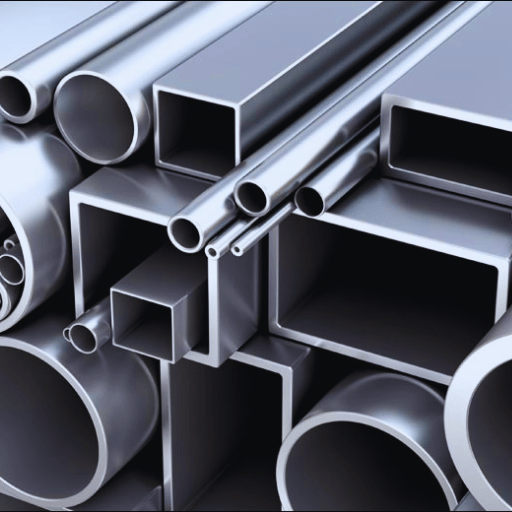

Steel is a must in modern engineering and construction and lends itself to myriad industrial applications. What exactly then makes steel so versatile and able to hold up under such loads? The density of steel is a crucial matter. A knowledge of the density of steel-almost always concerning mild and carbon steel-is indispensable when choosing the proper material for different projects, whether it be skyscrapers or automobile manufacture. This article goes into steel density, focusing on how it varies between mild and carbon steel, why it matters, and practical applications for steel density. Whether you are some veteran or have just stepped into the field of materials science, the article will harbor thought provoking ideas and depth into a topic, which is at the very foundation of a lot of innovations.

Introduction to the Density of Steel

This term refers to the fact that steel materials are made up of more or less massive atom configurations with their degree of density given in units of mass per unit volume such as g/cm^3 or kg/m^3. The density of steel generally ranges between 7.75 and 8.05 g/cm^3, depending on the composition of the steel. Mild steel possesses a lower density somewhere around the lower end of that range due to its lower carbon content; carbon steel, on the other hand, may have a slightly higher density because it contains more carbon. For practical installation, one is always interested in the density of steel to make weight and strength choices. For example, building and manufacturing are put on the scale of weight and strength.

Importance of Steel Density across Industries

Steel density in various industries acts directly on material selection, product design, and overall efficiency. In metric values, steel density is around 7850 kg/m^3, while variation may exist depending upon its alloy composition. For instance, stainless steels containing chromium and nickel could possess densities slightly different from 7.7 to 8.1 g/cm^3.

Recent information teaches us that density computations are crucial in the automotive and aerospace industries. The automotive industries work towards minimizing the weight of their vehicles without compromising safety; thus, they resort to the use of stronger and lighter steel grades to save the gasoline consumption. Similarly, in the aerospace industry, they focus on using alloys such as Maraging steel with a strong high strength-to-weight ratio so that it best serves and weighs less. It is conclusive from studies on the use of lightweight steel that it may undermine the carbon footprint of vehicles and airplanes by 20 percent, thereby stressing its environmental importance.

Moreover, in civil engineering, the measurement of density ensures structural stability for bridges, buildings, and pipelines. For instance, high-density steels are adopted in skyscrapers and critical infrastructure to guarantee resilience against heavy loads and environmental exertion. Usage of such information directs industry towards an effective balance among cost, sustainability, and performance.

An Overview of Mild Steel and Carbon Steel

Mild steel, also called low-carbon steel, contains carbon in amounts ranging from roughly 0.05% to 0.25%. Minimal percentages of carbon make it very ductile and weldable, so it finds use in automobile bodies, pipelines, and general construction. The malleability of mild steel combined with relatively low manufacturing costs has made it one of the predominantly used form of steel around the world today.

The other type is carbon steel, which covers a wide range of carbon content, generally from 0.05% to as high as 2.0%. Carbon steels generally fall under three categories depending on the percentage of carbon: low carbon steels (up to 0.3%), medium carbon steels (0.3%-0.6%), and high carbon steels (0.6%-2.0%). High carbon steel is used for making cutting tools and springs where hardness and strength are of essence, whereas medium-carbon steel is used in such automotive components which require strength and ductility in almost equal measure.

Global steel production exceeded 1,800 million tons in 2022, with mild steels and carbon steels accounting for the bulk of output, according to World Steel Association figures. Selection between mild and carbon steel usually rests on specific requirements of the application in question. For example, when extreme durability is needed for the application, the higher tensile strength of carbon steel becomes an advantage, whereas mild steel, with its lower amount of carbon, is good for welding and shaping in processes.

The effects of these modern developments have further enhanced the applicability of these materials by mechanically modifying their properties through heat treatment operations such as annealing and quenching for several industrial applications. On the other hand, continuous efforts toward the development of new alloying elements and manufacturing routes render both mild and carbon steels cheaper and environmentally benign, and these efforts in turn make the steel industry toward sustainable development, balancing performance-aided ecology.

Relevance of Density in Material Selection

Materials and their density are assigned a very wide application and influence how and whether a material performs well in a given environment. Density is defined as mass per unit volume; however, its measurement affects strength, weight, and structure efficiency. For example, aerospace technologies prefer materials that are low in density such as titanium and aluminum alloys for their high strength-to-weight ratio, thereby reducing fuel consumption while increasing performance. In contrast, construction prefers dense materials such as reinforced concrete or steels because they are able to resist great loads and provide stability.

Newer data suggest material engineering advancements are being made resolving the density challenge against other mechanical properties. For instance, carbon fiber-reinforced polymer (CFRP) has densities as low as 1.6 g/cm³, compared with steel which usually has a density of 7.85 g/cm³, and yet possess top-notch tensile strength. These innovations have fueled the development of lightweight and tough materials within the automotive sector all the way to renewable energies. Such a concentration on density optimization not only enhances performance but further nurtures sustainability by cutting energy consumption and raw material wastage through manufacturing.

Factors Affecting Steel Density

Steel density may vary due to several factors, such as temperature, composition, or processes. Some alloying elements like carbon, nickel, or chromium change a steel’s density by altering its inner structure. Temperature also comes into play; steel plumps up with an increase in temperature, thus slightly decreasing its density. Moreover, the changes in the processing methods, such as casting, rolling, or forging, can affect the microstructure that in turn alters steel density.

Composition Difference between Mild Steel and Carbon Steel

The classification of steel as mild or carbon steel largely depends on the amount of carbon treated as the chief parameter affecting their properties and density. Typically, mild steel contains less than 0.25 percent carbon, thus making it more ductile and highly workable when compared to higher grade steel. It stands at approximately 7.85 grams per cubic centimeter in density and almost all grades of steel carry the density of about 7.85 g/cm³ due to their iron basis in composition. Mild steel is commonly applied in construction, automotive parts, and general fabrication due to its welding ease and low costs.

Carbon steel includes carbon contents from 0.25% more in low-carbon steels to above 1% in high-carbon steels. That is, the greater the carbon content, the greater the strength and hardness, but the less ductile it becomes. Therefore, medium-carbon steel situated at or near 7.85 g/cm³ differs slightly because of carbon and other alloying elements, such as manganese or silicon. With their superior hardness and wear resistance, these steels are mostly used for making tools and cutting implements, though they probably have slightly less density because of finer microstructure.

Comparative studies from the most current materials science literature reveal that temperature further affects density. For example, heating tests above room temperature show slight expansion and consequent reduction in density for both mild and carbon steels in the heating cycle. Such adjustments could influence applications in sectors requiring high thermal tolerances, such as aerospace or power generation.

Key Data for Steel Compositions:

| Type of Steel | Carbon Content (%) | Typical Density (g/cm³) | Usage Examples |

|---|---|---|---|

| Mild Steel | < 0.25% | ~7.85 | Construction, automotive parts, general fabrication |

| Low Carbon Steel | 0.25% – 0.6% | ~7.85 | Structural components, pipelines |

| High Carbon Steel | 0.6% | ~7.80–7.85 | Tools, knives, railway tracks |

These figures and comparisons illustrate how composition and processing influence steel properties, helping industries choose the right material for their specific needs.

Temperature and Its Effect on Density

The density of steel, like any other material, changes with a variation in temperature. When steel is heated at higher temperatures, it tends to expand, and hence, its density slightly reduces. In contrast, when cooled at lower temperatures, contraction takes place inside the steel, and its density slightly increases. Such a relationship can usually be approximately estimated with the help of coefficient of thermal expansion of the material.

Mild steel has a coefficient of thermal expansion roughly 12 × 10⁻⁶ /°C, which means the dimensions of steel increase by almost 12 microns per meter for every degree Celsius increase in temperature. For example:

- At room temperature (20°C), mild steel has a density of nearly 7.85 g/cm³.

- At 500°C, the density decreases due to expansion, coming to approximately 7.72 g/cm³.

- At freezing, -50°C, contraction possibly increases density slightly to nearly 7.88 g/cm³.

Calculations such as these provide assistance to engineers who need to consider temperature-induced changes during construction, manufacturing, or aerospace projects where accurate measurements and material properties are paramount.

By the way, the mechanical properties of steel could also change significantly over temperature, meaning lubricity, yield stress, or even thermal conductivity. To counteract such changes, thermal processing and temperature-resistant alloys will often be applied in some instances of high performance.

Manufacturing Processes Impacting Steel Density

Steel density is, indeed, affected by the level of manufacturing processes involved in its production, and it is vital to comprehend these factors to optimize the steel for its industrial applications. Casting, forging, heat treatment, and cold working can introduce slight variations in density due to the different changes in microstructure and materials that could be present as impurities or porosity.

Heat treatment, such as days of annealing or quenching, will strongly affect the crystalline structure of steels and therefore have an impact on density and mechanical properties, with annealing relieving internal stresses and improving ductility whilst quenching hardens the steel but could marginally increase material porosity. According to recent research, high vacuum casting techniques can reduce gas inclusions in steel by 90%, thereby achieving improved consistency in density and hence in strength.

Similarly, cold working operations, such as cold rolling or cold drawing, compress the internal lattice structure, thereby increasing material density. With increased tensile strength, such steel is used for structural purposes. Cold rolling is said to be able to modulate the density of steel within a tiny margin but has tremendous effects on its load-bearing capacity.

In efforts to better control density variations, modern manufacturing will introduce alloying elements like nickel, chromium, and manganese that improve thermal resistance and strength and actually influence density. On the other hand, chromium may improve hardness and corrosion resistance sufficiently without imparting considerable changes to the gross density of steel, which stands somewhere around 7.85 g/cm³, depending on composition and processing.

By synergistically combining accurate manufacturing with materials science advances, industry is qualified to ensure that steel density and related properties meet stringent demands imposed on modern-day applications.

Impact of Steel Density on Engineering Applications

Since steel density can affect the engineering applications by determining strength-to-weight ratio, load carriage, and the stability of the whole structure, it finds relevance in engineering applications. Generally, heavier steels resist wear from deformation processes better; hence heavy steels are conventionally used where heavy markets are under construction or heavy machinery. Light steels are preferred in weight-saving applications, usually within industries of automotive and aerospace where efficiency and performance are paramount.

Impact of Steel Density on Structural Integrity

With density, steel is a property influencing certain aspects of strength, stability, and appropriateness of use for a given application. Higher-density steel affords greater strength and sturdiness, which makes it perfect for heavier infrastructure works such as bridges and skyscrapers. Whereas low-density steels find applications wherein light materials are a criterion, like automobile or aerospace designs. Usage of the right density ensures best usefulness and reliability in the context.

Density Considerations in Construction Projects

Both the type of steel considered for a structure and the characteristics afforded by the steel itself must weigh in on the consideration of density of steel in construction. High-density steels in the range of about 7,750 to 8,050 kg/m³ are generally used for skyscrapers, bridges, and other such infrastructural works because of their load-bearing capabilities and resistance to weather conditions. Lower-density steels or lightweight steel alloys, which often have aluminum in their composition, go a long way in helping reduce the weight of a structure while maintaining its structural integrity, therefore becoming the best choice for modular constructions or environmentally friendly residential designs.

Recent studies have shown that using high strength dense steels in the design of skyscrapers will increase load capacity by about 20% compared with the use of ordinary grades of structural steels. In a similar vein, lightweight steel in prefabricated construction has managed to cut down on construction periods and materials transport costs by 25% or more. Such statistics are witnesses that the proper selection of materials produces efficient, cost-effective, and sustainable models for contemporary architecture.

Implications for Manufacturing and Fabrication

Materials selected determine the manufacturing efficiency and costs. Use of modern steel grades and lightweight materials during fabrication would lead to an ease in manufacture; reduce wastage and transportation cost. They would also allow for faster assembly, further shortening project timelines without compromising structural integrity. Thus, employing such innovations shall be of great importance in the realization of sustainable and cost-efficient manufacturing solutions without any compromise in quality.

Recent Studies and Data on Steel Density

Steel density ranges between 7.75 and 8.05 grams per cubic centimeter (g/cm^3), depending on the alloy composition. Therefore, according to recent studies, steel density ensures steels are strong and durable yet versatile enough for all kinds of applications.

Latest Research Findings on Carbon Steel Density

Carbon steel, readily used by construction and manufacturing domains, generally has its density between 7.85 and 7.88 grams per cubic centimeter (g/cm^3) depending on its carbon content and other specifics embodied in its composition. With reference to recent studies, lower-carbon steels tend to have slightly lesser densities because of greater atomic packing within high-carbon steels. Thus, any reports indicate mild steel, which usually contains about 0.05-0.25% carbon, has density near 7.85 g/cm^3, while high-carbon steel, with approximately 0.6-2% carbon, trends somewhat higher because of its structural compactness.

Its density maintains the structural integrity and allows for fine tuning on the engineering of components such as automotive parts, building frameworks, and machine tools. Most importantly, it is those advances in alloying and heat-treatment processes allowing carbon steel properties of interest in applications where materials need to be light yet strong.

Comparative Analysis of Mild and Carbon Steel Densities

Mild steel, also known as low-carbon steel, typically has a carbon content of approximately 0.05 to 0.25%. The term carbon steel, however, covers a wider range of 0.25 to 2.1%. Differences in these ranges comprise one of the major factors affecting their density and mechanical properties. Mild steel has a density of about 7.85 g/cm³, while carbon steel, because of its similar basic composition, also varies around 7.85 g/cm³.

The density of either medium or high-carbon steel varies from medium to high, with medium being around 7.85 g/cm³ and high being slightly greater. This slight variation is due to higher carbon content resulting in higher density for high-carbon steels and vice versa. The normal variations in this range do not amount to significant density differences, but the change is enough in other properties such as hardness, tensile strength, etc. Thus, the carbon steel due to high carbon content becomes inferior in properties such as hardness and tensile strength. It is also used in areas where the steel must take load however tools and cutting implements are amongst the applications. Mild steel with less carbon content is more ductile and easier to weld-highly suitable for use in construction and automotive bodies.

Continuing advances in material science now provide the means for precise alteration of the steel compositions and consequently vary their densities and properties according to requirements. These include, in particular, high strength and low alloy (HSLA) steels. Steels that maintain the lowest densities possible while accepting applications that require an intermediate strength level are among the most important for these industries in aerospace and construction. Recapping briefly the latest advanced developments, the overall trend is very much towards optimizing mixtures of density and mechanical performance in the various grades of steel. For instance, intensive development work is under way, through heat treatment and through proper selection of alloying elements such as manganese, chromium, or vanadium, to be able to “fine-tune” the density of steel, which opens new areas of application for both mild and carbon steel.

Trends in Steel Density Data Over Time

Steel density is a vital value influencing steel performance upon various applications. Measured typically in gram per cubic centimeter (g/cm^3), steel density varies with alloy composition. For example, mild steel is about 7.85 g/cm^3 in density, whereas stainless steel, depending on chromium and nickel content, stands anywhere between 7.70 and 8.00 g/cm^3.

Given the recent data, one can discern an upsurge in trends toward the development of high-strength, low-density steel solutions. Having a great emphasis on density, its role on material performance is exceedingly studied and utilized in the formation of advanced high-strength steels (AHSS) that find wide applications in the automobile industry. It remains the considerable balance of density with strength that the AHSS rating about 7.8 g/cm^3 provides such a high tensile strength of more than 1000-1500 MPa, on the other hand, enables the design of light-weight components without compromising on safety.

Such comparison across time never fails to show how steel composition has been changed to accommodate for modern needs of the industry. Modern-day steel used in construction would cater for very good durability and light weight, whereas steel used in early 20th-century-based constructions would guarantee durability far and away above anything else. The lowest-density steel that is high-performing is realized through the melding of the alloying elements manganese and titanium of the alloyed steel types at densities of approximately 7.6 to 7.9 g/cm³ depending on the actual application.

Computational modeling and machine learning methods are enabling more and more applications of low-density, high-performance steel. The analysis of global steel production data shows a steady increase in lightweight alloys from year to year as a consequence of sustainability efforts and technological evolution.

Practical Applications and Tips for Professionals

Low-density, high-performance steel professionals should first pay attention to understanding the various material properties and uses. Major fields of use include automotive industry corporations where they reduce vehicle weight to improve fuel efficiency, and aerospace industries where strength-to-weight ratios are favorable. In collaborative partnership with materials scientists, however, it is prudent to have customer alloy compositions meet the precise needs of the project and apply computational modelling to predict performance. Granted, sustainability and cost-effectiveness are a hand in hand must when selecting these materials to meet all the similar trends of the industry and the environment.

Steel Selection Based on Density

I consider the specific application and its requirements such as strength, durability, weight-related constraints, and like when selecting steel based on density. I look into the different grades of steel along with their density properties to see which ones form a perfect union of performance and efficiency. Having looked through their data sheets, I also consult with experts to ensure that the steel being chosen satisfies both functional needs and the aim of the projects, including cost and sustainability.

Work Practices for Mild and Carbon Steel

Follow this best practice while working with mild and carbon steel:

- Cutting and Welding: Make use of the appropriate tools to cut or weld and take care that your working technique does not cause warping or weakening of the steel during fabrication. Weld properly according to the welding procedures relevant to the type and thickness of steel being worked on.

- Surface Preparation: Ensure the steel surface is clean before coating or welding. The presence of contaminants-having rust, grease, or oils-may compromise the steel surface integrity and performance.

- Corrosion Protection: Depending on whether it is in use outdoors or any other place prone to moisture or aggressive atmosphere, the steel surface should be treated by applying anticorrosion mediums such as paints, galvanizing, or another protective coating.

- Handling and Storage: Keep the steel safe in a dry place. During handling, cover the steel with something safe enough from rust and damage.

Following these procedures helps maintain the quality and longevity of the material, safe, and efficient to use.

Future Considerations in Steel Density

New technological and material developments keep changing the ways steel is employed in different industries. According to recent trends, high-strength, low-density steel alloys are trending for applications in the automotive, aerospace, and construction sectors. These novel alloys intend to cut down the overall weight of the structure while holding their strength and durability or even enhancing the two attributes with examples of the new grades of advanced high-strength steel (AHSS) that currently promise reducing vehicle weight by 25% against the conventional steel, thereby increasing fuel efficiency and emission reduction.

This has also pushed the sustainability agenda, and hence the production of recycled steel is under research. Statistics show that approximately 86% of steel is recycled worldwide, with the current steelmaking processes putting on emphasis on energy consumption reduction and carbon emissions. Using electric arc furnaces (EAF), for instance, which mainly uses recycled scrap steel can lead to a decrease in CO2 emissions by 60 percent compared with traditional blast furnace routes.

Future innovations are likely to include the development of ultralow-density steel composites with nanostructured properties, further widening steel’s frontiers into industries requiring lightweight yet strong materials. Keeping abreast with such developments guarantees better material selections and sustainability practices in industrial applications.

Reference sources

Thermal Changes in the Mass, Size and Density of Steel Fiber Concrete after Calefaction

- Authors: D. Zaitsev

- Publication Date: May 25, 2021

- Summary: This study investigates the effects of high temperatures on the mass, size, and density of steel fiber concrete. The research indicates that exposure to heat results in a reduction in linear size, mass, and density of the concrete. The study emphasizes the need for further research to understand the impact of different types and quantities of steel fibers on these changes.

- Methodology: Experimental study involving the exposure of steel fiber concrete to temperatures ranging from 20°C to 1100°C, measuring changes in physical properties(Zaitsev, 2021, pp. 434–439).

2. Combined effect of powder properties and process parameters on the density of 316L stainless steel obtained by laser powder bed fusion

- Authors: S. Ziri et al.

- Publication Date: April 6, 2022

- Summary: This paper explores how various powder properties and processing parameters affect the density of 316L stainless steel produced through laser powder bed fusion. The findings suggest that optimizing these parameters can significantly enhance the density of the final product.

- Methodology: The study involved a systematic review of existing literature and experimental measurements of density using different processing parameters(Ziri et al., 2022, pp. 6187–6204).

3. Influence of processing parameters on the density of 316L stainless steel parts manufactured through laser powder bed fusion

- Authors: João P. M. Pragana et al.

- Publication Date: April 13, 2020

- Summary: This research focuses on the impact of various processing parameters on the density of 316L stainless steel parts produced via laser powder bed fusion. The study concludes that specific parameters can lead to densities exceeding 99%, which is crucial for the performance of the manufactured parts.

- Methodology: The authors conducted experiments to measure density and analyzed the effects of parameters such as vector size and gas atmosphere on the density of the produced parts(Pragana et al., 2020, pp. 1246–1257).

Frequently Asked Questions (FAQs)

What is the density of steel, and why is it important?

Density is a mechanical property that defines nature, characteristics, and uses of materials. Steel generally has a density of 490 lb/cu. ft. though this value varies with the specific alloy and carbon content in the material. This density value is of particular interest to engineers and manufacturers, who need to specify the weight that will adjoin structures such as steel beams and columns into intense calculations.

How can I calculate the density of steel?

You calculate the density of steel by calculating the density as mass divided by volume. Cluster the mass of the steel in pounds, cluster the volume in cubic feet, and mass over volume will give you pounds per cubic foot or, simply, the density of that steel.

What is the very difference between the density of the tool steel and the carbon steel?

Density values for carbon steels and tool steels vary because of their compositions: A plain carbon steel is approximately 490 lb/cu. ft., whereas that of tool steel could be slightly different, as tool steels contain elements added to obtain hardness. This fact, density of steel, thus becomes an important consideration in selecting a steel for a particular application.

How does carbon content influence the density of steel?

The carbon content of steel directly influences its density. High carbon content increases density as it accounts for the weight that the alloying carbide of the steel carries. This becomes very important when looking at the mechanical properties of steel products; a high density means high strength and better performance in a given context.

Are the density values the same for all grades of steel?

Different grades of steel will vary in their density. High-speed steel, for instance, may have another density compared to structural steel used for building construction. Depending on which particular alloying elements are used and to what degree, the density may vary; hence, it is critical to know the density of a steel alloy when selecting the material for applications.

What are common units used for defining steel’s density?

The steel density is expressed by common weight unit per common volume unit, like pounds-inches-cubed or pounds-feet-cubed. Most engineering works use pounds per cubic foot. This number is usually around 490 pounds per cubic foot. These units demonstrate the weight of the substance and make it easy to weigh the steel load.

How does understanding steel’s density help a construction project?

A construction project using the knowledge of the density of steel ensures sufficiency of materials to resist the loads imposed upon them. The knowledge of density allows for the weight of steel beams and columns to be worked out accurately, resulting in a very safe and economical design. This, in turn, assures the load-bearing capacity of the entire building.

Can steel change its density with time?

Usually, steel does not change, if unaltered, with density over the lapse of time; corrosion or addition of some materials, however, may change the effective density. Steel components may sometimes be coated or contaminated, thus creating variation in perceived density. It is in the interest of quality performance that maintenance and inspection become the watchwords for steel products in construction.