Aluminum ranks among the most versatile and practical materials available for construction and aerospace applications. With its characteristic lightweight and strength features, it is the material of choice for cases where strength and resistance to harsh environmental conditions are crucial. And yet, the suspicion lurks as to whether aluminum also undergoes the process of rusting? Understanding the properties of aluminum when it comes into contact with hostile environments over an extended period is crucial for understanding the reasons behind its susceptibility to corrosion and how such occurrences affect the metal’s durability and functionality. In this article, further, the influence of aluminum oxidation is examined, and how it differs in this aspect from other metals whose corrosion is inevitable. At the end of this article, the reader will understand aluminium’s corrosion resistance and that the material is designed for specific applications.

Introduction to Aluminum and Rust

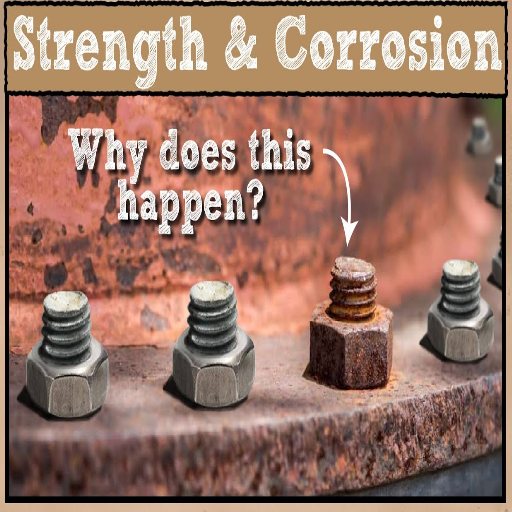

Iron does not develop rust the way steel does. Rust is related to the reddish-brown material found on iron and its alloys, namely steel, due to the reaction with oxygen and moisture. Although it doesn’t develop what is well known as rust, aluminum effectively experiences a process referred to as oxidation. The term “oxidation” is an appropriate description for the alloy’s interaction with environmental air. In the process, a layer of aluminum oxide, which is both very thin and very hard, covers the Aluminum metal, thus protecting it from further corrosion and providing good anti-corrosive resistance even in very harsh environmental conditions. This self-preservation ability is the principal reason behind the native metal’s most abundant use in activities that expose it to usable conditions in most cases.

What is Rust?

Rust, comprised mainly of iron oxides, is a naturally occurring phenomenon that forms when iron is exposed to the action of oxygen and moisture. The redox reaction occurs in the presence of oxygen and water, initiated by the iron. The iron weathers exposed to the weather and forms rust on the surface, which weakens the stability of these structural features by making the material brittle rather than steel. However, unlike a few other metals, which form a dense and protective oxide layer, the corrosion of iron is self-destructive, as the presence of initial rust provides it with the necessary water and air to continue. The protection of iron from rusting is a broad field of research, with solutions involving the use of surface coatings, galvanizing (coating steel with zinc), and introducing new metals that do not readily corrode, such as stainless steel.

Why Aluminum Does Not Rust

Aluminum does not get rusty for a specific reason – its reaction with oxygen is different than that of iron. Exposure to oxygen will cause aluminum to form a layer of aluminum oxide, a rich blue, thick film on the surface, which forms very rapidly. This oxide layer is highly developed and compact, acting as a barrier against further oxidation and preventing oxygen and moisture from reaching the metal. However, in contrast to iron, where rust eats into it and weakens it, the formation of an oxide over aluminum helps prevent corrosion, making it immune and permanently sealing the surface of the metallic part.

Aluminum’s resistance to rusting has made it a beneficial material in various applications, including construction and the automotive industries, as well as in household items such as cookware and packaging. Furthermore, technological advancements have enabled the enhancement of aluminum’s properties, making it superior to stainless steel through anodizing, which increases the thickness of the oxide layer of the material, thereby increasing its resistance to wear and tear. This property of aluminum is very essential as it allows the amount of resources to be used to be reduced and efficiency to be increased due to the design of the range.

The Science Behind Aluminum Oxidation

Aluminum is said to have been oxidized once the surface experiences rapid loss of electrons, in basic terms. Aluminum reacts with the environment due to its two major components: aluminum metal and oxygen. Naturally, with the combination of these two components, aluminum metal forms a skinny layer at the surface, known as an oxide coat – the layer consists of aluminum oxide (Al₂O₃). It is also significantly weaker in air, entirely unlike the protection provided to such steel. This is, on the contrary, as the oxide product of the paint that is exposed to air on the surface works as a deterrent without having to recede into the steel.

Several trends have been observed from my data presented in the literature, which reflect that the oxide layer can, in most cases, behave as a free-standing element, fixed on the emery-polished aluminum surface and showing negligible face detachment, and is non-reactive to water, salt, and practically stands up to most other chemical exhumation. Factors such as these make aluminum a highly suitable material for use in regions with humid or harsh weather conditions. Additionally, industrial procedures such as anodizing specifically enhance the protective oxide coating, providing improved efficiency and aesthetic appeal.

The resistance of aluminum metal to rust and its ability to reconstitute itself, becoming even stronger than it was initially, are the primary reasons for its widespread application in modern use, ensuring long-term durability.

The Rust Resistance of Aluminum

Aluminum resists rust because it forms a protective oxide layer when exposed to oxygen in the air. This renders it durable even in challenging scenarios, such as high humidity or corrosion. Aluminum is not corroded in the same way that iron is, and therefore doesn’t flake; hence, it is much more applicable, as it has a longer life. The compound formed also has the propensity to repair itself in the event of any breakage, making it even harder for the elements of rust to reach the aluminum, among others.

How Aluminum Protects Itself

It’s essential to note that aluminum’s chemical properties enable it to develop corrosion resistance when exposed to oxygen. This characteristic is due to the formation of a thick layer of aluminum oxide, which is highly chemically active. This barrier then prevents the metals from reacting further with nearby substances, such as water surfaces, saline solutions, or media with specific chemical concentrations. This layer is so cohesive and stable in the atmosphere that it is difficult to remove on purpose. For example, in marine engineering, the coating will not easily come off in the water. This property also allows for the high-strength alloys to be economically produced in the 6000 series. It is necessary to note that aluminum and its alloys are used in a wide range of products. For example, in cases where weight or stress constraints are crucial, high strength is of utmost importance, regardless of the cost.

Factors Affecting Aluminum Corrosion

Various aspects affect aluminum’s corrosion behavior, and these can influence its performance and lifespan under specific conditions. Listed below are the five most important factors:

- pH Levels

Aluminum retains its useful resistance to corrosion in environments with a pH range of 4 to 9. Out of these pH levels, adverse corrosion is accelerated, especially when strong alkalis or acids are used, which can hurt the aluminium surface.

- Temperature

High temperatures cause more chemical reactions in aluminum, weakening the oxide layer, which in turn accelerates the corrosion process. For example, parts of aluminum exposed to high temperatures in industrial processes may corrode over a short period.

- Exposure to Chlorides

Chloride ions from environments such as marine conditions or de-icing salts can penetrate the protective oxide film on aluminum, causing crevice corrosion, including pitting, which results in metal damage.

- Surface Contaminants

Dust, grease, and other impurities present on the surface of aluminum retain water, rendering it challenging to dry and creating conditions that facilitate the occurrence of corrosion processes. Proper surface treatment and overall cleaning ameliorate the condition.

- Environmental Pollutants

Industrial pollution sources, such as sulfur dioxide (SO2) and nitrogen oxides (NOx), contribute to the acidification of moisture, which subsequently causes corrosion of metallic aluminum. Cities and industries are typically the regions where such destruction is most vigorous.

Through a good understanding of these issues, the appropriate means of defense, including the application of protective coatings, constructing anodised layers, or regulating specific actions, can be taken to ensure that aluminum serves for a longer time.

Aluminum vs. Other Metals: A Comparison

Aluminum is lightweight, corrosion-resistant, and has a high strength-to-weight ratio. In contrast, other metals, such as steel, copper, titanium, and magnesium, vary in terms of strength, cost, and specific applications.

|

Parameter |

Aluminum |

Steel |

Copper |

Titanium |

Magnesium |

|---|---|---|---|---|---|

|

Density |

2.7 g/cm³ |

7.85 g/cm³ |

8.96 g/cm³ |

4.5 g/cm³ |

1.74 g/cm³ |

|

Strength |

Moderate |

High |

Moderate |

Very High |

Low |

|

Corrosion |

Excellent |

Poor (unless coated) |

Moderate |

Excellent |

Poor |

|

Cost |

Moderate |

Low |

High |

Very High |

Moderate |

|

Applications |

Aerospace, auto |

Construction, tools |

Electrical, plumbing |

Aerospace, medical |

Lightweight structures |

Types of Aluminum and Their Properties

Aluminum plates come with various grades that are suitable for different tasks, and some of them include the following:

- Pure Aluminum (1000 Series): This alloy is more prone to corrosion than other types, yet excels in electrical and chemical applications due to its high thermal conductivity and excellent electrical conductivity.

- Aluminum-Copper Alloys (2000 Series): These alloys exhibit very high tensile strength, and due to their ability to perform well under tension, they are widely used. However, they are less resistant to corrosion than the other two, and thus have numerous applications in aerospace and other fields.

- Aluminum-Manganese Alloys (3000 Series): These have reasonable chemical resistance, possess moderate strength, and are readily used in building materials and food service parts.

- Aluminum-Silicon Alloys (4000 Series): These alloys are characterized by being resistant to galling and, simultaneously, exhibiting controlled expansion behavior. These are used in large automotive engines, where any form of distortion is prohibited.

- Aluminum-Magnesium Alloys (5000 Series): These alloys compete with the 5000 series. In contrast, they are highly weldable and corrosion-resistant, which has enabled them to find wide applications in the fields of marine and automotive engineering.

- Aluminum-Zinc Alloys (7000 Series): Best known for their high tensile strength and good fatigue resistance, these alloys have also been used extensively in the manufacture of military and aerospace hardware.

Each of these fulfills a specific function, thus demonstrating the versatility of aluminum in various industrial sectors.

Common Aluminum Alloys

Aluminum has a wide range of applications across several industries, primarily due to its lightness, corrosion resistance, and exceptional strength-to-weight ratio. The following is a compilation based on the most commonly used aluminum materials:

- 3003 Aluminum Alloy: This is typically the first choice in the 3000 series due to its excellent corrosion resistance and ease of fabrication. It can usually be found in applications such as roofing and cladding, and even in a few instances in food and chemical processing, where it is practically useful aerodynamically, mainly due to the decadent finishing suitable for the durable market environment.

- 6061 Aluminum Alloy: It is one of the most popular options in the 6000 series used in various applications. This class of alloy combines good corrosion resistance, weld capability, and high strength, which explains why it is the most widely used aluminum alloy globally today for various applications.

- 5052 Aluminum Alloy: Another source of celebration in the marine industry since it exhibits very high corrosion resistance in salty water. It is perfect for working on tanks, fuel tanks, sea vessels, and hydraulic pressure fittings due to its toughness, which does not disappoint even under challenging conditions, such as rough sea conditions.

- 7075 Aluminum Alloy: This material is primarily used in the aviation industry, most notably in aircraft, where high strength and high fatigue resistance are desired. Other spares, which are commonly made from this material, such as structural parts, portions of aircraft wings, and weapons, must be able to withstand and perform even under extremely harsh circumstances, because performance is the primary aim of the entire operations of a military squad.

Given the continuous progress in the field of Aluminum alloy fabrication technologies, enhancements are being achieved in terms of improved strength, corrosion resistance, and various applications of what was once considered an outdated engineering material, Aluminum.

Physical and Chemical Properties of Aluminum

- Density

Aluminum has a relatively low density, with a value of approximately 2.7 g/cm³, which implies that it is lighter than most other metal materials.

- Melting Point

The t-melting point of aluminum is approximately 660.3°C (1220.5°F), indicating that it can withstand temperatures within a specific range.

- Corrosion Resistance

Due to the layering of aluminium oxide film on the surface of aluminium, its corrosion resistance has always been superb.

- Electrical Conductivity

Aluminium’s home run mile historical fact is its electricity conductivity where it has 61% of that of copper – it is from here that it is ubiquitously utilized in electrical.

- Malleability and Ductility

Aluminum is very amenable and ductile, which means that it can be rolled, drawn, or shaped into thin sheets, ornaments, and wires without any barrier.

Applications of Aluminum in Various Industries

- Aerospace

Given its favorable strength-to-weight ratio and lighter weight, aluminum is a critical material in the aerospace industry. Structures, typically in aluminum format, primarily comprise the airframe’s skeleton, the airframe itself, and the engine. The ingredients that make up approximately 75% of the reinforcement in the structural elements of the body of any new cabin comprise aluminum alloys.

- Automotive

The automotive industry utilizes aluminum to such an extent that weight optimization and fuel efficiency become a primary concern. Instead of choosing traditional materials like iron, steel to ensure the strength of engine blocks, wheels, and body panels, car manufacturers use aluminum or aluminum alloys Developed a car modeling guide to ease costs of developing cars which is typically prosses between, 60% Extensive industry data has proven derivative but fitting plans show that as much as 30% can be shaved off the car’s weight by adding aluminum to the structure.

- Construction

Aluminum is extensively used in the construction industry for the installation of windows, doors, roofing, and siding. Aluminum offers excellent performance, is weather-resistant, and can therefore be used in both domestic and industrial buildings. Adding aluminum cladding to a building does not lower the maintenance of a structure, thereby preventing problems.

- Packaging

Aluminum packaging is prevalent in the environment, as aluminum products currently in use, such as beverage can foils and trays, are lightweight and non-toxic. The current market has been able to achieve nearly 75% of the aluminum used today over the years because aluminum in packaging is 100% recyclable.

- Electrical and Electronics

Aluminum is extensively used in power lines, electrical wiring, and electronic components due to its high conductivity plus lightweight properties. Contemporary applications, such as LED lighting and mobile phones, utilize materials like aluminum that enhance the aesthetics of the gadgets while providing heat dissipation and ease of use.

Common Misconceptions about Aluminum Rust

Many people believe that aluminum rusts over time, much like iron or steel. This is inaccurate because rust is exclusively a term for the oxidation of iron or iron-based alloys. Similar to how Iron oxide forms on the surface of metal, aluminum forms an aluminum oxide layer on its surface when it comes into contact with oxygen. This layer or coating, formed due to the reaction with atmospheric oxygen, prevents further damage from air acting on the metal as a surface. Hence, there are fewer chances for corrosion of metallic aluminium, even in corrosive surroundings.

Understanding Aluminum Corrosion vs. Rust

Aluminum does not rust like iron but corrodes by forming a protective oxide layer, which can degrade under certain conditions.

|

Parameter |

Rust |

Aluminum Corrosion |

|---|---|---|

|

Definition |

Oxidation of iron |

Oxidation of aluminum |

|

Appearance |

Red-brown flakes |

White/gray powder |

|

Protection |

None, flakes off |

Forms a protective layer |

|

Causes |

Moisture, oxygen |

Moisture, oxygen, pH |

|

Prevention |

Coatings, treatments |

Anodizing, avoid chlorides |

Myths Surrounding Aluminum and Rust

One of the enduring myths about metal suggests that aluminum rusts like iron or steel, showing damage over time until the initial symptoms of weakness become apparent. However, as disclosed by the latest data and studies on corrosion, there is no possibility that these metals rust since steel and iron have no relation to aluminum. Most people would ponder why aluminum is considered “rust-proof” or “corrosion resistant”. This confusion arises from a misunderstanding of the purpose of the oxide layer covered with carbonated moisture. Any corrosion formation is now limited to within x–x mm, and these are not a threat to the structural safety of aluminum.

Another belief is that aluminum’s resistance to corrosion cannot be breached at all. Even though aluminum is said to be resistant to the greater part of environments in which twenty graceful hours generally cannot buttonhole, the point of their existence can thence dwell, in the same: with this psychosocial stressor of a character such a seawater which is salicious when allowed to stay on a material for extended periods; and as well in grinding solutions known as hydrochloric acid or sodium hydroxide. In such cases, however, this corrosion is not the same as corrosion caused by rust, but is specific to its type, as it is an outcome of chemical treatment on the metal known as aluminum. This distinction is crucial for enhancing the utility of aluminum in industries where it is used most, such as the construction, aerospace, and automotive industries.

How to Identify Rust in Aluminum

Contrary to what many people think, Aluminum does not rust the way steel or iron does because it does not contain iron, which forms Iron oxide, commonly known as rust. This metal develops a thin layer of oxide, which acts as a protective barrier against the development of rust or corrosion over time. However, aluminum corrodes over time and appears after the evaporation of a significant amount of space containing hard natural resources, such as salt, acids, industrial releases, and other substances. Identifying corrosives in such an environment requires checks, such as discoloration, a matte surface finish, frosty and grey patches, or even surface damage. Such pittings may be flaky or powdery, depending on the intensity of the corrosion, and may ultimately lead to the loss of the metal’s strength over time.

It is also prudent to understand the distinction between the natural process of oxidation, which forms a protective film on the surface, and corrosion, which is uncontrolled and results in a pitting effect that becomes ingrained, necessitating changes. Corrosion can be observed in its early stages when viewed using a magnifying glass or under extreme magnification. Normal prevention measures, such as cleaning and performing regular checks, and, where applicable, protecting the equipment, can also be used to avoid severe corrosion in the Al components.

Preventing Aluminum Rust

To protect aluminum sheets from oxidation, several easy steps can be taken. Peeling off any sort of dirt is not a good motivation for using dirt results once the metal gets scratches, as this attracts moisture, which, in turn, causes constant corrosion. To reduce the rate of continued corrosion, a barrier, such as paint, anodizing, or cladding, is advised. Therefore, if aeropusker-type materials are already in use and are likely to remain so, it will be important to regularly inspect them for any signs of concern, so that corrective action can be taken promptly. Moreover, storing these products in a soft, warm, and dry place will also be instrumental in enhancing their lifespan and efficiency.

Effective Coating Solutions

The importance of choosing an appropriate coating for aluminum materials cannot be underestimated. Modern coating technologies provide solutions tailored to the specific environment. Among the most popular types of coatings is powder coating, which offers uniform, hard-wearing, and decorative coating properties while also facilitating the application of a corrosion-protective coating onto the aluminum substrate. Also good under harsh conditions is an extraordinary range of fluropolymer etap coatings that offer excellent resistance to weather conditions, protection from UV light, and extensive flexibility in general. Anodizing is yet another alkaline solution that enables not only an increase in pitting resistance of aluminum, but also the obtaining of regulated, decorative, coloured coat finishes, enhancing the properties and beauty of the aluminum component.

Additionally, studies have been conducted that elaborate on how layering, involving primers, intermediate coats, and finish coats, effectively enhances the quality of protective coatings designed to prevent salt or industrial contamination. Such methods make it much easier to find an optimal and cost-effective solution because the assumptions for the service and the impacts of the system boundaries are already specified.

Cleaning and Maintenance Tips for Aluminum

- Regular Cleaning

Aluminum should be cleaned by washing it periodically with a small amount of mild detergent, set up in the intake of warm water. Harsh cleaning agents should not be used on this surface because it is prone to damage from heavy exposure to over-scrubbing, and it is also susceptible to scratching. If a stain persists during the first cleaning process, a soft brush should be used, with its bristles gently brushing the surface.

- Protect Against Oxidation

When finishing the cleaning of aluminum, a protective agent or special aluminum polish must be applied to prevent oxidation. To avoid moisture and air oxidation, an oxidation treatment can help protect the processed surface from rust.

- Avoid Harsh Chemicals

Be cautious when using acidic and alkaline cleaning solutions when cleaning aluminum. It is possible that the material would react and stain or deteriorate the surface.

- Inspect and Repair Damage

Damage, such as scrapes, impacts, or worn areas, can result in unnecessary expenses when it comes to paying for preventive care services. Whenever such damages are noticed, appropriate remedies should be undertaken immediately through a process of polishing or by applying refinish solutions to prevent further deterioration.

- Prevent Buildup of Dirt and Debris

Do not allow aluminum to become grimy and dirty or accumulate salt stains, especially in outdoor and coastal areas, which are extremely important. Always wash the surfaces thoroughly with clean water after exposure to the elements to keep the product looking fresher and lasting longer.

Best Practices for Storing Aluminum Products

When storing aluminum articles, I always work to keep them in a dry, indoor place away from moisture and other harmful factors. I use soft materials or padded supports to minimize any chances of abrasion. At the same time, I keep them apart from different types of metals, mainly to avoid the process of galvanic corrosion. As part of my role in care, I also conduct investigations in the storage areas to ensure they are clean and free from dust and other dirt particles. This is necessary to maintain the brightness and composition of the aluminum over time.

Reference Sources

-

ScienceDirect: Aluminum Corrosion – an overview – Discusses aluminum’s corrosion resistance and behavior in different environments.

-

Industrial Metal Service: Does Aluminum Rust? – Explains why aluminum does not rust and its interaction with oxygen.

-

CORDIS (EU Research Results): Why doesn’t aluminium rust? – Provides insights into aluminum’s resistance to rust compared to iron.

-

ScienceDirect: Evaluating the effect of aluminum on the corrosion – Examines aluminum’s role in corrosion mechanisms.

-

IOP Science: Corrosion Mechanisms for Aluminum Exposed to the Atmosphere – Details aluminum’s degradation and corrosion processes in various conditions.

Frequently Asked Questions (FAQs)

Q: Does aluminum rust when exposed to air and water?

A: No, aluminum doesn’t rust in the same way that iron and steel do. Rust is specifically the term used to describe the corrosion of iron, which results in a flaky, reddish substance. Since aluminum doesn’t contain iron, it does not rust. Instead, it undergoes a different type of corrosion process.

Q: What happens when aluminum is exposed to salt water?

A: When aluminum comes into contact with salt water, it can experience accelerated corrosion. The presence of salt increases the conductivity of water, which can lead to the formation of aluminum oxide on the metal’s surface. Although aluminum has a strong corrosion resistance, prolonged exposure to salt water can compromise this protective layer.

Q: Can corroded aluminum be repaired?

A: Yes, corroded aluminum can often be repaired. If the aluminum surface is scratched or damaged, it may expose the underlying metal to air and water, leading to further oxidation. Repairing the surface and applying a protective coating can help prevent further corrosion of the aluminum.

Q: How does aluminum protect itself from corrosion?

A: Aluminum protects itself through the formation of aluminum oxide when it is exposed to oxygen. This oxide layer is highly protective, preventing the underlying metal from further corrosion. This means that even if the surface of the aluminum is scratched, the oxide layer can reform quickly, maintaining its corrosion resistance.

Q: Why is aluminum a widely used metal?

A: Aluminum is a lightweight metal with excellent corrosion resistance, making it suitable for various applications. Its ability to resist corrosion without rusting makes it ideal for use in outdoor environments and marine applications, where it can be exposed to moisture and air.

Q: What is the difference between rust and corrosion?

A: Rust refers explicitly to the corrosion of iron and its alloys, which forms a reddish-brown flaky substance. Corrosion, on the other hand, is a broader term that encompasses the deterioration of metals due to chemical reactions. Since aluminum doesn’t rust, it experiences corrosion differently, often forming a protective layer of aluminum oxide.

Q: How can I prevent aluminum corrosion?

A: To prevent aluminum corrosion, it is essential to keep the surface clean and free from contaminants. Applying protective coatings, ensuring proper drainage, and minimizing exposure to salt water can also help. Regular maintenance and inspections can identify and address areas where the aluminum may be susceptible to corrosion.

Q: Does aluminum corrosion affect its strength?

A: Aluminum corrosion generally does not significantly affect the material’s strength unless it leads to extensive degradation. The protective aluminum oxide layer can help maintain the structural integrity of the metal. However, if the surface of the metal is compromised, it may weaken the overall strength.

Q: Is aluminum corrosion reversible?

A: In many cases, aluminum corrosion can be treated and reversed. Cleaning the corroded area and applying protective coatings can restore its appearance and prevent further damage. However, severe corrosion may require more extensive repairs or replacement of the affected aluminum components.

- Does Alloy Steel Rust? Understanding Corrosion Resistance in Alloy Stee

- 2-Methylcyclohexanol: Understanding its Properties and Safety

- Common Laser Cutting Materials for Your Laser Cutter

- The Ultimate Guide to Sheet Metal Fiber Laser Cutting Machine

- CNC Router vs CNC Mill: Understanding the Key Differences Between These Popular CNC Machines

- Discovering the Melting Point of Beeswax for Candle Making at Home

- Mastering the Art of Burr Cutting: Carbide Burrs and Double-Cut Methods

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide