Properly caring for your CNC router goes hand-in-hand with maintaining its cutting performance which, in turn, protects the longevity of your machine and mitigates expensive repairs. Whether you’re a veteran in the industry or a fresh face to the world of CNC routers, the secret to consistent accuracy and trustworthiness is preventative maintenance. This detailed checklist outlines all the steps necessary for taking care of your CNC router to avoid wasting time, money, and effort. We will discuss everything from everyday cleaning habits to occasional checkups that are required to ensure the optimal performance of your machine. Continue reading to learn how careful maintenance can profoundly improve your workflow and productivity.

What daily maintenance does a CNC router require?

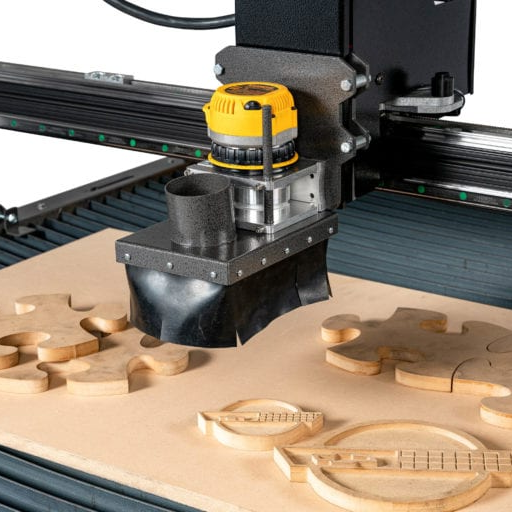

- Machine Cleaning: Ensure workspaces, spindles, and linear guides are free from dust, debris, and chips to facilitate optimal operation.

- Inspect Moving Parts: Examine rails, bearings, and belts for dirt, obstructions, and signs of wear.

- Lubricate as Necessary: To augments be directed friction per the manufacturer’s instructions, apply grease onto suggested components.

- Inspect Tools: For accuracy maintenance, worn or damaged tools are identified to be replaced.

Factors that Affect CNC Performance

CNC machines stand to benefit the most when specific relations are kept in mind, these being in the form of alignment, overall cleanliness, along with machine components tending to spindle efficiency. Optimization suggests sustained well-aligned parts in combination with debris-less areas heavily increase efficiency more than 20%.

Another key point revolves around rotation quantity which is spindle speed, detailing the dimensions of the material, and tool engagement. For instance, applying an HSS tool on aluminum requires a specific range of feed rate in order not to overheat, otherwise, wear will diminishes tool longevity significantly. Studies prove increased productivity surges up by 15% when feed and speed settings are adjusted further.

Finally, advanced technologies associated with computer programming need modern machine software. The new algorithms incorporated in Computer Aided Manufacturing (CAM) software provide accuracy of machining complex geometries and decrease cycle time. Adopting technology of this kind enhances the processes of machining and the economical efficiency of operations.

Significance of Routine Maintenance in Cleaning for Optimal Functioning of CNC Router

In order to increase the durability of your CNC router as well as its function, it is crucial to frequently clean it of dirt and debris. The buildup of dust can not only damage the CNC components but lead to overheating, electrical problems, or misalignment over time. Some reports indicated that a lack of maintenance has shown that the overall efficiency of a CNC router reduces by almost a third.

The very first thing you need to pay attention to is the colet and the cutting tools as they suffer debris pile-up. To a certain extent, the latter is responsible for speeding up the damage and resulting in uneven cutting. Besides physical destruction, too much dust can result in the clogging of air or coolant systems leading to degraded cooling ability. High efficiency ventilating dust clean systems are able to deliver up to 99% of ease airborne particles honesty giving comfort in the workspace. With these systems, timely maintenance helps in significant reduction of downtime and expensive repairs.

Research indicates that clean equipment boosts the safety levels for the operators. Fine dust, a byproduct of abrasive materials, poses a respiratory hazard if inhaled over long periods. Proper high-efficiency air filtration can greatly alleviate this problem, providing a cleaner working environment. Adopting a regular CNC router cleaning schedule, therefore, not only extends the life of the machine but also enhances safety and efficiency throughout the manufacturing process.

The Significance of Regular Lubrication for CNC Routers

Protecting the longevity and operational efficiency of the CNC router depends greatly on the periodic lubrication of its essential parts. Strategic lubrication reduces operational friction and wear and tear while lessening overheating on critical components like ball screws, linear guides, and spindle bearings. To explain, ball screws that are not lubricated correctly will lead to uneven motions and poor machining accuracy which shorten the overall lifespan of the machine.

The latest insights from the industry show great value in automated lubrication systems with precise periodic lube delivery. Research has shown that machines equipped with automated lubrication systems can achieve up to 30% decrease in maintenance downtime when compared with manually lubricated systems. In addition, performance can be further enhanced by using purpose-made CNC lubricants, preferably high-temperature resistant and anti-corrosive lubricants.

It is critical that operations and maintenance personnel adhere to lubrication schedules, as neglecting routine maintenance will undoubtedly drive up repair costs over time. Routine maintenance also includes keeping a logbook, which ensures that all critical components receive the necessary attention and care over an extended period.

How to create an effective CNC router maintenance schedule?

- Understand Manufacturer Guidelines: Consult the maintenance manual for your specific machine to follow proper upkeep procedures and timelines.

- Structured Inspection Planning: Establish a daily, weekly, and monthly inspection routine for spindle, bearings, and belt operations.

- Scheduled Lubrication and Cleaning: All moving components must be cleaned and lubricated as per the above schedule. In addition, dust must be wiped clean from the machine’s surfaces after usage.

- Checking Fasteners: Operationally critical loose screws or bolts need to be checked and fastened regularly.

- Software and Calibration Monitoring: It is necessary to update CNC software at the set intervals and periodically recalibrate the router for precise tasks.

- Documentation: Oversight becomes more systematic when maintenance, repairs, and updates are documented in a maintenance log.

Balancing daily, weekly, monthly and yearly maintenance tasks

- Daily Tasks: Clear the router of dust, check for manual wear, and ensure moving parts are free from dust.

- Weekly Tasks: Inspect lubrication, tighten, and inspect tooling for wear at set intervals.

- Monthly Tasks: Perform software updates, adjust calibration checks, and inspect belts or other components for wear.

- Yearly Tasks: Inspect all mechanical and electrical systems, replace worn parts, and assess the machine performance.

Tracking Maintenance Records to Prevent Unexpected Downtime

It is my practice to keep detailed maintenance records for my CNC router and to log routine checks, repairs, and replacements which helps me recognize patterns, predict issues, and solve them ahead of time. This, in turn, avoids unexpected operational delays, maintaining the smooth and continuous functionality of my machine.

Preventative Maintenance Scheduling Based on Machine Usage

Preventive maintenance is essential for the durability and performance efficiency of your CNC router. Authoritative figures suggest that rather than using preset timeframes, one should schedule maintenance to be performed based on actual usage to ensure that the upkeep is commensurate with the workload demands. For example, routers that are operated over a 40-hour work week will require more inspections than those that are used infrequently.

Adjusting your maintenance to rely on data will significantly improve your operations. Many recent model CNC Routers come equipped with usage tracking features or can connect to software capable of tracking operational hours, spindle activity, or toolpath engagement. Industry experts recommend waiting about 200-300 hours before performing maintenance to key components such as bearings, linear guides, and motor couplings. However, these intervals fluctuate depending on manufacturer guidelines and the operating environment of the machine.

Implementing new technologies such as vibration analysis or thermal imaging can optimize your maintenance schedule. For instance, vibration sensors are able to capture small changes in motor behavior which could indicate misalignment and help rectify the issue before it escalates. Furthermore, thermal imaging can spot electrical component areas overheating which can be fixed before a more serious failure occurs.

Routine preventive maintenance informed by active monitoring greatly reduces the risk of unforeseen equipment failure while potentially increasing the service life of your CNC router, maintaining production availability, and lowering overall costs.

What are the critical lubrication points on a CNC router machine?

- Linear guideways: These require smooth movement as well as prevention of wear, both of which occur through regular lubrication.

- Ball screws: The life of these components is prolonged when proper lubrication is given as friction is reduced.

- Spindle bearings: These must be lubricated if optimal performance is to maintained and overheating avoided.

- Gears and chains (if applicable): Also, excessive wear on these components can be avoided through regular checks and lubrications.

Maintenance Requirement for Ball Screws and Linear Rails

For the safety of the machinery, servicing ball screws and linear rails is extremely important. To maintain the proper functioning of linear guides, clean guides and clean ball screws must be maintained. Any solid material must be kept away from the ball screw as it rotates; also, lubrication needs to be applied to prevent friction and wear. Linear rails need servicing as well, in the form of constant wiping to prevent accumulating dust and particles that can obstruct motion. Research shows that ball screws and linear rails suffer a 50% reduction in lifespan due to lack of lubrication, showcasing the need for maintenance of these parts.

To ensure overall efficiency, using industrial-class lubricants specifically designed for the components in use will offer maximum results. The properties of the lubrication products selected, such as their ability to withstand extreme temperatures, along with their anti-corrosive capabilities, are critical factors as well. Also, evenly balanced tension and alignment of linear rails is critical in avoiding misalignments which lead to uneven load distribution. For example, longitudinal adjusments of about 0.1 mm are shown to increase wear rate by up to 30%.

Proactive environmental control is also critical to achieving peak performance. Without humidity control, ball screws and linear guides will require significantly more maintenance because of excessive care needed due to dust, vibration, and other unwanted particles. Routine evaluations coupled with sophisticated surveillance systems will increase the detection of initial stages of damage or wear, thus minimizing associated repairs and downtime.

Lubricant Selection Per Each Component of CNC Routers

Choosing the correct lubricant for the components of a CNC router is critical to its operational life and efficiency. In the case of ball screws, the selection of high quality grease with appropriate viscosity and load capacity will be of utmost importance. It is common to recommend lithium greases or synthetic lubricants with molybdenum disulfide additives. These greases are not only recommended but used widely because of the superb protection they afford against wear and oxidation. Research studies indicate that premium synthetic greases can reduce the friction in the equipment by 20 percent when compared to traditional options based on mineral oil, directly enhancing performance and longevity.

For linear guides, the smooth running of the machine while preventing the addition of contaminants makes light oil based products the lubricant of choice. The operating environment, load, and speed needs to be taken into consideration when choosing a lubricant. Take for example dusty industrial environments or places with fuel exhausts and high temperatures. In these cases, it is essential to prioritize the lubricants with thermal stability, as well as enhanced resistance to particle build up. Certain advanced products, like micro-mist oil lubricants, are proven to reduce maintenance as much 25%.

Fulfilling the guidelines for lubricant selection while incorporating new developments in lubrication technology enables the operator to avoid premature wear, reduce friction and maintain consistent CNC router performance over the years.

Spindle motor lubrication: Best practices and common mistakes

Lubrication of spindle motors is a fundamental maintenance task for CNC routers that directly affects the spindle’s longevity and efficiency. One of the most common best practices is to implement lubrication practices that use recommended lubricant types or brands, as using off-brand lubricants can lead to degradation of components. Recent studies show that synthetic thermal lubricants with greater thermal stability relative to traditional options can increase the operating lifespan of spindles up to 30%. Those lubricants maintain favorable viscosity at elevated temperatures, lowering the likelihood of overheating and wear.

Noteworthy is that over-lubrication is a key mistake to avoid; the spindle housing is filled with grease, which can lead to heat build-up, leading to failing bearings prematurely. Studies show that more than 60% of the bearing failures seen in spindle motors are results of over-lubrication or insufficient lubrication. Following manufacturer’s instructions, such as specific amounts of lubricants for predefined operating hours or cycles, is critical.

Another essential aspect is the avoidance of contamination. The effectiveness of the lubricant can be compromised by dust, debris, and moisture. These issues can be prevented by utilizing sealed bearings and implementing regular cleaning schedules. Moreover, monitoring intervals of lubrication through automated systems or data monitoring has been noted as an effective approach in sustaining good health of the spindles and reducing unplanned downtimes by almost 40%. Implementing these strategies promotes prolonged consistent and smooth operation of the CNC router system.

How to properly inspect and maintain the CNC spindle?

- Regular Cleaning– Clean the spindle and nearby parts to ensure no debris builds up that may impact performance.

- Check for Wear- Analyze the spindle’s bearings and belts for possible deterioration, considering any unusual sounds or vibrations.

- Lubrication– Confirm the spindle’s lubrication level is at the right amount according to company standards.

- Temperature Monitoring– Track the spindle’s operational temperature keeping it within the prescribed limit.

- Alignment– Ensure that the spindle alignment with the machine is correct to preserve accuracy.

- Follow Manufacturer Guidelines– Comply with the prescribed maintenance check intervals and procedures as stated in the manual.

Signs of Spindle Wear and When Maintenance is Needed

It is essential to foresee the potential threats spindle wear can bring to your machine’s efficiency, accuracy, and overall productivity. Spindle wear is further defined as any deterioration in the spindle’s components that may reduce functionality, which includes excessive vibration, overheating, inconsistent machining precision, reduced speed, or decreased torque. For instance, vibration during a machine’s operation may suggest a loss of balance and bearing performance deterioration. If a spindle is too hot, it could mean that it is under too much physical load or there is not enough lubricant to assist motor action.

Industry studies suggest that improper lubrication or bearing contamination accounts for over half of spindle failures. Routine checks of the temperature and vibration parameters can detect underlying issues prior to escalation. Some vibration analysis tools enable the detection of abnormal signature patterns, which indicate wear and provide insight into the condition of the spindle.

When these precautions are breached, action must be taken as soon as possible. Failure to act upon early signs of trouble will result in extensive repairs and costly downtime. One way to mitigate risks is to establish proactive behavior, such as stringent real time monitoring based on temperature and vibration threshold limits set at the manufacturer’s guidelines. It is important to always assume the worst, as real-time systems can drastically improve spindle reliability and life expectancy.

Cooling and Pneumatic System Maintenance for Spindle Longevity

Optimally performing spindles require the constant cooling and pneumatic system supervision as primary maintenance. The spindle’s infrequent overheating during the operational cycle improves its nearly constant thermal expansion (which leads to significant misalignment) accuracy). Overheating is a critical and common challenge which data estimates the lifespan of spindles operating consistently within the recommended temperature range by over 50% when compared with those subjected to frequent overheating incidents.

On the pneumatic side, having clean and dry compressed air is key to avoiding contamination of the spindle system. Airborne particles, moisture, and oil residue can accumulate and hinder spindle performance progressively over time. Statistics show that effective filtration systems can mitigate Pneumatic contamination concerns by up to 70%, reducing the likelihood of malfunctions and downtime.

To improve system performance, routine inspections and maintenance checklists should include leak detection, pressure stability, and coolant flow rate assessment. Optimizing the coolant pump flow rate can enhance heat transfer efficiency by over 20%. Real-time monitoring of the cooling and airflow systems utilizing IoT sensors is encouraged, as these systems can take action and enable predictive maintenance, decreasing chances of failure.

Bearing Inspection and Replacement Guidelines

Being able to properly inspect and replace the bearings is essential in maintaining the machinery performance and longevity. To accomplish this, a stock of bearings must be checked periodically against a set of criteria, such as wear, corrosion, and lubrication cleanliness. New estimates indicate that over half of bearing failures are due to lubrication mismanagement. A simpler approach based on operating conditions like load, speed, and temperature can greatly reduce these risks through using designed correct volume and type of lubricant.

Vibration analysis and thermographic imaging are examples of sophisticated technologies that can be applied to identify early indications of bearing degradation, as well as monitoring the health of machinery. For example, excessive vibration may signal misalignment or some other form of destructive interference with the rolling components. Research indicates that implementing these technologies as part of a predictive maintenance approach can reduce unplanned downtime by over thirty percent.

The removal and installation of bearings must adhere to very specific steps provided by the manufacturer regarding load capacity and rotation speed. If identified, replacing bearings in a timely manner will mitigate the levels of secondary damage contributed by the surrounding components, which in turn will be more efficient and cost-effective in the longer time span.

What tools and supplies are needed for routine CNC maintenance?

- Moving parts of a CNC Router require lubricants and grease for protection and to lower friction.

- Rags or clean cloths are ideal for dusting off surfaces, wiping clean traces of light dirt or fine dust.

- Chips and particles within the equipment can be cleaned using an air compressor or a vacuum.

- Wrenches and screwdrivers are required to modify and lock the parts.

- Coolant and filters is required so that the cooling system can function properly.

- To determine whether an object is worn out or damaged and concealed, an inspection flashlight or a magnifying glass should be used.

- Alignment tools and gauges are used to confirm the values and placement of the parts.

CNC Router Care – Essential oils, lubricants, and CNC greases

A CNC router must always be lubricated so that the machine works properly, as well as extending its life. Moving parts of the CNC machine are greased and lubricants added to prevent friction, so that there is no excessive damage. Research indicates that CNC machines are expected to last for an additional 30% of their total lifespan if they are regularly serviced. Highly industrial oils, especially the synthetic types, are usually preferred due to their wide operational range and good thermal stability.

Greases are typically applied for components such as axial bearings and ball screws where a thicker consistency improves staying power and protective characteristics. Lithium-based reserves and calcium-sulfonate greases are especially used for their high load bearing capabilities as well as resisting contamination from dirt or water.

Lighter lubricants like spindle oil are suggested for high-speed spindles and other precision parts. These lubricants enable effortless motion without drag which is important in precision work. Following manufacturer’s recommendations, especially in regards to viscosity and additives, is crucial in ensuring that the CNC router works well with the specific requirements.

Cleansing Tools and Solutions for Effective Maintenance

Cleaning is an essential part of the maintenance of your CNC router especially for the smooth operation of its parts and calibration. Cleansing eliminates dust, chips, and residue from the cutting and milling processes. To tackle this issue, soft brushes as well as vacuum systems for CNC Machines are best suited for clearing away debris without harming the machine. For more thorough cleansing, non-abrasive cloths along with isopropyl alcohol or non-petrolic industrial cleaner are effective for machine oil, grease and tough remnants on machine parts.

Although compressed air is a helpful tool it may be problematic if it is misused, as it can force debris deeper into sensitive areas. Cleaning procedures must be followed, especially in high accumulation areas like linear guides, ball screws, and tool holders. As research suggests, consistent cleaning not only enhances the accuracy of operations, but also significantly reduces the wear and tear on components, thereby maintaining optimal performance and precision with every operational cycle.

Proactive Analysis for Preventive Measures Against Breakdown

The integration of specialized tools is crucial in ensuring continuous operational efficiency while reducing expensive downtimes. One such tool, vibration analysis, is a particularly strong method for evaluating the condition of moving parts because it measures irregular shifts in the frequency of one or various rotating elements. Moreover, sensors that measure acoustic emissions are capable of detecting sounds well before damage is visible, which means maintenance can be planned ahead of time.

Another example of these advanced tools is the thermal imaging camera, which measures heat above the normal levels in machines or components. Recent evidence suggests that more than 40% of failures are caused by some form of equipment overheating, which is why infrared devices are essential in locating components that overheat and preventing unnecessary damage from being sustained.A highly emerging technique is the application of machine learning algorithms to predictive maintenance based on real-time data from IoT sensors. Such algorithms are capable of measuring equipment performance, predicting failures with almost 90% accuracy. This field is receiving great attention, and research states that the entire predictive maintenance market is estimated to be worth $23.5 billion by 2026 with a compound annual growth rate of 31%.

With these diagnostic tools, operators coupled with regular cleaning and scheduled maintenance can now achieve greater reliability and efficiency leading to improved production results.

Reference sources

- Study: Proposal of a Process of Mass Customization of Kitchen Cabinetry1

- Objective: To integrate Building Information Modeling (BIM) with CNC router operations for mass customization in small and medium enterprises (SMEs).

- Methodology: The study employed action research to develop a BIM-based workflow for designing and fabricating custom kitchen components. It utilized a BIESSE Rover CNC router for production.

- Key Findings:

- BIM integration reduced setup and programming efforts for CNC routers.

- The approach improved design coordination, reduced rework, and automated CNC code generation.

- The study highlighted the importance of staff training and process reconfiguration for effective CNC router maintenance and operation.

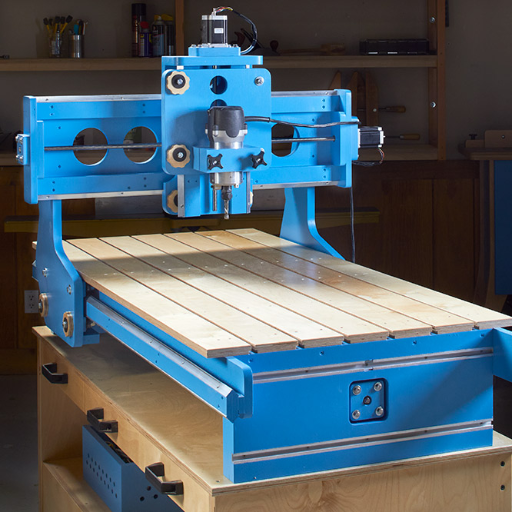

- Study: CNC Routing Machine2

- Objective: To design and build a cost-effective CNC router tailored to local needs, addressing maintenance challenges and high import costs.

- Methodology: The project involved designing a three-axis CNC router with a focus on mechanical structure, stepper motor-driven axes, and a custom drive circuit.

- Key Findings:

- The study emphasized the importance of user safety through features like limit switches and emergency stop buttons.

- Maintenance challenges were addressed by simplifying the design and using locally available components.

- The project demonstrated the feasibility of building CNC routers with reduced reliance on imported parts and external technicians.

- Top 3D CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What does a complete checklist for the maintenance of a CNC router include?

A: A complete CNC router maintenance checklist is daily cleaning of dust and debris, checking and lubricating the moving parts, inspecting belts and pulleys for any wear, verifying tool tightness, checking basic electrical connections such as ground strap, coolant/cutting fluid levels, inspecting guide rails for any debris, and ensuring the emergency stop functions correctly. Preventive maintenance aids in avoiding costly breakdowns. Many shop owners create a structured checklist that machine operators can follow daily or weekly which helps ensure maintenance tasks are completed and not overlooked.

Q: Describe the suggested frequency for routine maintenance to be performed on a CNC router.

A: For routine maintenance, the schedule will vary for CNC routers based on intensity of usage. Daily maintenance includes cleaning the areas around the machines, checking the tools, and inspecting fluid levels. Weekly maintenance consists of lubrication of moving parts and cleaning toner filters. Monthly tasks include inspection of electrical parts, checking the connections in the control box, and inspection over lubrication of all moving parts. As a norm, high production environments tend to increase need for occurrence of maintenance than setups on occasional-use basis.

Q: What lubrication is absolutely crucial for CNC router precision maintenance?

A: CNC router precision maintenance requires proper lubrication. Linear rails, ball screws, and bearings need regular servicing with recommended light machine oil or specialized grease. Oil must not be applied excessively, as it attracts sawdust and debris, resulting in an abrasive mixture. Cleaning hydraulic systems requires checking the fluid level and replacing the oil, hydraulic oil, per hydraulic system regulations. Oil has to be changed according to the established schedule. At high precision sections such as linear guides and ball screws, it is important to remove old grease to add new grease to ensure the machine works correctly.

Q: What are the steps I can take to troubleshoot basic precision problems with my CNC router?

A: Sometimes the simplest steps, like rough mounting of tools or workpieces, can create a precision problem. Also, check the wear of guide rails and bearing systems, as they have a direct influence on accuracy. Ensure proper tension of all belts in addition to checking for backlash in the drive system. Squareness of the machine should be checked with precision tools. Also, check the calibration software settings for the unit steps, as steps-per-unit settings may hinder precision. In scrapped materials and products, restoring precision can save thousands of dollars, so for the unsolved problems, contacting a specialized technician may be beneficial. Temperature varies while working in multi-calibration environments, so take several scrapped products with you to the technician.

Q: What are the signs that a CNC router needs immediate maintenance?

A: CNCRouters with immediate attention needs display signs like strange sounds and vibrations while operating, loss of cutting accuracy, erratic head movement, computer control errors, frayed belts and cables, fluid seepage from hydraulic and lubrication cylinders, overheating elements, and inconsistent finish smoothness on several workpieces. While some breakdowns are inevitable even with the best maintenance, addressing these warning signs can avert a catastrophe. These measures should adhere to a defined policy by a supervisor who encourages prompt symptom reporting rather than systems- compromised equipment operation.

Q: What are the steps to cleansing a CNC Router for regular maintenance?

A: As highlighted earlier, proper cleaning is part of routine maintenance on the machine. To achieve this, first use compressed air to blow out loose sawdust and any other debris, bugs, etc. Exercise caution around sensitive parts of the machine. Mechanical means such as a shop vacuum cleaner with suitable attachments may be used for a finer cleanup. Surfaces exposed should be wiped with microfiber clothes become free from residue. For exposed surfaces, use precision rail cleaners recommended by the manufacturer. Carefully clean and inspect tool holders and collets. Clean all components of cooling systems and examine fluids. For machines with vacuum pumps, ensure that dust collection systems are regularly emptied and filters cleaned. Always follow the manufacturer’s instructions regarding the cleaning of electronics, as they can be sensitive to certain chemicals.

Q: What specific maintenance does a Shapeoko or other hobby grade CNC router require?

A: Although compact in size, hobby-grade CNC routers such as Shapeoko do require attention to specific details of maintenance. Keeping V-wheels cleaned and properly tensioned against the rails is one of the maintenance aspects with attention to detail. Regular checkups and retightening of all belt drives is a necessity since these components are prone to stretching with use. The lead screws must be cleaned and lightly swabbed with appropriate oil. For Shapeoko, ensure it is done for the eccentric nuts controlling wheel tension on the mantles monthly. Regularly clean the control box cooling vents in order to avoid dust-related overheating issues. Unlike industrial machines, hobby grade routers tend to have more open unaprotected components and automation systems that are prone to dust infiltration and require more attention to cleaning, especially in dusty settings.

Q: In what way do you property the electrical parts of a CNC router?

A: Maintaining the electrical components begins with ensuring the control box is neat and devoid of dirt. Routinely check all cables for fraying, pinching, or any other forms of damage, especially those in motion with the machine. Verify the tightness of connections, as vibration may loosen terminals over time. Fans used in cooling and ventilation are to be free from obstruction. Furnish the electrical enclosures with low-pressure compressed air, but only after completely shut down the equipment. Compressed air should be delivered at low-pressure to avoid damaging enclosures. Sensitive electronics require surge protection. If the surrounding is humid, the use of a dehumidifier will be appropriate to placed close to the machine to eliminate those problems. For advanced troubleshooting of control systems beyond basic upkeep, consult an experienced technician to avoid unnecessary harm to expensive control systems.

Q: Which preventive measures are effective in extending the life of CNC router parts?

A: In order to preserve the components of your CNC routers, consider these CNC preventive maintenance steps: Set up a lubrication schedule for all moving components to avoid corrosion and damage. balance proper tension levels for belts and chains; Keep the machine operating within its rated capacity. Ensure that chips are evacuated correctly to avoid clogging and abrasive wear. Ensure that coolant/cutting fluid ratios and fill levels are kept in balance; Reduce the area temperature to control thermal expansion and contraction issues. Replace Portions that are prone to damage before they actually get damaged. d. Instruct machine operators on proper commencement and termination techniques; Keep maintenance logbooks to evaluate the lifespan of components. With these practices, a technician can support longer service intervals and minimize the domino effect in which one failing component leads to the failure of several cascading interrelated components.