The efficiency, precision, and versatility of fiber laser welding machines have changed the face of manufacturing and metalworking industries. If you are an engineer, production manager, or business owner wanting more insight into advanced welding tools, then having knowledge on fiber laser welding is crucial for remaining relevant in the ever-evolving industrial world. This article will comprehensively explain the functionality of these machines, their advantages over traditional welding techniques, and important factors to think about when choosing a system. In no time, you will understand why so many industries are gravitating toward fiber laser welding machines as their go-to option.

What is a Fiber Laser Welding Machine?

A fiber laser welding machine is a precision piece of equipment that utilizes a trapezoidal laser beam to weld two or more materials together. It functions by directing highly concentrated light energy to a certain point where the materials to be joined are heated to the point of melting to create a bond. The machines are thermally efficient, accurate, and versatile in terms of the different kinds of materials, metals and alloys, they can work with. Given the speed, quality of the welds, and minimal heat distortion associated with it, fiber laser welding is extensively employed in the automotive, aerospace, and electronics industries.

Understanding the Basics of Laser Welding

Fiber laser welding is rapidly evolving, driven by the increasing demand in automation and precision manufacturing, as Google’s search engine suggests. One of the most asked questions is, “Which sectors are the greatest beneficiaries of fiber laser welding?” The automotive industry certainly stands out; fiber laser welding technology is harnessed for the precise joining of lightweight parts and materials, which reduces vehicle weight and enhances fuel economy. Likewise, the aerospace industry uses fiber laser welding for the formation of bonds that are durably strong and rigid, but lightweight and non-intrusive to the materials themselves. Moreover, the medical device industry takes advantage of this technology to weld microscale components and subassemblies, as it can be done with little thermal alteration to preserve functionality and dependability. These are important advancements that illustrate the increased adoption of fiber laser welding in modern automation and high-precision manufacturing.

Main Elements of a Machine for Welding with Fiber Laser

Laser Source

In a fiber laser welding machine, the laser source is primary, as it produces the required high-intensity laser beam. Most fiber laser welding machines use models internal to the unit and have a working wavelength of 1,070 nm since it is more suited for fine welding. Efficiency, long operational life, and maintenance costs all favor the use of fiber laser sources in modern machines.

Beam Delivery System

From the source to the place where welding is done, the laser beam must be delivered. This section has optical fibers with some collimators, as well as other lenses that focus the lasers actually ensuring the separated energy is homogeneously distributed. New delivery systems permit the complex robotic control of advanced fixed setups for welding.

Control Unit

All interface functions are the responsibility of the control unit, from which the user sets and monitors unit parameters, to power, pulse length, and speed of the welding. Quality and wide application of materials welded was added with modern feedback and adaptive control to best ensure consistent across different weld outcomes.

Cooling System

In preforming and maintaining the operational reliability of any fiber laser welding machine, effective cooling systems remain a prerequisite necessity. These systems are capable of using water or air to cool down heat as it is generated during the welding processes. This consequently helps in extending the life span of machine components and also helps in preventing thermal damage to the sensitive parts.

How Fiber Lasers Differ from Other Welding Technologies

Fiber lasers differ from other welding technologies by offering higher precision, efficiency, and energy focus, making them ideal for intricate and high-speed applications.

|

Key Point |

Fiber Laser |

Other Technologies |

|---|---|---|

|

Precision |

High |

Moderate |

|

Efficiency |

Superior |

Variable |

|

Energy Focus |

Concentrated |

Dispersed |

|

Speed |

High |

Moderate |

|

Material Range |

Wide |

Limited |

|

Maintenance |

Low |

Higher |

|

Cooling Needs |

Advanced |

Basic |

|

Beam Quality |

Excellent |

Variable |

|

Lifespan |

Long |

Shorter |

|

Cost-effectiveness |

High |

Varies |

How Does a Laser Welding Machine Work?

An Overview of Laser Welding

Laser welding machines use a beam of concentrated light to produce high amounts of heat which melts and fuses the materials together. The process starts with the emission of photons from the laser, which are amplified and focused through different lenses to make a precise and high-pressure beam. This beam is aimed at the material to be worked on, where its energy is absorbed and localized melting occurs. The mighty joints go on to cool down and solidify forming strong and seamless bonds.

Especially fiber laser machines, most modern laser welding are flexible and pioneered in precision. They effectively cut across different forms of substances. From steels to aluminum cylinders and even reflective materials, the energy effectiveness is commendable. With automated controls integrated with CNC systems, weld quality uniformity is guaranteed which makes it suited for high precision and speed industries like aircrafts, vehicles, electronics production, and advanced science industries.

The Purpose of Laser Beam and the Head of Welding

Laser welding systems function within welcontrolled wavelength ranges (typically between 800–1100 nm for fiber lasers) to ensure minimal distortion and an exacting energy application. The use of alternating indices makes possible diverse propulsion techniques which are all suitable for physical exertion with good outcomes.

Penetration Depth: Depending on the type of material and power settings, laser welding can achieve penetration depths of up to 25mm in steel while preserving excellent joint quality.

Speed of Operation: In mass production settings, laser welding systems are extraordinarily effective, reaching a remarkable welding speed of 10 meters a minute.

Energy Efficiency: Compared to other welding techniques, modern laser welding machines have an operational cost and environmental impact efficiency of around 30 percent in energy spent while executing work.

Importance of Laser Power and Wavelength

As with any tool, laser power and wavelength are fundamental in the execution and success of the application, in this case laser welding. The power of the laser will influence the amount of energy provided and subsequently how much of the material will be melted, thus how deep the weld would be and its quality. When working with thicker materials, higher laser power is a must. On the other hand, weaker power without precision may cause damage on sensitive alloys through spatter and overheating, which are very common defects of excessive power.

On the flip side, wavelength influences the efficiency of absorption of energy by the material to be welded. For example, ultraviolet or blue laser emits light of shorter wavelengths which will be absorbed more effectively by highly reflective materials such as copper or aluminium. This ensures better coupling with the materials and reduced energy wastage. Advances in laser technology as of 2023 have resulted in fiber lasers of customized wavelengths, making them suitable for various materials.

Defects can be minimized and joint strength maximized through optimal power settings in combination with a material-specific wavelength of course tailored for the workpiece. Goggle’s latest news based research indicates an evolving need for lasers with specific wavelengths on focus for precision cutting across aerospace, automotive and electronics manufacturing, paving the way for further industry-driven innovations. These developments highlight the need to set the parameters of the laser with consideration of all welding needs and the particular materials used.

What are the Applications of Fiber Laser Welding?

The Key Areas of Welding for Metal Joining

- Automobiles – a major source for body panel welding, fuel injection, and exhaust system welding.

- Aerospace industry – makes use of these welding technologies for lightweight, high-strength parts.

- Electrical engineering – fundamental in welding procedures for tiny, fragile parts to ensure accuracy.

- Production of surgical devices – focuses on the production of surgical devices.

Application in Automotive and Aerospace Industrial Sectors

Fiber laser welding has multiple benefits including accuracy, speed, and flexibility across different sectors. Most of which were highlighted in the most current trends observed through Google engine. These key trends include:

Unmatched Control and Accuracy – lasers yield precision like no other which guarantees consistent welds on even the most intricate and fragile parts.

Low Heat Affected Zone (HAZ) – lower than usual heat distortion when a fiber laser delivers dense energy which in turn protects the integrity of the material being welded.

Increased Speed – High volume production can now be realized with fiber laser welding as it is quicker than conventional methods.

Flexible to Different Materials – Used across many industries, from stainless steel, aluminum, alloys, and titanium, fiber lasers have no limits.

Lower Maintenance Expenses – Lasting reliability and cost-effectiveness over time is observed in fiber laser systems due to their high energy efficiency and fewer moving parts, which translates to lower maintenance costs.

Benefits for Stainless Steel and Carbon Steel Fabrication

Fiber laser welding offers high precision, strong weld strength, and minimal material distortion, making it ideal for stainless steel and carbon steel fabrication.

|

Key Point |

Description |

|---|---|

|

Accuracy |

High precision in welding |

|

Weld Quality |

Strong and clean joints |

|

Distortion |

Minimal warping of metal |

|

Efficiency |

Fast processing speed |

|

Versatility |

Supports complex designs |

|

Cost |

Reduced operational cost |

|

Heat Affected |

Limited heat-affected zone |

|

Material Range |

Suitable for diverse alloys |

Why Choose a Handheld Laser Welder?

Benefits of using Handheld Fiber Laser Welding

Fiber laser welding machines are modern equipment incorporating high precision, speed, and versatility whilst joining materials because of the use of high-intensity laser beams, which makes them suitable for industries with high requirements on weld quality.

Operability and skill for welding

The handheld fiber laser welder is easy to operate owing to its lightweight construction, ergonomic features, and intuitive laser controls which greatly ease the learning process for a novice operator. The lightweight construction further improves upper limb mobility which increases precision in very tight spaces or on complicated parts. Additionally, the system allows adjustable parameters which enhance the device’s performance by optimizing weld quality thus reducing the fatigue experienced by operators across various skill levels. This makes the system practical across all levels of welding professionals.

Flexibility and freedom for effective and high-quality welding

- Lightweight and compact design for unrestricted use in confined spaces.

- Wide-ranging materials and thicknesses can be accommodated with adjustable power settings.

- Enhanced precision, operational accuracy, and reduced errors due to automated features.

- Control features that minimize operational fatigue during prolonged use.

How Does Fiber Laser Welding Compare to Traditional Welding?

Analyzing the Techniques of TIG and MIG Welding alongside Laser Welding

TIG welding boasts of precision and quality, especially for thinner materials; however, most TIG welder operators face issues with time and proficiency when it comes to large-scale production, considering it tends to be slower than alternative methods.

On the contrary, MIG welding is faster and more efficient than TIG welding and can be performed on considerably thicker materials. Although MIG welding has an advantage in terms of ease and speed, it is less precise than TIG welding and adds sizable molten splatter, increasing post-welt cleaning requirements.

Laser welding is remarkably precise, quick and efficient when compared to MIG and TIG welding. Clean, high strength welds with extreme geometric accuracy and minimal thermal distortion are achieved with the application of concentrated laser energy. Laser welding not only works better on complex geometries, but is also faster and reduces the workload for the operator. With reduced amounts of operator skill needed, it is easier to boost productivity and consistency. As a result, industries that are focused on high-quality products depend on laser welding techniques for improved results and efficiency.

Assessing the Quality of Welds along with the Weld Speed

- Accuracy: Laser welding achieves welding tolerances as fine as ±0.1 mm which is especially beneficial for complex design and assembly work as results are accurate and repeatable.

- Weld Depth: Depending on the type and thickness of the material, and the power of the laser used, weld depths can vary from a minimum of 0.1 mm to greater than 25 mm.

- Rate of Welding: At times, welding speeds can go beyond 10 meters per minute in certain applications which further increases productivity in industrial environments.

- Heat Effects: The amount of heat used is translated to as a zone (HAZ) where damage to the material due to heat will be less at the minimal range, therefore allowing low warping or degradation of material which improves the weld’s strength.

Welding Techniques and Cost Efficiency

Factors affecting operational efficiency of a method of welding includes the energy spent, material cost, level of automation, and the demand of the specific welding method in question, noting the fact that laser welding is low cost for operational expenditure in cases involving precision work in large quantities.

Reference Sources

- A New Method to Assess Fiber Laser Welding Quality of Stainless Steel 304 Based on Machine Vision and Hidden Markov Models

- Authors: Xin Tang et al.

- Publication Date: 2020

- Journal: IEEE Access

- Summary: This paper presents a novel method for assessing the quality of fiber laser welding in stainless steel 304. The method utilizes machine vision to capture real-time images of the welding process and employs Hidden Markov Models (HMM) to classify defects based on the geometric features of the keyhole formed during welding. The study demonstrates that this approach can effectively monitor welding quality and identify potential defects such as porosity and penetration issues.

- Methodology: The authors used machine vision to acquire images during the welding process, followed by image processing techniques to extract keyhole features. A pre-trained Hidden Markov Model was then applied to establish the relationship between the keyhole geometry and welding quality defects. Experimental validation was conducted using stainless steel 304 to confirm the effectiveness of the proposed method(Tang et al., 2020, pp. 130633–130646).

- A Spectroscopic Method Based on Support Vector Machine and Artificial Neural Network for Fiber Laser Welding Defects Detection and Classification

- Authors: Yuanhang Chen et al.

- Publication Date: December 1, 2019

- Journal: Ndt & E International

- Summary: This study explores a spectroscopic method for detecting and classifying defects in fiber laser welding using Support Vector Machines (SVM) and Artificial Neural Networks (ANN). The findings indicate that the ANN outperformed the SVM in terms of classification accuracy, although both methods demonstrated their respective advantages. The proposed method was validated using a test dataset, confirming its effectiveness in defect detection.

- Methodology: The authors conducted experiments to collect spectroscopic data from welded samples, which were then analyzed using SVM and ANN algorithms for defect classification. The performance of both models was compared, and the results were statistically analyzed to determine their effectiveness(Chen et al., 2019, p. 102176).

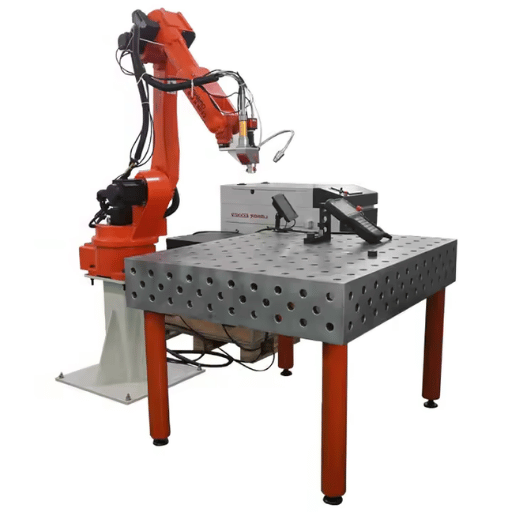

- Investigation of Production System for Sheet Metal Parts of Machine Tools with a Fiber Laser Welding Robot

- Authors: Yohei Yamaguchi et al.

- Publication Date: 2021

- Conference: Proceedings of International Conference on Leading Edge Manufacturing in 21st Century

- Summary: This paper investigates the production system for sheet metal parts using a fiber laser welding robot. The study focuses on optimizing the welding process to enhance efficiency and quality in manufacturing environments. The findings suggest that integrating fiber laser welding robots can significantly improve production rates and reduce operational costs.

- Methodology: The authors analyzed the production workflow and conducted experiments to evaluate the performance of the fiber laser welding robot in various operational scenarios. Data on welding speed, quality, and production efficiency were collected and analyzed to assess the impact of the robotic system on the overall production process(Yamaguchi et al., 2021).

Frequently Asked Questions (FAQs)

Q: What is a fiber laser welding machine?

A: A fiber laser welding machine is a modern joining equipment which is used to cut metal parts. It applies to melt and join materials with a very high intensity laser beam. Some other components like laser head, wire feeder, and optics are also part of the system in order to achieve high quality welds.

Q: What sets a handheld fiber laser welding machine apart from other methods of welding?

A: The handheld fiber laser offers a greater improvement over traditional welding in terms of process flexibility and automated control. Its compact structure means all of its parts can be moved easily thus solving the problem of constrained weld access. Additionally, it also reduces excessive heat input, makes the materials better, and thus improves weld quality.

Q: What are the benefits of employing a handheld laser welding machine for different welding operations?

A: The benefits include fulfilling the work with optimal speed, having the weld of deep penetration, and controlling the parameters of the process. They also excel in welding different materials together and do it in a simple way. Handheld laser welding would need him to apply with great precision minimal distortion at the weld useful for seamless and precise.

Q: Is it possible to use a fiber laser welder on all sorts of materials?

A: Stainless steel, aluminum, and various other metals can be worked on using fiber laser welders. Their flexibility enables them to perform effective welding of both identical and different workpieces, making them suitable for various fields of engineering.

Q: What role does the laser welding head play in the welding process?

A: The laser welding head is a fundamental element of a fiber laser welding system. It combines and focuses thoughts with words using the laser beam onto workpieces, thereby controlling the level of heat to be added for the joining processes. The consistent nature of the welds performed depends significantly on the performance of the head.

Q: In what ways does a wire feeder increase the effectiveness of a handheld welding gun?

A: A Handheld welding gun is complemented by a wire feeder which serves to provide filler material as needed throughout the welding operation. It has a means for effortless and uninterrupted wire feeding, which is very important for uniform and quality welds, particularly for thick materials, for example, workpieces 2 mm to 4 mm thick.

Q: How helpful is an Omtech laser welding system?

A: Omtech laser welding system is helpful in many ways; it is technologically advanced, has precise control of the welding parameters and is built to last. It is such a preferred option for professionals because, in addition to its durability, it is efficient and reliable, with various welding applications and functionalities due to its 3-in-1 features

Q: Why is argon gas used in the process of laser welding?

A: Argon is a type of shielding gas and is used in the process of laser welding primarily to keep the weld pool free from air impurities. This contributes to stabilizing the arc which is essential in obtaining a smooth weld finish, resulting in better weld quality.

Q: What factors matter for choosing optics in a fiber laser welder?

A: The choice of optics for a fiber laser welder must take into account the focusing lens, the integration with the laser welding head, and the intended welding type. Selecting proper optics allows for correct delivery of the laser beam which improves the overall experience and results during welding.