Various industries have automated their business operations to achieve maximum efficiency and sustainability. One great example of this is the use of fiber laser cleaning machines. These modern tools are changing the approach to industrial surface treatment. Unlike traditional methods that rely on toxic chemicals and destructive scrubbers, fiber laser cleaning uses a non-invasive and sustainable approach. This article will focus on the purpose of fiber laser cleaning machines and the industries currently taking advantage of them. This is one of the most significant advancements in surface treatment, and we hope to explain why everyone, from business leaders to сonventional people interested in technology, needs to learn more about it.

What are Fiber Laser Cleaning Machines?

These machines use powerful laser beams to extract dirt, rust, paint, and other markings from metal, wood, and stone products. They work by emitting high-powered laser light pulses to the surface to clean without scratching or destroying the material underneath. Their high accuracy, efficiency, and eco-friendliness are admirable because they do not use chemicals or abrasives, which laser cleaning machines eliminate.

How does a fiber laser cleaning machine work?

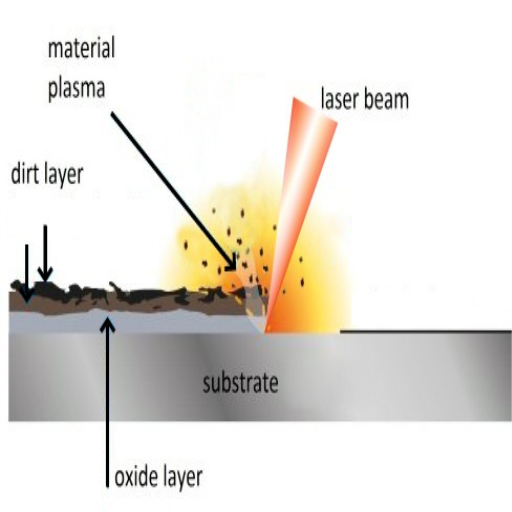

As with all laser cleaning tools, fiber laser cleaning machines use advanced lasers to meticulously remove surfaces’ dirt, rust, paint, oil, or other coatings. The process begins with a focused laser beam emission that varies per machine; some lie between 1064 and to1080 nm. This beam is aimed at the unwanted layers removed via laser ablation. This process breaks down the contaminants into vapor or tiny particles while leaving the base material unharmed.

Versatility is one of the features that modern fiber laser cleaning systems offer. They have adjustable power settings that allow users to customize the cleaning intensity depending on the material being cleaned and the type of impurity present, for instance, between 20W and 2000W. Moreover, tougher impurities such as industrial grade rust and thick coatings require higher wattage for fast cleaning, while delicate materials require lower wattage.

One of these machines has a distinguishing feature – their efficiency. Researchers have discovered that fiber lasers can clean surfaces up to ten times faster than traditional methods, proving useful in aerospace, manufacturing, and automotive industries. In addition to their impressive efficacy, fiber lasers do not come in contact with the substrate and do not use damaging chemicals or abrasive media that are customary to traditional cleaning methods. These aspects ensure that it is eco-friendly and does not harm the structure being cleaned.

For even more sophisticated laser cleaning requirements, some fiber laser cleaning machines have advanced control features such as AI-assisted settings or real-time monitoring, enabling higher levels of automation and precision. Such flexibility illustrates why these machines are popular in precision-demanding fields.

What are the key components of a laser cleaning machine?

A laser cleaning machine consists of several parts working together for optimal efficiency:

- **Laser Source**

The core component of any machine is the laser source, which produces a laser beam. Fiber lasers are the ideal choice for cleaning procedures as they are stable, efficient, and have a long lifespan. These lasers often range from 20W to over 1,000W, depending on the cleaning requirements. With higher power levels, faster and deeper cleaning becomes possible.

- **Optical System**

An optical system is primarily used to direct and shape the laser beam. It also includes a lens and mirror system that guarantees exact beam targeting onto the substrate. High-quality optics that ensure accuracy and consistency are very important for high cleaning performance.

- **Control System**

Users can adjust laser parameters with modern, powerful interfaces that employ software for regulation, such as controlling power, pulse duration, or the focus of the beam. More sophisticated devices have AI-assisted features for optimizing cleaning workflows and precision or offer real-time monitoring.

- **Cooling System**

The generation of power while using a laser cleaning machine usually results in significant amounts of heat. To avoid overheating and ensure long-life products, air or liquid cooling systems have to be implemented. The efficiency and reliability of the parts also need to be maintained for the system to function long-term.

- Scanning Head

The scanning head controls the movement and location of the laser beam. It includes galvanometer scanners, which offer fast and exact movement of the beam, thus permitting even cleaning over the entire surface of the target area. Some systems allow for pattern scanning tailored to the specific cleaning requirements.

- User Interface

An intuitive interface, which is easy to navigate, controls cleaning and operation. Current models have touch screens and allow different programs to be set up based on the type and amount of cleaning required by the material.

- Power Supply

Every laser and its systems require energy for operation, which is supplied by the energy provider. A cutting-edge industrial laser needs constant and reliable power to function optimally, and this is ensured by high-performance power supply units.

- Protective Enclosure and Safety Mechanisms

To eliminate user risks, laser cleaning machines are fitted with protective housings and shields against the laser, as well as emergency stop buttons and safety features. In addition, turning lasers on and off in different states compliantly with several standard lasers like IEC 60825 escort zones the area where dangers posed during operation are bound with safety procedures.

What are the benefits of laser cleaning technology?

Increasing Popularity of Laser Cleaning Technology

Lasers are an advanced technology that has been increasingly prevalent in recent decades, especially for cleaning. Unlike conventional cleaning methods, laser cleaning guarantees protective measures for the surface to avoid any potential harmful damage.

Losers are indeed a strong alternative. Unlike the customary techniques often used within most domains, laser cleaning yields and guarantees lower expenses for the use of additional work tools, often related to chemicals.

The laser cleaning method is superior to conventional cleaning methods that guarantee harmful wastes like eco-friendly chemicals.

When compared to the methods of dealing with composites, metals, and even plastics, this technology appears to be the most advanced.

How does laser cleaning compare to traditional cleaning methods?

Laser cleaning remedies problems arising from abrasive blasting, chemical cleaning, or manual scrubbing. Such traditional cleaning methods use petrophilic solvents, which are hazardous to the environment and require safety precautions during utilization. Chemical scrubbing also generates theistic waste that needs proper disposal, emits harmful residues over surfaces, and harms the air.

Unlike scrubbers, laser cleaning does not use solvents or chemicals, making it eco-friendly. Abrasive cleaners have a high negative impact due to the high volume of contaminants. Eco-friendly laser cleaning generates the least environmental waste since contaminants are vaporized instead of displaced.

Another issue with traditional methods is spatial cover with surfaces of intricate geometrical arrangements. Unlike traditional methods, laser cleaning does not compromise spatial coverage as it yields high precision and control und staying below the cavities above guided surfaces. For instance, CO2 laser systems can remove coatings or rust from metal surfaces without altering the substrate’s foundation.

Moreover, laser cleaning often reduces labor time and costs in industrial applications. A study evaluating abrasive blasting compared with laser technology for rust removal from steel found that the laser method achieved up to 50% faster cleaning without compromising surface-grade quality. This is particularly beneficial for laser technology in the aerospace, automotive, and historic preservation industries.

Despite the higher purchase price of laser equipment compared to other cleaning tools, the investment pays off in the long run with lowered maintenance, fewer consumables, and faster processing times. Moreover, microwave-powered laser systems increase productivity and worker safety, as these systems automatically clean without human involvement in dangerous cleaning tasks.

Crossing multiple industries with precision, efficiency, and sustainability, laser cleaning is a powerful alternative to traditional methods.

What are the environmental advantages of using a fiber laser cleaner?

The advantages of fiber laser cleaners go beyond just aesthetics since they are considered eco-friendly due to their environmental benefits. First and foremost, abrasive industrial-strength chemicals, ovens, and solvents used in cleaning are eliminated. This reduction aids incineration, chemical despising, and waste minimization systems, decreasing the risk of environmental contamination. Moreover, unlike sandblasting or chemical stripping, which leave behind enormous remains of debris that has to be thrown away, fiber laser cleaning does not produce any secondary waste, including dust or blasting media.

Furthermore, the power consumption of fiber lasers is exceptionally low. For example, modern cleaner systems command more electricity than auxiliary industrial cleaning equipment but derive more excellent carbon dioxide emission benefits. Additionally, their precise, selective targeting capabilities help minimize resource wastage, which contradicts traditional laser shift cleaning systems. Further shifts in laser technologies have reported some fiber laser cleaning systems as low as 30% more efficient than conventional systems, ensuring the jets’ effectiveness. This makes them preferable for carbon footprint-sensitive industries, sustaining effectiveness but aiming towards sustainable resilience divisions.

To conclude, office safety and environmental well-being are additional positive effects of fiber laser cleaners. These devices aid in creating a more environmentally friendly workplace by removing dangerous emissions and reducing airborne pollutants associated with chemicals or abrasive methods. Collectively, these benefits amplify the environmentally minded advancement of fiber laser technology.

What industries utilize fiber laser cleaning solutions?

Fiber laser cleaning solutions are growing across different industries because of their effectiveness and accuracy. Major industries include:

- **Automotive:** Cleaning the rust, paints, and other impurities associated with metal parts.

- **Aerospace:** Removing the dirt from fragile parts with zero mechanical impact.

- **Manufacturing:** Cleaning molds, preparing surfaces, and maintaining machines.

- **Restoration:** Erasing abrasively responsible stains on old artifacts and monuments.

- **Ship Building:** Cleansing metallic surfaces off oxidations and plasters.

These industries use Fiber laser cleaning technology because of its precision, non-contact nature, and low environmental impact.

What are the industrial applications of laser cleaning machines?

As a result of their accuracy, ease of use, and environmentally friendly practices, laser cleaning machines are used across various industries. Some of their uses include the following:

Automotive Industry: Before welding or bonding, surface preparation using laser cleaning is very common. Reports claim that this practice improves the quality of weld seams and adhesion, which improves the durability of automotive components. Moreover, grey and rusted industrial machinery parts can be cleaned without chemicals, which significantly reduces maintenance costs.

Aerospace: Laser cleaning is best suited for removing coatings like paint or oxides because of the extremely high quality and safety standards in aerospace. Research shows that laser cleaning helps prolong the life of components by minimizing surface abrasion, compared to other methods, thus increasing their performance and safety.

Electronics Manufacturing: In the electronics sector, delicate components are cleaned with precision that leaves them unscathed, using machines such as lasers. For example, solder joints and connectors, which are boosted in terms of electric functionality and reliability, are cleaned with perfect precision that does not damage the more delicate parts.

Oil and Gas: Laser cleaning is utilized for the upkeep of pipes, valves, and storage tanks. Remnants such as oil, slack, and rust are removed. There is no corrosion or leakage. This solution is environmentally friendly since no chemicals are used, thus reducing the carbon footprint.

Heritage Conservation: Monuments and relics of history have striking modern beauty thanks to the precision offered by laser cleaning. This technique enables accurate extraction of soil, filthy water, and biological growth while preserving fragile surfaces, thus maintaining authenticity.

Shipbuilding and Marine Industry: For ship shrines washing, laser cleaning removes old rust, paint, and biological growth from the hulls and other metal portions of the ship. It’s less risky for the environment and less expensive in labor, thus increasing overall operational efficiency as a result of reduced spending.

Renewable energy: Cleaning wind turbines and solar panels with lasers improves their performance and maintenance. These cleansers remove dirt, corrosion, and other unwanted materials. As a result, energy efficiency is boosted, and downtime is significantly reduced.

These applications exemplify the range and creativity offered by laser cleaning technology, making it relevant to maintenance and manufacturing activities worldwide. For example, improvements to pulsed fiber lasers have enabled higher precision levels and faster cleaning rates, with one system accomplishing up to 1,000 square millimeters per second. Such speed and performance demonstrate the increasing importance of laser cleaning machines in many fields.

How is laser rust removal applied in manufacturing?

Manufacturers employ laser rust removal technology to make processes easier and better while reducing environmental impacts. This technology is used for cleaning metal surfaces and restoring equipment. Unlike abrasive methods, laser rust removal offers an eco-friendly solution since it operates without the need for harmful chemicals.

Highly focused laser beams that vaporize rust and contaminants while leaving the base metal undamaged can be precisely etched with advanced systems. For example, modern industrial-grade lasers can achieve rust cleaning rates of up to 15 square meters per hour, depending on the material and level of corrosion, making them ideal for use in automotive factories, shipbuilding, aerospace maintenance, and precision instrument fabrication. In addition to all these benefits, laser rust removal also mitigates substrate damage and ensures minimal waste and shortened component maintenance downtime, reducing overall company costs.

What should I consider when selecting a laser cleaning machine for sale?

When purchasing a laser cleaning machine, it is essential to pay attention to the basic specifications and the latest features and trends in the industry. To help you further with the key considerations, I have listed their details under the following pointers:

Power and Efficiency: As was explained above, higher-powered machines with output levels for lasers upto 2000W are better suited for cleaning industrial tasks. At the same time, lower models (e.g. 50-100W) are better for details and precision work. Also, check the energy efficiency as it impacts operating costs, ensuring they do not inflate due to added expenses and loss of performance.

Material Compatibility: Different machines are optimized for different types of materials, such as metal, stone, glass, and so on. For example, fiber lasers are best for getting rid of rust on metal, while delicate parts are often better dealt with pulsed lasers, as they don’t allow for a lot of material damage to tender surfaces.

Automation and Software Integration: Many modern laser cleaning machines have sophisticated software designed for process automation, remote control, and live progress checks for advanced laser cleaning devices. Assess if these devices have programmable and AI-enabled adjustability for optimal cleaning systems.

Portability and Size: More compact, portable models are widely used for on-site servicing in the aerospace and automotive industries. A lightweight laser cleaning unit with wheels is easy to transport and position, making it immensely practical.

Eco-Friendly Laser Cleaning Machines:

Choose laser cleaning machines that are eco-friendly and limit the use of harsh chemicals and secondary waste. Such devices comply with strict environmental regulations and prove to be smart investments in the long run.

Financial Impact: Assess the initial payment against projected savings from maintenance, operation, and other cost factors. Small-scale laser cleaning machines are priced from 8,000 to over 100,000 for high-end industrial ones. Always be mindful of your budget and consider the ROI of the machine’s projected life and performance.

Machine Safety: Check for laser protective barriers, safety interlocks, protective interlocks, and emergency buttons, among other features. Having them onboard guarantees compliance to FDA or CE safety standards for the operator’s protection.

These details, alongside any new technological changes, should give you the confidence needed to invest in a machine.

What are the differences between handheld laser cleaning and stationary options?

There is a remarkable difference between handheld and stationary laser cleaning, as each serves its own purpose and function. Handheld laser cleaning systems encourage mobility and flexibility, which enables the user to perform detailed or remote cleaning, on-site cleaning, and intricate cleaning tasks. These devices are portable, simple to operate, and agile enough to easily suit target-specific poses. Mobility advantages make handheld systems beneficial to operators in automotive upkeep, aerospace, and artwork restoration.

Stationary laser cleaning machines, unlike portable ones, are more tailored towards repetitive or high-volume cleaning activities than handheld units, which have fixed structures. However, portable ones outperform stationary ones for intricate, detailed cleaning. These devices have immense cleaning systems, making them highly effective for extensive paint or rust removal from large surfaces like metal. Stationary systems outperform handheld ones in basic fabrication system processes requiring uniform speed and extensive application.

Nonetheless, the differences in power output and investment costs remain. Power ranges for handheld systems are between 20W to 200W, while stationary systems can exceed 1000W, enabling deeper and quicker cleaning. This additional power demands more upfront capital, space, and setup time. In addition, stationary systems are equipped with automation features like robotic arms, allowing them to operate with little human supervision for long periods.

Ultimately, choosing between handheld and stationary laser cleaning systems will depend on the nature of the tasks to be performed, the working environment, and budgetary constraints. Businesses may prefer handheld systems for mobility and flexibility, while those focused on large-scale or automation will find stationary systems more suitable.

How effective is pulse laser cleaning?

The pulse laser cleaning technique enables the removal of contaminants, coatings, and residues from several surfaces, and it does so efficiently without damaging the surface. It does so because of its focus on the minutest details, making it useful even for delicate or intricate objects. Furthermore, laser cleaning is a safe technique because no scrubbing or solvents are required. The construction sector, automotive engineering, and aerospace industry widely use it because of its effectiveness and dependability.

What contaminants can be removed using a pulse laser cleaning machine?

Cleaning surfaces with a laser beam cleaner will help remove oil, grease, and paint and is very effective. Such machines enable technological marvels as they assist in preparing surfaces in construction and maintenance, irrespective of the nature of the task. For instance, in the aerospace and automotive sectors, the oxide layers on metals, which are usually present, can be abraded without inflicting damage to the base part. Moreover, residues due to burning, such as carbon deposits and other industrial wastes, can also be removed easily from components, thereby improving their durability and performance in industries.

More recent developments and research suggest that cleaning pulses emitted by lasers can clean other residues, such as biological remains, dust, and molds from intricate surfaces, which can be very helpful in cleaning cultural relics. Tests about industrial work suggest that lasers can potentially clean rust with a width of 300 microns from surfaces exceptionally accurately. Moreover, they do not use artificial and harmful compounds, making the procedure more environmentally friendly. The diverse fields of application highlight the conservation of cultural material and laser cleaning and the high-precision manufacturing industries, which illustrates why laser cleaning pulses have become popular in other sectors.

How does pulse laser cleaning differ from continuous laser cleaning?

Pulse and continuous laser cleaning differ in one or more applications and effectiveness. Depending on the intensity and precision of the work needed, one type of material pulse laser cleaning might be best for delicate materials like historical artifacts and precision instruments. At the same time, continuous is used on industrial and bulkier objects. Pulse laser cleaning uses high-intensity laser beams in a short span with precise control. As a result, without meaning any harm to the surface beneath, they tend to heat and vaporize dirt and dust that remain on the surface. This works as an ideal solution for furniture made of delicate materials. However, the pulse duration, for instance, is in the range of femtosecond and nanosecond, allowing for better results. Research has shown that pulse lasers with an accuracy of 1-micron level work best when protecting fine details to get the best results.

Continuous pulse is almost the complete opposite when using lasers for cleaning. Instead of working with short controlled bursts of laser, prolonged heating is used, resulting in cutting lasting beams that gently erase dirt off the surfaces without having them come into direct contact. Unlike pullse, it is fantastic for bulkier items like sizeable industrial machinery and metal surfaces being worked on. However, with new exceptional abilities comes new difficulties. Continuous cleaning works well with objects that do not require additional care, although there needs to be caution about the level of thermal damage.

Another difference is in cost efficiency and power consumption. While systems with pulse lasers are more versatile and precise, they require more advanced control tech. Continuous lasers are usually the better option for large-scale industrial measures because they are more energy-efficient and simpler to use.

Ultimately, pulse or continuous laser cleaning depends on the cleaning requirement, such as the material to be cleaned, area size, and the desired balance between accuracy and output level.

Reference Sources

-

Mechanism and Applications of Laser Cleaning1:

- This review highlights the evolution of laser cleaning, focusing on mechanisms like laser dry cleaning, liquid-assisted cleaning, and shock wave cleaning.

- Applications span cultural relics preservation, industrial metal surface treatment, and semiconductor cleaning.

- Challenges include optimizing efficiency and avoiding substrate damage.

-

Fundamental Mechanisms and Industrial Applications2:

- Discusses mechanisms such as thermal ablation, thermal stress, and plasma shock waves.

- Applications include cleaning metallic and non-metallic materials, semiconductor elements, and nuclear decontamination.

- Emphasizes the importance of selecting appropriate laser parameters to avoid damage.

- Top Fiber Laser Cleaning MachineManufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a laser cleaning machine?

A: A laser cleaning machine uses high-power laser energy to remove contaminants, rust, coatings, and other unwanted materials from surfaces. This industrial laser technology offers a precise and efficient cleaning process suitable for various applications.

Q: How does a handheld fiber laser cleaning machine work?

A: A handheld fiber laser cleaning machine emits a focused laser beam that vaporizes contaminants on the surface. This portable laser cleaning solution is ideal for tasks like mold cleaning, paint stripping, and other applications requiring mobility and flexibility.

Q: What are the benefits of using a laser cleaning system?

A: The benefits of using a laser cleaning system include minimal environmental impact, reduced waste production, precise cleaning capabilities, and removing rust and coatings without damaging the underlying material. Additionally, it is a cost-effective laser solution compared to traditional cleaning methods.

Q: Can laser cleaning machines be used for paint stripping?

A: Yes, laser cleaning machines are highly effective for paint stripping. The high-energy laser surface interaction allows for the precise removal of paint layers without harming the underlying substrate, making it a preferred method in various industries.

Q: What applications can a laser cleaning machine manufacturer cater to?

A: A laser cleaning machine manufacturer can provide machines suitable for numerous applications, including rust removal, mold cleaning, coating removal, and even laser marking. Their products can be tailored to meet specific industrial cleaning needs.

Q: What types of laser power are available in cleaning equipment?

A: Laser cleaning equipment is available in various power levels, including low-power CW fiber lasers for delicate tasks and high-power lasers for heavy-duty cleaning applications. The right laser power will depend on the specific cleaning requirements and the treated material.

Q: What is the difference between portable and stationary laser cleaning machines?

A: A portable laser is designed for flexibility and ease of use in various locations, making it ideal for on-site cleaning applications. In contrast, a stationary laser cleaning machine is typically used in a fixed environment where larger, more complex cleaning tasks are performed.

Q: Are there any safety concerns associated with using a laser cleaning machine?

A: Yes, using a laser cleaning machine involves safety considerations. Operators should wear protective gear, such as laser safety goggles, and follow safety protocols to avoid exposure to laser energy. Proper training and awareness of the equipment are essential to ensure safe operation.

Q: How does a laser cleaning head contribute to the cleaning process?

A: The laser cleaning head focuses the laser beam precisely on the surface being cleaned, allowing for targeted removal of contaminants. This precision enhances the efficiency of the cleaning process and minimizes damage to the underlying materials.

Q: What makes handheld laser cleaning machines cost-effective?

A: Handheld laser cleaning machines are considered cost-effective due to their low maintenance requirements, reduced need for chemicals and consumables, and ability to perform multiple cleaning applications effectively. This versatility can lead to significant cost savings over time.

- Why CNC Machining is More Popular Than 3D Printing in Modern Manufacturing

- Ultimate Guide to Fiber Laser Cleaning Machines: The Revolutionary Rust Removal Technology

- Discovering the Benefits of UV Laser Marking Machines: A Comprehensive Guide

- CNC Router vs. CNC Mill: Key Differences Between a CNC

- The Ultimate Guide to Laser Surface Cleaning Safety: Protecting Yourself While Using a Laser Cleaner

- Discover the Versatility of a CO2 Laser: What It Can Cut, Etch, or Mark?

- Understanding CNC Routers: The Ultimate Guide to CNC Routing vs Mill Technology

- 3D vs 4D Laser Levels: Precision and Innovation Guide