The introduction of Electrical Discharge Machining (along with its specific innovations focused on Wire EDM) certainly marks a critical milestone in achieving precision engineering during manufacturing activities. The unmatched Wire EDM (Electrical Discharge Machining) has made its place in the industry because of its ability to cut curves and shapes with utmost precision. It is popularly used to cut ye stamping, shaping or threading tools from hard metals. This blog focuses explicitly on Wire EDM’s adnd its critical prospects as a funnel to new opportunities in precision machining. Moreover, it is also intented towards professionals from various backgrounds in relation with EDM technology guiding them towards efficient and precise machining. Therefore, stay tuned as we uncover the potential these innumerable machines have in regard to the endless possibilities becoming possible.

What is an EDM Machine and How Does it Work?

An EDM (Electrical Discharge Machining) machine is a highly specialized tool required for high-precision cutting and shaping of particularly hard materials. It works by controlled electrical sparks between an electrode and the workpiece which sparingly erodes material. During this operation, a dielectric fluid is present which promotes the sparking and aids in material cooling. In Aerospace, EDM machines are mainly used for intricate design construction, detailed mold making,for and assembling parts which need severe precision, and in automotive and electronics industries.

Understanding The Electrical Discharge Process

The procedure for electrical discharge is based on a technique known as controlled erosion which is EDT in basic terms. By passing a voltage through the electrode and the workpiece, the dielectric fluid remains insulator until the breakdown value is surpassed. A spark is created at this threshold and extremely high temperature, capable of reaching several thousand degrees, is generated which melts and vaporized small portions of workpiece material. The dielectric fluid flushes away these minute particles. Direct contact between the tool and the workpiece is eliminated allowing EDM to achieve highly accurate and complicated features, providing low mechanical stress, top precision, and detail even the most demanding tasks.

The Importance of Dielectric Fluids in EDM

The Electric Discharge Machining (EDM) process performs machining using dielectric fluids which are critical aids to control and engineer the efficiency of machining. As an electric insulator fluid dielectric is non-conducting, however, under electric field they become conductive which allows spark formation. The dielectric fluid is needed mainly for cooling of the workpiece and electrode, flushing of the debris , and a steady machining environment to be achieved for precision.

Special modern fluids also include deionized water and hydrocarbon oils which now serve differently to provide optimum performance. Fluids with dielectric strength, viscosity and thermal conductivity are selected. Hydrocarbon oils are commonly used due to their high insulation and surface finish provision. Reports indicate with optimal dielectric fluids tool wear can be achieved to reduce by 50% alongside improving precision, speed, and enhancing machining rate.

Contamination mitigation advanced filtration systems are equipped with ensuring capturing of particles removed during machining for the filtered fluid. Filtration systems enhance up to the cleanliness of their processes alongside extending dielectric fluid life and achieving particle filtration as small as 5 microns.

In general, fluid dielectric selection and maintenance done by the manufacturers can significantly enhance the efficiency, balance the cost, and improve the sustainability of EDM operations.

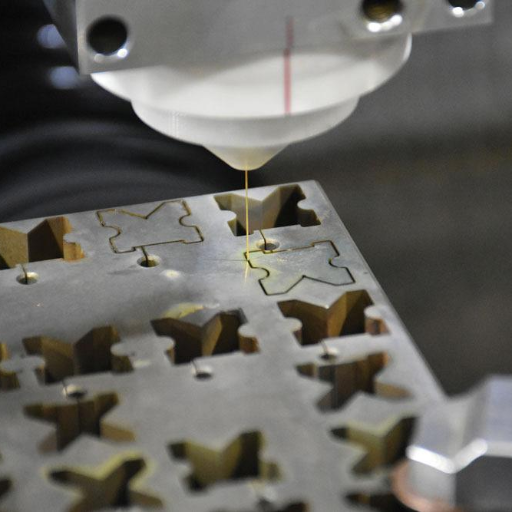

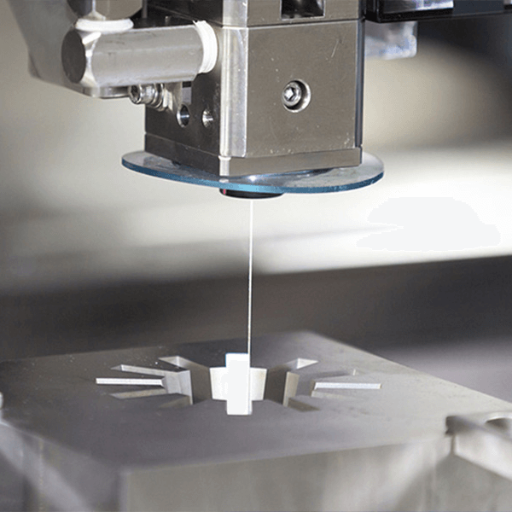

Categories of EDM Machines: Wire Cutting vs. Sinker EDM

Wire Cutting EDM slices conductive materials into desired shapes using thin, electrically charged wires which makes it possible to achieve precise engraving as well as complex designs. Sinker EDM makes use of a pre-shaped electrode to ram or sink shapes into the material, which is good for parts with internal cavities or complex geometries. Both types are extremely accurate and serve diverse manufacturing requirements based on the design.

How Does Wire EDM Differ from Conventional EDM?

Routine EDM, or electrical discharge machining, has a different technique for cutting materials as compared to wire EDM. Wire EDM uses thin electrically charged wires to create sharp and precise cuts and is best for complex contours and shapes. Sinker EDM, a type of conventional EDM, uses electrode-shaping to “sink” intricate patterns into the material, which makes what’s mostly best for internal structures and voids. Both types of machining have equal levels of precision, yet the difference lies in two-dimensional versus three-dimensional shaping; Wire EDM is for the former while conventional EDM focuses on the latter.

Merits of Wire EDM Technology

The application of wire EDM technology offers exceptional benefits to the precision manufacturing industry, especially those in need of high detail, such as medical, aerospace, and automotive industries. One advantage is that it is capable of working with very hard materials including titanium, tungsten, and other high-carbon steel. Since there is no mechanical force applied during the process, distortion of the material is minimized, so construction of complex geometries is possible with very tight tolerances, even up to around 0.0001 inches.

Another major benefit of Wire EDM is the exceptional surface finish that can be achieved throughout the process. Currently, with innovations in technology, the procedure allows for multi-pass machining and smoother surfaces from fillers that are non-contributing to the overall geometry. Advanced models of Wire EDM machines are capable of achieving surface roughness values (Ra) of 0.1 microns which are required in application such as molds and parts that are high precision.

In addition, Wire EDM possesses a greater range in cutting versatility. Tapered cuts, elaborate contours, and even sophisticated geometric designs are cut with the needed accuracy, thereby making it useful for prototype or small batch production. The addition of other forms of technology, such as CNC (Computer Numerical Control), have also enhanced the accuracy and reliability of the entire process. It is of great importance to modern Wire EDM systems are capable of operating at cutting speeds of 500 millimeters squared per minute, thus enhancing productivity significantly.

Like other manufacturers, to increased productivity, these companies wire automation for wire threading and adaptive control systems that help in decreasing energy KPIs and also in cutting downtime. Some wires EDM of better class have IoT integration changing the maintenance that can be done in predictive maintenance windows making the equipment reliable in the field and enhancing maintainable operability and trustable mission capable timelines.

Advantages of Precision Through Wire EDM Machines

There is no Precision and intricacy like that which is offered by Wire EDM machines; this is so because they are perfect for fields with stiff rotational requirements and complex shapes. As recent reports state, wire EDM machines achieve tolerances of as low as ±0.0001 inches which is quite common in the medical, aerospace, and automotive industries. These machines also have the ability to cut hard materials without struggle, for example, titanium, tungsten, and carbide.

Moreover, wire EDM systems outfitted with modern machines 5 axis enable technologies have better capability to engrave complex shapes with no leeway in precision. Predictive maintenance IoT integration in real-time has shown a decrease in machine downtimes of over 30%, maintaining consistent production levels for the manufacturer. In addition, the Predictive Energy-efficient modern Wire EDM machines have incorporated these concepts, resulting in around 20% reduced energy costs while operating and meeting the requirements of going green.

All these factors contribute to why manufacturers rely on these to reach wire EDM machines to achieve accuracy, sustainability, and reliability on various use cases under cost-effective measures.

Aerospace and Other Areas Involving Complicated Shapes

Wire EDM serves as a fundamental machine in the aerospace sector due to its accuracy and precision. Such machines effortlessly provide cutting services for complex shapes ranging from turbine blades to engine parts as well as structural components. Take for instance, the components that are manufactured for the aircrafts. They consist of very difficult to work with titanium, nickel alloys and even composites. These materials are hard to cut with traditional methods. Wire EDM actually helps because it provides good surface roughness with minimum processes.

Further wire EDM proved very useful in the aerospace aerospace industry where components require very precise EDM machines as recent estimates suggest that such machines are capable of working with tolerances of about ± 0.001 mm. This is extremely important in the case of working with aerospace parts for the reliability and performance factors. Research suggests that the use of Wire EDM in aerospace manufacturing has improved efficiency by up to 30% in the mid time of wire electric discharge machining, reducing material wastage, improving time and quality of parts that are processed. These features makes Wire EDM outstanding for meeting the requirements for safety and design in the aerospace industry

What are the Key Components of a Wire EDM Machine?

- Wire Electrode: A thin wire, usually of brass or brass alloy which conducts the electrical current employed for material cutting.

- Workpiece Table: A workstation where the blank to be machined is placed.

- Dielectric Fluid System: A system which supplies and controls the insulated fluid used for controlling the spark and flushing away the cut chips.

- Power Supply Unit: Provides and controls the current used during machining.

- CNC Controller: Takes care of holding the wire and workpiece to be cut according to the designed program during cutting.

- Wire Drive System: A system that holds the wire and works on sustaining the tension of the wire electrode while cutting is in progress.

Uses Of Brass Wire And Wire Electrode

In wire EDM (Electrial Discharge Machining), brass wire and wire electrodes play an important role cumulatively, affetcting the precision, operational effectiveness and quality of the surface finish of the workpiece being machined. Brass wire, composed of copper mixed with zinc is famous for its electrical conductivity and tensile strength. These characteristics are useful when precision and uniform machining is needed since electrical discharges are done in intervals, and errors in the cutting path are greatly reduced with intricate shapes.

The thickness of brass wires also significantly influences the cut speed and tolerance. Common sizes are from 0.1 mm to 0.35 mm, as thinner wires allow for more precision with cut details while thicker wires enable quicker cutting speeds. Recent research indicates that even thinner brass wires, like those with a 0.1 mm diameter, can provide tolerances up to ±0.002 mm, which is appropriate for very sensitive devices such as aerospace or medical parts.

Moreover, high-performance electrodes are enhanced by recent advancements in wire coating and treatment technology. For instance, high zinc content coated wires demonstrate better cutting efficiency coupled with lower wear rates, thus improving productivity and cost savings. These advancements make certain that contemporary wire EDM processes sustain the ever-increasing standards of precision and quality demanded by various industries.

The Role of Deionized Water in the Procedure

Deionized water is very important in wire EDM (Electrical Discharge Machining) because it functions as a dielectric fluid. This form of water aids in regulating the electric discharges, as well as flushing away the debris left after machining. Because the water is void of ions, deionized water greatly reduces the chances of unexpected electric conductivity, making certain that the flow of sparks is directed along a predetermined route needed for accurate machining.

The resistivity of deionized water, which falls within the range of 0.1 to 20 megohm-cm, is important in determining its usefulness. Effectively tapering the conductivity enables the machining process to be stable and effective. Research indicates that improperly managed deionized water is more likely to cause increased wear of the wire electrode, consequently damaging the workpiece and increasing costs. Regular monitoring and replacing dielectric fluid is necessary electric discharge machining (EDM) to maintain consistent performance.

Moreover, diionized water helps in regulating temperature during processes. Efficient removal of heat prevents expansion and distortion of the workpiece, preserving precision even for complex operations lasting hours. This is very beneficial in aerospace, medical, and automotive industries where precision is crucial. The overall wire EDM has greatly enhanced with advanced treatment systems for water, boosting dependability and driving the growth of modern technologies.

Surface Finish and Tolerance Holding

In my opinion, the discipline of keeping the tolerance limit and attaining a good surface finish for wire EDM processes is deeply reliant on the control of machine parameters and the efficiency of the flushing processes. Consistent wire tension control, careful thermal equilibrium, and high-quality water treatment systems permit me a level of accuracy and smoothness in even the most demanding applications.

What are the Challenges in EDM Cutting?

- Wire Breakage: The process of work completion may be interrupted due to excessive stress or inappropriate tension leading to wire breakage, which interferes with productivity.

- Thermal Effects: Cutting induces heat which might distort the material or affect the finish adversely.

- Flushing Efficiency: Inadequate flushing contributes towards debris which lowers precision and increases wear on the wire.

- Material Limitations: Certain materials which are difficult to cut such as those with high thermal conductivity.

- Accuracy in Complex Geometries: Sustaining tight tolerance in complex features is challenging without absolute command over all parameters.

Dealing with Wire Breaks and Cutting Tool Wear

These problems can be resolved by a combination of optimized parameters, enhanced technology, and preventive maintenance. Executing these steps improves the productivity and quality of precision machining.

Recent research in machine design and materials science have come up with techniques to reduce wire breakage and increase tool life. For example, employing coated wires such as zinc or brass coated ones enhances conductivity and lowers thermal stresses resulting in reduced breakage risk. Evidence indicates coated wires under similar conditions outperform uncoated wires increasing lifespan by up to 50%.

Moreover, the use of adaptive control systems in modern machines allows for real-time changes to be made to cutting parameters such as the current and pulse duration. This reduces the likelihood of wire breakage during high-speed operations which improves cutting stability and productivity. In some cases, adaptive control technology has wired break incidents by up to 30% in specific use cases.

Additionally, regular cleaning and maintenance of the machine with respect to wear on contact areas must also be performed. Proper removal of debris from the cutting zone can optimize tool life. Newer models of flushing tools featuring enhanced pressure and flow rates are more capable of debris clearing and therefore smoother and more precise operations. Flushing efficiency used with high-pressure systems is increased by 40% which impacts intricate cutting directly.

By implementing these measures with improving technologies, better wire breakage rates as well as the functional lifespan of cutting tools can be achieved while upholding precision and efficient productivity.

Managing Conductive Materials and Workpiece Characteristics

Machining procedures and all other steps that may be associated with them are significantly impacted by selection and business of conductive materials. Some conductive materials like copper or aluminum have to be managed properly on account of their thermal and electrical properties. This is crucial especially in terms of the increase in yield. For example, the large thermal conductivity of aluminum can assist in reducing the extent of local temperature rises during machining, but has to be managed in a consistent manner.

Moreover, workpieces’ hardness, thickness and surface condition also have to be tackled as they critically determine efficiency of processes in question. Research indicates that upper workpiece thickness limits accelerate cutting or marking operations. Harder materials involves greater energy and longer time to process. For instance, the imposition and control of certain parameters like pulse frequency and dwell time has to be set properly so that tools wear out is minimized and results achieved when dealing with materials having more than 500 HV hardness value.

Recently, these processes have been focused on for different materials in some industries by means of smart sensors and integrated feedback systems. Such systems guarantee the implementation of changes on a step by step basis in real time. For instance, a proportion of up to 30% really indicated reduced defects in processes by adjusting power that was sent as a result of dynamic assessment of characteristics of the workpiece. These systems focused on reliability in construction and adjustment of purpose with adaptive capability while responding in flexible manner to different conditions.

In regard to dealing with the intricacy of the workpieces, the combination of new techniques, controls, and specific worked materials has greatly aided the manufacturers. “Greater efficiency with high-quality output” has now become achievable.

Optimization of Feed Rate and Process of Machining

The modern refinement of machining techniques has led to better control over feed rates as well as other process parameters. One research indicates that optimized feed rate alone can reduce the cycle time by as much as 20% while still conserving the component’s integrity. Manufacturers are now able to maintain the expected level of accuracy and precision consistent to the processes being performed with tools, owing to frictionless predictive analytics and real-time monitoring systems.

The addition of advanced dynamic algorithms has further eased the problems at hand by reducing the consumption of energy by 15%. This was achieved through altering the rate of machining in correspondence to the material’s type, hardness, and thickness. The aforementioned technology not only minimizes operational cost but also achieves sustainable manufacturing by lowering energy consumption as demand increases. Decisional analytics concerning machining processes performed are guaranteeing unmatchable speed and accuracy, even with the delicacy of operations involved.

How to Optimize Wire EDM Performance?

- Selecting Appropriate Settings: Alter the cutting speed, voltage, and wire tension of the machine according to the material and precision for the job to be done.

- Use Proper Quality Wires: Use wires of specific composition including diameter that will give a reproducible outcome.

- Keep the Machine Clean: Clean and maintain the machine on a regular basis to avoid inaccuracies due to deposits and to ensure cleanliness.

- Control Dielectric Fluid: Maintain the desired range of fluid cleanliness and conductivity for effective cutting.

- Routine Component Checks: Look and replace worn out parts like the guides and electrodes.

Improving Productivity with CNC Technology

In order to improve productivity with CNC technology, attention must be placed on the functional and tactical utilization of the equipment. To begin, pay special attention to the programming stage; sophisticated CAM tools will eliminate a big portion of errors dramatically shortening the time spent on machining. Moreover, make sure that tools and materials are used according to the needs of the specific project to prevent excessive usage of resources and enhance speed of operation. Performing regular maintenance on the CNC machines will reduce idle time and facilitate seamless operation. Finally, performance monitoring and automation implementation will enable decision making based on real time data enhancing CNC productivity. Altogether these steps will provide a streamlined workflow harnessing the full potential of CNC technology.

Selecting a Coated Wire for the Specific Requirements of the Job

Selecting a coated wire which will suit a certain assignment requires a number of important considerations that affect its compatibility and function. First, determine the application needs like environmental factors, required load, and flexibility. For example, outdoor wires should be resistant to moisture, ultraviolet radiation, and extreme temperature. The coating material like PVC, polyurethane, or Teflon must withstand these factors if it is to provide protection and durability. Then, consider the standards and industry regulations which claim safety and reliability. Further, for the project, analyze the electrical and mechanical requirements to confirm that the wire has sufficient voltage and tensile strength. Making sure all these considerations are made, guarantees that a coated wire will be chosen which will operate safely and effectively for the application.

Enhancing Surface Finish and Tolerance

Choosing suitable machining activities and tools is critical in enhancing surface finish and tolerance. To improve surface finish, it is ideal to start with precision cutting tools that are correct for the surface material since these reduce imperfections. In addition, proper machine setup, calibration and settings including feeds and speeds must be set to achieve smooth surfaces and correct finishes. Surface finish can also be improved by polishing, grinding, and coating. Routine servicing of tools and equipment is important for consistent results and achieving tolerances in the finished product.

Reference sources

- A Review on Current Research Trends in Electrical Discharge Machining (EDM)1:

- Key Findings: This study highlights advancements in EDM techniques, including ultrasonic vibration, dry EDM, EDM with powder additives, and EDM in water. These methods improve machining efficiency, reduce environmental impact, and enhance performance prediction through modeling.

- Methodologies: The research reviews various EDM techniques, focusing on their applications in machining hard materials and intricate parts. It also discusses the environmental benefits of using water and dry EDM.

- New Applications for Micro-EDM3:

- Key Findings: The study explores the use of Wire Electro-Discharge Grinding (WEDG) for producing micro-milling tools. It demonstrates the potential for creating tools with diameters smaller than 100μm, suitable for high-precision applications.

- Methodologies: The research involves developing and testing micro-milling tools using WEDG, emphasizing the advantages of EDM in producing intricate geometries with high surface quality.

- Current Research Trends in Electric Discharge Machining (EDM)4:

- Key Findings: This review discusses the evolution of EDM techniques, including ultrasonic-assisted EDM and powder-mixed EDM. It emphasizes the importance of optimizing process parameters for improved material removal rates and surface quality.

- Methodologies: The study reviews advancements in EDM, focusing on the integration of ultrasonic vibration and powder additives to enhance machining performance.

Frequently Asked Questions (FAQs)

Q: What is Electrical Discharge Machining (EDM)?

A: Electrical Discharge Machining or EDM refers to the eroding of electrically conductive materials with sparking and is a modern machining process. It consists of a series of rapid electrical sparks which form between an electrode wire and a work piece, thus, enabling very precise machining.

Q: How does wire electrical discharge machining work?

A: Wire electrical discharge machining or wire-cut EDM is a form of EDM that utilizes a thin metal wire as a cutting electrode. A work piece of desired geometry is placed in a dielectric bath and exact shape is cut out using electrical discharges from the wire.

Q: What are the advantages of using EDM cutting?

A: EDM cutting has many benefits, the most notable being its capability to cut oblique and complex angles in very hard materials such as tool steels. Unlike other methods of machining, EDM cutting does not need the workpiece to undergo mechanical force, which reduces the mechanical stresses.

Q: What materials can be machined using EDM?

A: The method of EDM is applicable to machining metals that can conduct electricity like tool steels, titanium, various forms of aluminum, and several of its alloys. Other than metals, non-metallic materials like graphite can also be EDM machined.

Q: What is the difference between wire-cut and die-sinking EDM?

A: The metal wire used as an electrode in wire-cut EDM is in a continuum, while in die-sinking EDM, a shaped electrode sinks into the material to create cavities. Both methods remove materials using electrical discharges but differ in their applications and electrode types.

Q: Can EDM be used for hole drilling?

A: EDM is indeed applicable to hole drilling which is referred to as hole EDM or EDM drilling. This procedure is most suitable for machining small, deep holes in hard materials which would be extremely difficult using conventional methods.

Q: What are some challenges associated with EDM cutting?

A: The challenges with EDM cutting include precision control over electrical potential with discharge, maintenance of the electrode wire, external heating on the work piece, and its thermal management. All of these steps require an experienced machinist who can set them up and manage them accurately.

Q: In what ways does EDM differ from laser cutting?

A: Metal fabrication EDM and laser cutting share the purpose of precision cutting; however, they do it through different mechanisms. As the name implies, laser cutting uses a laser beam while EDM uses electrical discharges. Laser cutting can work with more types of materials, including non-electrically conductive materials, while EDM is constrained to electrically conductive materials.

Q: What role does the dielectric fluid play in EDM?

A: For one, the dielectric fluid in EDM maintains electrical insulation between the electrode wire and work piece until the voltage reaches a breakdown threshold where a spark can form. It also aids in the work piece cooling, debris removal, and process stabilization.

Q: Why is EDM referred to as a non-contact machining method?

A: EDM is classified as non-contact as the work piece and electrode wire does not have any physical interaction throughout the cutting process which renders contact pointless. Subsequent material removal occurs through electrical discharges, a feature unique to EDM that sets it apart from traditional machining processes which depend on physical contact between the tool and workpiece.