Whether you are looking to transform your workshop with a CNC machine or are thinking of getting one, you may be drowning in the plethora of options available out there in the market. Pricing, specifications, features – one look at everything and I’m sure that you’d feel like running in circles. Fret not – this guide is everything you need.

After reading this guide, you will be equipped with all the knowledge to make an informed buying decision for the ideal CNC machine suited for your home projects. Depending on whether you are a woodworking enthusiast, metalworks hobbyist, or someone who wishes to bring complex designs to life, you will find value added information about the various types of CNC machines available, their essential features, and tips tailored for novice buyers. You will be empowered by the information presented to you so that you can choose a machine aligned with your requirements, skill level, and financial budget. Let’s jump right into transforming your workshop!

What Types of CNC Machines Are Available on the Market?

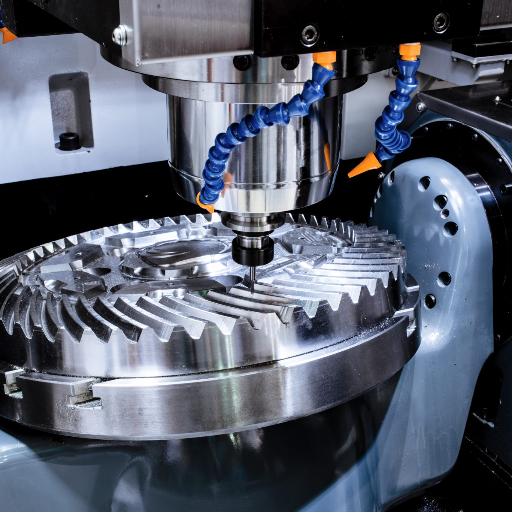

- CNC Mills: Perfect for workshops which helps to shape and cut materials like as metals, wood, and plastic.

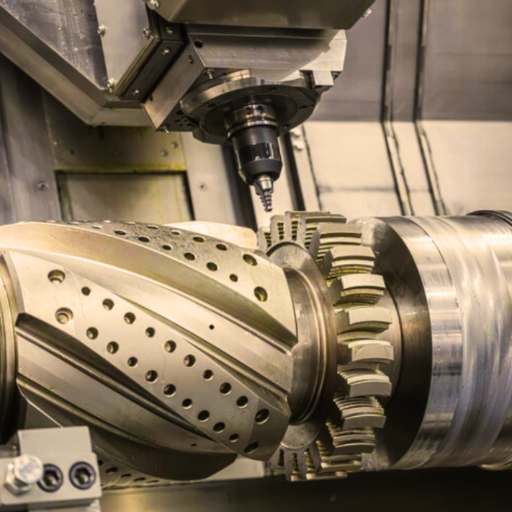

- CNC Lathes: Used to design parts which are cylindrical in nature like rods, shafts and fittings by rotating the work piece material.

- CNC Routers: Appropriate for large scale projects where carving and cutting of softer materials like wood and plastic is done.

- CNC Plasma Cutters: Used to slice electrically conductive materials such as steel and aluminum using a plasma torch.

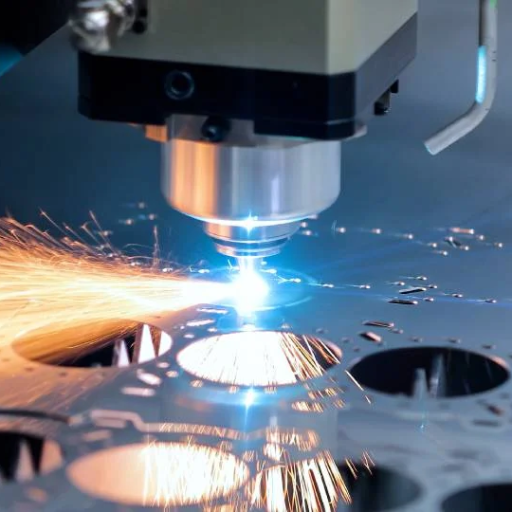

- CNC Laser Cutters: Used when exact cutting bronze, wood, acrylic and metals is needed as well as engraving using a focused beam laser.

Choosing between CNC Routers and CNC Mills: Key Factors

When trying to pick between CNC mills and routers, question yourself the importance of precision, scale of the project and type of material needed. For tougher materials like metals, CNC mills work best and they need to be precise. For softer materials which include wood, CNC routers do the job best, and all types of projects can be done from small to big. For different project needs, different tools are required so, always make sure to check all project requirements before making a tool decision.

CNC Lathes vs. Milling Machines: Which One Do You Need?

Choosing a CNC lathe and a milling machine requires knowing the functions of each for the CNC production process. CNC lathes are specialized for generating cylindrical components such as shafts, bushings, and threads. A workpiece is rotated against a stationary cutting tool, and material is removed with great speed and precision. Recent data shows that CNC lathes can achieve incredible tolerances of ±0.0001 inches, proving vital in automotive, aerospace, and medical device manufacturing where extreme precision is necessary.

The other type of machining that CNC milling machines do is completely different. While the workpiece is stationary, the cutting tool rotates, making it possible to accomplish more intricate features such as complex shapes, flat surfaces, slots, and holes. Modern CNC mills can have 3, 4, or even 5 axes which significantly increase flexibility. 5-axis milling machines are reported to reduce production time by 75% because of fewer setups and better access to tools.

When evaluating these two technologies, considering the type of material, geometry of the part, and how much production volume there will be is crucial. For designers, it may also be advantageous to evaluate the particular specifications of tool requirements so that the design and the engineering processes of a project gain the desired accuracy and speed.

Advancements in CNC Machining Technology

The development of CNC machining technology has been astonishing with the introduction of new 3-axis and 5-axis machines. Recent research indicates a growing adoption of 5-axis CNC machines in the aerospace, automotive, and medical device manufacturing sectors because these machines can create highly complex parts. An industry report from 2023 reveals that approximately 60% of intricate aerospace components are now produced with 5-axis systems, underscoring the technology’s remarkable efficiency with complex geometric features.

Furthermore, unlike 3-axis machines, 5-axis milling machines have demonstrated 25% reduction in waste material during machining processes. This is due to more effective and precise toolpath optimization that reduces secondary finishing operations. On the other hand, 3-axis machines are still indispensable for simple, repetitive, mass production jobs because they have lower operating costs and require less training time for the operators. For companies choosing between these technologies, it is important to consider the part shape and the quantity, but also look at the new directions and changes in technology development which are constantly modernizing CNC functionalities.

How Much Should I Budget for a CNC Machine?

The category, size, and capabilities of a CNC (Computer Numerical Control) machine play a major part in its pricing. For hobbyists, entry-level CNC machines that can handle small projects are priced from $2,000 to $10,000. Mid-range models designed for small to medium scale production fall between $20,000 and $75,000. Industrial CNC machines with high precision and advanced features start at $100,000 and can exceed $500,000. Always remember to factor in software, maintenance, and tooling in addition to the basing price.

Factors Influencing CNC Machine Costs

When factoring in expenses, additional costs to make a specific type of model need to be considered. One such model of importance is the material types and cutting capacities of the CNC machine. More basic models like beginner CNC machines are limited to less dense materials and softer woods, while advanced ones can handle production grade materials like aluminum, plastic, and even titanium.

Along with these, maintenance and operational expenses are important too. More advanced industrial grade CNC machines need periodic servicing that can cost several thousand depending on the complexity of the machine and the desired performance.

Modern CNC machines come with cutting-edge 5-axis operation or the integration of AI and software compatibility. While these features improve CNC efficiency and performance, they also raise the initial investment cost. For example, tools with AI automation capabilities can lend significantly higher to the price, but prove helpful within production lines.

The costs associated with standard prerequisites also bear consideration. Professional software often comes with a subscription fee ranging from $1,000 to $2,500 annually; while a single piece of high-quality tooling can range from $50 to $1,000. Keeping these factors in mind highlights the financial obligation involved in obtaining the machine.

Factors Influencing CNC Machine Performance

When evaluating the effectiveness of a CNC machine, precision, machining time, and assets utilized are some of the numerous parameters that must be taken into account. The accuracy of a machine tool greatly impacts rapid prototyping. For example, the level of accuracy required in the aerospace industry or precision medical device manufacturing is extremely high. Advanced tools in the banking sector automate various processes including electronic check processing, enabling speedy transaction settlements within milliseconds. Most modern CNC machines possess tight tolerances of ±0.001 inches, ensuring repeatability in multifaceted projects.

Moreover, a speed is significant in performance and is impacted by spindle power, feed, and material hardness variables. Greater spindle motor power, which often ranges from 2 to 30 horsepower, provides higher feed rates for acceleration in production schedules. However, excessively high speeds also impact accuracy and increase overall wear on the machine and tooling.

Another important aspect for determining the right CNC machine for a specific application is material adaptability. For instance, sophisticated 5-axis CNC machines can process a soft plastic as well as a hardened steel alloy, thus broadening a manufacturer’s scope. Higher strength materials often necessitate the use of better cutting tools like those made from tungsten carbide or diamond composites. While this improves production efficiency, it increases the cost of operations in the long run.

Along with routine maintenance and software upgrades, all these considerations add to the multifunctional performance capabilities of CNC machines.

CNC Machine vs. 3D Printing: Cost-Benefit Analysis

Both the cost and efficiency of CNC machines and 3D printing technologies have to be analyzed before determining the better suited option for a given application. Due to their precision and capability of machining parts from tough materials like metals and composites, CNC machines are well regarded in the machining industry. Although their investment can range anywhere from $5,000 for basic machines to over $500,00 for industrial setups, they tend to be more economical for high volume manufacturing due to exceptional durability and speed of production.

3D printers, as compared to CNC machines, have unparalleled cxpabilities when it comes to prototyping and customization. Unlike the CNC 3D machines, these are more costly, with basic models starting at $200 and industrial-grade models costing upwards of $100,000. Through additive manufacturing processes, there are no by-products generated within the process making CNC machining a sustainable alternative. Yet, due to the limitations of the printed materials’ mechanical properties, not only does 3D printing falls short in production rates, but it also struggles to perform in certain applications.

Recent statistics reveal the accelerating growth of both technologies. An industry report published in 2023 revealed that the global CNC machining market is anticipated to expand by 8% compound annual growth rate (CAGR) from 2023 to 2030, due to increasing demands from the automotive and aerospace industries. In the same context, the 3D printing industry is also projected to increase by 21% CAGR during the same timeline, particularly due to expansion in the usage in healthcare and consumer goods. Splitting project complexity, scalability, and material considerations efficiently is imperative to reducing the associated costs for businesses.

Both CNC machining and 3D printing are cost-effective solutions. Their contrasting attributes nurture the possibility of hybrid systems to maximize production efficiency for specific parts. A case in point, 3D printing enables fast turnaround of prototypes while other components are finished on CNC mills.

What Technical Specifications Should I Consider When Buying a CNC Machine?

- You should verify that the machine dimensions and cutting area are in agreement with the dimensions of the intended parts to be produced.

- Confirm that the machine can work with the materials that will be used, including, but not limited to metals, plastics, and wood.

- The selected equipment should guarantee to deliver the necessary tolerances of accuracy and precision.

- Select a spindle with the requisite speed and power to match the machining operations to be performed.

- Check that the CNC machine will use the design and programming software you intend to utilize.

- Take care to check both the initial purchase and long-term maintenance to ensure that the budget goals are met.

Sufficient Work Area and Machine Dimensions

Surface area as well as machine size, together with the workplace, remain as the most important reasons why businesses are getting into CNC machines as they enhance productivity. The machine dimensions must match the materials that you intend to work with, ensuring operational precision and accuracy. As a case in point, small projects such as engraving or prototyping can be carried out with smaller CNC machines which have a work area of 12 x 8 inches. In contrast, larger scale industrial CNC machines are frequently equipped with work areas greater than 48 x 96 inches to accommodate cabinetry and other large metal fabrication works.

Moreover, the footprint of the machine should also occupy the workspace. Hobbyists or small workshops can use compact desktop models, but factory floor space is often required for larger machines which have additional considerations such as ventilation and safety protocols. Also take into account how far the Z-axis can travel as this defines how thick the material is that the machine can work with. For general purposes, Z-axis capabilities commonly range from 4 and 12 inches, for dependenced, specialized variants can offer even higher clearances.

Optimally configuring the size and ergonomic positioning of the CNC machine in relation to other components of the workstation will assist in increasing productivity while reducing downtime related to material handling and workspace constraints. Choose a machine that not addresses the current requirements, but also provides flexibility for operational growth.

Considering Spindle Power, Torque, and Speed

The effectiveness, accuracy, and overall functionality of CNC machines are greatly influenced by spindle’s power, torque, and speed. Power, often stated in horsepower or kilowatts, measures the cutting energy available to the machine. Higher powered spindles are critical when cutting heavy duty materials, such as steel and titanium, to avoid performance issues like stalling. Softer materials like aluminum and plastics can usually accept lower spindle power without issues.

Spindle torque is a measure of rotational force and is just as important. High Torque spindles excel in low-speed fine detail work and tapping heavy material removal while low-torque spindles thrive at high speeds.

Operational efficiency alongside surface finish is impacted by speed, which is measured in revolutions per minute (RPM). CNC spindles can vary significantly in speed ranges, from low-RPM heavy cutting spindles (typically under 10,000 RPM) to high-speed spindles that can exceed 60,000 RPM, typically suited for small-diameter tools and delicate materials.

To foster the ideal performance of a machine, the harmonious relationship between power from the spindle, torque, and speed needs alignment with the intended application. For instance, a machine cutting thick stainless steel would require high torque at moderate RPMs, while micro-machining or engraving would necessitate ultra-high-speed spindles to achieve the desired results. Today, more sophisticated CNC machines come with variable speed control and torque monitoring systems, offering greater flexibility for specific tasks. Industry benchmarks indicate that tailoring spindle attributes to align with materials and cutting criteria has the potential to reduce cycle machining times by 15-30% on average. This data highlights the value of well-designed configurations.

Control Systems – GRBL and Other Options Considered

One of the most popular options available today is GRBL because of how simple and adaptable it is. GRBL is an open-source CNC machine control software that is easy to use because it supports G-code, a standard form of CNC programming language. This makes GRBL accessible for not just hobbyists, but also professionals in the field. As mentioned earlier, GRBL runs on Arduino-based hardware which is affordable. In addition, GRBL performs real-time motion planning which makes it precise and reliable during operations.

Of course, other control system alternatives can be more advantageous depending on the complexity of the machine needs to be done. LinuxCNC, for example, is the best fit for industrial use because of its extensive customization capabilities and support for multiple axes of the machine. Also, Mach3 is still well-known to many users due to its simple interface, as well as incorporating complicated macro functions to enhance efficiency for automated machining.

There is data to show that using the appropriate control system offers great advantages. A case in point would be companies that use high-end controllers like siemens or Fanuc, which have reported an overall machine uptime of 20 to 25% due to faster diagnostics and troubleshooting support. Productivity and efficiency improvement makes operational CNC machining efforts less time dependent, which showcases how much modern control systems are relied on.

Which CNC Machine Matches My Project Needs?

- Material Type: Regardless of whether your material is metal, plastic, wood, or composite, choose a machine that is capable of working with them. In the case of tougher materials, be sure the machine has enough power and is built from sufficiently tough material itself.

- Precision Requirements: Especially for projects that are highly accurate, focus on picking machines with sophisticated control mechanisms that have tight tolerances.

- Production Volume: For projects with little scale such as prototypes, an entry-level affordable machine will do. For mass production, purchase industrial machines built to operate quickly and efficiently.

Best CNC Machines For Woodworking And Making Furniture

- X-Carve by Inventables- Ideal with precision and ease of use for hobbyist and small business owners for small to medium woodworking projects.

- Shapeoko CNC Router– This option is versatile and budget friendly which every woodworker looking for flexibility and dependability in design needs.

- BobsCNC Evolution Series- Outstanding value and excellent performance on wood makes this machine ideal for beginners and intermediate users.

- Axiom Precision AR Series- Built for professional-grade tasks, this machine excels in the precision needed as well as the sturdy construction required for heavy duty furniture making.

- ShopSabre CNC Router- The ShopSabre CNC Router is a premium choice for industrial-level woodworking because it provides unbeatable speed, accuracy, and durability during large-scale production.

The right machine to use for engraving and small projects

With the various factors of precision, user-friendliness, and multi-material usability, choosing a machine for smaller projects is of utmost importance. Smaller designs and intricate details can be performed with advanced, smaller models like the desktop CNC router or laser engraver. A great example is the xTool D1 Pro, a highly rated laser engraver that supports many materials, including wood, leather, and stainless steel, with flawless engraving accuracy of up to 0.01mm. In addition, its remarkable working speed of up to 24000 mm/min makes it suitable for time-sensitive projects.

The Glowforge Plus is one of the many engraving machines that strike a good value-for-money balance with its superior engraving depth of 0.5 inches on softer materials, including acrylic and hardwood, while still maintaining reasonable prices. Offering easy setup and operation while maintaining quality for both cutting and engraving, the device is ideal for hobbyists and small businesses.

For those who enjoy making metric comparisons, the latest models of engraving machines offer the best combinations of speed and precision. Some machines, for instance, come with upgraded light sources which enhance the clarity of marks made without affecting the throughput time. This marks increase in completion time while high quality outputs are still achieved. This is especially useful when detailed engravings are required for personalized items or when prototyping. Think, when making a choice, about the materials you will work with mostly, the scale, and the complexity of your projects so that the machine can fulfill specific requirements without compromise.

Factors Influencing Marking Efficiency in Laser Machines

The balance among several essential aspects like marking speed, compatibility of the material, and configuration of the machine determines optimal marking efficiency when laser machines are used. Marking speed is a result of the combination of laser frequency, wavelength, and scanning mechanism employed. For example, the latest galvo scanners make it possible to move quickly and accurately which leads to shorter cycle times while achieving precision for complex designs.

In addition, stainless steel, aluminum, and titanium metals usually have deeper engravings done to them, which requires a higher energy input. Softer materials, such as plastics, utilize lower power settings but have the potential to either warp or be burned. Fiber lasers, diode type lasers that are more precise than CO2 lasers, have shown marked improvements of up to 33% in their marking times on metals over CO2 lasers, due to marking electrochemically, chemically, or thermally, as opposed to electrically evaporating the materials.

The configuration of your laser machine also affects efficiency. AI technology is now finding its way into modern laser systems, as the software is designed to adjust and optimize its functions according to the user-provided project details. This helps brands bypass lengthy setup processes and improves consistent results, aka repeatability. With the use of customizable presets, operators can limit their downtime to 20% or more when working with numerous materials in a rapid sequence.

No matter what your interests or company goals are, with these points, one can easily ensure that the capabilities of laser machines whether for small-scale or industrial use, are fully utilized to deliver sharp, effective results that are accurate and efficient.

How Do I Assess CNC Machine Quality Before Purchasing?

- Build-quality factors: During the criteria outlining the check visit, consider the machine frame, the components used in the construction of the machinery, and its general build to avoid clashes with accuracy, longevity, and durability as well as precision.

- Checking criteria: Measure the level of tolerances the machine has against the tolerances that the proposed machine is supposed to work with.

- Ease of integration: Confirming pre-compatibility of the CNC machine with the other components of a given system, and more specifically with the hinged software, allows for unit functionality and alleviates integrative challenges.

- Warranty consideration: Check availability of customer care support alongside the coverage of the warranties with regard to the parts and servicing needs of the particular machine fabrication and assembly.

Credibility through reliability criteria: Check the reviews done on the machine or ask the machines industry professionals to get a professional take on the reliability versus performance ratio from years of using it.

Factors affecting the machinability of materials using a specific machine

- Quality of construction: Lack of machinery breakdowns and greater dependable wear time are presented among the constructions using durable materials including but not limited to cast iron and hardened steel.

- Maintenance requirements: Performing regular cleaning and lubrication to the subjects mentioned above will greatly aid prolonging the assisted machine’s period of life.

- Operational behavior: Following the prescribed surrounding environmental and load operative conditions eliminates unintentional dominant forces that stress the machine negatively.

- Durable parts: Subjecting the machine to some of the durable parts like tough motors or bearings aids in extending the multi-life of the machines.

The Impact of Laser Power on the Speed of Marking

The efficiency and what the marking processes involves is highly influenced by the power of the laser. Powerful lasers enhance the marking speed rate because adequate energy is supplied to interact properly with the surface of the material. To illustrate, in industrial settings, a 30W fiber laser is capable of achieving speeds between 500 mm/s to more than 2000 mm/s, depending on the type of material, depth of marking, and complexity of the design.

Balancing the increase in power with the laser’s thermal parameters is essential to avoid overheating or catastrophic surface destruction. For instance, stainless steel and aluminum require higher powers to achieve deep engravings than other metals, while nonmetals such as plastics and wood will char or warp under excessive power levels.

Advancements on laser technology introduced recently have added features for optimal power settings, enabling specific output energy for different materials and requirements of marking to be set with precision. As per insights from an industry report, improved laser performance has been integrated with cooling systems along with special software algorithms which ensure consistent results during variable power settings without compromising the quality of engraving.” With these developments, manufacturers can achieve high-speed, high-resolution markings while improving operational efficiency.

Important Considerations When Getting a Laser Engraver

As far as laser engraving machines are concerned, there are several aspects which, if evaluated carefully, will enhance the performance as well as effectiveness concerning your work. The engraving speed and precision is almost always the function of the laser power, which determines what kind of materials the laser can work with. A 20W to 30W fiber laser would be satisfactory for most metals and some plastics, whilst CO2 lasers are rather better in the range of 40W to 150W for wood, acrylic and leather.

Autofocus feature and real time monitoring have also emerged as important features. Autofocus guarantees that the laser beam is correctly aligned, which impacts the quality of the engraving ons uneven surfaces, Real-time monitoring systems, on the other hand, observe the performance and notify the user of possible defects which minimizes excess material use and downtime.

Another overriding consideration is the software compatibility of the machine. A self-explanatory software significantly boosts productivity and hurries up the process thanks to the scanners easy to operation. Configuration of the design for a particular material and setting enhances efficiency as well as output uniformity.

Finally, pay attention to the factors regarding the machine’s reliability and durability. As a rule of thumb, some industry standards say that good quality machines can maintain productivity for anywhere between 10,000 to 100,000 working hours before severe maintenance is needed, usually dictated by the laser source. Equally important for a seamless and lasting experience with the product is paying attention to warranty clauses and aftersales customer service.

Reference sources

- Study: Risk Assessment of CNC Machine Service Quality1

- Objective: To address the risks associated with CNC machine downtime and its impact on productivity and service quality.

- Methodology: The study applied the Analytical Hierarchy Process (AHP) to assess and prioritize risks in CNC maintenance. It integrated risk management techniques with CNC operations to develop a quantitative risk assessment model.

- Key Findings:

- Downtime risks significantly affect productivity and customer satisfaction.

- AHP proved effective in identifying and mitigating risks, enabling better decision-making for CNC machine maintenance.

- The study emphasized integrating risk management into CNC operations for improved efficiency and reduced disruptions.

- Study: A Comprehensive Solution Approach for CNC Machine Tool Selection3

- Objective: To develop a robust methodology for selecting CNC machines based on multiple criteria.

- Methodology: The study used the Best-Worst Method (BWM) to determine criteria weights and applied GRA, COPRAS, and MULTIMOORA methods for ranking CNC machine alternatives. It incorporated expert opinions to enhance decision-making.

- Key Findings:

- Cost, productivity, flexibility, and dimensions were identified as the most critical criteria for CNC machine selection.

- The proposed methodology provided reliable and consistent rankings, helping decision-makers choose the most suitable CNC machine.

- The study highlighted the importance of combining multiple decision-making methods for comprehensive evaluations.

- Top Mini CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: How do I know if I need a CNC machine?

A: A CNC machine is appropriate for you if you wish to automate precision tasks that involve cutting, carving or machining. Think through your workflow and the type of work you will be doing to establish a budget first. Examples of where CNC machines are helpful include scenarios with repetitive production of intricate parts and instances where automation is needed to achieve a high level of precision impossible with manual labor. In addition, those seeking to fabricate wooden furniture, flat wooden shapes, as well as cut metal pieces will greatly benefit in accuracy and efficiency from a CNC machine.

Q: What types of different machines are available in the CNC market?

A: The set of CNC machines differs to address specific needs, such as woodworking, soft materials, or lathing cylindrical objects. The main types are CNC routers, CNC mills which work with metals and rigid materials, CNC lathes, plasma cutters, laser cutters, and even 3D printers. There are also multi-function specialized machining centers. The choice of a machine depends on the material used and the design of the part which is going to be manufactured. Note that each machine has different levels of precision and speed as well as geometrical complexity that they are capable of achieving.

Q: What factors should I consider when selecting the right CNC machine?

A: Think of the following while selecting a CNC Machine, 1) Types of Material to be used Wouk, Metal, Plastic 2) Size of Projects (Work Envelope) 3) Accuracy needed 4) How many axis are needed (3-aixs, 4-axis, 5-axis) 5) The Amount of Money to be Spent (From Hobby Level to Industrial Grade Machinest) 6) Need to ensure the Software will integrate with existing CAD CAMsys 7) Space available on Shop Floor 8) Power requirements 9) How it will integrate with your existing machines. Balancing these factors will help you make the right choice for your specific requirements.

Q: To what degree does the type of machining center affect a CNC’s selection?

A: As it dictates the scope of your production capabilities, machining center type is critical. Both forms of VMCs (vertical machining centers) can serve most general applications. HMCs (horizontal machining centers) are better for chip evacuation and high-volume production. Multi-axis machining center is more flexible to configure for complex parts, but costs and learning curves are equally complex. Balance your choice with the complexity of the machine parts you intend to create, the levels of production you wish to achieve, and the shop floor space you have available. The efficiency, quality, variety of work undertaken, and strive performed are significantly hampered or enhanced by the choice of center.

Q: What should I know about CNC software if I’m new to CNC?

A: If you are new to CNC, paying attention to the software specifications is a must. CNC machines are programmed with CAD (Computer-Aided Design) software to create a digital blueprint of the component and CAM (Computer-Aided Manufacturing) software to prepare the instructions to be fed into the machine. Common examples are Fusion 360, ArtCAM, as well as several options without charge. Though a few simple designs may be implemented using G-code which can be manually entered, the majority of tasks will necessitate the usage of adequate CAD/CAM software. Think of your capabilities, as some systems are beginner-friendly. Also, check if your device and software will work together. Numerous companies provide basic supporting software with their machines, but more difficult tasks may require purchasing an advanced version.

Q: How do I now if I need a CNC with more than 3 axes?

A: The machine’s configuration will depend on the design’s details. Most 3-axis machines, (X, Y, and Z) are capable of performing flat work along with basic 3D carving. However, if you need to machine more complex parts, multi-sided features, or undercuts, you will need additional axes. A 4-axis adds rotation about one axis which is generally used for cylindrical work. 5-axis machines add a further rotational axis allowing for near unlimited approach angles. Don’t forget to consider your future requirements. For instance, although the LongMill is a great beginners CNC, catering for more advanced designs, many other options provide additional axes which comes with learning obstacles and cost increases.

Q: About how much would I need to set aside for a CNC machine?

A: The price of CNC machines starts from as low as $1,500 for entry-level desktop CNCs to hobbyists, while industrial grade machines cost northwards of $100,000. CNC machines are paired with tools and spinning motors, and their prices explode when advanced technology is integrated into the machine to make it self-operating, achieving a price range over 250 thousand. Used machines, alongside their lucrative pricing require validation for their functionality and availability for replacement parts, though still offer some savings. Of grave importance is assessing both the expense laden software and tools needed for the ventures, self maintaining machinery enables transfer of workshops. Invest infrequently and equip yourself with professional grade CNCs like that of 20 thousand. Maintain high speed precision and value durability when manufacturing. Exceeding total expenses of 7 pairs increase the initial range of small business grade machines.

Q: What is the process for checking a CNC machine’s compatibility with the materials I plan to use?

A: Start by evaluating the machine spindle’s power, torque, and speed range in relation to the material plastic and woodworking entry level machines are sufficient for. Metal cutting, on the other hand requires greater construction, higher power, and greater rigidity. Also consider cooling capabilities of the machine for materials subject to overheating during cutting and pay attention to the tool holding system to ensure it accommodates proper cutting tools for intended materials. For machines that require versatile material capability, choosing one specialized for the primary material is ideal. Before purchasing the machine, user reviews from similar projects and requesting a sample cut on intended materials can provide insight.

Q: Should I consider acquired CNC machines when making my first purchase?

A: Spending on a used CNC machine could directly benefit you, especially at the beginning, as it may maximize your initial investment, but it does come with quite a few drawbacks. Advantages can include a lower barrier to entry and a chance of acquiring a higher quality machine than what would be realistically possible if purchased new. On the flip side, obsolete Contoller problem, wear and tear on critical components, and inability to interface with modern software systems could pose some real challenges. Verify if the control system can process outputs from contemporary CAM software prior to acquisition; also check for availability of replacement components and service parts, and if feasible, inspect the unit while operational. Support and documentation also pose significant issues. Some users have leveraged services like Quora for Cross model-exchange documentation and were successful in seeking Others with model-specific expertise. If you’re a novice user, the support of the documentation might outweigh several advanced features of the machine.