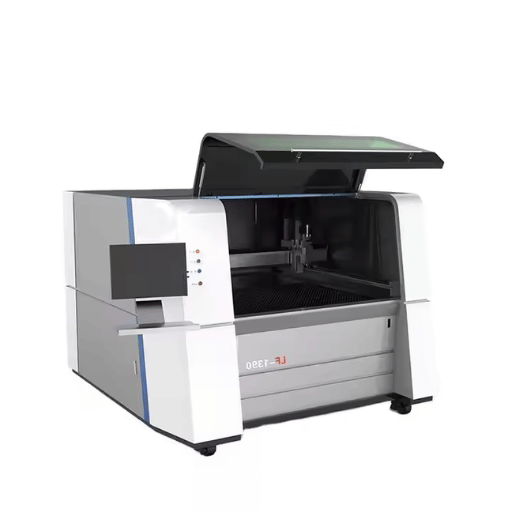

Precision, efficiency, and the ability to cut and engrave a variety of materials makes laser cutting machines necessary tools within many industries. Unfortunately, one of the most important considerations with regard to operational costs and environmental impact—energy consumption—is often overlooked. In this blog, we will analyze the energy consumption of laser cutting machines, focusing on the aspects that measure electricity usage, what elements shape demand, and how demand can be optimized. From business owners, operators, or even those curious about the technology, there is everything in this article to answer all your questions regarding the topic at hand.

How Much Power Does a Laser Cutting Machine Consume?

Laser cutting machines are estimated to use between 1 kW to 15 kW of power depending on the make, model and purpose of the machine. CO2 lasers use Fiber lasers machines for CO2 lasers, and fiber laser machines generally consume lower energy due to their efficiency. Also, actual power consumption is determined by other factors like laser power settings, material composition, thickness, cutting speed, etc. For precise calculation, it is best to cross-check with the manufacturer’s specs or keep an eye on the energy meter.

Understanding Laser Power and Energy Consumption

In an attempt to clarify the energy consumption of laser machines, I have detailed the main aspects and their quantifiable effects in the sections below.

Laser Power Settings:

Increased output or higher settings will result in a greater amount of energy consumed. A 10kW laser will consume 10 kWh on a full blast and around 5 kWh if the flame is turned down to half.

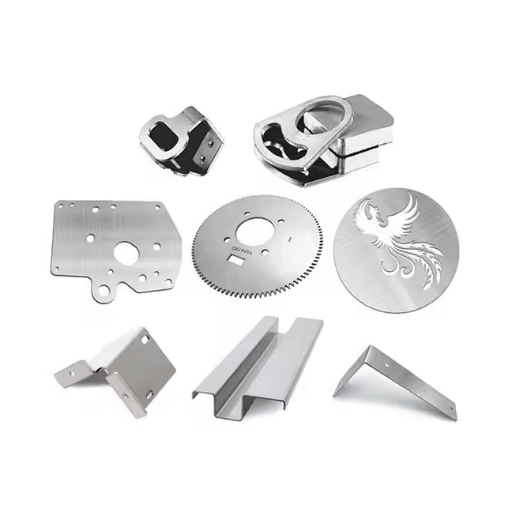

Material Type and Reflectivity:

Aluminium and copper have a higher reflectance which makes it harder to cut, meaning more energy is needed. As an example:

1 Mm thick Stainless Steel would be easier to cut compared to 1 mm thick stainless steel which requires approximately 1.2 kWh per hour.

Aluminum that is 1 mm in thickness can use up to 1.8 kWh due to its reflective nature.

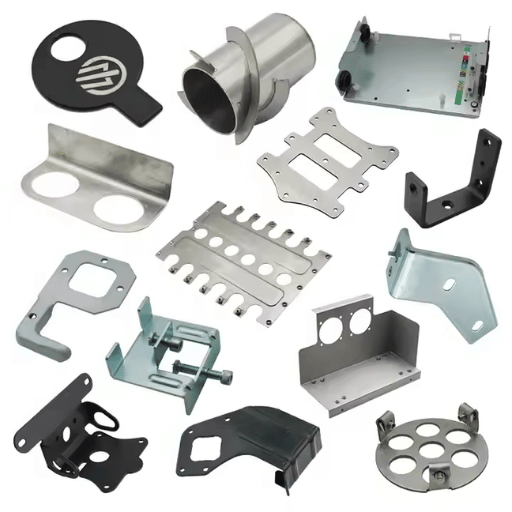

Material Thickness:

As thickness increases, the type of material being cut in addition to the thickness increases energy demand because of how much harder the laser has to work. Testing shows that:

Mild steel that is 6 mm in thickness is estimated to require around 3.5 kWh energy to cut.

Mild steel that is 12 mm on the other hand, could require over 6.5 kWh.

Cutting Speed:

Faster cutting speeds tend to decrease energy used per unit of material processed, although this hinges on various factors. For instance:

High power settings while cutting stainless steel that is 3 mm thick will likely result in 2.5 kWh being used per hour.

Lower power settings will use around 3 kWh for cutting due to the length of time required for completing the task.

Other Operational Considerations:

Auxiliary systems consume a great deal of energy; cooling systems, fan, and ventilation systems are additional components of energy systems already in place. These expenses could account for an additional $.5-$1 in costs without factoring current operating expenses.

From CO2 Lasers Fiber lasers:

Fiber with CO2 lasers has proven to be about 30% optimal and efficient. For example:

A CO2 laser that outputs 6kW will spend up to 7 kWh on top of operating energy when auxiliary systems are included.

Operating a 6 kW CO2 laser could cost significantly more, from 12-15kWh, attributed to its poor energy efficiency and excessive cooling needs.

This information illustrates why a specific type of a laser and its operating parameters cut particular shapes and features with laser should be chosen precisely to minimize the energy consumed.

What Affects The Energy Consumption Of A Laser Cutting Machine The Most

Attention to cutting materials and their thickness, the speed at which the machine operates, as well as the quality of the laser beam play a crucial role in achieving optimal energy savings with laser cutting machines. CO2 lasers are less popular because they are less energy efficient than fiber lasers with the addition of being more expensive to operate. More frequent maintenance to optics and system calibration dramatically reduces energy consumption of the system as a whole. Optimal energy expenditures are possible with intelligent software that automatically calculates all the necessary parameters for the carried out operation.

CO2 and Fiber Laser Power Consumption Comparison

Presented below is an analysis of CO2 and fiber lasers power consumption alongside each other in one table.

Overall Power Efficiency:

The efficiency of CO2 lasers sits at 5-10% considered to be Revenues.

They are outperformed by fiber lasers with an efficiency of 25-30%.

Operational Power Consumption:

Industrial-scale applications of CO2 lasers usually need an input of between 50 to 70 kW of power.

For similar operations, Fiber lasers use considerably less power, burning only 20 to 30 kW, which mark them as superior in energy efficiency.

Power Usage of Cooling Systems:

CO2 lasers incur higher energy cooling requirements of about 20-30 kW owing to their greater heat generation.

Fiber lasers, on the other hand, have less cooling needs incurring about 5-10 kW.

Maintenance Power Expenditures:

Owing to the complex optical system, CO2 lasers require more frequent gas refills and bear greater maintenance-related energy costs.

Because of the simpler solid-state structure, fiber lasers incur almost no extra expenses for upkeep.

Analyzing the above metrics demonstrates that fiber lasers are more efficient in energy use, cheaper, and more environmentally friendly compared to CO2 lasers, making them the favorable option among the two for a variety of industrial uses.

What is the Impact of Laser Cutting Technology on Electricity Bills?

How to Estimate the Electricity Consumption of Laser Machines

The work with laser machines can be better understood if the power draw can be divided into specific components. For example, a CO2 laser system with a 4 kW rated power has an electrical energy consumption of approximately 10-15 kW considering the lost optical and cooling energy. In comparison, a fiber laser operating at the same level of power would only require 5-7 kW of energy owing to its greater economy and lower thermal management system.

Another important parameter influencing the electricity consumption of the laser machine is its duty cycle. For example, a CO2 laser would consume approximately 80-120 kWh while a fiber laser would only consume 40-56 kWh over an 8 hour work shift. These numbers result in huge differences in monthly charges for energy in high energy cost regions where laser systems are in continuous use throughout the day.

The provided numbers clearly state that fiber lasers, unlike CO2 ones and most other types of lasers, are more economical and very reliable for demanding applications. Clearly, these metrics demonstrate the laser-using companies that switching to fiber laser technology is a guaranteed way to reduce electricity-related expenses.

Factors Contributing to Increased Cost of Electricity

The degree to which fiber lasers consume energy differs from that of traditional laser systems, which depends on the application at hand. For instance, a traditional CO2 laser system has an efficiency ranging from 10 – 20% while fiber lasers surpass traditional CO2 lasers with an efficiency of 30 – 40%. This greater efficiency results in less power consumption.

With regards to industrial applications of medium scale, a CO2 laser system with 20kW input electrical power yields approximately 2-4 kW laser output while a fiber laser system provides 6-8 kW output with the same or lower input power. This difference can result in over 36,000 kWh savings in annual energy consumption over 8 hours of daily operation for 250 days a year.

Operational expenses, in this case, are estimations of the entire value of service a business provides to its customers which stems from average energy cost of $0.12 for each kWh. In this case, the CO2 laser system will spend approximately $24,000 on electricity a year while the fiber laser system reduces their expenditures to around $14,400. When combined across multiple facilities and systems, that amounts to annual savings of $9,600 on operational expenses, which equals additional savings for CO2 laser.

These operational enhancements not only provide cost savings in energy expenditures, but also in the heat and cool costs associated with the operation, thus improving sustainable business practices.

Estimating Electricity Cost for Operating Laser Cutters

The starting step in estimating the electricity bill of a laser cutter is finding the power usage of the laser cutter, expressed in kilowatts (kW). The device’s manual or specification sheet typically contains this information. After that, total energy consumption for the machine can be achieved through the multiplication of power consumption by the number of hours the machine works. Take, for instance, a laser cutter which has a power rating of 1.5 kW and is operated for 8 hours, it will consume 12 kWh (kilowatt-hours) in a day.

After determining energy consumption, it’s important to establish the electricity rate set by the local utility provider, which is usually expressed in monetary terms per kilowatt-hour (kWh). The sum of power consumption should then be multiplied with electricity rate to achieve daily expenditure. For example, should the electricity cost $0.12per kWh, daily expenditure will amount to 12 kWh x 0.12 = 1.44. This can further be scaled for weekly, monthly, or even annual estimates ought to be based on usage frequency. To increase precision and enhance automated report generation concerning the operational expenditures, these estimations can be automated with the help of energy monitoring software.

How Can You Reduce Power Consumption in Laser Systems?

How to Save Energy While Using a Laser Cutting Machine

Routine Maintenance: Schedule regular cleaning and servicing of the machine’s parts, such as the lenses, mirrors, and nozzles to ensure they are in good working condition. Performance losses from dirty or damaged parts can increase power requirements.

Work Scheduling: Employ the laser system only when necessary. Avoid idling by grouping operations, as going into standby mode during inactivity can save a significant amount of energy.

Operational Setting: Set the power and speed to the lowest possible level that is safe and effective for the specific production task at hand. Avoid unnecessary overdrive.

Component Upgrades: Additional newer components, such as newer models of laser sources or modern cooling systems, may be purchased to reduce the overall electricity spent, advanced features of these new addons are designed to better improve energy use over time.

Following these recommended practices helps aggregate energy efficiency costs and operational costs while extending the machine’s usable lifetime.

Optimizing Cutting Speed and Power Levels

The selection of the material moves the lever for the efficiency and results of Laser cutting operations. For example, materials like aluminum and copper which possess a high degree of reflectivity will require high amounts of power along with careful tuning to ensure that the cutting process does not damage the cutting beam due to reflective cutting. In contrast, non-reflective substances such as carbon steel and acrylic are straightforward to process and can be cut at much higher rates and with less power demand. Furthermore, the thickness of the material is directly proportional to the amount of energy consumed. Selecting materials that synergize with the machine’s attributes enhances performance, especially when the machine in question is optimally configured—put forth in the form of interfaces vacuumed of dust segments and dirt—which significantly boosted the energy efficiency.

Maintenance Practices to Minimize Energy Use

Maintenance of the equipment also tends to the proper cutting energy in an indirect manner. For one instance, it has been reported that cutting operations became up to fifteen percent more economical just by routinely servicing and cleaning the cutting gear. This effectiveness stems from reduced abrasive tangles and misalignment that in sum raised friction and work needed to slice tools. Annexed friction counters power supply, where movement lubrication is prescribed at intervals of one hundred operational hours according to the instruction manual fort he machine, This means better partitioning order and together add renewed value.

Another notable aspect of the data involves component wear. Analysis shows that dull cutting tools or worn components can increase energy consumption by 20-30%. To maintain optimal performance and energy efficiency, cutting tools need to be replaced sooner than the degradation thresholds, which is optimally after 10,000 linear meters of material is processed. Furthermore, employing automated monitoring systems equipped with sensors that detect machine operation anomalies can provide additional energy savings of up to 10% by enabling preemptive maintenance to address inefficiencies before they escalate.

With these refined methods and meticulous monitoring of usage data, operators are able to achieve significant reductions in energy consumption alongside sustained productivity and precision.

Do Different Materials Affect the Power Usage of Laser Cutters?

Effect Of Material Type On Power Consumption

The material being processed by the laser cutter has an effect on the power used because of its density, thermal conductivity, and reflectivity. For example, hardwood or stainless steel requires a denser cutting power than read more acrylic or some flimsy plastics. Reflective materials also tend to require greater power force because some of lasers power would get lost in the reflection of glare. If the laser power is set correctly to the material properties, the efficiency can still be improved with reduced energy wastage. The understanding of these properties will help accurately set the parameters for reduction in overall power usage with precision during the actual cutting.

Change With Different Cut Focused Operations Power Settings

To get good results during cutting, precise setting regulations of power should be done to the desired level. This is necessary in meeting the desired precision as well as focus cut per each piece. A balanced set power ranges should not be set lower than the level needed to achieve successful complete cuts, while at the same time, helping to achieve desired minimum energy use without subsequent destruction of the piece. Proper set ranges on power levels should take the material thickness along with density and conductivity into consideration. Proper matching to the parameters will keep operation expenses as well as fuel costs low while accuracy of cut set high.

What are the Average Power Levels for Various Laser Systems?

Understanding Maximum Power Output and Average Usage

The average power levels for laser systems differ with their types and uses. With 1 to 10 watts of output, diode lasers are suitable for low-energy tasks such as engraving and barcode scanning. CO2 lasers have higher power capabilities circulating from 30 to150 watts and are primarily utilized to cut and engrave non-metal materials like wood and acrylic. Depending on the industrial needs, fiber lasers, perfect for metal cutting and marking, operate within the range of 20 to 2,000 watts. For precise use in automotive or aerospace industries, the power might exceed these levels. Selecting suitable levels of power ensures productivity and reduces material wastage.

Comparing Power Levels Between Diode and Fiber Laser Systems

The table below provides a comprehensive comparison of power levels and common applications for diode and fiber laser systems.

Diode Lasers:

Power Range: 30 to150 watts

Applications:

Cutting and engraving non-metal materials which include wood and acrylic, among others.

Best serviced by small-scale, precise and low-power operations in artistic production.

Fiber Lasers:

Low Power: 20 to 100 watts (ideal for marking or engraving on metals and plastics)

Medium Power: 500 to 1,000 watts (applied in metal etching, and cutting thin sheets of metal)

High Power: 1,000 to 2,000+ watts (industrial and high precision work like cutting thick metals)

Use Cases:

Metal marking (such as engraving serial numbers or barcodes)

Fabrication of automotive and aircraft parts.

Specialized cutting of thick metal sheets with minimal wastage of materials

With an understanding of the applications associated with each of the listed power ranges, users can maximize efficiency of laser system operations within preset conditions.

Reference Sources

- “Energy consumption and performance optimisation of laser cleaning for coating removal”

- Authors: J. Ouyang et al.

- Publication Date: 2022-05-01

- Key Findings: This study investigates the energy consumption associated with laser cleaning processes, particularly for coating removal. It highlights the importance of optimizing laser parameters to improve energy efficiency while maintaining cleaning effectiveness.

- Methodology: The authors conducted experiments to measure energy consumption during the laser cleaning process and analyzed the performance based on different operational parameters.

- Citation: (Ouyang et al., 2022)

- “Laser specific energy consumption: How do laser systems compare to other manufacturing processes?”

- Authors: Lewis C. R. Jones et al.

- Publication Date: 2022-11-01

- Key Findings: This paper presents a comprehensive analysis of the energy consumption of various laser processes, including cutting, welding, and cleaning. It concludes that laser systems can have high energy intensity compared to conventional manufacturing processes, particularly due to the energy demands of auxiliary systems.

- Methodology: The study involved a systematic analysis of energy consumption across different laser processes, incorporating time and subsystem-level studies to quantify all energy components.

- Citation: (Jones et al., 2022)

- “A Bi-Objective Optimization Method to Minimize The Makespan and Energy Consumption On Parallel SLM Machines”

- Authors: Junjie Lin et al.

- Publication Date: 2023-08-26

- Key Findings: This research addresses the scheduling problem in selective laser melting (SLM) machines, focusing on minimizing both makespan and energy consumption. The study provides insights into the potential for energy savings in additive manufacturing without sacrificing productivity.

- Methodology: A mixed-integer linear programming model was developed, and numerical experiments were conducted to validate the energy-saving potential of the proposed optimization method.

- Citation: (Lin et al., 2023, pp. 1–6)

Frequently Asked Questions (FAQs)

Q: What is the power consumption of a laser cutting machine?

A: The power consumption varies with a number of factors, including the type of laser (CO2 laser vs fiber laser), the cutting parameters, and the materials. Knowing power consumption and estimating energy costs is important as it determines overall operational efficiency.

Q: Does a different material make a laser cutter consume more or less energy?

A: Yes, the material does affect laser cutter energy consumption. The harder, thicker, and denser materials require a greater amount of energy for the laser to cut through, causing higher power demand from the machine.

Q: What is the impact on power consumption with a CO2 laser cutter?

A: A CO2 laser cutter is cutting-efficient but can be very power hungry depending on the laser tube’s wattage and the max laser power applied. It cuts non-metal materials excellently, so it is widely used for its cutting speed and accuracy.

Q: How does a fiber laser cutting machine compare in terms of power efficiency?

A: Laser fibers are more effecient as they cut metal and do not need much energy when compared to other types like CO2 lasers.

Q: What role does laser welding play in the power consumption of laser cutting equipment?

A: Both fiber laser welding and cutting machines are alike in that the power consumed depends on the welding parameters and material composition that is being worked on. The output capacity settings and energy usage settings for the machine also dictate power expenditure during the process which impacts overall power efficiency of the machine.

Q: Can the wattage of a laser affect how much power is consumed?

A: Indeed, the wattage of a laser, for example, a watt laser, impacts how power is consumed. Lasers with higher wattage will consume more power, however, they can process material more rapidly or cut thicker materials, which could improve efficiency.

Q: How can one calculate the power consumption of a laser cutting machine?

A: To assess the power use of a laser cutting machine, one must have the machine’s watt power rating, active working time, and the laser’s performance. The product from multiplying all these factors will be the energy consumed which is often expressed in kilowatt-hours (kWh).

Q: Does running the laser at maximum power increase energy costs?

A: Yes, running the laser at maximum laser power will increase power consumption, and therefore, increases energy expenditures. It’s necessary to find a middle ground between the power settings and the cutting needs to achieve the desired result without incurring unnecessary expenses.

Q: In what way do diode lasers fare power-wise?

A: In terms of energy efficiency, diode lasers have a CO2 laser counterpart that is less energy-efficient in comparison. Diode lasers are most economic in situations with lower power requirement which makes them more efficient in energy usage.

Q: How do you consider the reduction in the power consumption of a laser cutting machine?

A: The overall energy consumption can be lowered if the operating conditions and the type of materials used are improved. Moreover, the use of suitable components for the machine and running it under optimized conditions also helps reduce energy consumption.