Are you ready to take your crafting, woodworking, or prototyping projects to the next level? Whether you’re a hobbyist, a DIY enthusiast, or an aspiring maker, building your own CNC (Computer Numerical Control) router can be a game-changer. A DIY CNC router combines the power of precision machining with the satisfaction of creating something with your own hands. But where do you begin? What tools, skills, and materials will you need? And how do you turn a pile of components into a fully functioning machine?

This guide is here to walk you through every step of the process, offering clear explanations, insightful tips, and practical advice. From understanding the core components and selecting the right design to assembly, calibration, and operation, we’ll cover it all. By the time you reach the end, you’ll have the knowledge and confidence to successfully build your very own CNC router—no prior experience required.

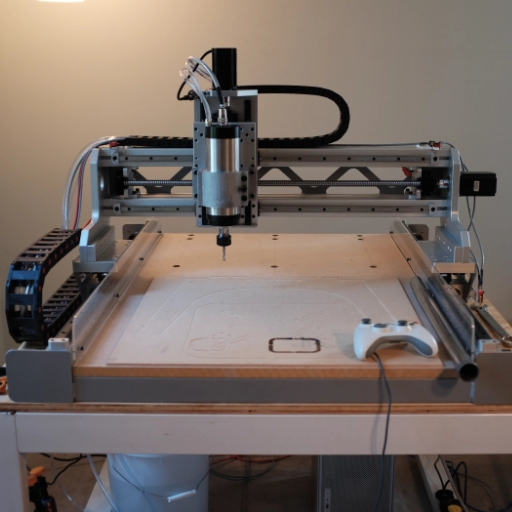

How to Start Your DIY CNC Router Project

Gathering Materials and Tools

To start your DIY CNC router project, the first step is collecting all necessary materials and tools. These typically include:

- Frame Materials (e.g., aluminum extrusions or wood, depending on your design)

- Linear Motion Components (such as rails and lead screws)

- Stepper Motors (for precise movement)

- Control Board (compatible with your chosen software)

- Power Supply

- Cutting Tool (like a spindle or router)

- Wiring and Hardware (bolts, connectors, and cables)

Planning Your Design

Define the size and purpose of your CNC router. Consider factors like workspace dimensions, material types you’ll work with, and projects you want to complete. Sketch out a detailed plan or use CAD software to map your design.

Choosing Software

Select software for both design (CAD) and control (CAM). Ensure the control software is compatible with your chosen hardware components.

Setting a Workspace

Prepare a clean, flat, and organized space for the assembly and operation of your CNC router. Ensure there is a stable power supply and proper ventilation for safety during operation.

By following these steps, you’ll create a strong foundation for your CNC router project, setting yourself up for success as you move into assembly and calibration.

What are the Essential Components of a CNC Machine?

A CNC (Computer Numerical Control) machine is made up of several essential components, each playing a critical role in ensuring precision, consistency, and efficiency. Below, we break down these components and their functions in detail:

- Control Unit (CNC Controller)

The control unit acts as the brain of the CNC machine. It interprets the G-code (the programming language used for CNC operations) and translates it into precise instructions for the other machine components. Modern control units are highly advanced, capable of handling complex designs, adjusting parameters in real-time, and improving overall machine efficiency.

- Machine Frame and Structure

The machine frame forms the backbone of any CNC device. Designed for strength and stability, most frames are made from materials like aluminum, steel, or cast iron. A solid structure is essential for minimizing vibrations during operation, which ensures higher accuracy and smoother finishes.

- Drive System (Motors)

CNC machines use stepper motors or servo motors to control movement along the axes. Stepper motors offer simplicity and precision, while servo motors provide enhanced speed and torque. The drive system ensures smooth and accurate motion, governed by instructions from the CNC controller.

- Guideways and Bearings

Guideways facilitate the precise movement of the tool and workpiece along various axes (X, Y, and Z). Linear guideways or box guideways, often supported by ball bearings, are commonly used to reduce friction and maintain alignment.

- Spindle

The spindle is a critical component that rotates the cutting tool or workpiece at high speeds. The speed and power of the spindle directly influence the quality of cuts, with modern spindles capable of reaching tens of thousands of RPMs for fine detailing and precision machining.

- Cutting Tool

Cutting tools vary depending on the material being worked on and the type of operation (e.g., milling, drilling, engraving). They are typically made from durable materials like carbide or high-speed steel to withstand the stress of machining.

- Table (Work Surface)

The table is where the material (workpiece) is held during the machining process. CNC machines typically feature clamps, vices, or vacuum systems to secure the workpiece in place, allowing for accurate and consistent machining.

- Power Supply

The power supply ensures that all the machine’s electrical components, including motors and controllers, function seamlessly. A reliable power system is crucial for uninterrupted operation and prevents errors caused by power fluctuations.

- Cooling and Lubrication System

To combat heat generated during high-speed operations, CNC machines commonly employ cooling systems such as liquid coolants or air misting systems. Proper cooling and lubrication prevent tool wear, ensure better finishes, and extend the machine’s lifespan.

- Software Interface

The software interface is used for creating, editing, and loading designs into the machine. Popular CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software such as AutoCAD or Fusion 360 are used to design parts, while the CAM software generates the G-code required for machine operation.

- Sensors and Feedback Systems

Modern CNC machines are equipped with sensors to monitor speed, tool positioning, and other parameters. These systems provide feedback to the controller, ensuring precision and enabling automated adjustments during operation.

Each of these components combines seamlessly to create a highly efficient and precise CNC machine, capable of tackling a variety of complex manufacturing tasks. By understanding their roles, you’ll be better prepared to select, assemble, and optimize your CNC router for your specific needs.

How to Choose the Right Motor and Spindle?

Selecting the right motor and spindle is crucial for the performance and efficiency of your CNC machine. The decision should be based on several key factors, including your project needs, material types, and desired precision levels. Here’s a breakdown to guide you through the process:

1. Determine Your Power Requirements

The power of the spindle and motor significantly affects cutting capabilities. A higher wattage or horsepower (HP) is ideal for cutting through harder materials like steel or aluminum, while lighter materials, such as wood or plastics, may require lower power. For instance, a spindle with 1.5 kW to 3 kW power is often sufficient for woodworking projects, whereas metals may demand a spindle exceeding 5 kW for optimal performance.

2. Evaluate Speed (RPM)

The spindle’s rotational speed, measured in revolutions per minute (RPM), determines the precision and finish quality. High-speed spindles (15,000–30,000 RPM) excel in detailed work and cutting soft materials. However, lower-speed spindles (5,000–12,000 RPM) are better suited for harder materials to reduce overheating and tool wear. Adjustable-speed spindles offer added versatility, making them a popular choice.

3. Consider Torque Output

Torque is essential in applications requiring slow, powerful cuts. A motor with high torque ensures consistent performance, especially when machining dense materials at lower speeds. For instance, servo motors are often favored over stepper motors in torque-demanding tasks because of their precise control and consistent force.

4. Check Compatibility

Ensure the spindle and motor are compatible with your CNC machine’s controller and power supply. Look at specifications such as voltage (e.g., 220V or 110V), connection types, and mounting configurations. A mismatch can cause inefficiencies or damage to your system.

5. Focus on Cooling Mechanisms

Spindle motors can overheat during prolonged use, leading to reduced durability. Air-cooled spindles are easier to maintain and lighter, making them suitable for light to medium tasks. Water-cooled spindles, on the other hand, offer superior cooling efficiency, making them the preferred choice for heavy-duty and high-speed operations.

6. Analyze Costs and Longevity

While stepper motors are more affordable and ideal for simple setups, they may lack the precision and power of servo motors. Similarly, high-speed spindles may have a higher initial cost but can save you money in the long run by reducing processing time and improving product quality.

By carefully assessing these factors, you’ll be well-equipped to choose the ideal motor and spindle combination to suit your specific manufacturing projects. Take the time to align your selection with your operational goals to get the best balance of cost, efficiency, and performance.

Understanding the Controller and Software Options

Modern controllers and software are the backbone of efficient and precise manufacturing operations, playing a pivotal role in achieving seamless integration between machines and processes. Controllers, often equipped with advanced microprocessors, manage machine movements and coordinate multi-axis operations with incredible precision. Features such as real-time monitoring, adaptive control, and error compensation ensure high levels of accuracy and consistency during production.

On the software side, Computer-Aided Manufacturing (CAM) software has evolved significantly, offering intuitive user interfaces, automated toolpath generation, and compatibility with various CAD (Computer-Aided Design) programs. Many software solutions now include simulation tools, allowing manufacturers to test machining processes virtually, reducing waste and minimizing setup time. Studies suggest that adopting powerful CAM software can improve machining efficiency by up to 30%, a vital boost in high-volume production environments.

Additionally, modern controllers and software are increasingly incorporating Internet of Things (IoT) capabilities. IoT-enabled systems allow for remote monitoring, predictive maintenance, and data-driven decision-making. For instance, analytics tools integrated into controller platforms can provide detailed insights into machine performance, downtime patterns, and maintenance needs. These innovations streamline operations significantly and ensure that manufacturers can adapt to dynamic production demands.

By leveraging the latest advancements in controllers and software, companies can enhance productivity, reduce operating costs, and achieve unparalleled precision in their manufacturing processes.

Designing and Building Your Own CNC Router

Designing and building a CNC router requires careful planning and precise execution. Follow these essential steps to create an efficient and functional machine:

- Define Your Purpose

Determine the primary use of your CNC router—whether for woodworking, metalworking, or another application. This will shape your design considerations, such as size, strength, and functionality.

- Create a Design Plan

Draft or use CAD software to design the frame, gantry, and worktable. Ensure that the dimensions meet your workspace and project requirements.

- Choose Materials and Components

Select durable materials for the frame and components. Common options are aluminum for lightweight builds or steel for added rigidity. Key components to source include stepper motors, linear guides, a spindle, and control electronics.

- Assemble the Frame and Gantry

Construct the frame first, ensuring it is level and stable. Mount the gantry securely to enable smooth and accurate movement along the axes.

- Install Motion Systems and Electronics

Attach motors, belts, and rails for axis movement. Wire the control board, power supply, and other electronics carefully, following safety guidelines.

- Test and Calibrate

Once assembled, run test programs to fine-tune movement accuracy and ensure proper motor operation. Adjust settings as needed for precision.

By following these steps, you can build a CNC router tailored to your needs while gaining valuable hands-on experience.

How to Create a Router Frame Using Aluminum Extrusions

Using aluminum extrusions to construct a router frame is a cost-effective and reliable approach, offering both stability and flexibility in design. Below, we outline the detailed process to ensure precision and durability in your build.

1. Plan Your Frame Design

Begin by determining the dimensions and requirements of your CNC router. Consider the types of materials the router will work with, the maximum workpiece size, and the required travel distances for each axis. A common frame size might use 20x20mm or 40x40mm aluminum extrusions, depending on the rigidity needed.

For example:

- Small to Medium CNC Router: 20×20 or 30x30mm extrusions.

- Larger or Industrial Rigs: 40x40mm or larger for added stability.

2. Select the Aluminum Extrusions

Aluminum extrusions are typically made from high-grade materials like 6063-T5 or 6061-T6 alloy for a balance of strength and lightweight properties. Profiles come in a variety of slot sizes (e.g., 6mm, 8mm, 10mm), so select a profile compatible with your mounting hardware. Anodized finishes are recommended for durability and corrosion resistance.

Example specifications:

- 6063-T5 offers excellent corrosion resistance and good mechanical properties.

- 6061-T6 is stronger and robust, ideal for high-stress areas of the frame.

3. Cut and Prepare the Extrusions

Obtain pre-cut lengths of aluminum extrusions from suppliers or cut them yourself using a miter saw with a blade designed for aluminum. Use precision tools like a square and caliper to ensure all pieces are cut at the correct lengths and angles. For added accuracy, deburr the edges after cutting to allow snug connections.

4. Join the Extrusions

Use T-slot nuts and screws to assemble the extrusions, or consider connectors like corner brackets and gusset plates for reinforcement. Some high-stress points, such as connections at the corners, may benefit from internal bracing or reinforced joints. Align all parts carefully to avoid misalignment during assembly.

- Fasteners: M5 or M6 screws with compatible T-nuts.

- Brackets: Keep a mix of 90° corner brackets and heavy-duty plate connectors on hand.

5. Add Support Components

Enhance the sturdiness of your frame by including cross bracing or diagonal supports if additional rigidity is required for high-speed operations. Mechanical vibration or wobble can be minimized with proper bracing, especially for larger frames.

6. Install the Work Surface

Attach a flat base plate, typically made from MDF, aluminum sheet, or phenolic material, as the work surface. Ensure it is perfectly level and secured firmly to the frame. You may also incorporate adjustable leveling feet at this stage for uneven floors.

7. Verify Alignment and Leveling

Once the frame is complete, use a spirit level or laser level to confirm it is completely straight and horizontal. Misalignments can impact the precision of cuts or engravings performed by your CNC router.

How to Implement Linear Rails and Ball Screws

Implementing linear rails and ball screws is crucial for ensuring precision and durability in your CNC router. These components work together to provide smooth, accurate movement and reduce wear over time. Let’s break down the process:

1. Select the Right Linear Rails and Ball Screws

Start by choosing linear rails and ball screws that match the specifications of your CNC design. Ensure the linear rails have adequate load ratings and the ball screws offer a high lead accuracy. For example, ball screws with a lead accuracy grade of C5 or better are ideal for most CNC applications. Check the material and coating of the rails — hardened steel with an anti-corrosion coating is recommended for long-term durability.

2. Align the Linear Rails

Precise alignment is essential for the proper operation of your linear rails. Mount the rails on a flat, rigid surface, such as the gantry or bed of the CNC router. Use a precision straight edge or laser alignment tool to ensure they are perfectly parallel. For maximum accuracy, measure the distance between the rails at multiple points during installation and ensure there is no deviation beyond 0.01mm if possible.

3. Ball Screw Installation and Preloading

Install the ball screws parallel to the linear rails. Secure them firmly at both ends using bearing blocks to eliminate axial play. Preloading the ball screws is important to reduce backlash and improve machining accuracy. Preloading can often be adjusted through the use of double nuts or spring tensioners to minimize any slop in the system.

4. Lubrication and Maintenance

Ensure both the linear rails and ball screws are properly lubricated to reduce friction and wear. Use high-quality grease or oil recommended by the manufacturers and establish a regular maintenance schedule. For example, inspecting and re-lubricating every 100 operating hours can prevent premature degradation.

5. Test and Adjust

After installation, manually move the router carriage along the rails to check for smoothness and consistency. If you detect vibration or resistance, inspect for misalignments or debris. Use a dial indicator to confirm motion accuracy within your target tolerances. Adjust as needed to achieve precise movement.

Implementing linear rails and ball screws correctly enhances the structural integrity and functional precision of your CNC router, ensuring optimal performance for a variety of applications.

What is the Ideal Working Area for Your DIY CNC Machine?

When determining the ideal working area for your DIY CNC machine, it’s crucial to consider the materials you plan to work with, the scale of your projects, and your available workspace. For hobbyists and small-scale operations, a working area of 24 x 24 inches is often sufficient, accommodating a range of wood, plastic, and light metal projects. If your work involves larger items, such as furniture components or signage, a working area of 48 x 48 inches or more may be appropriate.

Industry trends also highlight the importance of scalability; many DIY CNC builders opt for customizable designs that allow for later expansion of the working area. Additionally, the physical space in your workshop plays a significant role. Always ensure there is sufficient clearance around the machine for material handling, maintenance access, and ventilation.

For precision-focused applications, a compact working area can also minimize inaccuracies caused by structural flexing or instability. Ultimately, balancing your project requirements and spatial limitations will help you choose the ideal working area, ensuring your CNC machine meets your creative and functional needs.

Understanding CNC Controller and Electronics

The CNC controller serves as the brain of the CNC machine, processing input commands and converting them into precise actions for the machine’s motors and tools. It interprets the G-code, a standardized programming language, to control movement along the different axes. Key components of the controller include the central processing unit (CPU), memory, and input/output interfaces, which ensure accurate communication between hardware and software. The electronics system, including stepper or servo motors and power supplies, works in harmony with the controller to deliver accurate and consistent performance. A reliable controller and electronics setup is essential for achieving precision, repeatability, and efficiency in all CNC operations.

How to Select the Right Arduino and GRBL Setup

Choosing the appropriate Arduino and GRBL setup depends on several key factors that align with your specific CNC project requirements. Below are the most critical considerations and insights to guide your decision-making process:

1. Project Type and Scale

The scale and complexity of your CNC project play a significant role in determining the suitable hardware. For smaller hobbyist projects like laser engraving or routing, an Arduino Uno paired with a GRBL 1.1 firmware is a popular and cost-effective choice. However, for more demanding or industrial-grade projects requiring advanced processing power, you might consider an Arduino Mega 2560, which offers more memory and additional analog and digital pins for complex operations.

2. Number of Axes Required

Standard GRBL firmware supports 3-axis control (X, Y, Z), making it ideal for most CNC mills or engravers. If your project demands additional axes (e.g., for rotary machining or 5-axis control), extensions or alternative firmware like GRBL-Mega may be needed, which is compatible with Arduino boards offering extended pinouts such as the Mega 2560.

3. Motor Driver Compatibility

The choice of Arduino board also depends on the motor drivers you plan to use. For instance, compact drivers like the A4988 or DRV8825 work seamlessly with Arduino Uno setups, making them a go-to option for stepper-based systems. On the other hand, industrial-grade controllers such as the TB6600 or DM542 provide higher torque and power handling, which may influence the selection of a robust Arduino board.

4. Power Supply Requirements

Ensure your Arduino and GRBL setup is compatible with the power requirements of your CNC machine’s motors. Smaller stepper motors may operate on 12V or 24V, while larger systems could require more robust power supplies. Choose an Arduino board that can be safely integrated with your motor driver and power supply without compromising stability or overheating.

5. Software Compatibility and Updates

GRBL’s reliability depends heavily on maintaining up-to-date firmware. With recent versions like GRBL 1.1 offering features such as laser mode and real-time overrides, selecting a setup that supports these capabilities ensures more robust functionality. Make sure your system runs with software such as Universal G-code Sender (UGS) for seamless communication between your design and machine.

6. Ease of Use and Community Support

Arduino Uno stands out for its simplicity and abundant community resources, making it an excellent starting point for beginners. With a vast ecosystem of tutorials, forums, and pre-configured libraries, troubleshooting and optimizing your setup becomes much easier. Advanced users, however, may benefit from exploring boards like Arduino Due or ESP32 (running GRBL-compatible firmware), which provide enhanced performance for sophisticated implementations.

What are Limit Switches and Their Importance?

Limit switches are critical components in CNC machines, ensuring safety and precision during operation. These devices function as sensors that detect the physical limits of machine axes, automatically stopping movement to prevent mechanical damage or errors. Installed at strategic points along the machine’s axes, limit switches provide clear operational boundaries, safeguarding both the equipment and the workpiece.

Their importance lies not only in safety but also in operational accuracy. Limit switches enable the machine to establish a reliable home position—also known as the reference point—at the start of every operation. This ensures consistent alignment and repeatability, which are essential for high-precision machining tasks. Additionally, they help prevent over-travel, a potential risk when the machine’s moving parts exceed their designed range of motion, which can cause costly hardware damage.

Modern limit switches come in various types such as mechanical, optical, and inductive sensors. Among these, mechanical switches are widely used due to their cost-effectiveness and simplicity, while optical and inductive switches offer higher sensitivity and durability, especially in environments with high vibrations or dust. Advanced CNC systems also allow integration of limit switch data into software, providing real-time feedback for troubleshooting and efficiency improvements.

According to industry analyses, the use of properly configured limit switches can extend the lifespan of CNC machines and reduce maintenance costs by up to 20%. Their role in enhancing the precision of operations also improves production quality, making them an indispensable part of any CNC setup.

How to Wire Your Stepper Motor and Controller?

Properly wiring a stepper motor and controller is crucial for ensuring optimal performance and preventing potential damage to the components. Here is a step-by-step guide to help you accomplish this effectively:

- Understand Your Components

Begin by consulting the datasheets or user manuals for your stepper motor and controller. Identify key specifications such as voltage, current ratings, and pinout configurations. Most stepper motors use 4, 6, or 8 wires, representing the phases of the motor, while the controller will have designated input and output terminals.

- Match Power Requirements

Ensure that the power supply voltage and current match the specifications of both the motor and the driver/controller. Overpowering or underpowering can lead to performance issues or permanent damage. Usually, stepper motor systems work within ranges of 12V to 48V, but always verify your specific equipment requirements.

- Connect the Motor to the Controller

Identify the coil pairs of your stepper motor using a multimeter, checking for resistance between wires. Connect these pairs (e.g., A+, A-, B+, B-) to the corresponding terminals on the controller. Incorrect connections can cause erratic movement or prevent the motor from functioning altogether.

- Interface Signal and Control Wires

Next, connect the controller’s input terminals to your control system, which might include a microcontroller, PLC, or CNC controller. Pay attention to control signal requirements such as step (pulse), direction, and enable signals. Use shielded cables to minimize interference and ensure stable operation.

- Test Polarity and Phasing

Switch on the system in a low-power mode to test for proper stepper motor movement. If the motor does not move as expected (e.g., vibrating instead of rotating), the wiring might need adjustment to correct the phase.

- Secure Connections

After confirming that the setup functions correctly, securely fasten all connections to avoid loose wires. Organize cables to protect them from wear or accidental disconnections during operations.

Exploring Different CNC Spindle Options

When selecting a CNC spindle, it is crucial to consider factors such as power, speed, and compatibility with your machine. The three main types of spindles include air-cooled, water-cooled, and electric router spindles:

- Air-Cooled Spindles

These spindles are straightforward, require minimal maintenance, and use airflow to remain cool. They are suitable for lighter workloads and environments where water cooling may not be feasible. However, they may produce more noise during operation.

- Water-Cooled Spindles

Water-cooled spindles provide superior cooling, making them ideal for extended use and heavy-duty applications. They run quietly but require a water pump and regular maintenance to ensure efficiency.

- Electric Router Spindles

These spindles are easy to set up and affordable, making them a popular choice for beginners or hobbyists. However, they may lack the precision and durability needed for intensive or professional projects.

Choose a spindle based on your workload, machine specifications, and the environmental conditions of your workspace to optimize performance.

What are the Different Types of Spindles?

Spindles are categorized into suspended (drop), supported, and grasped types, each suited for specific spinning techniques and yarn types

|

Parameter |

Suspended |

Supported |

Grasped |

|---|---|---|---|

|

Usage |

Hanging spin |

Rested spin |

Hand-held spin |

|

Yarn Weight |

Light to heavy |

Fine to medium |

Fine |

|

Mobility |

High |

Low |

Moderate |

|

Speed |

Moderate |

High |

Variable |

|

Stability |

Moderate |

High |

Moderate |

|

Examples |

Top/Bottom Whorl |

Tibetan, Russian |

French, Akha |

How to Mount and Adjust Your Router Bit?

To mount and adjust your router bit, I start by ensuring the router is completely powered off and unplugged for safety. Next, I loosen the collet using the provided wrench, insert the router bit, and then tighten the collet securely, making sure the bit is positioned properly without being too far in or out. Once mounted, I adjust the depth of the bit according to the requirements of my project, using the depth adjustment mechanism on the router. Finally, I double-check the tightness and alignment to ensure everything is secure before powering on the tool.

How to Ensure Safety with Spindle Enclosures?

When ensuring safety with spindle enclosures, I always start by inspecting the enclosure for any visible damage or wear before use. I verify that it is securely attached to the machine and properly aligned with the spindle to prevent accidents. I make sure all safety interlocks, if available, are functioning correctly to avoid unintended operation. Additionally, I keep the area around the enclosure clean and free of debris to ensure unobstructed movement. Finally, I never bypass safety features and always follow the manufacturer’s guidelines for proper use and maintenance.

Finalizing Your Homemade CNC Router Build

Once your CNC router is fully assembled, it is crucial to test and calibrate it before initiating any projects. Begin by powering on the machine and ensuring all components, such as the motors, spindle, and controller, are responding correctly. Next, calibrate the router by testing the axes to confirm they move precisely as intended—use simple shapes, like squares or circles, to verify accuracy. Adjust the stepper motor settings or tighten loose components as needed for better performance.

Finally, conduct a trial run with a soft, inexpensive material like foam or wood to confirm the router operates smoothly under real conditions. Regular maintenance and careful operation will keep your CNC router functioning efficiently for future projects.

How to Test Your CNC Router Machine for Accuracy

To ensure precise and repeatable results, integrating advanced testing techniques is crucial. Start by using a dial indicator to measure the machine’s axis alignment and movements. Mount the indicator securely to the spindle or the bed, and manually move the router along the X, Y, and Z axes. Record any discrepancies in alignment—ideally, these should be within 0.001 inches or less for high-accuracy machines.

Next, perform a calibration test using precision instruments such as a micrometer or calipers. Cut a test pattern, such as a square or a circle, into a stable material like aluminum or MDF. Measure the dimensions of the final cut and compare them to the original design file. Any deviations from the intended measurements should be corrected by fine-tuning the machine’s firmware or software settings, such as steps per unit.

Additionally, consider using laser interferometry for ultra-precise movement analysis. This method measures positional accuracy and backlash, providing detailed data for adjustments. Most high-quality CNC routers support this advanced calibration tool, which ensures tolerances within microscopic ranges.

Finally, execute stress tests to evaluate performance under extended or heavy workloads. Run the router for extended periods with varying speeds and depths of cut. Check for overheating, vibration, or loss of accuracy, and address these issues as needed. Keeping the machine properly lubricated and free from dust accumulation greatly contributes to overall reliability and efficiency.

By employing a combination of these techniques, you can achieve exceptionally accurate and consistent performance from your CNC router. Regular testing and maintenance will not only enhance output quality but also extend the lifespan of your equipment.

How to Troubleshoot Common Issues in CNC Machines?

CNC machines are precise and powerful tools, but like any technology, they can encounter issues that disrupt workflow. Understanding common problems and their solutions can save time and avoid costly delays. Below are some typical CNC machine issues and troubleshooting methods:

1. Machine Vibrations and Chatter

Excessive vibrations, often referred to as chatter, can lead to poor surface finishes and inaccurate cuts. This issue is commonly caused by issues such as loose fixtures, dull tools, or improper speed and feed rates. To address this problem, ensure all tools and fixtures are securely fastened. Use sharp, high-quality cutting tools and consult the manufacturer’s recommended speed and feed settings for the material being machined.

2. Tool Breakage

Frequent tool breakage interrupts machining processes and increases costs. This problem may result from incorrect tool selection, improper tool paths, or inadequate cooling. Ensure the cutting tool matches the job requirements, and double-check the tool path program for unnecessary load points. Proper lubrication and cooling systems should also be maintained to prevent heat buildup.

3. Positioning or Accuracy Errors

Precision is at the core of CNC machining, and any inconsistency in positioning can severely impact the final product. This issue might stem from calibration errors, worn lead screws, or loose servo motors. Regularly calibrate the machine to factory specifications and inspect all components for wear and tear. Tighten any loose components as needed, and replace worn-out parts immediately.

4. Material Feed or Loading Problems

When the material being machined gets jammed or doesn’t load properly, it can halt the entire operation. This issue often arises from misaligned loading systems, improper clamping, or debris obstructing the process. Regularly clean the machine’s material path and loading areas. Align feeding mechanisms precisely and use clamping systems suited to the material dimensions.

5. Software and Programming Errors

Errors in the CNC program can cause malfunctioning or incorrect operations. These include syntax mistakes, tool path issues, or outdated software settings. Always validate G-code before running it on the machine to detect and fix potential errors. Keep the machine’s software up to date to ensure compatibility with new features and technologies.

What are the Best Practices for Maintaining Your DIY CNC Machine?

Proper maintenance is essential to ensure the longevity, precision, and efficiency of your DIY CNC machine. Below are some of the most effective maintenance practices to keep your machine operating at its best:

- Regular Cleaning

Dust, chips, and debris accumulate during CNC operations and can compromise the machine’s performance over time. Clean the machine thoroughly after each use, focusing on removing material buildup from the bed, tool holders, and linear rails. Use compressed air or a vacuum for tight spaces but avoid excessive pressure on sensitive components.

- Lubrication

Friction between moving parts can lead to wear and tear, reducing the machine’s accuracy. Lubricate the ball screws, linear guides, and bearings according to the manufacturer’s recommendations, using high-quality lubricants or grease. Regular lubrication reduces friction and extends the lifespan of critical components.

- Inspect Belts and Couplings

Belts and couplings are prone to stretching and wear, which can lead to inaccuracies in the machine’s movements. Check them periodically for signs of cracks, fraying, or looseness. Replace worn-out belts and adjust tension to the appropriate levels to prevent slipping during operation.

- Check and Tighten Fasteners

The vibrations generated during machining can loosen screws, bolts, and other fasteners over time. Perform regular inspections to ensure all fasteners are securely tightened. Pay special attention to the spindle mount, tool holders, and stepper motors.

- Monitor the Spindle and Tooling

The spindle is the heart of your CNC machine, and its proper functioning is crucial. Regularly check for overheating, unusual noises, or vibrations during operation, which could indicate bearing wear or misalignment. Additionally, inspect your cutting tools for wear and replace dull or damaged bits promptly to maintain cutting accuracy and surface quality.

- Update Software and Firmware

Your CNC machine’s software and firmware play a vital role in its overall performance. Ensure you are using the latest versions provided by the manufacturer, as updates often include bug fixes, performance improvements, and new features. Regular updates help avoid compatibility issues with G-code files and ensure seamless operation.

- Calibrate the Machine Periodically

Precision is paramount in CNC machining. Regularly calibrate your machine by checking the alignment of all axes, verifying tool offsets, and recalibrating the work coordinates. Misaligned axes or incorrect offsets can lead to errors in your projects, so this step is critical for consistent accuracy.

- Maintain the CNC Controller and Electronics

Inspect cables, connections, and the CNC controller for signs of wear, corrosion, or damage. Poor connections or faulty electronics can cause erratic machine behavior. Keep the control box clean and free from dust to prevent overheating and electrical malfunctions.

- Implement a Maintenance Schedule

Establish a routine maintenance schedule to ensure critical tasks are performed consistently. For example, daily tasks may include cleaning and inspecting the machine, while more extensive checks, such as calibration and lubrication, can be done weekly or monthly. A well-documented schedule will keep your maintenance organized and reduce the likelihood of oversight.

- Operate Within Recommended Parameters

Overloading your CNC machine with speeds, feeds, or workload beyond its capacity can cause premature wear or damage. Always adhere to the manufacturer’s guidelines for optimal performance. Using a lower depth of cut and appropriate feed rates can also extend the life of both the machine and tooling.

By actively following these maintenance practices, you can optimize the performance of your DIY CNC machine, minimize downtime, and prevent costly repairs. Reliable data shows that well-maintained CNC machines achieve a lifespan of over 20 years, providing high-quality results and consistent output throughout their operational life.

Reference Sources

- Setting up a Desktop CNC Router – UNC Greensboro – Discusses the setup and applications of CNC routers for DIY makers.

- Building a CNC Machine for the SJSU Makerspace – San Jose State University – Details the process of building and calibrating a CNC router.

- Techno HDS CNC Router – UNLV Digital Fabrication Lab – Provides insights into CNC router tools and configurations.

- Intermediate CNC Router Techniques – NCSU Crafts Center – Covers advanced CNC router techniques and applications.

- Build Your Own CNC – Densem.edu – Explores the customization and design of DIY CNC machines.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What are the basic steps to start building a CNC router?

A: Starting to build a CNC router involves several key steps. First, decide on the type of CNC you need, such as a CNC wood router or a milling machine. Next, gather the parts required to build, including ballscrews, a router table, and a router mounting kit. It’s also crucial to plan for the 3 axis or more, depending on your project. Once you have all the components, you can begin the assembly process and calibrate your machine to ensure precision.

Q: What are the different types of CNC machines?

A: There are various types of CNC machines, each designed for specific tasks. Common types include CNC milling machines, CNC routers, CNC engraving machines, and 3D printers. A CNC wood router is specifically used for cutting wood, while milling machines are used for more precise metal and hard materials. Understanding the types of CNC machines helps in choosing the right one for your DIY CNC build.

Q: How do I choose between ballscrews and rack and pinion for my CNC build?

A: The choice between ballscrews and rack and pinion depends on your CNC machine project’s requirements. Ballscrews are known for their high precision and efficiency, making them ideal for CNC milling machines. Rack and pinion systems, on the other hand, offer speed and are often used in larger CNC routers. Consider the machine’s purpose, size, and required precision when making your decision.

Q: What is the importance of a router table in a CNC build?

A: A router table is a crucial component of a CNC build, providing a stable platform for the cutting operations. It holds the material in place and ensures precise cuts, especially in CNC wood routers. A well-built router table enhances the accuracy of cuts and can significantly affect the overall performance of your CNC machine.

Q: How can I optimize the Z axis travel in my CNC router?

A: Optimizing the Z axis travel is essential for achieving the desired depth and precision in your CNC projects. Ensure that the Z axis is properly calibrated and has enough range to accommodate various material thicknesses. Use quality components such as strong linear guides and ensure that the axis is free from obstructions for smooth operation.

Q: What materials can I cut with a DIY CNC router?

A: A DIY CNC router can cut a wide range of materials depending on its design and components. Common materials include wood, plastics, and soft metals. With the right tools and configurations, some CNC routers can also handle harder materials. Always ensure that your CNC machine is equipped with the appropriate bits and settings for the material you intend to cut.

Q: How do I ensure accurate router mounting in my CNC machine?

A: Accurate router mounting is critical for the performance of your CNC machine. To ensure precision, use a standard router mount that securely holds the router in place. Align the router carefully with the CNC router table, and use shims or adjustments to correct any misalignments. Proper mounting helps in reducing vibrations and improving cut accuracy.

Q: Can 3D-printed parts be used in a CNC machine build?

A: Yes, 3D printed parts can be used in a CNC machine build, especially for non-structural components. They are a cost-effective way to create custom parts, such as brackets or enclosures. However, ensure that the 3D printed parts are strong enough for their intended use and not subjected to excessive stress or heat.

Q: What are the benefits of using a vacuum table in a CNC router?

A: A vacuum table is beneficial in a CNC router as it securely holds the workpiece in place during cutting operations. This ensures that the material does not shift, leading to more accurate and consistent cuts. Vacuum tables are especially useful for materials that are difficult to clamp or when working with thin sheets that require uniform support.

Q: How does a CNC machine project differ from a traditional milling machine?

A: A CNC machine project differs from a traditional milling machine in that it is automated and controlled via computer software, allowing for more complex and precise operations. While traditional milling machines require manual operation, CNC machines can execute intricate patterns and designs with high accuracy and repeatability, making them ideal for detailed engraving and cutting tasks.

- Explore the Advantages of Fiber Laser Marking Machines

- The Unmatched Tungsten: Exploring the Melting Point of the Metal with the Highest Melting Point

- 3000W Fiber Laser Cleaning Machine: Rust Removal and Metal Cleaner

- The Ultimate Guide to Sheet Metal Fiber Laser Cutting Machine

- Melting Point of Lead: Understanding the Basics and Applications of This Heavy Metal

- Harnessing the full potential of technology Fiber Laser: A Step by Step Guide

- Discover the Materials That Are Not Suitable for Laser Cutting and Engraving

- CNC Router vs CNC Mill: Understanding the Key Differences Between These Popular CNC Machines