Although modifying laser devices creates new marking methods, not all marking techniques are synonymous. There is no universally accepted definition for each marking type; thus, marking types such as laser engraving, laser marking, and laser etching tend to be used interchangeably. Whether you are a designer, manufacturer, or technology enthusiast, knowing the differences considerably impacts making significant choices related to your projects. This article thoroughly analyzes every process and its implementation so that you achieve the most suitable solution for your requirements. Get ready to clear the confusion surrounding these advanced marking systems.

What is the Difference Between Laser Marking and Laser Engraving?

Engraving and marking are two different procedures aiming to alter an object’s surface permanently.

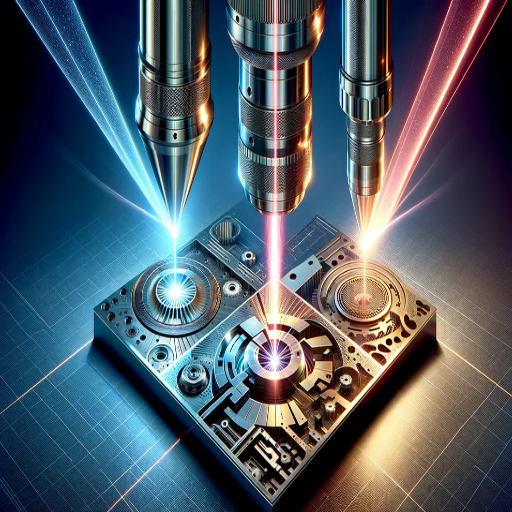

Laser engraving requires a more powerful laser beam and more energy than laser marking. In addition to removing part of the upper layer of the material, the marking underneath is also more profound, enabling a greater degree of contrast across the surface. Examples include emblems, logos, and company names.

Laser engraving, on the other hand, excavates material to form a noticeable mark. A high-powered laser burns into the surface to create detailed and textured marks. This method is ideal for intense applications such as industrial components or for unique goods that feature a deep and touchable impression.

The fundamental distinction varies with the laser’s strength and the mark’s depth, which makes each technique ideal for particular purposes and materials.

How does the laser marking process work?

Laser marking uses a beam of light that is concentrated to the extreme, creating a mark, pattern, or design on the surface of a specific material. This process begins with marking the desired design on the computer, the mark is then forced to the computer-controlled laser system which guides the laser to the material with extreme accuracy and precision. The laser does not actually make physical contact with the material, instead, the heat the laser aequfires burns off the surface to the material in question. The results are a product of the force attempting to cut, foam, engrave, or change the color of the material surface being targeted.

One of the advantages of laser marking is the exceptional accuracy level, even achieving millimeters tolerances. Now, it is even possible to operate modern systems over 1,000 characters per second. With recent advancements in technological data, it has also come to my attention that fiber lasers, which are often in use, now last up to 50,000 to 100,000 hours. This is a great development made for ensuring long-term efficiency.

Moreover, laser marking can also be done in various materials, such as metals like stainless steel and aluminum, wood, certain types of plastics, and ceramics. The cutting mechanism also does not create contact with the targeted material; therefore, the wear and tear done to materials is significantly lesser and helps maintain consistency across measurement units. Outside of industrial use, laser marking is extensively used in medical electronics, aerospace industries, and spaces that need enhanced precision and consistency.

What are the applications of laser marking?

Laser marking is used in various industries due to its incredible accuracy, strength, and adaptability.

- Medical Device Manufacturing: The laser marking process is vital for marking surgical instruments, implants, and various medical devices. Markings such as UDI (Unique Device Identification) codes are permanently etched onto devices to enable traceability and compliance with regulations as rigorous as those set forth by the FDA. Since this process is non-contact, it avoids contamination.

- Aerospace and Automotive: Both industries utilize laser marking to identify parts and serial numbers, as well as safety marking on engines and electrical systems. Items such as engine parts, electric systems, and other safety-critical tools are marked with lot numbers and barcodes to enable traceability and quality assurance throughout the supply chains. Laser marking provides accuracy on granite to more alloyed metals like titanium which are extensively used in aerospace and automotive engineering.

- Electronics and Semiconductor Industry: The increasing miniaturization of electronic devices makes marking small surfaces like microchips, PCBs, and connectors easy. Markings such as logos or QR codes can be placed on these devices, and they will endure wear caused by prolonged use or exposure to environmental factors.

- Jewelry and Luxury Goods: In the jewelry sector, lasers are automating the art of marking intricate designs, logos, and serial codes of gemstones and metals. This aesthetic process aids in counterfeiting prevention and does not harm the item.

- Packaging and Branding: Marking lasers are used to create consumer goods expiration dates, logotypes, batch numbers, and even in pharmacology. This technology’s contactless nature is appropriate for delicate packaging like plastic, glass, paper, and others.

- Industrial and Manufacturing Tools: Engraving and industrial machines require precision in marking parts, and laser engraving provides that for tools and their components. With the ability to expose the equipment to extreme conditions like high temperatures or chemical contact, the durable deep marks engravings ensure enduring identification.

Industry growth data backs up laser marking technology’s rapid expansion. For example, as of this year, the global laser marking market is approximately $3.6 billion and is predicted to rise at an 8% CAGR until 2030. The technology’s expansion across almost all industries highlights its importance in manufacturing branding and modern mark-tracing systems.

When should you choose laser marking vs laser engraving?

The selection of procedures between laser marking and laser engraving relies on the materials to be used and the expected outcome. As previously mentioned, these two techniques offer different benefits, and understanding them deeply assists in making the correct decision.

For every one of the cases that require accuracy, attention to surface details, and integrity, Laser Marking works the best. This involves permanent contrast markings on the material’s surface without any surface removed. This technique is preferred for barcodes, QR codes, logos, and item identifications. It can be used on metals, plastics, ceramics, and coated materials. Traceability and compliance in aerospace, medical devices, and electronics industries heavily depend on these laser markings. Some recent statistics show its reliability, for example, laser-marks data matrices in medical device manufacturing are scannable even after repeated sterilizations which shows no surface damage.

Unlike laser engraving, laser marking does not involve removing any material, resulting in a more shallow mark. Applications that require deep marks to be durable and quickly noticed often use laser engraving. For example, laser engraving is standard for high-durability permanent markings in the automotive and heavy equipment industries. Laser engraving can fathomably be used in harsher environments due to its abrasive, chemical exposure, and extreme temperature resistance.

It is crucial to distinguish each engraving or marking from the other, as both differ significantly in cost and efficiency. Laser marking does not remove any material, rendering it faster and more cost-effective than engraving, earning its reputation as the most optimal choice in high-speed and volume production. While laser engraving does require a significant investment of energy and time, it stands unrivaled in its ability to create marks that endure for ages.

As with all decisions, the above factors depend greatly on your needs. If the importance of surface precision and the level of contrast required are critical, then marking would be an appropriate choice. Laser engraving offers the best results if strength and how deep it is done into the object matters most. Both solutions are advancing and provide more options for various business and manufacturing purposes.

How does Laser Etching vs Laser Engraving Compare?

Two of the most popular methods of marking or customizing materials are laser etching and laser engraving. They might seem similar at first, but they differ significantly in process, application, and results. Understanding the differences between the two methods can make all the difference for companies and individuals looking for the optimal solution. This blog post analyzes laser etching as compared to laser engraving and showcases the key features, advantages, and methods for selecting the most suitable option. This article is for you, whether you aim to improve product branding, design a lasting impression, or achieve precise markings on various materials.

What is the laser etching process?

Laser etching is a type of laser marking that employs a powerful laser beam to create a raised mark on the surface of a material. This works by changing the material’s surface topography to induce a contrast without significant depth alteration. Typically, the laser heats the material to a melting point, resulting in slight relief from some surface softening. Laser etching works best for soft materials, such as metals, ceramics, and coated polymers.

The most notable advantage of laser etching is speed since shallow penetration means faster marking compared to engraving. For example, industrial-grade lasers have guaranteed etching speeds of 2.5 meters per second. This is acceptable for high-volume production lines. However, it must be noted that the etching depth is usually limited within the range of 0.001 inches to 0.005 inches, depending on the material and the laser.

Laser etching is commonly used in cases where intricate designs or text need to be added such as in barcodes, logos, and serial numbers. The marks produced using this method resist scratches, chemicals, and even ultraviolet radiation. This also makes the markings secure and readable even in very tough settings. Additionally, it is a non-contact method that ensures less likelihood of damaging the material and guarantees accuracy and precision.

What materials are suitable for laser etching and laser engraving?

Laser engraving and etching can be performed on various materials, making them useful for all sorts of industries. Here is a list of the most frequently used categories of materials:

- Metals

Stainless steel, aluminum, brass, copper, titanium, and tungsten are commonly used metals for laser etching and engraving. The metals show excellent results because the materials have smooth finishes and high thermal conductivity. From industrial components to jewelry-corded items and promotional products, metals have reliable uses with detailing precision.

- Plastics

Acrylic, polycarbonate, ABS, and polypropylene are examples of plastics that can be harnessed using laser technology. Specifics of some plastics specially designed to withstand laser marking leave sharp and clear marks that can be used to manufacture ID tags, key chains, and control panels.

- Wood

Natural and engineered woods like maple, birch, bamboo, and MDF are popular for laser engraving because they all respond exceedingly well to it. The process creates advanced deep engravings that make wood a popular option for crafting furniture customization and signage.

- Glass and Ceramics

Glass is a perfect material for laser etching because you can create frosted or textured designs without compromising the integrity of the material. This method can be used for branding on wine glasses, trophies, or even decorative tiles. These materials are perfect for this purpose.

- Textiles and Leather

Using laser technology, cotton, denim, felt, and synthetic textiles can be accurately marked or cut. Moreover, both genuine and synthetic leather can be engraved for use in customized wallets, handbags, and footwear.

- Composites

If the correct parameters are set, carbon fiber and fiberglass composites respond well to laser engraving. They are extensively used in the aerospace, automobile, and sports equipment industries.

- Stone and Marble

Granite, slate, and marble are considered hard materials and can be laser engraved with precision. They are often used for memorial plaques, architectural decorations, and artistic sculptures.

Each material differs in how best to optimize laser power, speed, and frequency for clarity and durability. As laser technology improves, the list of materials that can be processed with lasers is growing, making these technologies more versatile and easier to adapt to different applications.

What are the key differences between laser etching and engraving?

Laser engraving and laser etching use lasers to mark a material. Each differs in the depth of the mark, application, and best-suited materials.

- Laser Etching

The technique of laser etching works by melting the laser’s surface and raising it. Laser etching is relatively shallow and does not exceed two-tenths of an inch in depth (0.02). Some materials that do best with laser etching includes metals, glass, and even some ceramics as well as certain types of polymers.. In most cases, etching is preferable for ‘marking’ because it does not penetrate, such as barcodes or serial numbers, and can be done relatively quickly, which means no damage occurs to more delicate surfaces. Moreover, it is a common practice to use high contrast on coated materials that were previously anodized, which clearly illustrates that laser branding is done for aesthetic purposes.”

- Laser Engraving

Unlike laser etching, which only burns a design onto the surface, the laser engraving technique removes granular material from the top layer of a solid surface, yielding marks as dire as 0.125 inches. Regarding the material and project, guidelines can be set for the minimum marks required. This more strenuous marking process is typically best suited for industrial purposes or items designed to endure harsher environments due to the more permanent features that withstand intense wear or tear. Engraving is often done in metal, wood, plastic, or leather and is dominated by intricate logos, texts, or decorative patterns. These levels of depth are associated with increased wear and tear, making them easier to read over long periods.

What Industries Use Laser Etching?

Laser etching is employed in various industries, such as manufacturing, electronics, automotive, medical, and aerospace. The manufacturing and electronics industries use laser etching to mark logos, barcodes, and serial numbers on components. The automotive industry uses laser etching to mark various automotive components permanently. The medical and aerospace industries use laser etching to mark surgical instruments, implants, and other high-precision tools where the accuracy and clarity of the markings are critical.

How is laser technology applied in manufacturing?

The application of laser technology in the manufacturing industry has provided modern advancements in precision, efficiency, and versatility in a wide range of applications. Laser cutting is an essential application of lasers, which allows speed and precision when cutting shapes from different materials, including metals, plastics, ceramics, and composites, with minimum raw material waste. Industry sources claim that laser cutting systems can achieve positioning accuracy of up to ±10 micrometers, which is extremely helpful when precision etching intricate designs.

Laser welding is another application often used in the automotive and aerospace industries, which produces high-strength, one-piece seamless joints. Statistics show that the speed of laser welding reaches 50 millimeters per second, which improves production cycle time while maintaining the strength and dependability of the materials used.

Laser engraving and marking are essential for establishing a brand identity and traceability. Current systems can etch components at 180 characters per second, permitting serial number, barcode, and part description labeling.

In addition, laser technology is fundamental in additive manufacturing, mainly 3D printing. With techniques like Selective Laser Sintering (SLS) and Selective Laser Melting (SLM), complex and robust parts are built up layer by layer, which decreases waste relative to traditional manufacturing processes.

In general, the versatility of lasers within manufacturing industries translates to enhanced product quality, more incredible production speeds, and increased capability to address complex industry requirements.

What is the importance of laser marking machines in industries?

Laser marking machines have greatly improved operations in numerous industries due to their automation, precision, and adaptability. Such machines utilize lasers to etch or engrave surfaces that require permanent identification. Nowadays, engraving different materials such as glass, metals, plastics, and even ceramics is possible. One marking application is traceability, where components are labeled with serial numbers or barcodes to be tracked easily throughout the supply chain. This is particularly crucial for the automotive, electronics, and aerospace industries due to their rigorous quality control, compliance, and regulatory standards.

According to data, the industry has been growing at over 7% annually and is predicted to reach several billion dollars by 2030. There is an apparent increase in demand for durable and non-removable markings. Furthermore, the non-contact nature of the marking reduces material waste and preserves delicate parts, which are vital for medical devices, pharmaceutical packing, and other sensitive components. In addition, laser marking is unmatchable when it comes to traditional marking methods, as consumables like ink and chemicals are not needed. These features lessen operational costs and allow businesses to adopt sustainable practices.

Industries are adopting laser marking at an increasing pace because of its versatility and speed, which allows for the mass customization of goods without sacrificing quality. Whether guaranteeing a product’s part verification, enhancing operational efficiency, or marking logos for branding purposes, laser marking machines are incredibly useful in satisfying modern expectations in manufacturing and production.

What are the Differences Between Laser Marking and Other Techniques?

There are some key differences where laser marking stands apart from all other forms of marking techniques:

- Precision and Detail: Laser marking is ideal for intricate designs or small surfaces compared to traditional methods. It provides exact and detailed results, while conventional methods may struggle with fine details.

- Non-Contact Process: Unlike any other form of marking, such as stamping or engraving, laser marking is a non-contact process, which makes it much safer. There is less chance of damaging the material that needs to be marked.

- Durability: Some methods, like printing, can smudge or fade away over time, which makes lasers a better option. Marks created using lasers are often permanent and resistant to wear, chemicals, and environmental conditions.

- Versatility: Compared to conventional techniques, laser marking offers more application possibilities as it works effectively on various materials such as metals, glass, ceramics and even plastics.

- Efficiency: Laser marking is much more cost-effective and faster than manual and semi-automated methods. Its speed and automation capabilities make it easier to use in large-scale productions.

Laser marking techniques have become very popular because of the remarkable accuracy, high durability, and unmatched efficiency that industries need.

How does traditional engraving differ from laser marking?

Both traditional engraving and laser marking have distinct differences in the course, accuracy, techniques, and even the impact on the material. Because of modern technologies, specific key differences have been identified.

- Technique and Procedure

Traditional engraving requires cutting the material surface using a burin or mechanical cutter. A piece of material with a pattern is created using an orderly block of metal, which is highly skilled labor. Labor intensive and painstakingly slow is the term used to describe this process. On the contrary, laser marking is the complete opposite because it changes the surface of the materials by using heat, including oxidation and chemical modification, without removing any material. This technique is ensured to be cleaner and more controlled when compared to the mechanical approach.

- Detail and Accuracy

The ability to mark laser engrave is incredibly accurate because almost every design, small text, and image can be created with a micrometer degree of precision. On the other hand, traditional or straightforward engraving works well with larger designs only, hence lacking the precision and uniformity that modern age industries require, such as electronics or aerospace. Reproduction of different complex patterns becomes effortless through the use of laser technology.

- Speed and Automation

Thanks to Technology, machinery like laser engravers can effortlessly achieve a staggering three hundred characters per second. With all of the automation features alongside these high speeds, laser etching is best suited for mass manufacturing environments. Compared to traditional engraving, laser engraving is best suited for industrial-scale applications because traditional methods are engrained into time and are too slow.

- Material Compatibility

lasers easily etch various materials, such as plastics, metals, wood, glass, and even stricter materials like ceramics. Due to having a specific focus on a particular material, engravings are usually less versatile and suitable for performing on more delicate and softer materials, like glass, and thus suffer from fragility issues.

- Durability and Longevity

Compared to traditional engraving patterns, which certainly have their endurance, laser markings come out on top due to being free from changes to weather conditions like moisture, chemicals, and heat. Withstanding almost everything without fading or being worn down is a real game changer. On the downside, patterns can eventually be worn down from harsh environments and abrasive conditions.

- Environmental And Operational

Thanks to not needing any physical tools, chemicals, or consumables like engraving tools, markers become more eco-conscious. Due to marking using such little resources, there is less waste during the engraving process than tools, resulting in frequent replacement and sharpening, and the cost in the long run adds up.

These differences underscore the growth in popularity of laser marking in different industries due to its unparalleled accuracy, adaptability, and speed compared to traditional engraving.

What is the Laser Engraving Process?

Engraving, or laser engraving, is a method that uses a laser to etch a permanent mark or design on an object. The procedure begins by directing the laser over the object using a pre-loaded contour and outline. Energy in the form of a beam is applied, and its intensity melts or vaporizes surface material, resulting in clear engravings. Laser engraving is of great importance because of its precision, rapid engraving speed, and enduring results, all while working on metal, wood, plastics, glass, etc.

What are the steps in the laser engraving process?

- Creation of a Design

The laser engraving process involves designing a pattern with specialized software like Adobe Illustrator, CorelDRAW, or CAD. The chosen design is modified to fit the material’s dimensions to be engraved appropriately.

- Preparation of Material

After the design is approved, the engravable material is selected and meticulously prepared. Engraving different materials requires different settings. The laser power, speed, and frequency must be set differently according to the nature of the material to be engraved. For example, steel metals require higher power settings, while softer materials such as wood or leather require lower power settings.

- Calibration of Laser Machine

Pre-engraving processes include calibrating the laser engraving machine to perform engravings with precision. Setting the machine involves adjusting the focal length, leveling the laser head, and setting the optimal parameters for the selected material and design. For instance, lowering the power level is necessary for high-quality glass engravings to prevent cracks or chips.

- Execution of Engraving Processes

Upon calibration, the laser machine utilizes a design file to automate engraving by following the programmed paths. The engraving is completed with a laser beam, vaporizing, melting, or burning the material. The precision of modern laser machines can achieve delicate details as small as 0.001 inches, meaning even the most intricate designs have lasting, durable impressions.

- Residual Cleaning and Quality Inspection

Post-engraving, the material undergoes a cleaning step, where all the remaining residue, soot, dust, and fragments are removed. Specialized cleaning agents may be needed for more fragile materials like glass or acrylic. The final product undergoes inspection as a last step to evaluate quality and see if the design aligns with the original specifications document.

Recent Advancements in Laser Engraving

Technology developments and the use of lasers for etching patterns integrated into fibers have led to laser engraving being executed faster than before, at a level of detail and intricacy unheard of in the past. Metals, for example, can easily be imprinted on using fiber lasers, while wood and glass are better done with CO2 lasers. Furthermore, modern automation machinery equipped with software AI makes the engraving process streamlined and effortless. In modern-day systems, these engravings can achieve up to 200 inches per second, forever changing the outlook on laser etching from whether it should be done for bulk orders to a need for precision craft in larger orders.

How deep can laser engraving go?

When dealing with laser engraving, its depth is dependent on the material’s density, the power of the laser being used, and the number of times it rotates over said material. Based on what I have experienced, glass and plastics can be engraved to a depth of merely a few microns. However, if you’re dealing with metal, powerful lasers and multiple passes allow a depth of several millimeters.

Reference Sources

-

Laser Marking Methods1:

- This study systematizes various laser marking methods, focusing on their applications across different materials and shapes.

- It highlights the importance of selecting specific methods based on material type, marking type, and production needs.

- The research emphasizes the need for a database to optimize laser marking processes for diverse customer requirements.

-

Laser Marking of Metal Materials4:

- This paper explores the technical aspects of laser engraving and marking on metal and non-metal materials.

- It discusses the influence of laser parameters on the final appearance of engraved surfaces.

- The study includes visual and microscopic evaluations to understand how parameter changes affect material outcomes.

-

Innovative Laser Technology in Textile Industry5:

- This article examines laser marking and engraving in textiles, particularly for denim and leather.

- It highlights the environmental benefits of replacing conventional processes like sandblasting with laser technology.

- The study classifies laser marking types and discusses their advantages in textile applications.

- Top Co2 Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the main difference between laser engraving and laser etching?

A: The main difference between laser engraving and laser etching lies in the depth of the mark. Laser engraving is a process where the laser beam physically removes material to create a more profound mark. In contrast, laser etching typically creates a shallower mark and often results in a discoloration of the surface rather than material removal.

Q: How does a laser marker work?

A: A laser marker uses a focused beam of light to create marks on various materials by either removing material (as in engraving) or altering the surface (as in etching). The laser process can vary depending on the material being marked, such as metal or plastic.

Q: What materials can I use for laser etching and engraving?

A: You can use laser etching and engraving on various materials, including metals, plastics, glass, and wood. However, the effectiveness of the laser process can vary based on the material’s properties.

Q: What is the maximum engraving depth achievable with a fiber laser?

A: The maximum engraving depth achievable with a fiber laser depends on the engraved material and the settings used. For metals, deep laser engraving can reach depths of up to several millimeters, while for softer materials, the depth may be less.

Q: Can laser marking discolor the surface of the material?

A: Yes, laser marking can discolor the material’s surface, especially when using techniques like laser annealing or laser dark marking. This process alters the surface without removing material, creating a visually distinct mark.

Q: What are the differences between laser etching and engraving?

A: The differences between laser etching and engraving include the depth of the mark, the amount of material removed, and the final product’s appearance. Engraving results in a more profound and permanent mark, while etching creates a shallower mark that often relies on surface changes for visibility.

Q: Are there specific applications for laser engraving vs laser etching?

A: Specific applications often dictate the choice between laser engraving and laser etching. Laser engraving is commonly used for applications requiring durability and depth, such as on tools or jewelry. In contrast, laser etching is used for decorative purposes or when surface alteration is sufficient.

Q: What is laser ablation, and how does it relate to engraving and etching?

A: Laser ablation is a process where the laser beam physically removes material from the surface of an object. This technique is commonly used in laser engraving and etching, but the depth and effect on the material will vary depending on the intended outcome and settings used.

Q: What is laser coloration, and how does it differ from engraving and etching?

A: Laser coloration refers to the process of changing the color of a material’s surface without removing material, often used in conjunction with laser marking. Unlike engraving and etching, which involve material removal or alteration, laser coloration focuses on creating visual effects through heat or surface modification.