When considering the aspects of lasting durability and strength, countless industries turn to steel with the quality laboratory inside the core. Still, one customer issue lingers: does galvanized steel rust? Understanding the interplay between metal corrosion and its protective coating is key in making the right decisions in building, manufacturing, and everyday use. This article will take you through the scientific aspect of corrosion, the preventive streak of galvanization, and the maintenance tips on galvanized steel for ensuring longevity. This guide will enlighten a builder, a DIY enthusiast, or just a casual viewer concerned about how metals live on against the passage of time-namely, with useful insights into protecting and preserving galvanized steel.

Introduction of Galvanized Steel

Galvanized steel has the zinc coating by which it gets so-called, and this zinc coating prevents its rusting or corrosion. The zinc coating acts as a barrier, preventing moisture and oxygen from getting to the steel surface and degrading it. Put simply, galvanized steel with a bit of zinc offers very high durability and suitability for outdoor or wet environments since it can stay exposed to elements for long without much maintenance.

To define Galvanized Steel

Galvanized steel is truly the steel that resists corrosion by way of processes of galvanization, i.e., coating a steel component with a layer of zinc-metal. The zinc coating will not let moisture and oxygen reach the steel below the layer, and it also protects the steel cathodically. That is to say, if the protective layer of zinc gets scratched off and does expose the steel underneath, the zinc will start to corrode in place of the steel-this is known as the sacrificial protection.

According to the latest resources, galvanized steel can be divided into various types based on the different methods of galvanization, including hot-dip galvanization, pre-galvanization, and electro-galvanization. Hot-dip is more common, wherein the steel is dipped in molten zinc at about 840 degrees Fahrenheit (449 degrees Celsius). It will provide excellent durability by forming a strong metallurgical bond between zinc and steel with a series of zinc-iron alloy layers.

A study said that it is easy for hot-dip galvanized steel to last more than 50 years in rural places and roughly 20-25 years on the seaside or in an urban environment with greater exposure to moisture and pollutants. Based on their longevity, it thus becomes an economical option for industries such as construction, automotive, and agriculture, where structural integrity and corrosion resistance are critical factors.

Galvanized steel is also certified to be green because the zinc element is naturally occurring and can be recycled so many times. This gives products made of galvanized steel an edge with regard to sustainability because the present emphasis is on reducing environmental impact.

Some Common Applications of Galvanized Steel

Glancing at those properties of durability and corrosion resistance, galvanized steel has many applications in various industries. Following current views, constructions, automotive manufacturing, and infrastructure development are the primary applications driving the global galvanized steel market.

Construction Industry

Galvanized steel is used from structural components in construction to vandalism-laden items such as beam, roofing, and fencing. Building remains safe and useful for decades owing to the ability of the material to withstand harsh weather conditions and to resist rust. Recent data showed that galvanized steel accounts for about 40% of the total steel used in modern construction projects around the world.

Automotive Industry

Automotive manufacturers utilize this material in the manufacture of automobile frames, body panels, and underbody components due to its high tensile strength and rust resistance that contribute to vehicle longevity. Recent studies reveal that close to 80% of vehicles manufactured globally feature galvanized steel in the design to ensure safety as well as promote sustainability.

Agriculture

Usually, galvanized steel is used in the manufacturing of agricultural equipment, including water tanks, storage silos, and irrigation systems since the zinc application provides a protective barrier for the steel part, even in ambient moisture or chemical environments.

Energy and Infrastructure

From utility poles to mounting structures for solar panels, galvanized steel finds its way into infrastructure activities. Being able to perform under extreme stress lends it quite well as power transmission towers and setup for renewable energy systems. The demand for galvanized steel in the renewable sector rose 7% by 2023 aided by enormous global solar and wind projects.

With the application areas, it is understandable why galvanized steel stays a favored material for industries that wish to strike the right balance between performance, cost, and environmental sustainability.

Importance of Corrosion Resistance

Being resistant to corrosion is one of the striking features of galvanized steel. Resistance to corrosion extends the life of a structure and reduces maintenance cost. Whereas unprotected steel rusts in humid or marine atmospheres, galvanized steel with its zinc coating forms a barrier against those hostile elements. Recent studies showed that under proper conditions, galvanized steel can last for 70 years, far from the lifespan of untreated materials. This adds to its necessity in construction, automotive, and energy infrastructure industries, wherein durability and reliability stand on the priority list.

Additionally, corrosion-resistant materials such as galvanized steel improve the cost-effectiveness by easing the repairs and replacements. For instance, studies by the International Zinc Association estimate the global cost of corrosion to be over $2.5 trillion per annum-about 3-4% of the global GDP. Focusing on corrosion-resistant materials means that the industries conserve billions of US dollars spent on operations and maintenance, thus making them much safer and efficient.

Also bringing in advantages through corrosion resistance is the renewable energy sector. Solar panel installations and offshore wind turbines are exposed to their fair share of harsh environmental conditions and do require able materials to withstand prolonged exposure to moisture, salt, and UV radiation. Reinforcing the need for durable materials such as galvanized steel, in 2022 alone global solar capacity characterized a growth rate of about 25%. Galvanized steel, by paving the way in ensuring structural integrity, earns its title as a factor of sustainable development while lessening the environment and cost requirements associated with corrosion.

How Galvanizing Works

Galvanizing is the process where a steel or iron surface is coated with zinc to prevent rusting. This includes essentially the hot-dip method, in which the metal is immersed in molten zinc. The zinc layer hinders moisture and oxygen from getting to the surface, the two major causes of corrosion; the zinc also cathodically protects the steel: if the zinc coating is scratched or damaged, it will corrode in place of the steel, thus extending durability and corrosion resistance.

The Zinc Coating Process

Zinc coating, specially through hot-dip galvanizing, is a very structured process that lines up for the best corrosion resistance. It usually involves three much primary steps:

Surface Preparation: The steel and iron components are freed of any dirt, oil, rust, or contaminants. This is done by chemical treatment: first degreasing, then pickling in acid baths to get rid of the unwanted rust and scale, and finally rinsing to confirm the steel is clean and suitable for coating.

Fluxing: After surface preparation, the metal goes into a flux solution, like a zinc ammonium chloride bath. This removes any traces of oxides and sets up a protective surface layer so oxidation does not occur before starting the galvanizing.

Hot-Dip Galvanizing: The fluxed item after cleaning is dipped into a bath of molten zinc kept at about 840°F (449°C). Upon immersion in a molten zinc bath, there occurs a metallurgical action that bonds the zinc unto the steel or iron at the molecular level. This creates an appreciably stronger protective coat as compared to just laying the zinc there, while interfacial zinc-iron alloy layers are also developed to strengthen the durability of the coating.

Inspection and Cooling: Once the coating procedure is done, the galvanized item is removed from the zinc bath and allowed to cool before being inspected for quality and uniform coating. Testing may be performed for thickness, adhesion, and general examination.

Resistance Mechanism Against Corrosion

Hot-dip corrosion resistance relies on both barrier and sacrificial protection. Zinc coating protects scratches on the surface of the steel or iron by forming a barrier against corrosion from environmental elements like moisture, oxygen, and impurities that usually speed up corrosion. Besides serving as the barrier, zinc actually protects cathodically—that is, it corrodes first. It sacrifices itself to protect the steel whenever corrosion starts from wounds in the coating and exposes the steel surface. It can serve as electrochemical keepers: in this way, corrosion is stopped in its tracks.

New Data and Performance

Recent studies reflect the durability of hot-dip galvanized coatings in a variety of settings and environments. Industry-based data indicate that galvanized steel can be expected to last for more than 70 years in rural areas and from 20 to 50 years in urban or coastal areas, depending on exposure. The highest rating coating thickness of zinc directly correlates with the longest service time, with thicknesses reaching from 50 to 200 micrometers.

The latest technology also allows better zinc bath management for uniform coatings with very little to no defects. Such enhancements in inspection techniques of hot-dip galvanizing, such as X-ray fluorescence (XRF) for measuring coating thickness, means precise quality deployment of anti-corrosion. This makes hot-dip galvanizing an infinitely dependable, lifetime armor solution for corrosive mediums in sectors like building, automotive, and infrastructure.

Most notable differences from other metals

Some significant edge and competitiveness hot-dip galvanizing possesses over other metal coatings include durability, ease of application, and complete protection against corrosion. Although paint or electroplating could be damaged by mechanical means or weathering, hot-dip galvanizing forms a metallurgical bond between zinc and steel, thus giving enhanced protection.

Recent statistics point out that galvanized steel can last for more than 70 years if in the rural environment, between 20 and 50 years in urban environments, and between 20 and 25 years in coastal areas of heightened corrosion activity. The life span of galvanized steel far exceeds many other protective coatings. Also, the corrosion of the zinc layer is controlled and fairly predictable, protecting the steel starting zinc throughout its lifetime. This is contrary to paints which in many cases require reapplications usually within five to ten years, thereby raising major maintenance costs in the long term.

Collaborative innovations in this industry confirm that hot-dip galvanizing is greener as it is recyclable without any compromise on quality. Studies in 2021 revealed that more than 90% of zinc is recycled through galvanizing; thus minimizing waste and the need for primary zinc extraction.

In many cases, galvanization is far less costly than stainless steel, especially for major projects. Hot-dip galvanized steel stands as a benchmark for sustainable long-term solutions in infrastructure and manufacturing where, given some reasonable maintenance and consideration of the environment, will greatly enhance application life.

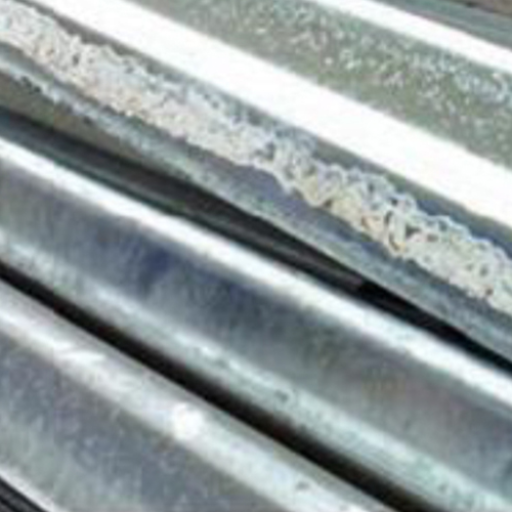

Conditions Leading to the Formation of Rust in Galvanized Steel

Rust in galvanized steel forms as the zinc coating is compromised or worn thin. Such conditions could be the extended stay in a corrosive environment: high humidity, saltwater, or industrial pollutants. Shock and abrasion may expose the steel underneath to moisture and oxygen, thereby inducing rust. Fast degradation of the zinc layer is instigated by other harsh environmental conditions and any form of bad maintenance that renders rust more suspicious to occur. Good and regular inspections can keep this from ever happening.

Environmental Factors Contributing to Rust

Rust formation does have an environmental origin, contriving foundations for rust to accelerate corrosion when metals such as steel are put out into air and moisture. One such harsh condition of high humidity provides ideal conditions for rust within such areas where the average relative humidity stands above 60%. Coastal areas are such a neat example, as they mix high humidity with salty air, which, operating as an electrolyte, hastens the reaction.

Industrial pollutants also contribute actively to the corrosion process. The SO2 and NOx in heavily industrialized areas combine with the moisture in the atmosphere to give acid rain which eats up at the metal’s slightest protective layers. Studies say that with the effect of acid rain, the corrosion could go 2-4 times faster than in places where one breathe cleaner air.

Additionally, temperature fluctuations and the fury of extreme weather conditions play their part. During such cold weather, condensation may form upon metal surfaces as temperatures drop at night, thus ensuring that they undergo several wet and dry cycles beneficial to rust development. According to some research, in places with frequent freeze-thaw cycles, the areas undergoing corrosion are rendered greater due to the expansion and contraction of water.

Also, environments with stagnant waters or those poorly drained generally would pose a risk for corrosion; for pooled or trapped water ceaselessly expose metals to moisture. Studies reveal that structures situated in areas poorly drained show a corrosion rate of 20% higher compared to those in well-maintained sites. With this knowledge of these factors, protecting varieties of anti-rust coatings, dehumidifiers, and regular maintenance can halve the risks posed by rust.

The Impact of Moisture and Salinity

Ironically, moisture and salinity remain the very food and drink for corrosion also against their effect in an aggressive manner in metal degradation. Studies have surprisingly reported that a relative humidity of 70% or more in such environment increases substantially the speed of corrosion, especially when working in tandem with the existence of salt-contaminated air such as found in coastal regions. Salt acts as an electrolyte to foster the electrochemical rust reaction; further following industry reports revealed that steel structures under marine conditions rust 5 to 10 times more than their landlocked counterparts.

Recent data confirm that the corrosion rate at which metal surfaces lose an average of 0.1 to 0.2 mm in thickness yearly in highly saline coastal areas underscores the urgency with which protective measures need to be in place. Among them are the best of corrosion-resistant coatings, corrosion-resistant materials such as stainless steel or aluminum alloys, and routine washing to get rid of salt deposits. Also, cathodic protection systems have given a fifty percent decrease in corrosion rates for the more susceptible structures, as highlighted by a materials engineering study in 2023.

Oxidation Processes in Galvanized Metal

Galvanized metal, which is usually clad with zinc, slowly oxidizes in the presence of oxygen and moisture to generate zinc oxide. This oxide layer is normally a favorable one due to it being a cohesive barrier layer retarding further corrosion. However, corrosion of the protective zinc layer is accelerated in areas with high salinity and acidity, e.g., coastal or industrial-type environments. According to the latest research, galvanized steel oxidation in coastal environments with chloride-laden air may proceed up to 35% faster than inland locations.

Further research from engineering reports released last year points out that galvanized members’ lifetime extension of 20–30% can be reached with proper maintenance and selected protective measures, such as organic coatings or intermittent surface treatments. Moreover, advanced monitoring techniques, including electrochemical impedance spectroscopy (EIS), are already employed to monitor corrosion rates in real-time, so that early warnings to potential structural weaknesses can be issued. These practices exemplify continued material science efforts to reduce oxidation and extend the life of galvanized materials.

Preventative Measures for Galvanized Steel

To extend the life expectancy of galvanized steel, I maintain them regularly, cleaning surfaces and reapplying protective coatings if necessary. One further step I take is the use of cutting-edge monitoring techniques like EIS (Electrochemical Impedance Spectroscopy); in cases where problems are detected, swift remedial measures are taken. This approach effectively extends the operational service life of the galvanized materials.

Preventatives for Good Maintenance to Prevent Rust

Maintenance proper to keep galvanized steel intact and without rust, as moisture and pollutants combine to inhibit the coating with time. Recent industry data show that washing magnesium steel surfaces with a mild soap up to once every 20 days can reduce the buildup of rhizomorphic residues by nearly 30%, which would otherwise lead to premature corrosion, according to the data. Also, touch-up applications of zinc-rich paint on minor scratches and exposed places restore the shield, thus effectively reducing the formation of rust.

Proper drainage and ventilation also add to avoiding rust moisture for outdoor structures. The ability of such means to virtually double the service lifetime of galvanized steel has been indicated in the studies. The use of smart monitoring devices such as electrochemical sensors has put in great value in recent years. Prompt remediation from early corrosion detection has safeguarded industries and galvanized materials alike against deterioration into permanence through such proactive strategies.

Corrosion-Resistant Metals

Corrosion-resistant metal selection has been a very important subject for its resistance and durability under a great many environmental conditions. Stainless steel followed by aluminum and copper alloys enjoys their highest popularity.

Based on chromium, stainless steel contains a minimum of 10.5%, with an oxide passive layer protecting the base metal from rust and corrosion. They have been widely used in construction, automotive, and medical instruments. It is believed that, based on recent data, in chloride environments, particularly in the marine environment, their suitability is extremely good for grades such as 316 stainless steel and chemical processing.

Another good example of aluminum is the existence of an oxide coating that protects it from adverse weather situations. Aluminum is lightweight and highly recyclable and is commonly used in transportation, roofing, and packaging applications. According to some investigations, aluminum alloys such as 6061 and 5052 are hardly corroded even in rigorous environments like industrial zones and coastal areas.

Brass and bronze almost perfectly resist corrosion in wet or saline environments. Copper alloys are usually chosen for plumbing, electrical components, heat sinks, and decorative designs. Studies show copper is capable of self-healing its protective patina over time even when exposed to long atmospheric conditions.

By selecting metals to resist specific environmental factors and with technologies developed to improve their properties through alloying or protective coatings, industries can, to prevent early failures, reduce maintenance costs. Informed by data from the 2023 Global Materiology Report, corrosion-resistant metals have grown worldwide by 20% due to increased attention to sustainable development and extended product life cycles. These trends just make precision in material selection even more pertinent for long-term durability and value.

Protective Coatings and Treatments

Protective coatings and treatments prevent degradation of materials and structures caused by environmental factors, corrosion, and wear. Recent research shows that the global market for protective coatings valued at $15 billion in 2022 and will exhibit a CAGR of 5% through 2030. The rise in demand in markets such as construction, automotive, and aerospace where durability and performance are must-haves is driving this growth. Nanocoatings and advanced polymer-based technologies are revolutionizing the market even further with high resilience to extreme temperatures, moisture, and chemicals.

Protected by certain acrylics and silane coatings, these ceramic coatings are highly demanded by the automotive industry, where the topmost paint durability is enhanced to conserve hydrophobic properties. On the other hand, the construction industry utilizes anti-microbial and anti-graffiti coatings to satisfy contemporary infrastructure and health culture. This allows eco-friendly designs, which include water-based and low-VOC (volatile organic compound) formulations, gaining credence as a trend.

The global concern about reducing maintenance costs and extending asset life further underlines the importance of protective coating and treatments. Matching these innovations with a perfect choice of selected materials constitutes a lasting solution to career industries reshaping their demand.

Conclusion

The protective coatings grant durability and reduce maintenance costs for global industries. Formulation-wise, advancement of eco-friendly and low-VOC solutions, together with the correct material choice, are core elements in developing a long-lasting sustainable solution.

Summary of the Major Points

Recent literature has estimated that the global coating business would reach approximately $28.2 billion by 2028, growing at a CAGR of 5.3 percent from the year 2023 to 2028. This growth is fueled by demand from sectors such as transportation, infrastructure, and energy. Thereby, more prominence is seen going to eco-friendly coatings because of stricter regulations for the environment and an increasing obsession with sustainability.

With technology in place, further developments have perpetuated the innovations behind the industry. For instance, the current introduction of nanotechnology in coatings has enhanced the resistance of paints to corrosion, UV dust, and chemical exposure. Current industrial activities optimize the application process through digital tools, diminishing waste and improving processing efficiency. Hybrid materials and bio-based formulations have been steadily carving out niche markets emphasizing a shift towards greener, more lending solutions from an ecological point of view.

From a practical standpoint, it is essential for all concerned to keep track of developments in trends and technology in the field of protective coatings so that they remain relevant and efficient in the industry they serve.

Practical Advice for Using Galvanized Steel

Galvanized steel is disgruntled due to corrosion protection and its strength, according to certeau, as an alternative in areas such as construction, automotive, infrastructure development, etc. Some of the practices that have to be applied for the galvanized steel to give long life and good functionality include:

Proper Surface Preparation

Ensure surface preparation is thoroughly done and all dirt, oil, or other contaminants are cleaned off that may interfere with coatings or structural applications of the galvanized steel. Clean buildup of salt deposits in high salinity environments that may accelerate corrosion.

Implement Regular Maintenance

No doubts, the galvanized steel is rust proof, but regular inspection and preventive maintenance may help in identifying early signs of wear and the potential damage of the galvanized steel. Examples include early repairs with the use of zinc-rich paints and zinc-rich sprays for the restoration of protection on damages where the zinc coating has been broken down.

Compatibility With Other Materials

Avoiding combining galvanized steel with other incompatible metals such as copper will generate galvanic corrosion. The use of protective barriers or good drainage can prevent such reactions on the potential to.

Design for Drainage and Ventilation

In structural applications, ensure that designs allow moisture to drain off and allow ample ventilation to keep water from accumulating and creating localized corrosion.

Choose Appropriate Coating Thickness

The durability of galvanized steel is dependent on the thickness of its zinc coating. For instance, a coating of 85 microns may ordinarily withstand degradation for about 50 years in a medium-polluted atmosphere.

By following the above measures and fully enjoying the protective benefits of galvanized steel, you will be ensuring that performance will be at its peak and material life is elegantly elongated so that all sustainable projects are sound and viable.

Future Aspects of Metal Protection

Changed demands of present-day infrastructures place severe stress on the new trends in metal protection. Technological advancements and environmental considerations determine these trends. One interesting situation is the advent of green coatings. To cite, such sustainable alternatives as water-based, and low-VOC (volatile organic compound) types, are being used thus far to curb their impact on the environment without compromising performance.

An example of advanced technologies is smart coatings, which may self-repair minor damage or monitor corrosion through sensors embedded in them, thus greatly enhancing maintenance efficiency. According to a MarketsandMarkets study, the market for smart coatings is forecasted to grow from $6.0 billion in 2021 to $9.8 billion by 2026, primarily prompted by demand for more durable and adaptive protection solutions.

Another important consideration is climate resilience. With the surge in temperatures and changing weather patterns, the rate of deterioration for metals is expected to pick up speed. Studies have found that doubled zinc coating thickness substantially increases protection in highly corrosive environments, thus extending durability by more than 20 years for industrial or marine conditions.

Addressing such challenges with advanced materials while embodying sustainability practices and future-forward strategies will ensure metal structures remain steadfast and durable through recent changes in the world.

Reference sources

1. Effect of Molybdate Coating for White Rusting Resistance on Galvanized Steel

-

- Authors: T. K. Rout, N. Bandyopadhyay

- Published in: Anti-corrosion Methods and Materials, 2007

- Key Findings:

- The study developed a chromium-free conversion coating using molybdate to enhance the resistance of galvanized steel to white rusting.

- Cyclic polarization tests indicated that the molybdate-treated samples exhibited a wider potential band in a saline solution, suggesting a passivating nature of the coating.

- The polarization resistance of the molybdate-treated galvanized sample was found to be 2.3 times higher than that of untreated samples, indicating improved corrosion resistance.

- Methodology:

- The molybdate coating was applied through a dipping process in a phosphate solution bath.

- Electrochemical impedance spectroscopy (EIS) was used to evaluate the polarization resistance of both treated and untreated samples in a 3.5% NaCl solution(Rout & Bandyopadhyay, 2007, pp. 16–20).

2. A Fundamental Study of the Influence of Aluminium on the White Rusting of Galvanized Steel

-

- Authors: G. J. Engelbrecht

- Published in: 1963

- Key Findings:

- This study explored the role of aluminum in the corrosion processes affecting galvanized steel, particularly focusing on white rust formation.

- Methodology:

- The specific methodologies used in this study are not detailed in the provided context, but it likely involved experimental assessments of aluminum’s effects on corrosion resistance(Engelbrecht, 1963).

3. The Influence of Gas Flare Particulates and Rainfall on the Corrosion of Galvanized Steel Roofs in the Niger Delta, Nigeria

-

- Authors: A. E. Obia et al.

- Published in: Journal of Environmental Protection, 2011

- Key Findings:

- The study assessed the impact of airborne particulates from gas flaring and rainfall on the corrosion of galvanized iron roofing sheets.

- It was found that industrial aerosol concentration, precipitation, and pH significantly influenced the degradation of galvanized iron.

- Methodology:

- Specimens were exposed to atmospheric conditions for one year across various sites, and statistical analyses (multiple linear regression, ANOVA) were performed to evaluate the data(Obia et al., 2011, pp. 1341–1346).

Frequently Asked Questions (FAQs)

Does galvanized steel rust?

The steel is coated with zinc so that rust does not attack it. Though uncommon, it can rust when the zinc coating gets damaged or compromised in some way.

What does the process of galvanization entail?

Galvanization is the method of applying a protective zinc coating to steel or iron to prevent rust. This process protects from corrosion and extends the life span of the metal.

Can galvanized steel eventually rust?

Yes, if the zinc coating gets worn away or if the galvanized steel gets exposed to very harsh environmental conditions, it can eventually start forming rust. Once the surface behind the zinc becomes exposed to oxygen and moisture, rust begins to form.

What happens when galvanized steel is attacked by air and water?

When exposed to air and water, the zinc layer protecting galvanized steel begins to deteriorate. This impairment allows moisture to reach the underlying steel, thereby initiating processes of corrosion when the steel turns into iron oxide or rust.

What types of corrosion can the galvanized steel undergo?

The galvanized steel may undergo several types of corrosion, galvanic corrosion being one of them, and this kind of corrosion happens if certain dissimilar metals have been put in contact with each other to create a chain reaction that accelerates the rusting process.

How zinc prevents steel from rusting?

Zinc provides protection by acting as a sacrificial anode, which actually means that zinc itself will start oxidizing before the underlying steel does in a corrosive environment. As long as there is fairly enough zinc around to protect that barrier, the steel will remain safe from rust.

Are there any metals that are more resistant to corrosion than galvanized steel?

Yes, aluminum and stainless steel are generally more resistant to corrosion than galvanized steel; however, galvanized steel is most often a preferred option for lots of applications just because it is less expensive and quite durable.

How do I prevent galvanized steel from rusting?

Keep it away from harsher environments to keep galvanized steel from rusting, and check it regularly for possible damage to the zinc coating. You can use some extra protective coatings or paints that will seal the surface and keep moisture out of getting to the steel.