Rust for metals is often synonymous with decay and degradation, so we wonder: Does copper rust? The question piques our curiosity about the intriguing properties copper holds for itself and its interactions with the outside world. Unlike iron or steel, copper does not undergo standard rusting processes; however, some interesting processes alter its appearance in ways that differ from most metals. Hence, this article describes the chemistry behind copper’s reaction to assault by the elements, what happens to copper as it ages, and the implications of these processes for its durability and use in various industries. Whether you are a student who stares at all that, a homeowner, or just someone curious about how long the metal will stay, this blog will give you an enlightening description of copper behavior and some of its most exciting properties.

The Science of Copper and Rust

Copper never rusts, as rusting is typically associated with the corrosion of iron or its alloys. Instead, copper oxidizes when exposed to the elements. After prolonged exposure to oxygen, moisture, and chemicals in the atmosphere, a protective layer called patina forms. This green or bluish-green patina protects the copper from further corrosion, thus making the metal highly durable and long-lasting. This very property makes copper valuable for multiple uses in architecture and outdoor installations.

Common Misconceptions About Copper Rust

- Copper Rusts Like Iron

Unlike iron, which usually forms reddish-brown rust when reacting with oxygen and moisture, copper develops a greenish patina due to oxidation. This patina is not a sign of corrosion, but rather a protective layer that shields the metal beneath.

- Patina is a Sign of Damage

Many believe that copper’s green patina spells deterioration. The reality is that this layer protects copper from further environmental damage, thus increasing its longevity.

- Copper Deteriorates Quickly

This is a common belief in the layman community. The truth is that once the patina starts forming, it can take months or even years before the process comes to a halt; the patina itself further contributes to the permanence of copper in various environments.

- Polished Copper is Always Better

Some people say that polished copper is best in terms of longevity, but exposed polished copper will naturally develop a patina over time. There’s no way to altogether avoid this unless you coat or seal the copper, which might compromise its protective characteristics.

- Patina is Always Green

Although green is the most commonly associated color with patina, the actual color of patina varies depending on the type of patina and the environmental conditions under which it forms. For example, patina can sometimes appear brown, blue, or even black, depending on the chemical makeup of its atmosphere.

The Process of Oxidation in Copper

Copper oxidizes on exposure to oxygen, moisture, and environmental elements. The appearing copper oxide forms a thin, dull reddish-brown surface. Exposure to carbon dioxide, sulfur compounds, or atmospheric chlorides can create a patina; the exact nature of the patina thus depends mainly on local environmental factors, such as humidity, pollution levels, and the salinity of the air. Investigations have shown that marine-type atmospheres containing chlorides significantly enhance the development of blue and green patinas. In contrast, the urban environment tends to produce darker deposits from sulfur compounds arising from extraneous emissions. This natural process lends aesthetic qualities while protecting the base metal and enhancing its durability.

Differences Between Rust and Patina

Rust is a reddish-brown, flaky corrosion specific to iron, while patina is a stable, protective layer formed on various metals, often valued for its aesthetic and protective qualities.

|

Parameter |

Rust |

Patina |

|---|---|---|

|

Composition |

Iron oxide |

Metal oxides |

|

Formation |

Rapid oxidation |

Slow oxidation |

|

Appearance |

Reddish-brown |

Varies (e.g., green, black) |

|

Texture |

Flaky, rough |

Smooth, stable |

|

Metal Types |

Iron, steel |

Various metals |

|

Desirability |

Undesirable |

Often valued |

|

Protection |

None, worsens corrosion |

Protective barrier |

|

Removal |

Necessary |

Often preserved |

Why Copper Does Not Rust Like Iron

Copper does not rust as iron does because they react differently when exposed to oxygen and moisture. Whereas iron is prone to rust, which is flaky and destructive, copper undergoes patina. Patina is a stable protective layer, and its formation in any significant amount prevents any further corrosion of the copper beneath it. Rust, conversely, neutralizes with iron a resistance to weathering for which the patina endows copper.

Chemical Differences Between Metals

What sets metals apart chemically is their atomic structure, electron arrangements, and their reactivity with elements such as oxygen, water, and acids. For example, iron readily reacts with oxygen and water, creating rust, or iron oxide, which, over time, erodes the substance. On the contrary, noble metals such as gold and platinum resist corrosion because of their inertness. Copper, as previously discussed, forms a patina (copper carbonate) that guards the surface against further oxidation.

Aluminum also exhibits peculiar behavior concerning oxidation. It generates a thin coat of aluminum oxide, which serves as a barrier against extensive corrosion of the metal, much like copper’s patina. Factors including electronegativity, density of the oxide layers, and bonding govern these reactions. Ultimately, these differences in behavior exhibited by metals point towards the complex chemistry that controls their lifespan, modes of application, and maintenance in different environments.

Oxidation of Copper vs. Iron

Copper forms a protective patina during oxidation, while iron forms rust that flakes off, exposing more metal to corrosion.

|

Key Point |

Copper |

Iron |

|---|---|---|

|

Oxidation Type |

Patina |

Rust |

|

Reaction |

Cu₂CO₃ |

Fe₂O₃·nH₂O |

|

Impact |

Protective |

Weakens |

|

Adherence |

Stable Layer |

Flaky Layer |

|

Speed |

Slow |

Fast |

|

Environment |

Air/Sulfur |

Moisture/Oxygen |

Understanding Copper Corrosion

Copper corrosion occurs when copper chemically reacts with its environment, including oxygen, water, or pollutants such as sulfur compounds. Initially, copper oxide forms on the copper surface, appearing as a dull, reddish-brown layer. Given enough time, exposure to moist air and pollutants results in the formation of a greenish patina, primarily composed of copper carbonate hydroxide. This patina acts as a protective layer, preventing further corrosion of the metal beneath, which is why copper structures, such as the Statue of Liberty, can last for centuries.

Recent studies also highlight contemporary pollutants, such as acid rain and industrial emissions, that alter the rates of copper corrosion. Airborne sulfur dioxide speeds the growth of discolored films and changes the chemical composition of the patina. Through this understanding, conservationists and engineers can plan for the protection of copper artifacts and enhance the efficiency of their utilization in modern applications, such as roofing, plumbing, and electronics.

Properties of Copper and Its Alloys

Copper and its alloys offer a range of properties, rendering them incredibly versatile and valuable. Copper is a good conductor of electricity and conducts heat well. Therefore, it is indispensable for electrical wiring and thermal applications. It resists corrosion, especially when exposed to prevailing atmospheric conditions, under which a protective patina takes form. With enhancements in strength, resistance to wear, and durability, copper alloys such as bronze and brass retain high malleability and machinability. These alloys are also recognized for their antimicrobial properties, which are utilized to minimize bacterial transmission in medical and public settings. Such exquisite qualities have ensured their primary use across the construction sectors, electronics, and healthcare.

Characteristics of Copper

- High Thermal and Electrical Conductivity

Copper is one of the best conductors of heat and electricity. As such, wire and electrical components are made out of copper, as well as heat exchangers. It has a conductivity rating of nearly 100% compared to the International Annealed Copper Standard (IACS).

- Corrosion Resistance

Being exposed to air and moisture, copper develops a patina that protects it from further corrosion. This feature is essential in maintaining their longevity, whether in outdoor or marine environments.

- Malleability and Ductility

It is very malleable and ductile: it can be drawn into wires, rolled into sheets, or pressed into intricate forms without losing its strength. This means it is readily processable and adaptable to the applications of interest.

- Antimicrobial Properties

Copper has natural antimicrobial properties, inhibiting the growth of bacteria, viruses, and fungi, and thus making it an excellent antimicrobial agent for medical fields, touch surfaces, and public spaces to promote hygiene.

- Recyclability

Copper is 100% recyclable, with no loss in quality. It is one of the most recycled metals in the world, with approximately 80% of all the copper ever mined still in use today, thereby making a significant contribution to sustainability and resource conservation.

Common Copper Alloys and Their Uses

Copper is commonly alloyed to increase strength, corrosion resistance, and durability, all while retaining excellent conductivity and antimicrobial properties. Some of the more common copper-based alloys and their applications are outlined below:

- Brass (Copper and Zinc)

Brass, being an alloy of copper and zinc, enjoys an attractive golden color and excellent machinability. It finds applications in musical instruments, decorative items, various types of fittings, and some household hardware because of its antimicrobial and corrosion-resistant properties.

- Bronze (Copper and Tin)

Bronze, an alloy of copper and tin, has outstanding durability and wear resistance. It is, therefore, used in marine applications, as well as in sculpting, bearings, and gears, where toughness and resistance to harsh environments are required.

- Copper-Nickel (Cupronickel)

This alloy of copper and nickel possesses excellent corrosion resistance, particularly in saltwater. Hence, it has been used in marine hardware, desalination plants, coins, and thermal equipment, where strength and corrosion resistance are required.

- Beryllium Copper (Copper and Beryllium)

Beryllium-copper alloys comprise a high-strength copper alloy with excellent electrical and thermal conductivity properties. Being non-sparking, it is used in applications such as tools, electrical connectors, and aerospace components, where strength and precision are vital.

- Constantan (Copper and Nickel)

Constantan is a copper-nickel alloy with nearly constant resistance over a wide range of temperatures. It finds use in thermocouples and strain gauges, allowing for the effective measurement of temperature and pressure.

Given the alloys above, copper is one metal that exemplifies flexibility and adaptability when combined with another metal, making it one of the most essential materials for industries ranging from electronics to architecture.

Durability of Copper in Various Environments

Copper is regarded as an incredibly durable metal that can stand against a variety of environmental factors. One characteristic of copper that is most commonly noted is its inherent resistance to corrosion. Whenever exposed to air and moisture, the copper forms a thin protective layer called patina, which is chiefly composed of copper carbonate. This deterioration layer does not destroy the metal but instead preserves it, rendering it longer-lasting and ideal for outdoor use, such as roofing and sculptures.

Recent studies and data have shed new light on how copper performs across a broad range of environments. For instance, the marine environment provides an ultimate testing ground for copper alloys, as bronze and cupronickel castings withstand real corrosive attack by saltwater. This is the very basis for their application in shipbuilding and offshore construction. The same logic can be applied in industrial places, where, in the presence of acidic substances, copper’s chemical corrosion resistance assures the performance of their piping systems and chemical processing plants.

In addition, there is emerging evidence that copper resists MIC, or microbially induced corrosion, a form of corrosion induced by bacterial activity, and therefore can be used ideally for water distribution systems. Collectively, these features establish copper as a viable material in any industry subject to environmental insult, even in extreme conditions.

Practical Applications of Copper

Copper has numerous industrial applications due to its unique characteristics. Copper is widely used in electrical wiring and electronics due to its excellent conductivity and resistance to corrosion. Heat exchangers, radiators, and air conditioning systems utilize copper due to its exceptionally high thermal conductivity. Because copper resists corrosion and microbiological activity, it is another important material used in water distribution works. It is also used in roofing and plumbing, and is a vital element in renewable energy technologies, such as solar panels and wind turbines. Indeed, these applications alone demonstrate the essential role of copper, both in typical applications and cutting-edge technological innovations.

Copper in Construction

Copper plays a multitude of roles in construction due to its enduring nature, versatile applications, and aesthetic value. Being one of the most common roofing materials, it is also considered very durable and corrosion-resistant, particularly in adverse environmental conditions. The antibacterial properties of copper make it suitable for touch surfaces, such as doorknobs and railing components in public spaces, as hygiene is a key concern. The material performs well with contemporary architectural design trends, returning a unique look with timeless sentiments to the structure. Environmental sustainability and metallurgy are among the virtues of copper, ensuring a green and energy-efficient status when implemented in various construction sectors.

Art and Aesthetics: Copper in Design

Throughout the ages, copper has enjoyed an enduring relationship with versatility and elegance, ensuring its place in design trends that span both classical and contemporary systems. This warm, reddish hue, endowed with a rustic charm, lends an appealing quality to both interiors and exteriors. Trends for copper in recent years, as well as ideas for copper decor, have been increasingly sought after, a telling sign that there is interest in adapting the material to new aesthetic dimensions. Typically, copper is used in accent pieces, kitchenware, and lights to enhance their utility and artistic ambiance. Another characteristic of this metal is that it develops a yellowish-green patina over time, lending a delightfully strange depth and character to its final application. This allows designers to create an ambiance of smooth elegance with a subtle hint of nature’s own. A trend in copper became a sort of eternal platform that gives rise to a blend of visual arts and design romance versus practicality.

Electronics and Electrical Applications

The malleable nature of copper makes it a natural fit for technologies such as electronics and electrical engineering, as it is the best natural conductor of electricity. Below are five major applications of Copper:

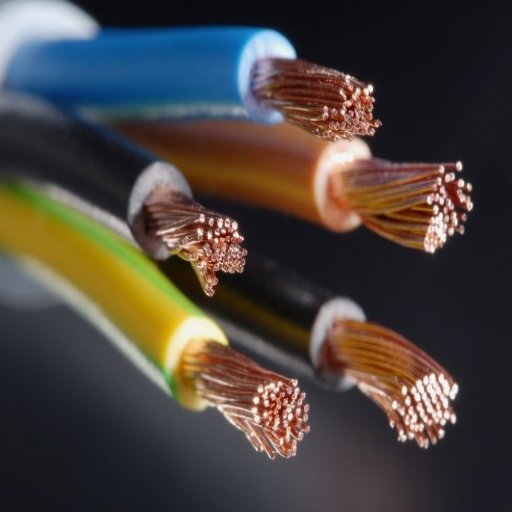

- Wiring and Cables – Almost all of the Electric power wires, including those of houses, are made from Copper due to the numerous qualities of copper, such as high electrical conductivity. This way, they are both environmentally and economically friendly, making them applicable in various settings, including residential and commercial areas.

- Electric Motors – The windings in electric motors depend on copper for effectiveness and efficiency. Able to conduct electricity very well, copper prevents heat losses as well as motor failure.

- Printed Circuit Boards (PCBs) – There is a practice within PCBs where copper is used as a conductive medium for the areas. Many electronic devices need PCB fabrication that contains copper in specific areas.

- Transformers – The fundamental structural features of the transformer, such as the copper coil, are essential for the conversion of voltage levels without loss of excessive energy. Being durable and resistant to harsh environments, copper substitutions ensure the constant functioning of the devices during severe duty applications.

- Renewable Energy Systems – In almost every source of renewable energy technology, it is challenging to design a system without utilizing materials such as copper. Copper can be found in electrical and electronic systems, serving as an unceasing source of energy, and it possesses other energy in a reasonable amount; therefore, such devices as energy-saving systems can control that power.

Maintaining Copper to Prevent Rust

Naturally, copper is unable to suffer the same fate as iron or steel, which is why copper items typically do not rust. Copper, however, undergoes a process that affects its appearance over time, making it look less appealing than it originally did. This is likely due to the formation of a green or brown glaze that thickens over time due to the inactivity of air and water. To preserve copper and stop tarnishing, here are the steps that can be taken:

- Clean Regularly – Rub gently using a damp, soft fiber cloth treated with a small amount of mild detergent.

- Apply Protective Coatings – Apply a good copper polish or a layer of wax to function as a sealant against air and water exposure.

- Store Properly – Store copperware in a cool, dry place to prevent exposure to humidity.

- Avoid Harsh Chemicals – The Use of cleaners that remove staining or other materials that could cause damage to copper is forbidden.

Continuous maintenance is crucial to sustain the quality of copper objects from the time they were shiny and new.

Tips for Preserving Copper’s Appearance

- Regular Cleaning – Copper items, such as pots, pans, and mugs, can often be cleaned in a warm mixture of water and mild dish soap to prevent the build-up of dirt, grime, and oils that accelerate tarnishing.

- Apply Protective Coatings – Rubbing on a thin layer of a protectant, such as beeswax, carnauba wax, or a commercial polish, is essential for any uncovered copper to last long enough for use. This way, the deterioration process is slower.

- Store in Low-Humidity Conditions – Copper has a high degree of interaction with water. Avoid placing copper items in a place that is not within arm’s reach from you, especially when high moisture content is present.

- Use Natural Polishing Methods – If one can gather, these are methods of cleaning that are capable of cleaning surfaces without releasing any toxins often found in Cleaning Products. For individuals with sensitive skin, a mixture of salt, lime, or vinegar and regular or cornstarch can be used as an additional buffering agent for scrubbing purposes.

- Avoid Abrasive Tools – Do not use steel wool or other abrasive tools when cleaning copper, as they can scratch the surface, which can then be worn down by oxidation and corrosion. Soft cloths and non-abrasive sponges would be preferable.

Using our advice, you can maintain the bright and smooth surface of your copper products for many years.

Preventing Copper Rust

I always ensure that all my copper-based items are clean and dry to prevent any tarnish. I usually remove any water from my clean flat items by wiping them regularly with a soft cloth, so that copper ores do not come into contact with excessive humidity. From special wax or tailored copper paint, I usually add a thin and basic layer to shield against corrosion. By placing the copper in a dry and cool location, taking care when doing so, and implementing other preventive measures, the risk of patina is significantly reduced, allowing the gold hue to last longer.

When to Seek Professional Restoration

Caring for copper objects regularly will help them last longer; however, there are times when the expertise of professionals is required to rescue the situation. If your copper object noticeably wears off or becomes disfigured due to the presence of deep corrosion, stubborn tarnish, or significant damage, such as dents or cracks, seeking professional help is recommended. Some old or very valuable objects made of copper may lose their worth or even get damaged when trying to fix them on your own. Handling advanced oxidation, repairing underlying structure issues, and fixing finishes are some of the services professionals are equipped to deliver without injuring the objects. And most cases when the object is badly destroyed or the item is valuable in terms of history or emotional, then by all means let the experts be involved.

Reference Sources

- University of Southern California: Unveil the Mystery: Does Copper Really Rust? – Explains that copper does not rust but forms a protective patina.

- Loyola Marymount University: Does Copper Really Rust? – Details the oxidation process of copper leading to patina formation.

- CiteSeerX (Pennsylvania State University): Copper Corrosion – Discusses copper’s vulnerability and its protective oxide films.

- NASA: Corrosion Fundamentals – Covers copper oxidation and its interaction with other metals in corrosion processes.

- U.S. General Services Administration: Copper: Characteristics, Uses And Problems – Explains copper’s behavior in contact with other metals and its corrosion characteristics.

Frequently Asked Questions (FAQs)

Q: Does copper rust?

A: Copper does not rust in the same way that iron does. Rust is specifically iron oxide that forms when iron oxidizes upon exposure to water and oxygen. Instead, copper develops a patina, which is a green layer of copper carbonate that forms over time when copper is exposed to the atmosphere.

Q: What happens to copper when it oxidizes?

A: When copper oxidizes, it reacts with oxygen in the air to form a thin layer of copper oxide. This layer can protect the underlying copper metal from further corrosion, preventing more significant damage over time.

Q: Can copper corrode?

A: Yes, copper can corrode, but it does not rust. Corrosion in copper may occur when it is exposed to certain chemicals or harsh environmental conditions, leading to the formation of copper salts or other compounds rather than iron oxide.

Q: What causes copper to develop a green patina?

A: The green patina on copper forms when the metal reacts with oxygen, water, and carbon dioxide in the environment. This oxidation process results in a layer of copper carbonate, which protects the copper underneath from further corrosion.

Q: Does copper corrosion affect its properties?

A: While copper corrosion changes the surface appearance and may alter some physical characteristics, the metal itself retains its overall properties. Copper is renowned for its exceptional corrosion resistance, making it a preferred material for pipes and electrical components.

Q: Is copper corrosion reversible?

A: Copper corrosion can be reversible to some extent. The green patina can be removed through cleaning, allowing the bright copper surface to reappear. However, repeated exposure to harsh elements may eventually lead to more permanent changes.

Q: How can I protect copper from corrosion?

A: You can protect copper by applying sealants or coatings that create a barrier against moisture and air. Regular maintenance and cleaning can also help prevent the buildup of oxidation and corrosion on copper surfaces.

Q: Does copper oxidize when exposed to water?

A: Yes, copper oxidizes when it is exposed to water and oxygen. This chemical reaction results in the formation of a copper oxide layer, which can help protect the metal from further corrosion; however, excessive exposure can still lead to deterioration.

Q: Are copper alloys more prone to rust?

A: Copper alloys, which may contain metals like zinc or tin, generally do not rust like ferrous metals. However, their corrosion resistance can vary depending on the specific metals included in the alloy and the environmental conditions to which they are exposed.

- Does Titanium Rust? Understanding the Corrosion Resistance of Titanium Alloys

- The Ultimate Guide to Laser Engraving and Cutting Machines for Acrylic

- Fiber Laser Cleaning: Laser Cleaning Machines & Applications

- Jewelry Laser Engraving Machine: Engrave Fine Details

- The Fascinating World of Toluene: Understanding Its Melting Point and Chemical Properties

- Understanding Laser Marking vs Laser Engraving vs Laser Etching

- Mastering EDM Cutting: Unleashing the Power of Wire EDM Machines and Electrical Discharge Machining

- Unleashing the Potential of Color Laser Marking Machines