Precision and reliability are at the heart of modern manufacturing, and laser cutting is a standout technology leading the way. Known for its ability to produce intricate, high-quality designs, laser cutting has become indispensable across industries ranging from aerospace to fashion. But how accurate is it really? This article dives into the fascinating world of laser cutting tolerances, breaking down the factors that influence precision and what they mean for your projects. Whether you’re a manufacturer, designer, or tech enthusiast, you’ll gain insights into how this advanced technology achieves unmatched accuracy and why it continues to set the standard in precision cutting.

What is Laser Cutting and How Does it Work?

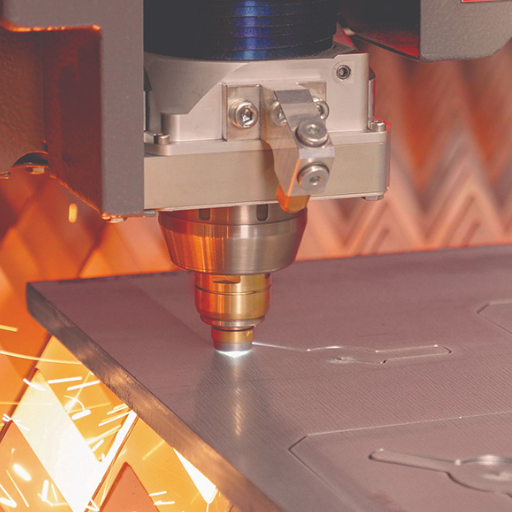

Laser cutting is a technology that uses a high-powered laser beam to cut through materials with exceptional precision. The process involves directing the laser onto the material, where the intense heat melts, burns, or vaporizes the surface, creating a clean and accurate cut. The laser is controlled by specialized software and guided by a computer system to follow the desired design or pattern. It is widely used for cutting materials like metals, plastics, wood, and textiles, offering a highly efficient and accurate solution for various industries.

Understanding the Laser Cutting Process

Laser cutting technology has revolutionized manufacturing and design processes by offering unparalleled precision, efficiency, and versatility. One of the standout advantages of laser cutting is its ability to create intricate and complex designs with accuracy up to 0.1 mm. This high level of precision reduces material waste significantly, making it a cost-effective choice for industries like aerospace, automotive, and electronics.

Additionally, laser cutting supports various materials, including metals, wood, acrylic, and textiles, all with minimal post-processing required. For instance, stainless steel cuts can maintain a smooth, burr-free finish, while textiles and acrylics benefit from sealed edges, reducing the need for further refinement.

Recent advancements in laser technology, such as the integration of fiber lasers, have further improved energy efficiency and cutting speeds. According to industry insights, fiber lasers now boast efficiency rates 2 to 3 times higher than traditional CO2 lasers, while also requiring 50% less maintenance.

Lastly, the automation potential of laser cutting systems, combined with modern CAD/CAM software, has enhanced scalability for high-volume production. This ability to handle large-scale operations seamlessly has cemented laser cutting as a vital tool in many industries, driving innovation and maintaining consistent quality.

Types of Laser Cutting Machines

- CO2 Laser Cutting Machines

CO2 lasers are among the most common types in the industry. They are highly efficient for cutting, engraving, and processing non-metallic materials such as wood, acrylic, plastics, and textiles. Utilizing a gas mixture of carbon dioxide, nitrogen, and helium, these lasers operate in the infrared spectrum, ideal for precise, smooth finishes. CO2 lasers generally have power outputs ranging from 25 watts to over 400 watts, depending on the application.

- Fiber Laser Cutting Machines

Fiber lasers are a newer technology known for their energy efficiency and speed. They employ optical fibers doped with rare earth elements, which amplify the light for high-intensity cutting. Fiber lasers excel in working with metals, including stainless steel, brass, aluminum, and copper, due to their increased absorption at shorter wavelengths. Power options often range from 1 kW to 12 kW, making them highly adaptable for a variety of materials and thicknesses.

- Crystal Laser Cutting Machines (YAG/YVO4)

These machines utilize neodymium-doped yttrium aluminum garnet (Nd:YAG) or yttrium orthovanadate (Nd:YVO4) crystals to produce intense, precise beams. Crystal lasers are best suited for detailed applications like engraving and cutting of metals and select ceramics. While offering excellent cutting quality, these lasers are less energy-efficient and tend to have higher maintenance costs due to the wear of the crystal.

- Diode Laser Cutting Machines

Diode lasers represent a compact, cost-effective solution primarily used for lightweight cutting and engraving tasks. Commonly applied in small-scale operations or hobbyist projects, they are ideal for materials like wood, paper, and some plastics. These machines often operate at lower outputs, typically between 2 watts and 10 watts, making them less suitable for heavy-duty industrial use.

- Hybrid Laser Cutting Machines

Hybrid systems combine multiple laser technologies, such as CO2 and fiber lasers, to create versatile machines capable of handling varied materials and tasks. These machines integrate the strengths of different types, offering precision, power, and efficiency for industries requiring diverse cutting and engraving functions.

The wide variety of laser cutting machines ensures that industries can select the best tool tailored to their unique materials, project demands, and desired outcomes.

The Role of Laser Beam in Cutting

The laser beam is a highly focused and intense source of light energy that serves as the core component of laser cutting technology. By concentrating energy into a minuscule area, the laser beam generates extreme heat capable of melting, vaporizing, or burning through various substances with exceptional precision. Modern advancements have enhanced the efficiency and accuracy of laser beams, enabling them to cut through materials such as metals, plastics, glass, and even delicate substances like paper and textiles.

For example, CO2 lasers, which operate at a wavelength of 10.6 microns, are highly effective for non-metallic materials, while fiber lasers with shorter wavelengths around 1 micron excel at cutting reflective metals like aluminum and brass. Today’s laser cutting systems can achieve cutting speeds of up to 20 m/min, and power outputs reaching several kilowatts make it possible for industrial machines to tackle materials of varying thicknesses, from thin sheets to dense steel plates up to 30mm thick.

A distinctive feature of laser beams is their ability to produce clean, smooth edges with minimal thermal distortion. This makes them an indispensable tool in industries requiring high levels of accuracy, such as aerospace, automotive, and medical manufacturing. The incorporation of computer numerical control (CNC) systems further enhances the capabilities of laser beam cutting, allowing for intricate designs and efficient, automated workflows. Continuous innovation in laser technology ensures its role remains vital in meeting complex industrial needs.

What are the Standard Laser Cutting Tolerances?

With respect to ease of material, thickness, and the machine utilized for the cutting, the standard tolerances for laser cutting is within ±0.1 mm or ±0.2 mm. More advanced machines can ensure tighter tolerances and greater accuracy. It is important to note that while the manufacturer’s specifications provide a baseline, tolerances may change depending on the specifications of the given project. Because of this variability, it is recommended to consult the provider so that the exact specifications can be completed accurately.

Defining Laser Cutting Tolerance

Laser cutting tolerance is a critical parameter in modern manufacturing processes, influencing both the functionality and quality of the final product. Precision levels for laser cutting can vary depending on key factors including material type, thickness, machine technology, and design complexity. Generally, standard laser cutting machines provide tolerances around ±0.1 mm, while advanced technologies, such as fiber lasers, can achieve even tighter tolerances, reaching as low as ±0.05 mm in ideal conditions.

Material properties significantly affect tolerance outcomes. For instance, metals like stainless steel or aluminum are typically cut to higher precision compared to softer or flexible materials like plastics or composites, which may present challenges due to heat distortion or material inconsistencies. Similarly, thinner materials often allow for superior accuracy compared to thicker, denser counterparts.

Advancements in laser cutting technology have also introduced real-time monitoring systems and computer numerical control (CNC) integrations. These innovations enhance accuracy by compensating for minor variations in material or environmental conditions, supporting industries such as aerospace, medical device manufacturing, and high-end automotive sectors where exact tolerances are non-negotiable.

For projects requiring extreme precision, manufacturers often recommend extensive calibration of equipment and additional quality checks, which contribute to consistency and adherence to specified tolerances. This emphasis on detailed control ensures laser cutting remains a reliable and efficient solution, even for the most complex industrial applications.

Factors Influencing Tolerance in Laser Cutting

The tolerance achievable in laser cutting is influenced by multiple factors, which can collectively determine the precision and quality of the finished output. Below are some of the key factors and associated data that highlight their impact:

- Material Type and Thickness

The type of material being cut plays a crucial role in determining achievable tolerances. Metals like stainless steel typically allow for tighter tolerances compared to softer materials like plastics or wood. Thickness is equally important—materials under 6 mm often yield higher precision, with tolerances as tight as ±0.001 inches in some cases. However, as material thickness increases, tolerances can widen due to beam diffusion and heat-affected zones.

- Laser Power and Beam Quality

Higher laser power results in better cutting efficiency but may compromise precision in thinner materials if not carefully calibrated. Additionally, beam quality, measured by factors such as M² value, directly impacts edge sharpness and dimensional accuracy. Modern high-power lasers with superior beam quality have demonstrated consistent tolerances of ±0.005 inches, even on intricate geometries.

- Cutting Speed

The speed at which the laser moves influences the size of the kerf (cut width). Slower speeds facilitate cleaner and more precise cuts by reducing material distortion. For example, to achieve tolerances under ±0.002 inches in aerospace applications, manufacturers often optimize cutting parameters to balance speed and heat application.

- Thermal Factors

Heat-induced expansion or contraction of the material can cause deviations in the finished cut. Advanced cooling systems, coupled with optimized cutting techniques, help mitigate these effects, ensuring consistent results even in temperature-sensitive projects.

- Equipment Calibration and Maintenance

Regular equipment calibration significantly enhances precision levels. Studies indicate that poorly maintained lasers can deviate by up to ±0.02 inches, while properly maintained systems maintain much tighter tolerances. Routine maintenance ensures the optical system and movement mechanisms remain in peak condition.

- Automation and Software Precision

The advent of CNC-controlled laser cutting machines equipped with high-precision algorithms allows for improved control over complex designs. For instance, smart nesting software optimizes material usage and improves part alignment, minimizing edge inconsistencies and enhancing overall accuracy.

By understanding and managing these factors, manufacturers can push the boundaries of what’s achievable with laser cutting, offering consistently high-quality results across diverse industrial needs. Precision and tolerance continue to evolve with advancements in technology, making laser cutting indispensable in industries like aerospace, medical devices, and electronics.

Comparing Tight Tolerances in Various Materials

The ability to achieve tight tolerances varies significantly depending on the material being processed, with factors like material composition, thickness, and thermal properties playing a crucial role. Metals such as stainless steel and aluminum are widely favored for laser cutting due to their consistent density and thermal conductance, which enable tolerances as tight as ±0.005 inches or even finer in optimal conditions. Aluminum, for instance, is particularly known for its ability to withstand precise machining without significant warping, even at higher thicknesses.

Ceramics and composites, on the other hand, present unique challenges due to their brittle nature and non-uniform composition. Advanced laser systems, such as femtosecond lasers, have been developed to address these challenges, delivering tolerances within ±0.002 inches for intricate applications in industries such as aerospace and electronics. However, processing these materials often requires specialized approaches and additional finishing treatments to eliminate microfractures.

Plastics and polymers, while offering flexibility, can pose issues with melting or deformation under high-intensity lasers. For materials like acrylic or polycarbonate, tolerance levels typically range between ±0.01 to ±0.02 inches, depending on the material thickness. These variations underscore the importance of optimizing laser power and cutting speeds to maintain precision without compromising structural integrity.

When dealing with exotic materials like titanium or nickel-based alloys, commonly used in medical and aerospace applications, laser cutting systems have demonstrated remarkable accuracy. With cutting-edge technology, tolerances as fine as ±0.0005 inches are achievable, especially for thin sheets, ensuring compliance with stringent industry standards for components like surgical instruments or jet engine parts.

Ultimately, material-specific characteristics must be meticulously considered when striving for tight tolerances in laser cutting. Technological advancements continue to reduce these limitations, pushing the boundaries of precision across a broader range of materials to meet the growing demands of diverse industries.

How Does Material Type Affect Laser Cutting?

Types of materials affect significantly on the quality and efficiency of laser cutting. Metals like aluminum and steel cut quite cleanly because of their uniform composition and reflective properties. Non-metal materials such as plastics and composites have varying responses depending on their density, melting points, and thermal conductivity. Softer materials are usually faster to cut, whereas thicker and harder materials require slower speeds or more powerful lasers. Additionally, some materials like copper may reflect incoming laser energy and pose problems as they can diffuse it through the work piece. These features must be understood to optimize cutting performance and achieve results across applications.

Impact of Sheet Metal Thickness

The efficiency, and more importantly, the quality of the laser cutting processes are impacted greatly by the thickness of the material. These thin sheets with a thickness of 6mm and below are easy to cut and have less laser power, thus resulting in speedier cuts without losing precision. An example would be the cutting of 1mm thickness stainless steel sheets that takes place at a rate of 6000 mm/min using 2kW lasers.

On the opposing end, the thicker a sheet, the more laser power is required to cut cleanly through the metal. An example of this would be cutting a 10mm mild steel sheet that could need 6kW of laser power while only reaching 1000 mm/min when cutting. The increased thickness can also result in a rougher surface finish that requires further polishing if a smooth end result is desired.

The relation of the laser strength and thickness of the material also determines the heat affected zones (HAZ). Metals that are thicker tend to have a larger HAZ which can negatively affect the mechanical strength of the material around the cut edge. This accentuates the consideration of changing the cutting features like the power, speed, and assist gas pressure for the sheet metal’s thickness to reduce defects during operations.

In the end, knowing how sheet metal thickness correlates with the laser cutting process is crucial for the efficiency of any manufacturing operation, since it improves accuracy, minimizes waste, and increases the speed of production.

Differences in Metal Laser Cutting and Non-Metal Cutting

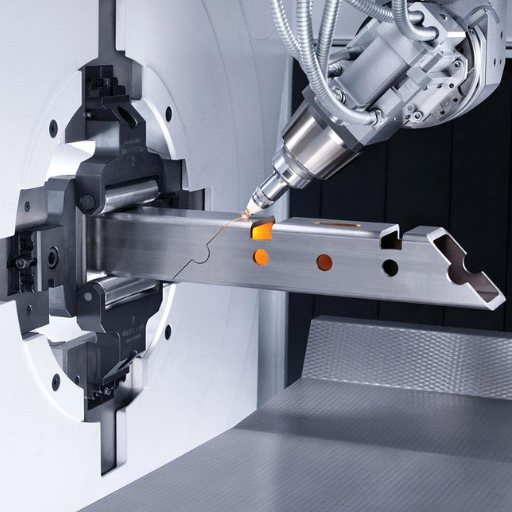

Metal laser cutting and non-metal cutting differ significantly due to the properties of the materials and the technologies required to achieve optimal precision and efficiency. Metals, such as steel, aluminum, and brass, require lasers with high power output and greater energy density to penetrate their dense molecular structure. Fiber lasers are commonly used for metal cutting due to their superior cutting speeds, consistency, and ability to handle reflective surfaces. For example, a 2 kW fiber laser can effectively cut stainless steel up to 6mm thick, while a 6 kW fiber laser can process even thicker sheets with high precision.

Non-metal materials, on the other hand, such as wood, acrylic, or plastic, are significantly less dense and do not require as much laser power. Carbon dioxide (CO2) lasers are widely used for non-metal cutting, as they offer a smoother and cleaner finish on materials like rubber or organic compounds. These lasers generally operate at a wavelength (~10.6 µm) that is well-suited for materials prone to burning or melting. For instance, acrylic sheets up to 20mm thick can be cut efficiently with a 150W CO2 laser, providing crisp edges without discoloration.

Another key distinction lies in the auxiliary gases used during cutting. Metal laser cutting often utilizes oxygen or nitrogen to enhance the cutting process by either increasing oxidation for faster cutting or creating a barrier to reduce thermal impact. Non-metal cutting usually relies on air or no gas at all, as the materials are more easily processed without additional chemical reactions. Additionally, the cooling requirements for non-metals are generally lower compared to metals, thanks to their lower thermal conductivity.

Ultimately, the choice between metal and non-metal laser cutting systems depends on the material’s composition, desired finish quality, thickness, and production requirements. Advancements in laser technology continue to broaden the capabilities of both processes, offering greater efficiency and versatility for various industries.

Choosing the Right Type of Laser for Different Materials

When selecting the right type of laser for a specific material, understanding the properties of both the laser and the material is essential to achieving precise and efficient outcomes. Different laser types, such as CO2, fiber, and Nd:YAG lasers, are suited to specific applications due to their varying wavelengths and power capacities.

CO2 Lasers: These lasers are highly effective for cutting and engraving non-metal materials like wood, glass, leather, and plastics. CO2 lasers operate at a wavelength of 10.6 microns, making them ideal for materials that absorb infrared light well. For example, industrial-grade CO2 lasers can cut through wood of up to 20-30 mm thickness with precision, making them popular in industries such as signage and packaging.

Fiber Lasers: Designed for metals, fiber lasers are known for their high power and efficiency. They operate at a wavelength of approximately 1.06 microns, enabling them to cut through reflective metals like aluminum, copper, and brass with minimal energy loss. With cutting speeds up to 5 times faster than CO2 lasers on thinner metals, fiber lasers are a mainstay in the automotive and aerospace industries for high-speed, precision metalwork.

Nd:YAG Lasers: Known for their versatility, Nd:YAG lasers are suitable for both metals and ceramics. Their short pulse durations and high peak intensities make them ideal for laser engraving, marking, and micro-machining. Industries such as electronics manufacturing rely on Nd:YAG lasers to engrave QR codes or create detailed patterns on circuit boards.

Key Considerations and Data

The laser’s power output, beam quality, and material thickness play a significant role in determining efficiency and quality. For instance, CO2 lasers with a power level of 150 watts are sufficient for engraving and cutting thinner materials, while fiber lasers may operate in the 1-6 kW range to cut through metals up to 30 mm thick.

Additionally, advancements in dual-source laser machines now allow for combined CO2 and fiber laser capabilities, providing manufacturers with the flexibility to handle varying materials on a single platform. For example, dual-source systems are capable of processing both 25 mm steel sheets and 10 mm acrylic panels within the same workflow, significantly improving operational efficiency.

By matching the right laser technology to the material’s properties and production requirements, businesses can ensure optimal performance, minimize waste, and maximize cost-effectiveness. Such informed decisions not only enhance productivity but also open new possibilities in precision manufacturing.

What Factors Affect Laser Cutting Accuracy?

Several factors influence the accuracy of laser cutting:

- Material Type and Thickness: Different materials respond differently to laser cutting. Thicker materials may result in wider kerf widths and reduced precision compared to thinner materials.

- Laser Power and Wavelength: The laser’s power and wavelength must suit the material being cut. Proper calibration ensures a clean, precise cut without unnecessary melting or charring.

- Focus and Beam Quality: Correctly focusing the laser beam is essential for sharp and detailed cuts. High beam quality results in a consistent energy distribution, enhancing accuracy.

- Cutting Speed: The balance between cutting speed and laser power affects the precision and quality of the cut. Too fast can lead to incomplete cuts, while too slow can cause thermal damage.

- Assisted Gas Selection and Pressure: The type and pressure of assisted gas, such as nitrogen or oxygen, help clear molten material from the cutting area and improve edge quality.

- Machine Stability and Maintenance: Regular maintenance and a stable, vibration-free machine ensure consistent performance and accuracy over time.

By managing these factors effectively, businesses can achieve precise laser cutting results tailored to their production needs.

The Influence of Laser Power and Cutting Speed

When it comes to the influence of laser power and cutting speed, I believe both aspects must be carefully adjusted to ensure optimal performance. Higher laser power is effective for cutting thicker materials, but it must be controlled to avoid overheating or damaging the edges. Similarly, cutting speed directly affects the quality of the cut; moving too quickly can leave rough edges, while moving too slowly might cause excess heat absorption. A precise balance between these two factors is critical for achieving clean, accurate cuts in any application.

Importance of Cutting Parameters and Spot Size

When it comes to the importance of cutting parameters and spot size, I believe they play a fundamental role in the precision and quality of laser cutting. Adjusting parameters like power and speed ensures that the cutting process is efficient and produces clean results without damaging the material. The spot size is equally critical, as it directly affects the focus and intensity of the laser, ultimately determining the accuracy of the cut. By carefully calibrating these factors, I can achieve optimal performance tailored to each specific application.

How Laser Machines Ensure Dimensional Accuracy

To ensure dimensional accuracy with laser machines, I focus on precise calibration and regular maintenance. This involves aligning the laser optics meticulously and routinely testing the machine’s performance to detect and correct any deviations. I also make use of advanced software to program precise cutting paths and leverage features like auto-focus, which ensures consistency across varying material thicknesses. By combining these techniques, I am able to achieve exceptional accuracy and reliable results for every project.

How to Achieve High Precision in Laser Cutting?

Achieving high precision in laser cutting requires a combination of proper machine setup, quality materials, and precise programming. Start by ensuring the laser machine is clean, well-calibrated, and regularly maintained. Investing in high-quality materials with consistent thickness is essential for reliable cuts. Use advanced software to program accurate cutting paths and optimize settings like power, speed, and focus to suit the specific material. Additionally, test on sample pieces beforehand to confirm the settings and make adjustments if necessary. Following these steps guarantees optimal precision and consistent results.

Optimizing Laser Cutting Technology for Precision

To optimize laser cutting technology further, leveraging modern advancements and best practices is crucial. One effective approach is incorporating automatic focusing features in laser machinery. Automatic focusing ensures precision by dynamically adjusting the laser’s focal point, which is particularly beneficial when working with varying material thicknesses or intricate designs. For instance, automatic focus can reduce the margin of error by up to 30% compared to manual adjustments, empowering users to achieve cleaner cuts consistently.

Another significant improvement comes from integrating real-time monitoring systems. These systems utilize sensors and cameras to analyze the cutting process as it happens, detecting anomalies such as overheating or material misalignment. This proactive approach minimizes waste and increases efficiency, with studies showing that manufacturers reduce material costs by approximately 20% by adopting such monitoring technology.

Additionally, beam shaping technology has emerged as a noteworthy innovation. This technique manipulates the laser beam’s profile to concentrate energy more effectively, allowing for smoother cuts even on highly reflective materials like aluminum or brass. This advancement enhances compatibility across diverse industries, including aerospace and electronics, where precision is paramount.

Finally, utilizing software-driven optimization tools enhances workflow efficiency. This software analyzes designs for feasibility and suggests adjustments to reduce cutting time or material waste. Combined with algorithms that predict wear-and-tear on machinery, companies can extend equipment lifespan while maintaining accuracy, saving up to 15% on operating costs annually.

By integrating these techniques, laser cutting technology becomes more efficient and reliable, catering to precision-driven industries with unparalleled accuracy and productivity.

Role of Fiber Laser Cutting Machines in Precision

Fiber laser cutting machines have revolutionized precision-driven industries by delivering unmatched accuracy and efficiency. Their ability to produce cuts with tolerances as tight as ±0.001 inches makes them indispensable in fields like aerospace, automotive, and medical device manufacturing. Furthermore, the advancement of high-power fiber lasers, such as those operating at 10 kW and beyond, has significantly improved cutting speeds and reduced cycle times, enabling manufacturers to handle thicker materials like steel, aluminum, and stainless steel with ease.

Notably, these machines are designed for energy efficiency, often consuming up to 50% less energy compared to traditional CO2 lasers. Additionally, their maintenance requirements are minimal, as fiber lasers have fewer moving parts, translating to up to 20,000 operational hours before significant servicing is needed. Coupled with automation and intelligent control systems, modern fiber laser cutters can optimize material usage, reduce waste by up to 30%, and adapt to intricate designs with consistency.

With growing market demand for clean and efficient manufacturing processes, fiber laser cutting machines also play a key role in sustainability by reducing emissions and scrap. Businesses adopting this technology report enhanced production capabilities, reduced operational costs, and a robust return on investment, positioning fiber laser technology as a crucial component of modern precision manufacturing.

Techniques for Precision Laser Cutting

Precision laser cutting involves a series of advanced techniques that ensure accuracy, efficiency, and high-quality outputs. One widely used method is gas-assisted laser cutting, where a focused laser beam is combined with an assist gas, such as oxygen, nitrogen, or compressed air, to enhance the cutting process. Oxygen aids in reactive cutting, increasing speed for thicker materials, while nitrogen ensures clean edges by preventing oxidation, particularly useful for stainless steel or aluminum.

Another key technique is pulsed laser cutting, ideal for intricate designs and materials sensitive to heat. By delivering laser energy in pulses rather than a continuous beam, this approach minimizes heat-affected zones (HAZ) and reduces material deformation. This technique is often employed in industries like medical device manufacturing and electronics where precision is paramount.

Beam delivery enhancements, such as using adaptive optics and dynamic beam shaping, provide further refinement in cutting capabilities. These innovations enable consistent cutting performance even on uneven or reflective surfaces, improving accuracy and reducing material waste.

Data from industrial reports highlight that modern fiber laser technology achieves cutting speeds up to 20 meters per minute on thin materials with tolerances as tight as +/- 0.01mm. This high-speed accuracy is combined with cost efficiency, as these systems consume 50% less power compared to older CO2 laser technology while providing superior cuts.

Lastly, automation in laser cutting has revolutionized production workflows. Advanced software integration enables real-time monitoring, predictive maintenance, and accurate nesting of parts for minimal material waste. Businesses leveraging these technologies report up to a 30% increase in productivity and significant reductions in lead times, underscoring the importance of adopting cutting-edge precision techniques.

Reference Sources

-

Experimental Assessment of Tolerances for Laser-Cut Steel Joints (2017)1:

- Focus: Investigates tolerance optimization for laser-cut steel joints, particularly in circular hollow sections (CHS) and I-beam connections.

- Key Findings: Laser cutting improves precision and reduces fabrication time, enhancing workplace safety and automation. The study emphasizes the importance of tolerance optimization for efficient fabrication.

- Methodology: Part of the LASTEICON project, this research used experimental setups to evaluate dimensional tolerances and joint quality.

-

Development of Laser Cutting Technology with High Surface Quality (2019)2:

- Focus: Explores thermal cutting technology for achieving high-quality surfaces in S235JR steel and AW-5754 aluminum alloy.

- Key Findings: Cutting speed significantly impacts surface roughness and perpendicularity tolerance. Mathematical models were developed to optimize cutting parameters for different materials and thicknesses.

- Methodology: Experimental tests were conducted to determine optimal cutting parameters, integrating findings into automated systems for consistent high-quality results.

-

Experimental Investigation of Industrial Laser Cutting (2020)3:

- Focus: Examines the effects of material type, thickness, cutting speed, and gas pressure on kerf quality using CO2 lasers.

- Key Findings: Identifies optimal cutting conditions for materials like aluminum alloys, low-carbon steel, and stainless steel. The study highlights the role of process parameters in achieving precise kerf geometry and surface quality.

- Methodology: A systematic experimental design approach was used, validated through Analysis of Variance (ANOVA).

- Top CNC Fiber Laser Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What factors affect the accuracy of laser cutting?

A: The accuracy of laser cutting is influenced by several factors, including the power of the laser, the type of laser head used, the maintenance of laser cutting equipment, and the specific laser settings. Additionally, the precision of laser cutting can be affected by the material being cut and the speed at which the cutting head operates.

Q: How does laser cutting precision compare to traditional cutting methods?

A: Laser cutting generally offers higher accuracy compared to traditional cutting methods like mechanical or plasma cutting. The precision of laser cutting is due to its ability to focus intense energy on a small area, allowing for clean and precise cuts with minimal material distortion.

Q: What is meant by ‘tolerance levels’ in laser cutting?

A: Tolerance levels refer to the permissible limits of variation in a physical dimension. In laser cutting, this relates to how closely the dimensions of the cut parts match the specified measurements. High-quality laser systems can achieve tight dimensional tolerances, making them ideal for applications requiring precise dimensions.

Q: Are there misconceptions about laser cutting accuracy?

A: Yes, there are common misconceptions about laser cutting, such as the belief that all laser cutters deliver the same accuracy or that they can cut any material with equal precision. In reality, different laser cutting methods and equipment can yield varying results, and material properties can affect accuracy.

Q: Can different laser cutting methods impact accuracy?

A: Absolutely. Different laser types, such as CO2, fiber, and UV laser machines, have unique characteristics that can impact cutting precision. The choice of laser technology should be based on material type and desired part accuracy.

Q: How do laser cutting services ensure high accuracy?

A: Laser cutting services maintain high accuracy by using modern laser cutting machines, regularly maintaining cutting equipment, and employing skilled operators who can optimize laser settings for each job. Regular calibration and maintenance of laser systems are crucial for ensuring consistent performance.

Q: What role does the power of the laser play in accuracy?

A: The power of the laser is critical in determining the cutting capability and speed. While higher power can lead to faster cutting speeds, it must be carefully controlled to avoid compromising the precision of laser cutting. Proper power settings help achieve accurate laser cutting results.

Q: Why is maintenance of laser cutting equipment important for accuracy?

A: Regular maintenance of laser cutting equipment is essential for keeping the laser head and other components in optimal condition. Proper maintenance helps prevent issues like misalignment or wear, which can affect cutting precision and the overall quality of the cuts generated by the laser.

Q: How does the choice of cutting method affect accuracy in laser cutting?

A: The choice of cutting method, including the type of laser and specific cutting head configuration, can significantly affect accuracy. Each method has its advantages and limitations, and selecting the appropriate one for the material and desired outcome is crucial for achieving high accuracy.