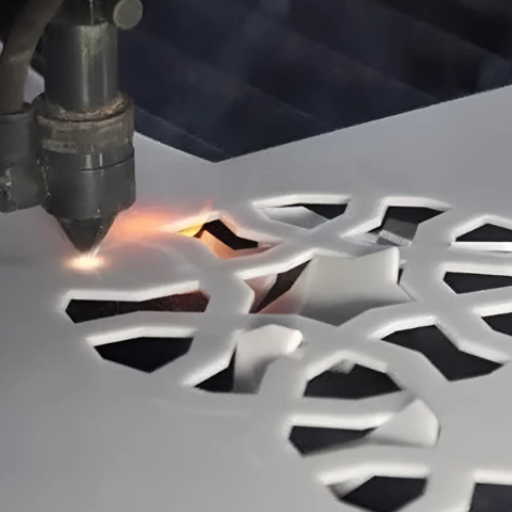

Laser cutting and engraving have revolutionized the way we approach design, manufacturing, and creativity, offering precision and versatility that few tools can match. However, while these techniques work wonders on a wide range of materials, not all substances are suited for the process. In fact, using the wrong materials can lead to poor results, damaged equipment, or even serious safety risks. This guide dives into the materials you should steer clear of when laser cutting or engraving, explaining why they pose challenges and how choosing the right medium ensures optimal performance and safety. Whether you’re a seasoned professional or just beginning your laser cutting journey, understanding these material limitations is crucial for achieving success in your projects.

What Materials Are Not Suitable for Laser Processing?

Certain materials are not recommended for laser cutting or engraving due to health, safety, or equipment damage risks. These include:

- PVC (Polyvinyl Chloride): When heated, it releases toxic fumes and corrosive substances that can damage your laser machine and harm your health.

- ABS Plastic: Known to melt and produce dense, harmful fumes rather than vaporizing cleanly.

- Polycarbonate (often found in bulletproof glass): Ineffective for laser cutting due to poor results and potential machine damage.

- Fiberglass: Contains embedded hazardous materials that release toxic emissions during processing.

- Painted or Coated Metals: The coating often disrupts the cutting or engraving process and can release harmful particles.

- Food Products or Organic Materials with High Resin Content: Can burn unpredictably and produce smoke that is harmful to breathe.

Avoiding these materials ensures safer operation, protects your equipment, and delivers better results for your projects.

Understanding the Risks of Laser Cut on Certain Materials

- PVC (Polyvinyl Chloride): PVC releases toxic chlorine gas when laser cut, which can severely damage the machine’s components and pose serious health risks. Studies suggest that even short-term exposure to chlorine gas can cause respiratory complications and skin irritation. Prolonged exposure may lead to chronic health effects.

- Polycarbonate (PC): Typically used in lightweight panels or protective equipment, polycarbonate tends to melt rather than cut cleanly, generating significant smoke and toxic fumes during the process. Its behavior under high-temperature laser operations makes it unsuitable for precise cutting tasks.

- Fiberglass: This material, composed of a plastic matrix reinforced with glass fibers, releases harmful particulates, including microscopic glass shards, which can damage machinery and potentially harm both skin and respiratory systems. Extensive material handling guidelines strongly discourage its use in laser cutting.

- Foam and Foam-core Materials: Depending on their chemical makeup, certain foams emit hazardous gases, including those classified as VOCs (volatile organic compounds). Many also melt unevenly, leading to fire hazards and inefficient outcomes.

- Metals with Coatings (Galvanized or Painted): Coated metals create inconsistent cuts while releasing potentially harmful substances. For example, galvanized steel produces zinc oxide fumes when heated, which can cause metal fume fever if inhaled over time.

Key Safety Recommendations

- Ventilation: Ensure adequate extraction and filtration systems to manage smoke, fumes, and particulates generated during the laser cutting process.

- Material Testing: Always consult material data sheets and perform small tests before working with a new material.

- Proper Maintenance: Keeping your laser cutter clean and well-maintained will decrease the accumulation of hazardous substances, improving machine longevity and operator safety.

By understanding these risks, operators can safely harness the incredible versatility of laser technology while protecting their health and improving project outcomes.

Why PVC and Polycarbonate Should Be Avoided

When using laser cutters, materials like PVC (polyvinyl chloride) and polycarbonate (PC) should be strictly avoided due to the harmful gases and residues they generate when exposed to laser processes. Cutting PVC releases hydrogen chloride, a highly toxic and corrosive gas that can damage your laser cutter’s components and pose severe health risks, including respiratory issues and chemical burns. Additionally, PVC’s chlorine content can lead to the breakdown of machine parts over time, increasing maintenance costs and jeopardizing operational safety.

Similarly, polycarbonate emits hazardous fumes and produces suboptimal results during laser cutting. While it may seem like a versatile material, PC tends to scorch or warp under laser contact, yielding poor edge quality and reducing precision in intricate designs. It also releases bisphenol-A (BPA) as a byproduct, a chemical linked to adverse health effects such as hormonal disruptions.

Studies and industry tests highlight that alternative materials like acrylic, laser-safe wood, or specialized plastics can deliver cleaner cuts, ensure operator safety, and enhance productivity without compromising on quality. Choosing the right materials aligns with both an environmentally responsible approach and a commitment to improved long-term outcomes for your machinery and projects.

Impact of Toxic Fumes on Health and Equipment

Health Risks of Toxic Fumes

Exposure to toxic fumes, especially those released during industrial processes like laser cutting, can have severe health implications. These fumes often contain volatile organic compounds (VOCs), particulates, and harmful gases such as carbon monoxide or nitrogen dioxide. Prolonged inhalation of these substances has been linked to respiratory issues, including chronic bronchitis and asthma, as well as exacerbations of pre-existing lung diseases. The World Health Organization estimates that indoor and outdoor air pollution contributes to over 4 million premature deaths annually, with toxic fumes being a significant contributor. Additionally, compounds such as formaldehyde and benzene that are often found in such emissions are classified as carcinogenic, posing long-term risks of cancer development.

Effects on Equipment and Machinery

The impact of toxic fumes extends beyond human health, significantly affecting the performance and longevity of equipment. Corrosive particles in fumes can settle on internal machine components, leading to the gradual breakdown of motors, lenses, and filtration systems. Studies show that equipment exposed to high concentrations of such emissions may require maintenance or part replacements up to 20% more frequently compared to machinery in safer environments. Furthermore, the buildup of residues can reduce cutting accuracy, hinder productivity, and increase operational costs over time. Ensuring a clean and safe operating environment, along with the use of proper ventilation and high-quality materials, is vital for preserving both worker safety and equipment efficiency.

Why Are Some Materials Not Suitable for Laser Cutting?

Certain materials are not suitable for laser cutting due to safety concerns, poor cutting quality, or damage to the machine. For instance, materials like PVC and other chlorinated plastics release toxic fumes when cut, posing serious health risks and potentially corroding machine components. Some materials, such as thick metals or highly reflective surfaces, may not cut efficiently or can reflect the laser beam, which could damage the equipment. Additionally, flammable materials like some foams or untreated fabrics present a heightened risk of fire. Using materials specifically recommended for laser cutting ensures both safety and optimal performance.

The Science Behind Reflective Materials and Laser Beam Interaction

When a laser beam interacts with reflective materials, such as polished metals or mirrors, the behavior of light becomes a critical factor in understanding potential challenges. Reflective materials tend to bounce back a significant portion of the laser’s energy due to their high surface reflectivity. This redirection can interfere with the cutting or engraving process, impact the precision of the task, and, in extreme cases, cause damage to the machine’s laser optics or components.

The reflection occurs because metals like aluminum, copper, and gold exhibit high reflectance at specific wavelengths, often exceeding 95% in certain cases. For example, aluminum reflects approximately 92-98% of infrared light, making it one of the most challenging materials to work with when using CO2 or fiber lasers. Copper, with its excellent thermal and electrical conductivity, exhibits similar reflective properties. These characteristics demand tailored approaches to enhance energy absorption and avoid inefficiencies.

To address this issue, advanced laser systems often incorporate anti-reflective coatings on machine optics or polarizing mechanisms to manage light scattering. Additionally, fiber lasers operating at shorter wavelengths (like 1 µm) have higher absorption rates for reflective metals compared to CO2 lasers with longer wavelengths (10.6 µm). For example, while CO2 lasers may struggle with brass or gold, fiber lasers can perform significantly better due to these materials absorbing more of the laser energy at shorter wavelengths.

Modern technological solutions also include beam-shaping techniques that optimize the laser’s energy distribution or integrating sensors that monitor and adjust for reflected light in real-time. Understanding the interaction between reflective materials and laser beams is crucial for safe operations and achieving precise, efficient results in industrial applications.

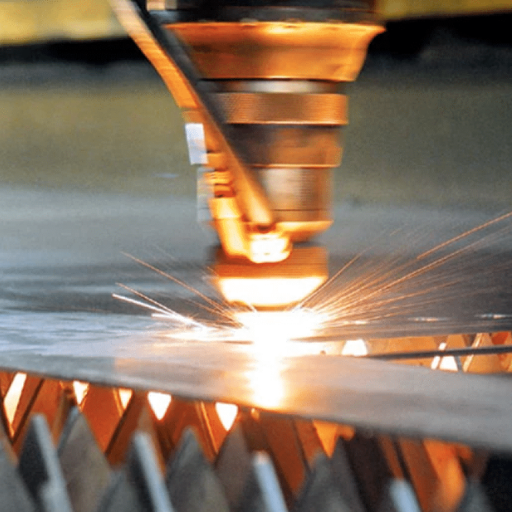

How Metal Materials Challenge Fiber Laser Systems

Reflectivity and Thermal Conductivity Challenges

Metal materials, particularly reflective metals like aluminum, copper, and gold, pose significant challenges for fiber laser systems due to their high reflectivity and exceptional thermal conductivity. For instance, copper’s reflectivity can exceed 95% at certain wavelengths, causing a substantial amount of laser energy to be reflected rather than absorbed. This reflected energy can backfire into the laser system, potentially damaging sensitive components and reducing operational efficiency.

Additionally, the high thermal conductivity of metals like copper and aluminum disperses heat rapidly across the material. This characteristic makes maintaining a stable and concentrated heat zone for cutting or welding more difficult. For example, aluminum exhibits a thermal conductivity of approximately 235 W/m·K, which means the heat generated by the laser can spread quickly, reducing the effectiveness of localized material processing.

Beam Delivery and Wavelength Optimization

To address these issues, modern fiber laser technology employs wavelength optimization and specialized beam delivery. Shorter wavelength lasers, such as green and UV lasers, have proven to be more effective in processing highly reflective metals. For instance, green lasers operating in the 532 nm range can reduce reflectivity in copper by as much as 50%, increasing absorption and facilitating cleaner cuts with less thermal distortion.

Special beam-shaping technologies further enable fiber lasers to adapt their energy profiles. Techniques such as the application of ring-mode beam profiles enhance edge quality by minimizing heat-affected zones. Advanced systems also integrate real-time feedback sensors to assess reflectivity levels and adjust laser parameters on the fly, mitigating risks of excessive energy reflection.

Advancements in Coating and Pre-Treatment

Another promising approach involves coating the surface of reflective metals with absorptive layers before laser processing. For example, using a thin coating of black oxide or specially designed nano-coatings can significantly increase energy absorption. Studies have shown that such pre-treatment methods can improve cutting speeds and reduce the need for post-processing tasks like deburring or polishing.

Metalworking and manufacturing sectors continuously explore these advancements to overcome the inherent challenges posed by fiber lasers’ interaction with reflective metal materials. Innovations in laser technology and material science are essential for improving efficiency and achieving high-precision results with challenging metals.

Exploring Alternatives for Materials That Cannot Be Cut with a Laser

While lasers are highly versatile cutting tools, certain materials either cannot be cut efficiently or are unsafe to process using lasers. These include materials like polyvinyl chloride (PVC), which emits toxic fumes when exposed to laser cutting, as well as highly reflective metals like copper and certain alloys that pose challenges due to their reflective properties. For such cases, manufacturers often turn to alternative cutting technologies that ensure precision and efficiency while maintaining safety standards.

Waterjet Cutting

Waterjet cutting stands out as a popular alternative, particularly for materials that are sensitive to heat. This method uses a high-pressure stream of water, often mixed with abrasives, to cut through materials like ceramic, stone, glass, and even metals. Waterjets can achieve tolerances as precise as ±0.001 inches, making them ideal for complex designs or materials prone to heat distortion. Additionally, since waterjet cutting is a cold process, it eliminates the risk of thermal damage to the material.

Plasma Cutting

For electrically conductive materials, plasma cutting is a powerful option. This process involves using a high-velocity stream of ionized gas (plasma) to cut through metals such as steel, stainless steel, and aluminum. With cutting speeds up to 200 inches per minute and the ability to handle materials up to several inches thick, plasma cutting is a cost-effective alternative for thicker and highly durable materials.

Mechanical Cutting Methods

Conventional methods like milling, sawing, and stamping remain relevant, especially for certain materials that resist laser or heat-based cutting techniques. These methods, while often slower, provide excellent control and can process a broad range of materials. Innovations in precision tooling continue to improve the capabilities of mechanical processes, particularly for metals and composites.

Future Trends in Material Processing

Emerging technologies like ultrafast lasers and hybrid cutting systems are also being researched for their potential to handle traditionally challenging materials. Ultrafast lasers, which operate on femtosecond or picosecond pulse durations, minimize heat generation and can process reflective materials with high precision. Additionally, advancements in automation and AI-driven cutting systems are improving material adaptability and efficiency, ensuring a broader range of materials can be processed more safely and effectively.

By combining established technologies with cutting-edge advancements, industries can overcome the limitations of laser cutting and deliver precise solutions tailored to specific material needs.

What Happens When You Try to Cut Materials That Cannot Be Cut with a Laser?

When trying to sever materials that a laser cannot process for some reason, difficulties arise. The laser may not completely cut through the part, which causes the piece to be cut unevenly or not be cut at all. Certain grade reflective metals are capable of bouncing the beam out, greatly reducing the productivity of the system and potentially harming the device. Other types, like some plastics and composites, may give off toxic gases or chemically sublimate when subjected to intense heat, creating safety hazards. All of these factors highlight directly the need for evaluating the material to be used prior to selecting the method of laser cutting, so as to ensure the optimum efficiency whilst having safe operations.

Potential Damage to Your Laser Machine and Laser Cutting Machine

When it comes to potential damage to my laser machine and laser cutting machine, I always prioritize proper maintenance and usage. I ensure that compatible materials are used and avoid those that could reflect the laser or release harmful fumes. Regular cleaning, monitoring for wear and tear, and following manufacturer guidelines are essential steps I take to protect the equipment and maintain its efficiency. These practices help me maximize the machine’s lifespan while ensuring safety during operations.

Understanding the Release of Toxic Fumes and Its Effects

When working with materials in laser cutting, I am cautious about the potential release of toxic fumes as it poses health risks and can damage my equipment. I carefully research the materials I use, avoiding those known to emit harmful substances when cut, such as PVC or certain plastics. Additionally, I ensure proper ventilation and use air filtration systems to remove hazardous particles, protecting both myself and those around me. By taking these measures, I reduce exposure to toxic fumes and maintain a safe and efficient workspace.

Why Laser Processing of Certain Materials Fails

One reason laser processing of certain materials fails is due to their chemical composition or structural properties. For instance, some materials, like PVC, release corrosive or toxic fumes when exposed to laser energy, which can damage the equipment and create a hazardous environment. Additionally, materials with high reflectivity, such as certain metals, can deflect the laser beam, reducing its effectiveness and risking operational inefficiencies.

How to Identify Materials That Should Not Be Cut Using a Laser?

To identify materials that should not be cut using a laser, start by checking the material’s composition. Avoid any material that contains chlorine, such as PVC or vinyl, as these release harmful gases when exposed to laser cutting. Additionally, steer clear of materials with highly reflective surfaces, like certain polished metals, as they can deflect the laser beam and cause inefficiencies or damage the equipment. Consult the material’s safety data sheet (SDS) for guidance since it often lists hazardous properties. If unsure, refer to the laser manufacturer’s guidelines or reach out to an expert to ensure safety and proper operation.

Key Characteristics of Materials Are Not Suitable for Laser Cutting

- Contains Chlorine or Halogens

Materials containing chlorine, such as PVC and certain plastics, are highly unsuitable for laser cutting. When these materials are exposed to a laser beam, they produce harmful fumes and toxic gases like hydrogen chloride, which can corrode machinery and pose serious health risks to operators. For example, PVC emits potentially carcinogenic byproducts, making its handling dangerous without specialized ventilation systems.

- Highly Reflective Surfaces

Metals like polished aluminum, brass, or copper can reflect the laser beam rather than absorbing it, leading to inefficiencies and potential damage to the laser’s cutting head. Reflective surfaces can also scatter laser energy, posing a safety hazard to nearby personnel. Non-reflective coatings or alternative machine settings may be required for these materials.

- Flammable or Combustible Materials

Materials that are highly flammable, such as foam, certain fabrics, or untreated wood, can ignite when subjected to the concentrated heat of a laser. These pose significant safety hazards and may even result in uncontrollable fires. For example, polyurethane foam generates a high fire risk when cut, as it accelerates flame spread quickly upon ignition.

- Materials Containing Fiberglass or Epoxies

Fiber-reinforced materials, such as fiberglass or epoxy composites, are problematic due to their composition. When exposed to laser cutting, they emit hazardous particulates and fumes that are harmful to both humans and the surrounding environment. The glass fibers embedded in the resin also result in uneven or unsatisfactory cuts, reducing the quality of the output.

- Unknown or Multi-Layered Materials

Materials with mixed or unknown compositions, like certain laminates, can behave unpredictably under laser cutting. Layers may have adhesive properties, moisture content, or chemical components that produce toxic fumes, leave sticky residues, or burn unevenly. Testing could be required for layered materials like MDF containing glue binders.

By understanding these key characteristics, manufacturers and operators can prioritize safety, efficiency, and environmental considerations when selecting materials for laser cutting processes.

Testing Different Materials for Compatibility with Laser Systems

Testing materials for laser system compatibility requires a thorough examination of their properties, response to laser exposure, and potential environmental impact. This process involves evaluating key factors such as thermal tolerance, reflectivity, and chemical composition to ensure safe and efficient laser operation.

1. Thermal Tolerance and Melting Point

Different materials absorb laser energy in varying ways, which can impact their melting or vaporization thresholds. Metals like aluminum and stainless steel have high melting points (1,221°F and 2,500°F respectively) making them ideal for high-power laser cutting, while softer materials like acrylic or plywood require lower power settings due to their lower ignition and melting points.

2. Reflectivity and Absorption Rates

Laser systems must account for material reflectivity to optimize cutting or engraving efficiency. High-reflective materials like copper and gold can reflect laser beams, potentially damaging the equipment or reducing performance. Advanced fiber lasers or CO2 systems often employ adjustments, such as wavelength shifting, to better handle reflective surfaces.

3. Chemical Composition and Safety Risks

Certain materials, particularly those with chemical binders or additives, may release toxic fumes when exposed to lasers. For example, PVC produces hazardous chlorine gas, while materials like MDF can emit volatile organic compounds (VOCs) during the cutting process. Employing proper ventilation, filtration systems, and operator awareness is critical for maintaining a safe working environment.

4. Material Uniformity and Layering

Composite or layered materials, such as plywood or laminates, pose unique challenges in laser systems. Variations in density, adhesive materials, or moisture content can lead to uneven cuts or poor-quality results. Pre-testing smaller sections of the material can help identify optimal laser settings for consistent output.

5. Customized Settings and Pre-Test Protocols

Before full-scale production, operators should perform controlled tests on new materials to determine the ideal settings for power, speed, and focus. This minimizes waste, reduces the likelihood of equipment damage, and increases precision for tasks like engraving or cutting delicate patterns.

By systematically assessing these compatibility factors, users can unlock the full potential of laser systems while ensuring safety, efficiency, and high-quality performance across a wide range of materials.

Consulting Material Safety Data Sheets for Laser Machine Use

Consulting Material Safety Data Sheets (MSDS) is a critical step in ensuring safe and effective laser machine operations. These documents provide comprehensive information about the properties of materials being used, their potential hazards, and recommended handling procedures. When using a laser system, understanding material-specific factors such as flammability, potential toxic emissions, and thermal behavior is essential to avoid accidents and maintain a safe working environment.

For instance, materials like PVC or certain plastics release harmful fumes, including chlorine gas, when exposed to laser cutting. This can pose severe health risks and damage equipment. MSDS data allows users to identify such risks beforehand and implement proper ventilation systems or substitute safer materials when possible. Metals, on the other hand, often reflect laser beams, especially aluminum or copper, which can reduce efficiency and cause unpredictable beam paths. The MSDS provides insights into reflectivity and heat resistance that guide operators in adjusting laser parameters accordingly.

By utilizing MSDS data alongside technical specifications for laser machines, users can optimize processes for different categories of materials. For example, wood requires specific laser power settings to avoid charring, while glass demands careful adjustments to prevent cracking. The detailed chemical composition and density information found in MSDS documents assist in calibrating the laser’s speed, frequency, and focus for precise, clean cuts.

Ultimately, integrating MSDS knowledge into everyday laser operations improves not only safety protocols but also the overall efficiency and durability of the equipment. Regularly reviewing these sheets ensures compliance with safety standards and empowers operators to work confidently with an extensive range of materials.

What Are the Safe Alternatives to Laser Cutting Materials Like PVC?

Identify safer options for materials like PVC that consider not emitting hazardous toxins when cut. Acrylic (PMMA) is one of the most common alternatives because it cuts well and doesn’t emit dangerous fumes. Cardboard as well as wood materials like plywood or MDF are safer options, but only if they are free of treatment and chemical additives. For lighter projects, paper and fabric can be utilized as they present minimal risk during processing. Be sure to check material specifications and guidelines by the manufacturer to confirm safety and compatibility with the laser system before use.

Exploring Cutting Machine Options for Problematic Materials

When dealing with materials that pose challenges during the cutting process, such as PVC, polycarbonate, or glass, selecting the right cutting machine is crucial for achieving precision and safety. Advanced laser cutters equipped with CO2 or fiber laser technology have emerged as effective solutions for non-metallic and metallic materials respectively. For instance, fiber lasers excel in cutting reflective metals like brass or aluminum, avoiding warping caused by heat. On the other hand, CO2 lasers are optimal for organic materials but may require special exhaust systems to handle potential fumes.

For glass cutting, machines using water jet technology or specialized laser systems deliver precise, clean results without the risk of cracking or shattering. Recent data indicates that water jet cutters, operating at pressures as high as 60,000 PSI, provide high efficiency and a smooth finish for brittle materials.

Hybrid cutting machines, which combine multiple technologies like laser and mechanical cutting, are gaining traction as versatile options. These are particularly advantageous for mixed media projects where different materials are involved. Modern machines also feature automated safety mechanisms and waste management systems, ensuring that users can work efficiently without compromising environmental or personal safety.

Key specifications to consider include power output, material compatibility, and cooling systems. It’s vital to choose a machine suited to the material’s thickness and composition to minimize risks and enhance productivity.

Using Diode Laser and CO2 Laser for Suitable for Laser Cutting Tasks

When selecting between a diode laser and a CO2 laser for laser cutting tasks, it’s essential to understand their respective strengths, applications, and performance characteristics.

Diode Laser

Diode lasers are known for their compact design, efficiency, and suitability for precision tasks. These lasers typically operate at wavelengths ranging from 400 nm to 980 nm, making them ideal for engraving and cutting thinner materials such as wood, leather, acrylic, and some types of plastics. Due to their lower power output compared to CO2 lasers, diode lasers are better suited for delicate materials that require precision without generating excessive heat. For instance, a diode laser with a power output of 10W-20W can achieve fine detailing at high precision, with cutting speeds of up to 10 mm/s depending on the material. This makes diode lasers well-suited for tasks such as intricate crafting or personalized engraving.

CO2 Laser

CO2 lasers, on the other hand, are more powerful and versatile, operating at a wavelength of 10.6 µm. These lasers are highly effective for cutting and engraving a broader range of materials, including metals (with post-treatment), glass, thick plastics, woods, fabrics, and even ceramics. With power outputs commonly ranging from 40W to 150W or more, CO2 lasers can cut materials up to several millimeters thick, such as 10 mm acrylic or 20 mm wood, while maintaining a cutting speed of 20-50 mm/s depending on the setup and material. CO2 lasers are widely used for industrial applications where both speed and material compatibility are crucial.

Choosing the Right Cutting Process for a Wide Range of Materials

Selecting the optimal cutting process for various materials involves understanding their properties and determining which technology delivers the highest efficiency, precision, and quality. Below is an overview of cutting methods suited to a wide range of materials, along with their advantages and considerations:

- Laser Cutting

Laser cutting provides unparalleled accuracy and is compatible with materials such as stainless steel, aluminum, wood, acrylic, and textiles. For metals, fiber lasers excel due to their ability to focus high-intensity beams, which result in clean, burr-free edges. Meanwhile, CO2 lasers are more effective for non-metallic materials, offering a smooth finish ideal for intricate designs. Recent advancements have achieved cutting speeds reaching up to 40 inches per second, improving throughput in industrial applications.

- Waterjet Cutting

Waterjet cutting is highly versatile and notable for its ability to handle a diverse array of materials, including thick metals, ceramics, composites, and even rubber. This process involves a high-pressure water stream, often mixed with abrasive particles to slice harder substances with precision. One key advantage is its capability to cut without introducing heat, preserving the structural integrity of heat-sensitive materials. Aerospace and automotive industries commonly use waterjet cutting for its clean, accurate results.

- Plasma Cutting

A fast and effective process for electrically conductive materials, plasma cutting uses a high-temperature ionized gas stream to melt and remove metal. It is particularly suitable for cutting thick steel and aluminum sheets, with modern CNC systems ensuring detailed patterns and complex shapes. Portable plasma cutting machines have become increasingly popular for on-site work in industries like shipbuilding and construction, with cutting speeds that can exceed 200 inches per minute.

- Mechanical Cutting

Traditional mechanical methods, such as sawing or milling, remain valuable for certain applications, particularly when working with materials like hardwood, plastics, or metal alloys. Advancements in tool technologies, such as the use of carbide or diamond-tipped blades, have extended the reliability and precision of these methods, making them a cost-effective choice for many medium-scale operations.

- Considerations for Hybrid Cutting Systems

Hybrid systems, which combine technologies like laser and mechanical cutting, are gaining traction in manufacturing. These systems integrate precision and speed with cost-effective performance, enabling enhanced flexibility across various industries.

When choosing a cutting process, factors such as material type, thickness, production volume, and required edge quality should guide decision-making. Modern data suggests trends toward automation and sustainability are increasing, with manufacturers now favoring energy-efficient systems and processes that minimize material waste. By carefully evaluating these aspects, industries can align their cutting strategies with performance goals and environmental standards.

Reference Sources

1. Influence of Pulse Duration on X-ray Emission during Industrial Ultrafast Laser Processing

- Published: 2022

- Key Findings:

- The study explored the impact of pulse duration on X-ray emissions during ultrafast laser processing of materials like stainless steel.

- Longer pulse durations increased X-ray emissions, posing safety risks.

- The research highlighted the need for careful parameter control to minimize hazardous emissions.

- Methodology:

- Experiments were conducted using ultrafast lasers with varying pulse durations and irradiance levels.

- X-ray dose rates were measured and compared with an extended analytical model to predict emissions.

2. Femtosecond Laser Processing of Membranes for Sensor Devices on Different Bulk Materials

- Published: Recent

- Key Findings:

- Materials like SiC and metals are prone to defects such as pinholes during femtosecond laser ablation.

- Pinholes are caused by Laser-Induced Periodic Surface Structures (LIPSS) acting as waveguides, concentrating laser energy.

- Techniques like polarization flipping were effective in reducing defects.

- Methodology:

- Laser ablation experiments were conducted on various materials, including SiC, glass, and sapphire.

- Simulations were used to analyze light propagation and defect formation mechanisms.

3. Fiber Laser Cutting of Alumina Substrates for Electronic Applications

- Published: Recent

- Key Findings:

- Alumina ceramics are challenging to process due to their hardness and brittleness.

- Laser cutting can cause cracks and reduce mechanical strength, especially in complex geometries.

- Digitally modulated fiber lasers minimized additional damage compared to traditional methods.

- Methodology:

- Experiments involved cutting alumina substrates with fiber lasers and measuring flexural strength.

- Simulations were used to analyze stress distribution and predict failure points.

4.Top Laser Engraving and Cutting Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What materials are not suitable for laser cutting and engraving?

A: Materials that are not suitable for laser cutting and engraving include PVC, polycarbonate, ABS, and certain types of foam. These materials can emit harmful gases or cause damage to the laser cutter.

Q: Why is PVC not recommended for cutting with a laser cutter?

A: PVC releases chlorine gas when cut with a laser cutter, which is hazardous to health and can cause severe damage to the laser cutter’s components.

Q: Can fiber laser cutting machines handle all types of materials?

A: No, fiber laser cutting machines are primarily used for cutting metals and are not suitable for non-metal materials like wood or certain plastics.

Q: What happens if materials that should not be cut using a laser cutter are processed?

A: Processing materials that should not be cut using a laser cutter can result in toxic fumes, fires, or damage to the laser equipment, compromising laser safety.

Q: Are there types of materials that are difficult to cut with laser technology?

A: Yes, materials such as glass and certain composites are difficult to cut with laser technology due to their reflective or heat-resistant properties.

Q: What is the risk of using a laser cutter on materials that can’t be cut?

A: Using a laser cutter on materials that can’t be cut may lead to inefficient processing, potential damage to the laser source, and safety hazards from emitted gases or fires.

Q: Can laser cutters cut metals effectively?

A: Yes, laser cutters, especially fiber laser cutting machines, are capable of cutting a wide range of metals effectively, making them a popular choice for laser cutting in industrial applications.

Q: What are common materials that laser engraved designs are typically made on?

A: Common materials for laser engraved designs include wood, acrylic, leather, and certain metals, as these materials are compatible with laser processing.

Q: Is there a difference between materials suitable for laser engraving and laser cutting?

A: Yes, some materials are suitable for laser engraving but not for cutting, such as certain types of stone or glass, due to their brittleness or thickness.

Q: How does laser light interact with materials used for laser cutting?

A: Laser light interacts with materials used for laser cutting by focusing intense energy onto a small area, causing the material to melt, burn, or vaporize along the desired cut path.