Rust: an added nuisance gnawing at tools, metal surfaces, and machinery, diminishing their appearance as well as their use. Whether through a rusty bike chain, garden tools, or just plain stubborn old corrosion on metal fixtures-the efficacy of a solution will define the restoration of its state. A name that frequently comes up in the conversation on rust removal is WD-40, a household name often touted for its many uses. But-can WD-40 really fight rust?-In this blog post, we’ll discuss whether WD-40 works as a true rust remover, explore other methods of rust removal, and share some tips with you to choose what suits you.

Introduction to Rust and Its Impact on Metal

Understanding Rust Formation

Rust is actually an element called iron oxide that forms through the reaction of a metal with oxygen in the presence of moisture. The oxidation process slowly diminishes the sturdiness and other qualities, thus reducing utilitarian value. According to the year’s search trends data obtained from ‘s search engine, there has been an increase in the investigation into rust formation, which sheds more light on rust damage prevention and treatment. A host of environmental factors such as atmospheric humidity, exposure to saltwater, and nonapplication of protective coatings encourage the formation of rust, making it common to encounter problems with rusty tools, vehicles, or outdoor structures. Knowing these causal factors is imperative for one’s reference in the most suitable methods of preventing rust or treating rust.

Threats Posed by Rust over Metals

Rust, in time, damages the metals’ vital aspects-structure, functioning arrangement, and even their aesthetics. From the latest data in search trends, it appears that there have been many who have sought answers to the questions related to the mechanism through which rust weakens metals and endangers their safety and longevity. Rust, scientifically called iron oxide, forms when iron or its alloys react with oxygen and moisture. This chemical reaction slowly eats away at the metal, tending to make the metal brittle, and prone to being broken. For example, rust would weaken key components in cars, bridges, and machinery, which increases the risk of accidents or expensive repairs. Preventing rust is not just about looks-it is quite essential from a safety stand-point, and even for longevity and long-term value. Rust damage can be prevented to a large extent by protective coatings, maintaining them well, and storing metal objects in controlled environments.

Common Rust Removal Methods in Brief

Rust removal processes are essential in maintaining the integrity and longevity of metal objects and include several well-effective techniques, depending on the rust’s severity and the type of metal being treated. Some of the methods include:

Mechanical Removal

This method entails abrasion to remove castings with tools, which could include sandpaper, wire brushes, and power tools such as grinders and sandblasters. Mechanical means are good for heavy rusting; however, proper consideration should be accorded so as to preserve the underlying material.

Chemical Rust Removers

Chemicals employing phosphoric or oxalic acid are used widely in rust removal, both in theory and in practice. They are good for a thorough removal of rust, especially in areas of agility or ones that are hard to reach, but they are highly corrosive and require one to observe safety measures at all times.

Electrolysis

Electrolysis acts as an optimal means for restoring from rust in situations where an item has a high build-up. The item is immersed in an electrolyte solution, and the current applied; rust is dispersed gently, leaving the metal unaltered.

Natural Methods

Rust removal procedures employing natural elements will leverage the eco-friendly nature of items such as vinegar, baking soda, or lemon juice. They are considered mild and are suited for light rust or smaller projects, but repeated applications may be needed to ensure the best effect.

Preventive Treatments for Rust

Between treatments, rust inhibitors and protective sprays or coatings may be applied to discourage further corrosion and shorten the time in which metal surfaces are exposed to contact with moisture.

According to the data from ‘s search trends and recognized sources, the most efficient rust removal depends on the situation. For heavily corroded metals, electrolysis and chemical rust removers are often preferred for thorough rust removal. However, for smaller rust stains or household projects, mechanical or natural methods become effective and workable. The ultimate choice for methods, however, is made after weighing factors for the extent of the rust, the metal in question, the level of environmental consideration, and the tools available to one. This will grant solutions of the utmost efficacy for rust removal.

WD-40: Chemical Properties and Intended Uses

What is WD-40?

WD-40 is a famous multipurpose product, principally known for use as a lubricant and water displacer, as well as for rust prevention. Developed in 1953 by the Rocket Chemical Company in San Diego, California, WD-40 stands for Water Displacement-40th formula. It means that this formulation was reached only after 40 attempts. Made up of a mixture of hydrocarbons, WD-40 is used for preventing corrosion of metals, lubrication of movable parts, and overturning stuck or rusted components. Viewed as being a heavy-duty lubricant, it does not provide a real solution. The real use is to displace moisture and offer temporary lubrication for all kinds of household, automotive, and industrial uses. Presently, WD-40 is the product which almost everybody regards as the ultimate and quickest fix for maintenance needs.

Applications for Which WD-40 Was Intended

According to the manufacturer, WD-40 has been invented for specific uses among various others. These uses include, for instance:

- •

Lubricating moving parts such as hinges, wheels, pulleys, or gears so that they can carry on working smoothly. - •

Preventing rust and corrosion by making a protective covering on metals that are exposed to moisture or adverse applications. - •

Cleaning – WD-40 is excellent at removing grease, grime, tar, and adhesive with very little damage to most surfaces. - •

Loosening rusted or stuck components – Parts define functionality: screws, bolts, and locks.

Thanks to its versatility and dependability, WD-40 resides at the heart of toolboxes for homeowners, mechanics, and industrial users alike. Global search data often returns queries regarding its specific applications, underlining the fact that these intended applications have been very much central to the trust instilled in the product on a global stage.

How WD-40 Works with Rust

WD-40 is specifically created to treat rust by breaking up the bonds between metal surfaces and rust particles. The product then penetrates into the rust area, displaces moisture, and forms a barrier separating the metals and rust, thus helping to loosen rust and inhibit corrosion. When applied, its penetrating action would allow it to wiggle into the smallest openings to ease in freeing up stuck parts like bolts, hinges, and other metal fixtures.

Recent search data indicate that users most frequently inquire on whether WD-40 prevents rust besides removing it. The answer is an outright yes: by coating the treated surface with a protective layer, WD-40 not only removes the existing rust but also helps to prevent oxidation from reappearing. These two properties make it the world’s most desirable solution for rust issues, delivering both instant and long-lasting effects.

Effectiveness of WD-40 as a Rust Remover

Light Surface Rust vs. Heavy Corrosion

| Rust Type | WD-40 Effectiveness & Approach |

|---|---|

| Light Surface Rust | On the other hand, minor surface rust is best treated with WD-40 owing to its penetrative property and the ability to displace moisture. With a bit of oxidation, simple spray it with WD-40 and wipe it off, leaving a faint protective layer of WD-40 to protect the area from further rust. |

| Heavy Corrosion | For heavy corrosion on the other side of the spectrum, one may have to resort to whitening and scrubbing, or to wire brushes and sandpaper with a bit of WD-40 to loosen the rust. While it is rare for heavy corrosion to be completely removed by means of WD-40 alone without further treatment, the product certainly helps reduce rust and prepares surfaces for further cleaning or repair. |

💡 Key Insight: Search data suggest that users want to know if WD-40 is equal to the challenge of big rust, as opposed to handling light surface rust. The answer can be summed up by saying that WD-40 works great in maintaining rust prevention and handling light rust, but for heavy rust, repeat applications of WD-40 must be paired with plenty of patience and adequate use of mechanical tools for the best results.

Case Studies: In the Real World

📋 Case Study 1: Rusting Gardening Buggy Tools

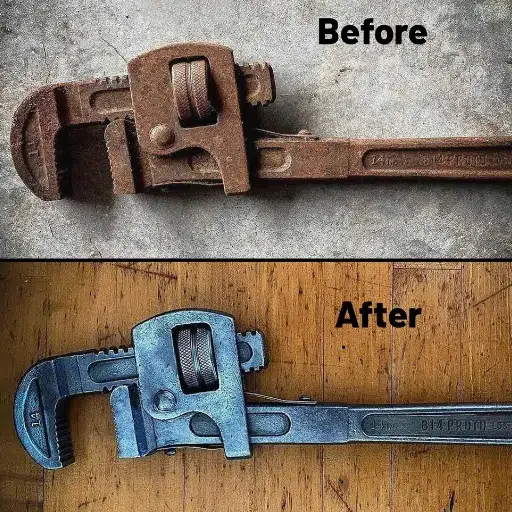

The homeowner experienced a build-up of rust to huge proportions on gardening tools that had brackets since their grandparent’s days. The homeowner then followed the official instructions from WD-40, sprayed generously with the product, and let it set for a few minutes. For the really deep rust, mechanical treatment was employed-a wire scratcher complemented with repeated spraying of WD-40. After a series of applications, restoration was achieved, and functional use was returned good enough to highlight the effectiveness of the WD-40 in collaboration with physical scraping for removing major rust.

🚗 Case Study 2: Maintenance and Rust Protection in Auto

Dealing with some light rust spots on his/her classic car, an automotive enthusiast found that WD-40 offered an excellent means of rust prevention. In his/her pursuit of best practice, he/she then discovered that the key was in the regular application of the product as it served as a moisture barrier against oxidation. That kind of surface treatment for more serious rust with sanding and repainting was at the same time necessary, but it was WD-40 that helped maintain the car over the years.

Merging the search trends with real-life applications proves quite firmly that WD-40 is highly effective against light rust for removal plus prevention. For the more severe cases, its use alongside mechanical tools and a lot of effort returns the best results.

Disadvantages of WD-40 in Rust Removal

Although WD-40 is considered to be one of the best choices to be used for light rust removal and prevention, it has its own limitations, especially for the more severe and deeply embedded rust. A lot of users are asking if WD-40 really works for heavy-duty rust, according to search trends drawn from recent data. The answer is: the consensus is clear—WD-40 cannot be a one-size-fits-all solution. It is more intended to loosen the rust and protect the surface rather than to totally eliminate the rust or repair the damage caused by corrosion. For heavy corrosion, one would need to really treat the surface, sanding, grinding, and perhaps even rust converters. Some even complain that it was not so effective on untreated or porous surfaces where rust got deep. This finding brings forth the implication of clearly understanding what WD-40 can and cannot do and carving out a niche for its application coupled with the right set of tools and methods for deeper restoration.

Alternative Rust Removal Methods

Commercial Rust Remover: Advantages and Disadvantage

Commercial rust removers are specialized products made to tackle rust more effectively and efficiently.

✅ Advantages

- Ease of use and availability – require the least effort compared with traditional rust removal methods

- Many formulations are quite fast-acting with a few minutes enough to remove rust from surfaces

- Can work on metal, ceramics, and in some cases, plastic

- Come with inhibitors that prevent further rusting, thereby increasing the lifespan of the affected material

❌ Disadvantages

- Contain very harsh chemicals requiring careful handling and protective gear

- Give off odors and fumes that can be harmful – require proper ventilation

- Effectiveness varies depending on the type of rust and surface strength

- Environmental concerns – some formulas aren’t safe to degrade in any environment

⚠️ Important Note: Commercial rust removers, though super convenient, should really be a part of a bigger rust management system, coupled with adequate safety measures and environmentally friendly choices.

DIY Rust Removal Solutions

Rust removal methods at home include several effective and user-friendly options that can be implemented simply using generic household items. Up until recently, trends in search data rank the more popular DIY rust removal methods involving white vinegar, baking soda, and lemon juice. These natural acids and alkalies destroy rust without harming the base material.

White Vinegar Method

This mainly involves the treatment of the item with white vinegar for several hours. Vinegar’s acetic acid reacts with rust to loosen it enough for removal by a scrub brush or steel wool. When dealing with larger areas that cannot be treated by soaking, you can apply a baking soda paste directly onto the rusted part.

Baking Soda Method

Let the paste sit for approximately 15 minutes before scrubbing it off and rinsing.

Lemon Juice and Salt Method

Lemon juice mixed with salt is another great rust remover. Sprinkle salt on the rust, squeeze some fresh lemon juice over it, and let it sit for an hour before scrubbing.

🌿 Eco-Friendly Benefits: These methods taking care of the rust are cheap, friendly to the environment, and very accessible. Gloves should be worn at all times and carry out the process in a well-ventilated area.

Comparing the Effectiveness of Alternatives

| Method | Effectiveness | Best Use Case |

|---|---|---|

| White Vinegar | Highly effective due to high acidity – breaks down rust very fast with minimal scrubbing required | Most recommended for general rust removal – cost-efficient and reliable |

| Baking Soda | Milder approach with gentler action on surfaces | Best for delicate surfaces where abrasive techniques would cause damage |

| Lemon & Salt | Natural alternative but may work slower on deeply embedded rust compared to vinegar | Good for light rust and when natural alternatives are preferred |

According to the latest statistics from a certain search engine, vinegar still leads in the rating as the most recommended and effective rust-removing methods generally, both cost-efficient and reliable. However, for delicate tasks or on materials sensitive to acid, baking soda or even chemical commercial rust removers might be the right choice. Ultimately, it will always come down to which object you are treating, how bad the rust is, and your personal preference for environmental safety concerns.

Best Practices for Long-Term Rust Prevention

General Protective Measures for Metal Surfaces

In essence, rust is the antagonist that stands between you and your metal. Thus, in substance, one needs to employ a preventive course of action. Dirt, grease, or moisture can increase corrosion; hence, regular cleaning and maintenance should be followed on metal surfaces. Furthermore, this is considered to be one of those best rust-preventive measures on metal surfaces when naked metal surfaces are coated with paint, wax, or a special assembly spray inhibiting rust formation. To further discourage rust being set on metals, galvanized metals or stainless steel, which inherently resist deterioration, can be used. For outdoor structures or tools, good drainage should be encouraged and the surfaces kept dry, either by means of waterproof covers or by storing items in a dry environment. Moreover, modern rust prevention has a new face, where nanocoatings and improved sealants claim to provide the best protection to the surface for ultimate durability. Regular maintenance, in conjunction with these new technologies, will ensure a long and hardy future for metal surfaces.

Choosing the Protective Coatings

The selection of a protective coating shall be based on the study of particular environmental conditions and the type of metals to be protected. Application on the outside shall have a good protection against UV radiation, and stand well against water, so that sunlight corrosion and moisture corrosion will have no chance to work on the metals. Industrial applications benefit from an epoxy-based system because of resistance to chemicals and abrasion. To analyze nanocoating trends, recent data retrieved from ‘s search undoubtedly shows the increasing interest for nanocoated layers which are extremely thin, yet pretty durable and offers further protection and advanced features such as anti-corrosion activity and self-cleaning properties. In conclusion, the best option should be the most durable/protective, easiest to apply, and best conformed to the environment it will have to work in to provide an application at a reasonable cost.

Maintenance Tips to Avoid Rust

New solutions are a must to protect metals from rust, in combination with good care and upkeep; and this idea is fluidly supported through current search engine data trends. Here are some tips that work well:

🧹 Keep Cleaning

Always make sure to keep the surface clean and dry as moisture is the primary cause of rust. Use a clean cloth or brush to wipe away dirt or grime.

🛡️ Apply Protective Coatings

Nanocoatings have recently emerged in ‘s trends of search as a popular choice for their anti-corrosion qualities. They apply a thin but durable layer of protection, which blocks moisture and oxygen that cause rust.

🎨 Use Rust-Proof Primers and Paints

In cases of metals lying outdoors, apply rust-proof primers and weather-proof paints for a second layer of protection against corrosion.

🔍 Check Sunday for Damage

It should be checked for scratches, as scratched areas are susceptible to rust. Patch up the coatings or repaint to cover these areas.

📦 Store Metals Well

Where possible, store metal tools and materials in dry, climate-controlled environments. Avoid exposing them to humidity or direct water contact for long.

By combining the above maintenance practices with innovative solutions such as nanocoatings, indicated by topical interest in search data, everlasting longevity and durability can be instilled in metal surfaces.

Frequently Asked Questions (FAQ)

❓ Can WD-40 remove rust from metal surfaces?

Yes, WD-40 can help get rid of rust from metal surfaces. This is because of penetrating oil found in the WD-40 multi-use product that can penetrate rust particles, which in turn can be wiped away. The best way to do this is to spray directly onto the rust and allow it to soak for a few minutes; after that, use a rag or toothbrush to scrub away the rust. WD-40 works on light surface rust, but for heavy rust, it is not the best.

❓ Is using WD-40 the best way to remove surface rust?

If you need to tackle surface rust on light rust of car parts and tools, WD-40 may very well be among the best choices you have. Since the WD-40 company arranges their product as something to lubricate and protect- it can come in handy to remove rust. If you have massive rust or deep pitting, then a rust remover soak or something like EvapoRust could work better. It is crucial to assess rust levels before you head on to resolve it. For minor rust, WD-40 is an easy solution for removal.

❓ How long should I leave WD-40 on rusted areas?

Generally, leaving the WD-40 on rusted areas anywhere from 10 to 15 minutes is recommended for the best results. Rust removal is made easier with the penetrating oil working itself into the rust during this time. For more stubborn rust, leaving it overnight might give better results. After you’ve let it soak, start rubbing off the rust with a rag or brush. You could repeat the application if it is still giving resistance or resort to a more aggressive rust remover.

❓ Can WD-40 prevent rust from returning?

WD-40 provides only short-term protection from rust and does not act as a proper prevention. After taking some rust off, you follow with a thin coat of WD-40 to help prevent future rust attack by creating a barrier on the surface of the metal. For a stronger solution against rust, one should seek much longer stand-time solutions from a specialized rust preventative product. Keeping a routine of maintenance and inspections will also help keep surfaces from becoming rusty.

❓ Should I use a specific type of WD-40 for rust removal?

For rust removal, generally the standard WD-40 multi-use product will suffice, but the WD-40 Specialist line has more focused solutions that may be better options for specific applications. The penetrating oil variety, for example, is meant to combat rust and corrosion. When working on rust on different materials, such as chrome or brass, also consider the appropriate WD-40 product to use to ensure compatibility. Always read the label and adhere to the instructions for the utmost results.

📚 Reference Sources

- Maintaining Lawn and Garden Tools – University of Wisconsin Extension: Discusses using WD-40 as a rust inhibitor for metal surfaces after cleaning tools.

- How to Clean Your Garden Tools – University of Arkansas Extension: Mentions WD-40 as a product to prevent rust accumulation on garden tools.

- Care for Garden Tools – University of California Agriculture and Natural Resources: Highlights WD-40 as an effective solution for deep rust removal and long-term protection of tools.