Zinc is one of those materials used in construction, manufacturing, and other everyday activities; in terms of its resistance to corrosion and durability, it significantly surpasses many materials. However, is zinc prone to rust? Many people often ask the question about zinc. Answering this question is crucial for anyone interested in understanding how the protective nature of zinc is influenced by external environmental factors and how it compares to other metals, such as steel or iron. Zinc Corrosion is a particularly vexing problem, and we will address it here, including its causes, this metal’s unique contributions, and why most industries prefer it over steel, as it accounts for 33% of all sales in India. After this session, you should have some idea of the way zinc functions after a period of operation, as well as why zinc is significant in the production of some sustainable and strong products.

Introduction to Zinc and Its Properties

Zinc is an adaptable metal that is remarkable for its properties of resistance to oxidation and ability to withstand the effects of weather. It is the nature of the material that enables it to rapidly create a self-regenerating film, or patina, if one or both of the two surfaces are exposed to the atmosphere, thereby preventing further oxidation. Easily adaptable, easy to handle, and resistant to pressure, zinc is also a workable metal for numerous industrial processes. Its low toxicity level and reusability have contributed to the acceptance of zinc as a more eco-friendly option by many. Zinc’s properties make it an indispensable material for the overlap of steel, production of alloys, and manufacture of long-life goods for diverse fields.

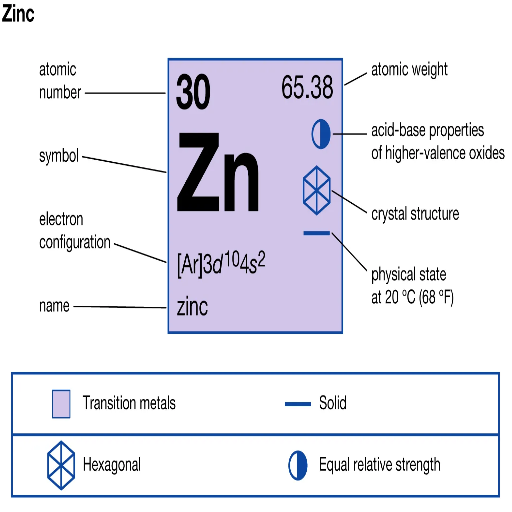

What is Zinc?

Number 30 is the atomic number of the chemical element Zinc. Zn is its symbol. We can observe and extract this lustrous metal from the Earth’s crust, although it isn’t a rare metal in itself. Zinc, although one of the least abundant of several trace elements, is critical in almost all forms of life. It participates in several other essential activities and is crucial for maintaining the health of an organism, as well as its ability to fight diseases. These activities include DNA synthesis and wound healing, which can benefit future generations. From the zinc in our diets and through the food that we eat, to in the absorption, Zn tenders various functions B cells, T Cells or its stability, or even physiological functions and It is widely used in stainless Zn and Other Alloys such as brass Zn is even is in batteries, roofing materials and even cooling agents or medicines used for medical purposes. Worldwide, the consumption of zinc has been on the rise because it is essential for building activities and clean energy systems, such as electric cars, among others.

Unique Characteristics of Zinc

Zinc is a popular metal with numerous characteristics that aid in its specific functionalities. Furthermore, among the many properties zinc can boast of is its corrosion resistance, particularly when used in the process of galvanisation, which helps prolong the life of steel and iron. It can be fused at a temperature that is relatively low, accounting for 419.5°C or 787.1°F, which in effect means that less energy is required for extrusion jobs. Zinc can also be used to make decorative elements, such as brass, as it pairs exceptionally well with other metals and materials.

In the context of natural science, zinc is essential for living organisms, including humans, plants, and animals, as it is a microelement. It is necessary for the development of growth, enzymes, and the immune system. New statistics show that zinc also requires an introduction when technologies start tapping into innovative veins, with a focus on renewable energy. For instance, an increased demand for zinc is on the rise for several reasons, including industrial and technological advancements, such as the development of zinc batteries. For example, the prices of zinc-air batteries are increasing because using zinc as a substitute for lithium-ion batteries is both safe and economical. So zinc remains as stalwart in everyday applications as the demand for this metal has apparent variations.

Advantages of Zinc in Various Applications

- Corrosion Resistance

The prevention of corrosion is what inspires many end-users to understand that zinc is commonly used to protect them from corrosion in Catasteel. They account for more than 50% of global coatings output, which significantly extends the lifespan of both infrastructure and vehicles.

- Energy Storage

The significant shift from conventional energy production to renewable energy makes environmentally safe concepts, such as zinc-based batteries (e.g., zinc-air or zinc-ion batteries), almost mandatory. They are more cost-efficient, safer, and pose less of a threat to the environment compared to lithium-ion battery systems.

- Alloy Production

Zinc is essential for alloy formation, particularly in the production of brass and bronze. They are known for their strength and durability, and are not easy to wear; hence, they are very critical in the production of tools, instruments, and crafts.

- Nutritional Benefits

Human beings cannot afford to do without zinc, as this metal is essential for various health matters involving the immune system, enzyme function, and cell physiology in the body. Thus, in healthcare and crop production, several ways, including the implementation of intensified fertilizing, have been adopted to correct these degenerative tendencies.

- Environmental Applications

Zinc is recognized as a substance suitable for environmentally friendly technologies, as seen in products such as zinc paints and other similar products made with it.

The Science Behind Zinc Rust and Corrosion

Zinc possesses inherent features that make it highly resistant to rusting, thus preventing it from corroding. Moreover, as the metal comes into contact with air, oxygen, carbon dioxide, and water combine to form zinc carbonate, a fragile and water-soluble compound. This means that the exterior level of the metal acts as a protective coating. Since this metal has curved inward, it does not allow other factors to affect the underlying materials. This is why zinc is often helpful as a top coat, in addition to protecting steel from all other harsh conditions, where providing an accurate amount of zinc is critical for surface enhancement.

Does Zinc Rust? The Truth About Zinc

In contrast to iron and steel, zinc does not corrode in the same way when it is treated. The term “rust” refers specifically to the corrosion of iron and its alloys when they are combined with oxygen and water, resulting in the formation of iron oxide. With zinc, there is one more process where corrosion is involved in its production. When air and water come into contact with zinc, it is oxidized, forming zinc carbonate as previously mentioned. This coating acts as a barrier to slow down the corrosion process and prevents degradation of the substrate beneath.

The number one property of zinc that people talk and boast about is its corrosion resistance, especially when it comes to galvanizing steel to make it last longer. Phasically, it can easily repair minor scratches or damage by applying naturally obtained new protective coats that can last and retain their effectiveness under much harsher conditions. In essence, zinc, as a metal, can develop corrosion under certain environmental conditions and over time. However, it does not generally rust as iron does, and its protective abilities make it a convenient material for both industrial and domestic use.

Understanding Zinc Oxidation

Despite zinc oxidation being a fairly natural phenomenon, it is still influenced by several factors, including environmental effects and the chemical reactions zinc undergoes. Exposing zinc to air is what leads to the formation of a protective film known as zinc oxide. The surface coating of zinc is then flowed with the gas to inter-react with the CO2 gas, forming a white, dense, lustrous coating that is soluble and very durable, known as zinc carbonate. This is primarily the reason why zinc is shielded mainly from further oxidation and corrosion.

However, in cases where higher-than-normal concentrations of acidic or alkaline environments are at play, the protection layer of zinc will wear off, thus triggering its oxidation. Metal dust particles are due to zinc corrosion and have relatively low resistance to environmental damage. Perhaps the most profound increase in surfacing residues in marine zones is related to the dynamic discharge of industrial effluents. What contributes to this effect is a decrease in ‘substitution levels’ reached, which in turn increases the demand for the metal in question. Yet, these situations exist, and people continue to use zinc due to a high level of faith in its inherent property of repeatability in the self-protection process.

The Formation of a Protective Patina

It is clear to the majority of users that zinc’s protective patina in strenuous conditions is a subject that elicits numerous questions. A typical protective layer on zinc, comprising mainly zinc carbonate, is formed when the central zinc mineral carbonate reacts with airborne carbon dioxide, water, and oxygen available. This form of corrosion, also known as white rust, is a slow process; as a result, over time, the layer becomes harder and thinner. Intermittent corrosion is a rare phenomenon. Users have recently shown signs of this resistance in more extreme conditions, such as marine and industrial environments, and the success of protective coatings in zinc has been well established.

Recent developments in material sciences have noted that zinc is capable of regrowing its protective coating without external or chemical intervention, even after being scratched. It is such functionality that ensures continued reliability, particularly in such applications as I/Zn; however, it is not practical to consider the extent of this protection for extreme climatic or industrial environments. For example, the behavior of galvanized buildings is quite satisfactory, as they can perform well due to the durability of galvanized steel. This is primarily due to the protective properties of zinc, which serves as a coating that addresses many of the issues associated with the most frequently searched topics.

Zinc’s Rust Resistance in Different Environments

Providing an effective barrier feature, zinc is known to be highly resistant to rust in several locations. As can be seen in the example, zinc resists all forms of damage in polluted urban and industrial atmospheres. It can combat sulfur dioxide or other aggressive environments without losing its protective properties. Furthermore, in conditions such as coastal and marine environments, zinc is highly resistant to corrosion by salt, which is a significant advantage in terms of the economic lifespan of the structures. With its various applications, it is a material that can be used in areas where high levels of strength are required, combined with minimal maintenance requirements.

Effects of Moisture and Humidity

Materials and systems are sometimes significantly affected by moisture and humidity; these effects may include durability and performance factors, as well as increased maintenance requirements. Consequently, this article outlines five impacts of moisture and humidity that are elaborately discussed:

- Corrosion Acceleration

High levels of humidity provide conducive conditions for the corrosion of certain metals, causing them to oxidize at a faster rate. To an extent, the chemical action of some materials, which are otherwise protected or do not corrode under normal dry conditions, is affected by the speed at which they deteriorate, with a decrease of up to 70% compared to dry conditions.

- Material Degradation

Moreover, moisture over time deteriorates porous materials, such as wood, concrete, and textiles. Wood in the presence of moisture can become larger, twist, or degrade. As for concrete, it will develop fissures due to water penetration.

- Structural Integrity Reduction

There are adverse effects of higher humidity on materials when they are used in construction or infrastructure, especially those that are not compact, allowing moisture to accumulate over time. This is quite typical, as seepage of water can often be seen through unsealed expansion joints or poorly grouted cracks, which later leads to structural distress.

- Mold and Mildew Growth

The ballooning families of Mucor and Penicillium breed ever faster in humid air and create layers of wall-ruining polypores swiftly, thriving in such frowzy corners. Causes ill-health to those who reside within.

- Electronic Malfunction

However, the most technical malfunction that can occur under humid conditions is water entering electronic devices, causing short circuits, component corrosion, or damage to insulation materials. The concern is noted when high humidity damages electrical installations in semiconductor/IC clean facilities.

Recognizing such dangers highlights the importance of planning the installation of machines and selecting materials that can withstand the harmful effects of moisture and humidity. The application of appropriate accessories, such as anti-corrosive coatings, humidifiers, and dehydratory fans, may help manage these dangers.

Impact of Temperature Changes

Temperature changes pose a risk to the functioning of electrical fixtures and devices, potentially leading to performance degradation and, in some cases, failure. Quantitatively, there are about five observed effects of temperature on a system:

- Thermal Expansion and Contraction

- When the temperature of a body fluctuates, it can undergo expansion and subsequent contraction. This cycle continues on and off, which sometimes causes the body’s systems to become overexerted. This force leads to cracked insulation, weak connections, and joint failures, among other things, with time.

- Reduced Lifespan of Components

- At higher temperatures, insulation and semiconductor materials tend to age more rapidly. For instance, experiments have shown that the lifespan of electronic devices is halved at each 10°C temperature increase during operation.

- Resistive Losses

- With increasing temperatures, the resistivity of conductors like copper and aluminum increases; as a result, energy dissipation increases, inefficiency and unnecessary heat are created in electric power systems.

- Condensation Issues

- A sharp decline in temperature could lead to the formation of condensation on the electrical components. Moisture can cause short circuits, lead to damage from rust, or even render the entire equipment unusable.

- Overheating of Equipment

- Heat exposure for an extended period will soon cause the transformers, motors, and other electric machinery driven by motors to overheat, which would otherwise require expensive repairs.

However, with the use of proactive measures in system designs, relays, and air conditioning, along with others, the impacts of temperature changes can be drastically minimized.

How Air Quality Affects Zinc

The corrosion and deterioration of zinc materials are caused by the quality of the air, which is a determining factor in the process. Air pollution affects the rate of zinc oxidation, especially in the forms of pollutants in the air, such as sulfur oxides. What tends to happen is that the zinc becomes a metal that exists in a deep state, and this condition arises through the formation of zinc sulfate or zinc nitrate during the oxidation of zinc. Such materials have a structured system that changes over time, reducing their strength due to the presence of sulfate or nitrate.

Activities such as industrial and vehicular emissions in the areas will therefore deteriorate the manufacturing of zinc due to the acidic substances in the air. Changes in climate, such as humidity and temperature, can also contribute to situations that give rise to these effects, as they make the environment conducive to such actions. Suppose we want to meet or exceed the design life of zinc elements in machinery and structures. In that case, it’s imperative to take the insurance of protective coatings, regular housekeeping, and environmental controls.

Applications of Zinc Across Industries

Due to its numerous valuable properties, zinc holds significant importance in various areas. It’s necessary to mention the use of the element in galvanizing steel as a corrosion protection measure for the development of high-rise structures, cars, and other civil constructions. Zinc plays a crucial role in the production of many alloys, such as solid brass and sterling bronze, which are used to produce tools, decorative items, and those incorporating precision engineering. For health purposes, it is worth noting that zinc is a constituent in various medications and tonics. Furthermore, zinc-containing substances are of great relevance for the development of products such as paints, rubber, and batteries, thereby contributing to advancements in various fields, while also promoting growth and environmental sustainability.

Zinc in Construction and Building Materials

Zinc is a durable, corrosion-resistant, eco-friendly, and versatile material, making it a preferred choice in modern construction.

|

Key Point |

Details |

|---|---|

|

Durability |

Long-lasting |

|

Corrosion |

High resistance |

|

Eco-Friendly |

Recyclable |

|

Versatility |

Malleable |

|

Aesthetics |

Unique patina |

The Role of Zinc in Automotive Manufacturing

A significantly important feature of utilizing Zn in the automotive sector is its good corrosion resistance. For example, one of the most widespread areas where its use is predominant, such as in the automobile industry, is in the zinc coating of steel used in car bodies and structural components. The above-mentioned galvanized coating is ideal due to zinc’s ability to protect the parts of an automobile from corrosion induced by moisture and road salt. In addition to anti-erosion compounding, zinc junctions and their compounds are applied in the automotive industry, particularly in die casting, where numerous engine parts, handles, and support components are manufactured. By ‘opening up’, strengthening, and copying the companies, these zinc die cast components have been able to enhance their power and align themselves with recycling, which is highly effective in the new automotive sector. Progress in the field of these materials has also enabled one of the key objectives of the modern automotive world – boosting eco-efficiency, reducing carbon emissions, and enhancing the fuel economy of transportation- to be met more effectively. All other things being equal, vehicle manufacturers should instead rely on the chemical element because it is inexpensive and can be used in almost every part of the car, which is why it is an essential factor in producing environmentally beneficial automobiles.

Use of Zinc in Other Industries

Zinc holds a significant grip far beyond the automotive industry, playing a strategic role in various other industries. For instance, in the construction sector, the use of galvanization – or more simply, steel coated in zinc – is prevalent to prevent damage due to corrosion, thereby increasing the useful life of structures. This sample is approximately half of all zinc produced, which is used in the galvanization process. This states that the need for this mineral is required to ensure durability and environmental conservation aspects in buildings.

It is worth noting that zinc plays a crucial role in both the healthcare sector and pharmaceutical manufacturing. Embodied in the content of nutritional medicines, including food supplements, vitamin supplements, zinc is the most essential mineral necessary for supporting immune system functions, as it is present, for example, in a large number of products against ARVI and vitamins. The evidence from numerous studies suggests that zinc deficiency may lead to serious health issues, implying that zinc is a strategic nutrient in various global health-focused interventions.

Another key area where zinc benefits are evident is in agriculture. In plants, it is necessary for plant growth as a vital micronutrient associated with enzyme activity and protein synthesis. Zinc-based fertilizers, for example, have been claimed to enhance crop output, thereby addressing the issue of food scarcity that arises in many nations in a growing world.

Zinc’s use in various fields, such as infrastructure, healthcare, and agriculture, holds promise for the future if the sector continues to develop, as demand for and improvements in the production processes of the element remain high.

Comparing Zinc with Other Metals

An excellently supple metal, zinc boasts illustrious qualities for several reasons. Unlike metals such as aluminum and copper, zinc is very resistant to decay, making it perfect for the steel enhancement process. While lacking in the corrosion resistance quality of zinc, lead contains a toxin, thereby limiting its scope in the products above. As a result, the substantial use of sunscreen and zinc-based anti-aging creams is not uncommon. Furthermore, zinc is non-toxic, allowing for the formulation of a wide range of consumer products that contain it.

Regarding the price, zinc is relatively less expensive than copper, compared to zinc-pura. It appears to be the more accessible metal due to its substantial wealth of applications in construction, medicine, and food processing. It is such factors that make this type of supply efficient and indispensable across many different industries.

Zinc vs. Aluminum: Rust Resistance Comparison

Zinc offers superior corrosion resistance compared to aluminum, especially in harsh environments, due to its self-healing patina.

|

Key Point |

Zinc |

Aluminum |

|---|---|---|

|

Corrosion |

High resistance |

Moderate |

|

Durability |

Self-healing |

Lightweight |

|

Melting Point |

Lower (420°C) |

Higher (660°C) |

|

Conductivity |

Moderate |

High thermal |

|

Applications |

Harsh conditions |

Lightweight needs |

Zinc vs. Stainless Steel: Performance Analysis

Stainless steel offers superior strength, durability, and corrosion resistance, while zinc provides cost-effective corrosion protection and self-healing properties.

| Key Point | Stainless Steel | Zinc |

|---|---|---|

| Corrosion | High resistance | Self-healing |

| Durability | Long-lasting | Moderate |

| Strength | Superior | Adequate |

| Cost | Higher | Lower |

| Applications | Harsh environments | Outdoor, coatings |

Understanding Zinc Alloys

In the context of zinc alloys, it is essential to remember that they are synonymous with overcoming the limits and definitions of properties. It is the use of zinc alloys that fall under the items typically used when zinc is mixed with elements like aluminum, copper, or magnesium to improve its integrity or enhance its plasticity. In my opinion, these alloys are preferred for processes such as die-casting, considering the precision and service life of the aluminum component. Since they can be remodeled easily and their cost of production is low, it is hard to do without them in many sectors, such as the automobile and electronics.

Reference Sources

- Massachusetts Institute of Technology (MIT): Will Zinc Rust – Explains that zinc does not rust but can corrode under certain conditions.

- Princeton University: Corrosion – electrochemical2 – Details the oxidation process of zinc and its protective properties.

- Lehigh University: Corrosion and the Environment – Discusses how zinc forms a protective oxide layer to prevent further corrosion.

- Illinois Department of Public Health: Zinc Fact Sheet – Highlights zinc’s role in preventing rust through galvanization.

- NASA: Corrosion Fundamentals – Explores zinc’s sacrificial protection in corrosion prevention.

Frequently Asked Questions (FAQs)

Q: Does zinc rust?

A: Zinc does not rust in the traditional sense, as it does not form iron oxide. Instead, zinc forms a protective layer of zinc oxide when exposed to moisture and oxygen, which provides corrosion resistance and prevents further degradation.

Q: What happens to zinc when it corrodes?

A: When zinc corrodes, it typically forms a white rust known as zinc carbonate or zinc hydroxide. This occurs when the zinc is exposed to moisture and environmental factors, but it does not compromise the underlying metal as much as red rust does in iron or steel.

Q: How does zinc protect steel from rusting?

A: Zinc protects steel by acting as a sacrificial layer. When zinc-coated steel is exposed to moisture, the zinc corrodes preferentially, preventing the underlying steel from rusting. This process ensures that the base steel remains intact and rust-free.

Q: What is zinc plating?

A: Zinc plating is the process of applying a thin layer of zinc to steel or iron to enhance corrosion resistance. This zinc coating acts as a barrier between the metal and environmental factors that cause rust and corrosion.

Q: Can zinc corrode in saltwater?

A: Yes, zinc can corrode in saltwater due to the presence of chloride ions, which can accelerate the corrosion process. However, zinc remains highly resistant to corrosion compared to many other metals, making it suitable for marine applications when appropriate protective measures are taken.

Q: What is galvanic corrosion with zinc?

A: Galvanic corrosion occurs when zinc is connected to a more noble metal in the presence of an electrolyte, such as water. In this scenario, zinc acts as the anode and corrodes to protect the underlying metal, which can lead to the faster degradation of the zinc layer.

Q: How can I prevent zinc corrosion?

A: To prevent zinc corrosion, ensure that the zinc coating is intact and apply protective measures such as paints or sealants. Regular maintenance and inspection can help identify areas of wear and prevent exposure to moisture and oxygen.

Q: What is the difference between white rust and red rust?

A: White rust forms on zinc when it corrodes and is comprised of zinc oxide or zinc carbonate, while red rust refers to the oxidation of iron, forming iron oxide. White rust is less harmful to the underlying metal compared to red rust.

Q: Is galvanized steel resistant to corrosion?

A: Yes, galvanized steel, which is coated with a layer of zinc, is resistant to corrosion. The zinc layer protects the steel by corroding first, thereby preventing rust from forming on the underlying steel.

Q: How does zinc react with environmental factors?

A: Zinc reacts with moisture and oxygen to form a protective layer of zinc oxide. This layer acts as a barrier, minimizing further corrosion. However, environmental factors such as saltwater can accelerate zinc corrosion, highlighting the importance of protective coatings in harsh conditions.