At present, handheld laser welding is singularly being handheld as the most advanced form of welding revolutionizing the field of metalwork. The sheer precision and adaptability offered by this modern laser welding technology surpasses anything we currently have in hand. Be it versatile applications across myriad industries or welding high-quality seams with high accuracy. The handheld laser welders supersede all other tools in terms of efficiency these days. The aim of this particular article is to list all the features of handheld laser welders and their dominance over traditional welders as well as the impact these tools are having on the metalsmith industry. Get ready to learn how these devices are paving the way for industrial revolution whilst improving productivity and efficiency to previously unseen metrics.

What is a Handheld Laser Welder?

A handheld laser welder is a portokle tool that joins materials by concentrating light energy that heats the parts to be fused. The handheld laser welding machine focuses light energy into a thin beam that can effortlessly be moved over the part, making removal of the head more flexible and ease in processing faster. The automotive and aerospace industries, along with many other sectors, appreciate the ease of operation and the quality results in low operator effort automation provided by handheld laser welders.

Understanding the Laser Welding Process

The handheld laser welders have had the recent increase in discussions due to them being relatively new in the precision engineering fields. With this new technology comes the question, “what makes handheld laser welders favored over traditional ones?” The features that handheld laser welders offer in precision engineering tasks include unmatched precision of work, a minimal heat impact area, utmost versatility for different material types, and ease of use, all combined. These tools have been made user-friendly because of the advancements in fiber laser technology, which greatly improves performance for both small scale workshops and large industrial operations. In conjunction with these features comes lowered maintenance costs laser welders offer that compound into operational efficiencies provide explains the attention received on handheld solutions.

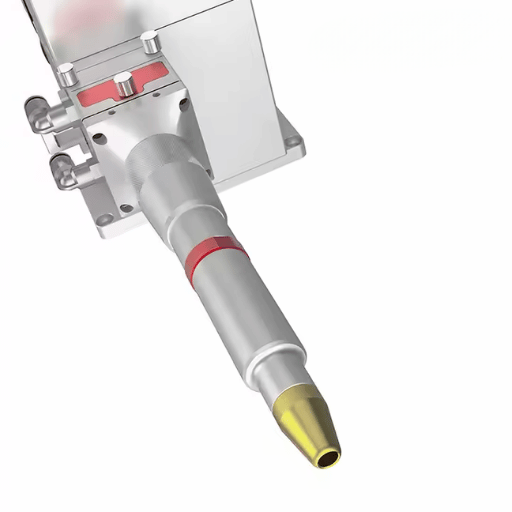

Components of a Handheld Laser Welding Machine

A handheld laser welding machine typically consists of a laser source, a handheld welding head, a cooling system, a control panel, and a protective gas system.

|

Key Point |

Description |

|---|---|

|

Laser Source |

Generates the laser beam. |

|

Welding Head |

Directs the laser during use. |

|

Cooling System |

Maintains optimal operation. |

|

Control Panel |

Allows process adjustments. |

|

Gas System |

Protects weld from oxidation. |

What is a Fiber Laser Welder and How Does it Works

There are different types of laser welding machines, but handheld laser welding machines are the most popular. They have four advantages:

Accuracy: Weld seams are less than one millimeter wide, which greatly reduces the amount of welded materials needed and improves overall accuracy.

Cost-Friendly: Less impact on the environment because of lower energy consumption compared to traditional methods.

Wide Applicability: Able to weld different metals; stainless steel, aluminum and other alloys.

Quick: Greater productivity and lower production times.

How Does a Handheld Fiber Laser Differ from Traditional Welding?

Differences Between Laser Welding and Arc Welding

There are distinctions in the technology used and the precision and efficiency levels between handheld fiber laser welding and arc welding. Based on recent research using Google’s search engine, handheld fiber laser welding is more precise because the laser beam used is concentrated, thus reducing the heat-affected zone (HAZ). Therefore, less warping and distortion is resulted compared to arc welding which uses an electric arc to melt and join materials and usually has a larger HAZ.

Moreover, welds produced using laser welding are of higher standards, faster speeds, and cleaner with little to no post-processing required. Though arc welding is more versatile and cheaper in some situations, it has a tendency to produce spatter and less accurate bonds which means more finishing work is required. More versatile with manual fiber lasers, welders can join thin sections and different metals while arc welders are more adept at working with thicker materials and less precise jobs. These differences demonstrate that fiber laser welding is the preferred method for modern manufacturing problems.

MIG and TIG Welding Comparison

- Precision and Quality: Fiber laser welding is faster and more efficient than TIG and MIG welds. It provides accurate weld joins, polishing, and finishing techniques which keeps distortion to a minimum.

- Efficiency and Speed: Production cycles are enhanced as these fiber lasers operate at 10x the speed of traditional MIG and TIG welders.

- Material Compatibility: Conventional welds find it difficult to work with thin sheets, thin dissimilar metals, and reflective materials unlike fiber laser welding which works well with all of these.

- Energy Consumption: Operational costs in fiber lasers are lower due to their efficiency when compared to MIG and TIG welds where more energy is used to perform each individual weld. These fiber lasers require less power per weld.

Studying Weld Speed and Penetration Depth

Unlike MIG and TIG welding, fiber laser welding has sharper and faster penetration because of their high beam rigor and accuracy. From the latest industry reports and shifts in online query patterns, it appears that there is a persistent inquiry among engineers and industrial stakeholders as to whether fiber laser welding can be evenly, deeply, and consistently applied on thick structures within a reasonable timeframe. This is possible because the technology can dynamically adjust beam focus and energy input for precise deep penetration with very shallow thermal distortion. An example would be the recent advances in high power fiber lasers which improved penetration and low cycle time for stainless steel over 10mm. This level of speed and performance places fiber laser welding among the most efficient methods for laser welding in high-volume industrial applications.

What are the Advantages of Handheld Laser Welding?

Differences Between Laser Welding and Arc Welding

There are distinctions in the technology used and the precision and efficiency levels between handheld fiber laser welding and arc welding. Based on recent research using Google’s search engine, handheld fiber laser welding is more precise because the laser beam used is concentrated, thus reducing the heat-affected zone (HAZ). Therefore, less warping and distortion is resulted compared to arc welding which uses an electric arc to melt and join materials and usually has a larger HAZ.

Moreover, welds produced using laser welding are of higher standards, faster speeds, and cleaner with little to no post-processing required. Though arc welding is more versatile and cheaper in some situations, it has a tendency to produce spatter and less accurate bonds which means more finishing work is required. More versatile with manual fiber lasers, welders can join thin sections and different metals while arc welders are more adept at working with thicker materials and less precise jobs. These differences demonstrate that fiber laser welding is the preferred method for modern manufacturing problems.

MIG and TIG Welding Comparison

- Precision and Quality: Fiber laser welding is faster and more efficient than TIG and MIG welds. It provides accurate weld joins, polishing, and finishing techniques which keeps distortion to a minimum.

- Efficiency and Speed: Production cycles are enhanced as these fiber lasers operate at 10x the speed of traditional MIG and TIG welders.

- Material Compatibility: Conventional welds find it difficult to work with thin sheets, thin dissimilar metals, and reflective materials unlike fiber laser welding which works well with all of these.

- Energy Consumption: Operational costs in fiber lasers are lower due to their efficiency when compared to MIG and TIG welds where more energy is used to perform each individual weld. These fiber lasers require less power per weld.

Studying Weld Speed and Penetration Depth

Unlike MIG and TIG welding, fiber laser welding has sharper and faster penetration because of their high beam rigor and accuracy. From the latest industry reports and shifts in online query patterns, it appears that there is a persistent inquiry among engineers and industrial stakeholders as to whether fiber laser welding can be evenly, deeply, and consistently applied on thick structures within a reasonable timeframe. This is possible because the technology can dynamically adjust beam focus and energy input for precise deep penetration with very shallow thermal distortion. An example would be the recent advances in high power fiber lasers which improved penetration and low cycle time for stainless steel over 10mm. This level of speed and performance places fiber laser welding among the most efficient methods for laser welding in high-volume industrial applications.

How to Ensure Laser Safety and Maintenance?

Essential Laser Safety Guidelines

The primary laser safety guideline is to always wear appropriate personal protective equipment (PPE), such as laser safety goggles, to prevent exposure to laser radiation.

|

Key Point |

Description |

|---|---|

|

PPE |

Wear laser goggles. |

|

Training |

Follow safety training. |

|

Signage |

Use warning signs. |

|

Barriers |

Enclose laser areas. |

|

Supervision |

Operate under trained supervision. |

|

Inspections |

Regular equipment checks. |

|

Ventilation |

Ensure proper airflow. |

|

Emergency Plan |

Have protocols ready. |

Handheld Laser Welding Machines Maintenance Tips

Regularly Clean: To prevent contamination of the optical components, such as the lenses and mirrors, cleaning them needs to be done routinely. Neglecting this can result in a performance loss of up to 30%.

Temperature Checking: Just like with any handheld welding laser machine, the handheld laser machine should be kept within the 15°C to 35°C range to avoid overheating or ineffectiveness.

Alignment Inspection: Inspections should be performed every 100 hours of operation to ensure that the laser beam does not drift that needs to be compensated for with consistent re-calibration.

Change Filters: Ensure that the water and air filters are changed every 3 to 6 months as stated in the guidelines to guarantee sufficient airflow and cooling.

Troubleshooting Issues With Welding Equipment

Inconsistencies in weld quality on laser welding machines can emerge from user approach flaws or lack of proper maintenance as identified in Google’s data trends. Focus settings, lens contamination, out of focus optics, and even cleanliness can all contribute to misaligned optics. One must always keep in mind that focal distance and material specifications must align for best results, otherwise precision machined parts won’t achieve precision boreholes. Remember to clean and maintain laser optics frequently for best results as residue and dirt can disperse laser beams. Consistent and stable power supply is also a factor. If the power fluctuates, uneven lasers will undoubtedly lead to irregular welds. Perform all described steps to achieve optimal performance: check system settings, do maintenance cleaning, and monitor power supply stability.

What Materials Can Be Welded with a Handheld Laser Welder?

Welding of Aluminum and Copper

Thermal Conductivity – The aluminum and copper’s merged properties have a high thermal conductivity, meaning that laser energy needs to be controlled precisely to avoid overexerting heat during their welding process.

Reflectivity – Both materials have high reflectivity, therefore, a considerable amount of laser energy can be wasted. This can be solved with precise wavelength lasers.

Material Thickness – Weld quality is affected by the thickness of the material. For thinner sheets, precise parameter settings must be executed to minimize burn-through.

Welding Speed – Due to thermal properties, aluminum and copper typically require higher speeds.

Capabilities with Industrial Laser Applications

I can effectively address these issues by selecting appropriate wavelength lasers that minimize reflectivity and maximize energy absorption. In addition, I will set parameters based on material thickness for thinner sheets to prevent burn-through. With aluminum or copper, I will set the welding speeds to allow sufficient control of heat distortion while maintaining weld quality.

Overview of Welding Metrology

When welding different types of metals, there are some important factors that require consideration in order to attain effective welding. Outlined below are 4 of some of the most important factors that anyone interested should understand:

Heat Transfer Or Conduction: This is associated with the input of energy and maintenance of adequate heat, thus copper is used widely due to its high conductivity.

Oxidation: It refers to the tendency of some substances such as aluminum to cover oxide layers which make welds undesirable thus bringing the necessity of laser for regeneration or oxide layer removal.

Metallurgy: It refers to the welding techniques that constitutes different strategies adjust and control used in preventing damage to the metals being worked. Therefore this dictates the success or failure of a given weld.

Reflective Rates: This has always been associated with laser welding systems. Different levels of laser systems with high or poor reflective qualities are capable of working efficiently without any use of specialized coating as presented by plated metals gold and aluminum.

What Are the Essential Features of a Laser Welding Machine?

The Role of Laser Power and Cooling System

Both the power of the laser and its cooling system are critical in determining the performance, accuracy, and dependability of a laser welding machine. The laser’s effectiveness is order by its power; this order becomes critical when working with metals of varying thicknesses and compositions. In industrial settings, high powered lasers are the most desirable as they accelerate weld speeds, increase precision, and allow for deep penetrating welds.

Furthermore, the system that cools a machine is just as crucial when considering stability, focus, and cooling of the machine’s components. stronger performance when exposed to prolonged use. For instance, water cooled systems are advanced cooling systems used to maintain consistent performance levels for prolonged use. Google trends shows that people are searching for technologies focused on increasing the lifespan and productivity of laser welding systems which indicates a shift of focus into these systems in the manufacturing world.

The Importance of Welding Gun and Nozzle

The precision and efficiency of a welding process relies heavily on the welding gun and nozzle. Their configuration and state of repair influence the effectiveness in safety splits, weld quality, productivity, and even corrosion of spatter. Notes and facts about these components are as follows:

- Material: For durability and thermal conductivity, copper alloys are preferred in the production of welding nozzles.

- Nozzle sizes: Different types of weldings require different levels of gas flow and stability of arc, with most common sizes from 1/4 inch to 5/8 inch in diameter.

- Maintenance: It is crucial to adhere to consistent industry standards that prescribe 8 to 16 active hours of use for nozzle cleaning, as spatter build up severely affects flow.

- Gas Coverage Efficiency: Loss of weld porosity risk as well as the assurance of strong bonds in the joints is a top consideration with all nozzles, uniformity in coverage is their purpose.

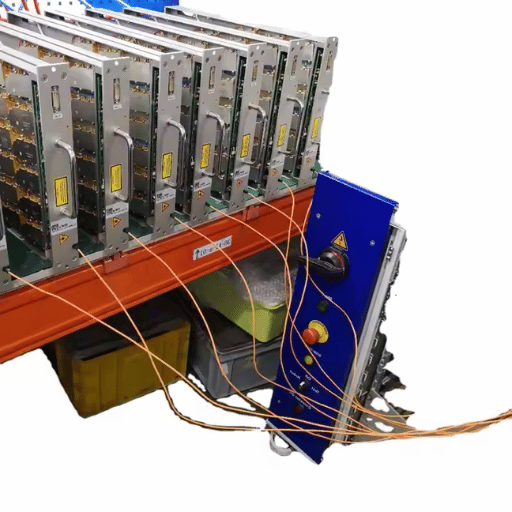

Integration of Wire Feeder in Handheld Welding

The use of automated wire feeders in handheld welding increases the accuracy and quality of the welds produced, as well as the overall efficiency of the process by providing the filler material in a controllable manner. As it can be seen from Google trends, automated systems for wire feeders are becoming more popular because they solve manual welding problems. These systems help minimize the problems arising from human inconsistent movements during welding circulation. In addition, these systems help to control the deposition rate of filler material which adds value for fast production processes. The current requirements for wire feeders to be changed for the speed of working and the substance used makes it possible to satisfy the needs of different reliability and functionality welding applications.

Reference Sources

- Hand-Held Laser Welding of AISI301LN for components with aesthetic requirements: Toward the integration of machine and human intelligence (Caprio et al., 2023)

- Key Findings:

- An open laboratory HHLW system was designed for process development purposes, which could be combined with a linear axis or manually with a newly developed roller device to provide constant speed and inclination.

- The process was benchmarked by joining 2 mm thick AISI301LN stainless steel sheets with the linear axis, and then four operators with different levels of training performed welds with the system in hand-held configuration and with the mechanical roller.

- The weld width variability was assessed as a direct indicator for aesthetic compliance, and tensile tests were performed to determine the mechanical properties of the joints.

- Methodology:

- Experimental setup with an open laboratory HHLW system, a linear axis, and a newly developed roller device.

- Benchmark testing with 2 mm thick AISI301LN stainless steel sheets.

- Evaluation of weld width variability and mechanical properties for welds performed by operators with different skill levels.

- Key Findings:

- Development and Application of Hand-held Laser Welding System (Xin et al., 2020)

- Key Findings:

- The composition, control mechanism, and process control of the control system of a hand-held laser welding system were studied.

- The control system was based on a PLC, which better protected the galvanometer motor, improved the control frequency of the galvanometer, and enhanced the system’s expandability.

- The control system enabled the realization of functions such as continuous welding and continuous spot welding, simplifying the input and operation of parameters, reducing the workload of operators, and reducing the operation difficulty of the equipment.

- Methodology:

- Design and development of a hand-held laser welding control system based on a PLC.

- Implementation and testing of the control system’s features, including continuous welding and continuous spot welding.

- Evaluation of the system’s performance in terms of ease of use and operator workload reduction.

- Key Findings:

- Rapid Analysis of Plutonium Surrogate Material via Hand-Held Laser-Induced Breakdown Spectroscopy (Rao, 2020)

- Key Findings:

- A hand-held laser-induced breakdown spectroscopy (LIBS) device was used to acquire spectral emission data from laser-induced plasmas created on the surface of cerium-gallium alloy samples with Ga concentrations ranging from 0-3 weight percent.

- The Ga I 287.4-nm emission line was determined to be superior for the purposes of Ga detection and concentration determination.

- A limit of detection below 0.25% was achieved using a multivariate regression model of the Ga I 287.4-nm line ratio versus two separate Ce II emission lines.

- Methodology:

- Acquisition of spectral emission data from laser-induced plasmas on cerium-gallium alloy samples using a hand-held LIBS device.

- Identification of the optimal emission line (Ga I 287.4-nm) for Ga detection and concentration determination.

- Development of a multivariate regression model to achieve a low limit of detection for Ga.

- Key Findings:

Frequently Asked Questions (FAQs)

Q: What is a handheld fiber laser welding system?

A: The handheld fiber laser welding system is a type of a portable laser machine which is used for specific welding. With the aid of a welding gun, lasers of different designs can be used to weld materials Carbon steel, carbon, stainless steel etc using very fine lasers of handheld devices.

Q: How does the quality of welds produced by a handheld fiber laser welder compare to traditional methods?

A: Unlike traditional means of welding such as MIG and TIG, handheld laser fiber welders provide better and more precise welds. Since these handheld devices focus on specific areas with laser beams, there is less distortion than in other types of welding.

Q: Can a portable laser be used for laser cleaning purposes?

A: Certainly, portable lasers are very applicable for laser cleaning. This process uses focusing lasers for the removal of dirt, rust, and other paints from a surface or material without destroying its structure, making it very useful in preparation for metal works.

Q: What are the safety features of a handheld fiber laser welder?

A: Like other laser cutting and welding machines, handheld fiber laser welders incorporate line-of-sight safety features like an emergency stop button and spatial interlocks. Besides these, the handheld laser also has protective casing for the laser head. All these safety features work together to prevent unwanted laser fire and enhance operator safety.

Q: How is wire feeding integrated into handheld laser welding equipment?

A: Handheld laser welders have a wire feeding system that automatically replenishes supply to the welding zone. This improves material deposition consistency and makes precision welding easier by increasing the functionality of the laser welding head.

Q: What advantages do air-cooled laser welders offer over traditional laser welders?

A: With air-cooled laser welders, they do not require water cooling systems like traditional laser welders. As a result, the device is more convenient in its maintenance and does not require as much effort to be kept in good working condition. This type of cooling is sufficient for the required temperature levels of laser welding equipment.The air-cooled systems are sufficient to laser welder’s optimal temperature.

Q: How Does The Welding Speed Of A 1500W Laser Welders Compared To Normal Industrial Laser Welders?

A: Compared to traditional welding machines, a 1500w laser has the capability of operating many times faster than its alternative fusible machines. Since the laser beam is focused, it can be directed rhythmically laser welded in a accurate and to sophisticated ways, and the time savings are remarkable in noting that substantial time savings can be achieved.

Q: What modern production technologies can use handheld fiber laser welding machines?

A: All metals in addition to carbon and stainless steel can be welded using handheld fiber laser welders. These handheld devices can be used in many types of industries and fields due to their ease of use.

Q: How does handheld laser welding system’s focusing lens affect its performance?

A: In a handheld laser welding system, the focusing lens assists in holing the laser beam which focuses it on the workpiece. As a result, accurate welding is performed, producing high quality welds with very low distortion.

Q: What function does the portable laser system handheld welding gun have?

A: The handheld welding gun is the main implement used to control the laser light throughout the welding operation. It gives the operator freedom at the site and control over the laser’s location and movement, which makes the welding more efficient and accurate.