process allows for precise and permanent markings without generating excessive heat, which helps protect delicate or heat-sensitive materials. The machine is controlled by specialized software, ensuring accuracy and repeatability for a variety of applications.

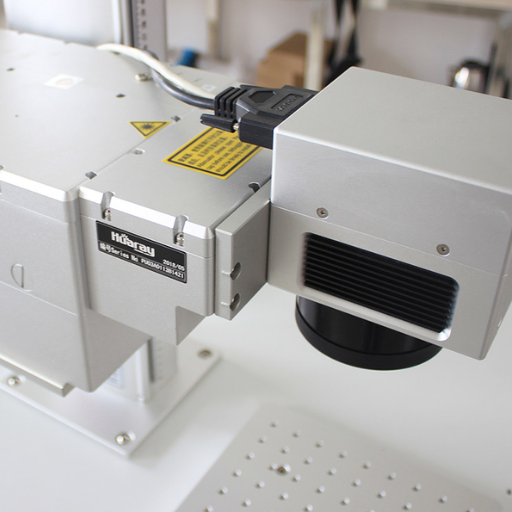

The Mechanism Behind UV Laser Machines

UV laser machines operate through the principle of photochemical ablation, where photons from the ultraviolet laser interact directly with the molecular structure of a material. These lasers typically emit light at wavelengths around 355 nm, a range that enables high energy absorption by many substances. This high absorption diminishes the need for elevated heat levels, a feature that ensures minimal thermal stress on the material.

The advanced optics of these machines allow for precise beam shaping and focus, often achieving spot sizes in the micrometer range. This enables detailing at incredibly fine resolutions, making UV laser systems suitable for micro-marking applications, as seen in industries like electronics and medical device manufacturing. For example, UV lasers are frequently used to mark QR codes, barcodes, or logos on circuit boards and surgical instruments with unmatched clarity.

One of the most impactful developments in UV laser technology is its incredibly high pulse repetition rates, often exceeding 100 kHz. This feature improves processing efficiency and production throughput, especially in industrial environments that demand high-speed marking or etching. Furthermore, modern UV systems are designed with energy efficiency in mind, reducing power consumption while maintaining impeccable precision and consistency. Such systems also support intuitive software configurations, granting users more nuanced control over the marking or engraving processes.

Understanding the Laser Beam and Its Impact on Marking

The laser beam represents the core mechanism behind high-precision marking systems, relying on concentrated energy to deliver unmatched accuracy and control. A typical laser beam used in marking applications is generated through an optical amplifier, which transforms light into a narrow and intensely focused beam. This energy is then directed to the surface of the material, allowing for precise etching, engraving, or marking.

One critical aspect of laser marking is beam intensity and wavelength. UV lasers typically operate at shorter wavelengths, such as 355 nm, enabling them to interact effectively with a variety of materials, including plastics, glass, and metals, without causing thermal deformation. Studies indicate that UV lasers can achieve precision within tens of microns, making them ideal for industries like electronics and medical devices where fine details are essential.

Additionally, pulse duration and repetition rates play a significant role in determining the final marking quality. For instance, shorter pulse durations between 1-100 nanoseconds reduce heat-affected zones, minimizing the risk of material damage while creating sharp, clean markings. High repetition rates, often exceeding 100 kHz in advanced systems, ensure faster marking speeds, which are especially beneficial in high-volume industrial settings.

Modern advancements in laser technology also focus heavily on energy efficiency and sustainability. Data reveal that contemporary UV marking systems can reduce energy consumption by up to 30% compared to older technologies, while still maintaining exceptional precision. This efficiency contributes to lower operational costs and aligns with environmentally conscious production practices.

By optimizing these key laser beam properties, manufacturers can achieve highly consistent and durable markings, ensuring a seamless blend of functionality and aesthetics in their products. Understanding the scientific principles and technological innovations behind laser beam interactions allows for continued progression in the capabilities and applications of laser marking systems.

The Importance of Precision in Laser Marking Systems

Precision in laser marking systems plays a pivotal role in ensuring the quality, accuracy, and longevity of markings across various materials. Modern manufacturing demands are more stringent than ever, and industries such as aerospace, medical devices, automotive, and electronics depend on highly detailed and reliable markings for traceability, compliance, and branding.

To illustrate the value of precision, consider the medical device sector. Laser marking is utilized to engrave serial numbers, barcodes, or logos on instruments without compromising their sterility or structural integrity. The process requires micron-level accuracy, as even the slightest deviation can lead to compliance issues or reduce the product’s usability. According to industry data, top-tier laser systems achieve positioning accuracy of ±10 micrometers, which is essential for industries requiring detailed micro-markings.

Furthermore, precision directly affects speed and efficiency. Advanced laser systems with high precision reduce material waste and ensure each marking is performed correctly on the first attempt. High repeatability ensures consistency across large production batches—a critical factor in mass manufacturing. Studies show that optimizing precision results in up to a 30% increase in production efficiency for high-demand industries like electronics.

The latest innovations in laser technology, such as fiber lasers and ultrafast lasers, further enhance precision by offering greater control over beam intensity, pulse duration, and wavelength. These features allow manufacturers to create detailed contrasts on diverse materials, including metals, ceramics, and polymers, without causing damage. By investing in precision-focused laser technology, companies can meet rigorous industry standards, minimize production errors, and reduce overall costs—ultimately achieving greater customer satisfaction.

Reference Sources

-

Marking (Excimer Laser Technology)1:

- Focus: This chapter discusses the use of excimer lasers for marking applications, emphasizing their precision and adaptability.

- Key Findings: UV lasers, particularly excimer lasers, are effective for marking due to their ability to create fine, detailed marks with minimal thermal impact. The study highlights the importance of wavelength and material interaction in achieving high-quality marks.

- Methodology: The chapter reviews the principles of excimer laser technology and its application in marking, supported by case studies and technical analysis.

-

Laser Marking (Handbook of Laser Technology and Applications)2:

- Focus: This chapter explores the mechanisms and applications of laser marking, including UV laser systems.

- Key Findings: UV laser marking is valued for its indelibility and precision. The process involves the absorption of laser energy within a thin surface layer, which is critical for achieving cosmetically appealing marks. The response of polymers to laser energy is also discussed.

- Methodology: The study combines theoretical insights with practical examples to explain the laser marking process and its material-specific considerations.

-

Mechanism of the Ultraviolet Laser Ablation of Polymethyl Methacrylate (PMMA)3:

- Focus: This research investigates the ablation mechanism of PMMA using UV lasers at 193 and 248 nm.

- Key Findings: The study identifies distinct regions of laser-induced ablation, including a threshold fluence for significant etching. It highlights the role of photodecomposition and multi-photon processes in material removal. The presence of dopants like acridine significantly lowers the energy threshold for ablation.

- Methodology: The research employs laser-induced fluorescence, chemical analysis, and doping studies to analyze the ablation process and its efficiency.

- Top UV Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What are the benefits of UV laser marking machines compared to other types of laser marking equipment?

A: UV laser marking machines offer high-resolution marking capabilities, known as “cold marking,” which minimizes thermal damage to different materials. This makes them ideal for precise marking on sensitive materials and achieving the best marking results without compromising the material’s integrity.

Q: How does a UV laser engraver differ from a fiber laser engraver?

A: A UV laser engraver uses ultraviolet light to perform “cold marking,” which is suitable for marking delicate materials with unparalleled precision. In contrast, a fiber laser engraver employs a solid-state laser for deeper and faster engraving, often used on metals and tougher materials. Each type of laser is suitable for specific marking needs.

Q: What types of materials can UV laser engraving machines mark?

A: UV lasers can mark a wide variety of materials, including plastics, glass, ceramics, and metals. Their ability to perform high-resolution marking on sensitive surfaces makes them ideal for marking a diverse range of materials without causing thermal damage.

Q: What is the principle behind UV lasers and how do they work?

A: UV lasers work by emitting ultraviolet light, which is absorbed by the surface of the material. This process allows for precise marking and engraving without generating significant heat, hence the term “cold marking.” This is particularly beneficial for materials that are sensitive to heat.

Q: What are the types of laser marking methods available?

A: The main types of laser marking methods include UV laser marking, fiber laser marking, and CO2 laser marking. Each method utilizes different laser technologies to achieve specific marking effects, depending on the material and desired outcome.

Q: What is the typical laser power used in UV laser engraving machines?

A: UV laser engraving machines typically use a laser power of around 3W to 5W, which is sufficient for high-resolution marking on a variety of materials without causing thermal damage or distortion.

Q: How does laser marking and engraving benefit industrial applications?

A: Laser marking and engraving provide durable, high-quality marks that are essential for traceability, branding, and compliance in industrial applications. These methods offer precise marking and are suitable for part marking across various industries, enhancing product identification and quality control.

Q: Can UV laser marking machines be used for both marking and engraving?

A: Yes, UV laser marking machines are capable of both marking and engraving. They offer flexibility in creating high-resolution marks for identification and decorative purposes while ensuring minimal material alteration.

Q: Why is UV laser marking considered ideal for marking sensitive or delicate materials?

A: UV laser marking is considered ideal for sensitive materials because it uses a process known as “cold marking,” which minimizes heat impact. This allows for precision marking without damaging or altering the material’s properties, making it suitable for delicate surfaces.

- Fiber Laser vs CNC Machine: Understanding the Cutting Edge of Technology

- Understanding How Laser Marking Machines Work: A Complete Guide to Laser Marking Technology

- Choose the Best Metal for Laser Engraving: A Guide

- Complete Guide: ATC vs MTC – Understanding Automatic Temperature Compensation and Manual Controls

- Laser to Cut Tree Branches: Transforming Sci-Fi Concepts into Reality

- Do Laser Cutting Machines Use a Lot of Electricity Understanding Power Consumption

- UV Laser vs Fiber Laser Marking Machine: Choose Your UV Marking

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide