The comprehension of aluminum’s density is not merely a material science lesson; it lets to realize its implication in various industries starting from aerospace and ending in construction. This blog post will examine the peculiarities of aluminum density, the reasons for its importance in different applications, and the way this property aids in its efficiency and adaptability. It doesn’t matter if you are an engineer, a student or just someone wondering about the science of materials, this article is going to give you a deep understanding of the fascinating world of aluminum.

Introduction to Aluminum Density

Aluminum’s Overview as a Multi-Purpose Material

Aluminum is considered one of the most versatile materials man has ever come up with due mainly to its combination of properties: it is very light yet very strong. These qualities are the reason for its use in so many different sectors such as, for instance, the aerospace industry, where it is often used for making aircraft parts and fuselages, and the packaging industry, where it is used to make containers and foils.

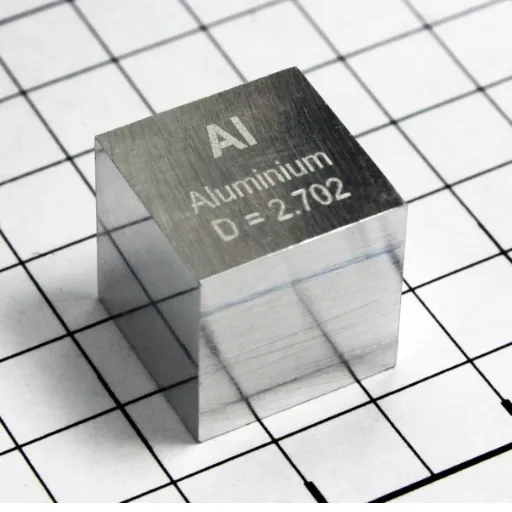

Key Fact: Aluminum has a density of 2.7 g/cm³, which means that its weight is only one-third of that of steel and thus allows for energy saving in both manufacturing and design.

Another advantage of this property of aluminum is that it will be able to easily take the place of other metals in places with a lot of water or corrosive chemicals since they will not be able to survive in such places. Aluminum recycling is very high too; almost 75% of the entire aluminum produced is still in its original form. These to properties, along with the good thermal and electricity conductivity, come together to support the claim that aluminum remains one of the most versatile and, at the same time, essential materials for modern industries.

Aluminum Density’s Crucial Role in Different Industries

Aluminum density is a decisive factor that makes this material universal; it is the perfect balance of strength and lightness. With a density of around 2.7 g/cm³, it is only one-third of the steel’s weight; therefore, it is the first option for the industries like aerospace, automotive and construction.

In aerospace for example, the engineers make use of aluminum’s low weight in order to enhance fuel efficiency and give better performance by cutting down the aircraft’s total weight without impairing the structure’s strength. The same situation is with the automotive industry where the manufacturers use aluminum in making the cars environment friendly and fuel-efficient thereby satisfying the market demand for green and sustainable transportation.

Also, apart from the hefty industries like packaging, where the lightweight material is a must for economic and protection reasons, aluminum’s density speeds up the production rate. Thus, this astonishing mix of attributes guarantees that aluminum will still be the primary material for both the future and the present to support the development of new technologies and industry.

The Case for Aluminum’s Lightweight Nature as a Game-Changer

Aluminum’s lightweight nature gives it great flexibility and is a game-changer. Especially in transportation, construction and packaging, the adaptable nature of aluminum is changing the game. The latest data, however, indicate that the terms “lightweight materials for EVs” and “sustainable metal solutions” have become much more popular than before, which means that not only has the energy efficiency and sustainability issue been raised but also that it is now being widely accepted.

Impact on Transportation & Construction:

- Reducing the weight of a vehicle brings about better fuel economy; this is particularly true for electric vehicles where battery range is the most critical factor.

- The conversely light transportation of building materials and packed goods is the result of the light weight of the aluminum that is, therefore, the reason for companies optimizing their logistics.

- The transition to greener practices in manufacturing has been the other side of the coin as the manufacturers have been using aluminum that has the least impact on our planet and is still performing well.

In fact, it is already considered to be one of the main materials used in the development of new, more eco-friendly technologies.

What is the Density of Aluminum?

Definition and Standard Value of Aluminum Density

The term density of a substance is normally understood to be its mass divided by the volume it occupies, the most common units for this measure being grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). Among the metals, aluminum which is the second most marketable after copper is generally considered to have a standard density of about 2.7 g/cm³ or 2,700 kg/m³.

Important Note: However, depending on the alloy various types of aluminum might exhibit slight variations in density, pure aluminum beyond question is found to be always at this density. One such factor that contributes to the metal’s wide use is its relatively low density especially in the case of applications where the determinants are weight reduction like the aerospace, automotive, and construction sectors that require materials with high strength to weight ratio.

Comparison of Aluminum Density with Other Metals

When one puts aluminum’s density of 2.7 g/cm³ alongside other commonly used metals, it is easy to understand why it is not only a choice but the number one choice for lightweight applications.

| Metal | Density (g/cm³) | Comparison to Aluminum |

|---|---|---|

| Aluminum | 2.7 | Baseline |

| Steel | 7.75 – 8.05 | Almost 3x denser than aluminum |

| Copper | 8.96 | By far higher than aluminum |

| Titanium | 4.5 | Denser than aluminum but less than steel |

The redoubtable lightweight characteristics of aluminum, together with its other properties, such as resistance to corrosion and ductility, position it as a material world-wide for industries that consider efficiency and weight as the most important factors. This characteristic is shown to be responsible for its continuing usage in the manufacturing of electric cars where weight is the most common factor affecting the energy efficiency and the range of the vehicle. Also, it is still the case that aluminum is the most popular choice in aerospace and consumer electronics because of its perfect compromise between strength and density.

Impact of Density on Material Properties

Density is one of the most influential factors when it comes to the performance and applications of a material in different fields. Low-density materials, among them aluminum, provide the advantage of weight reduction without significant strength compromise which makes them suitable for electric vehicles, aircraft and other related applications.

Recent reports have indicated that the industry is increasingly depending on low-density materials to achieve higher energy efficiency especially in the transportation sector as lightweight equals less fuel consumption or more battery life. On the other hand, high-density materials, such as steel, correspondingly are preferred in those fields that demand durability and heavy load resistance, for example, construction and infrastructure. Thus, the interplay of density and performance always results in the necessity of progressively evolving materials with very specific attributes dictated by their intended usage.

Why is Aluminum’s Density Important?

High Strength-to-Weight Ratio and Its Importance

Aluminum’s high strength-to-weight ratio has made it an important and necessary metal for various industries. Its density is around 2.7 g/cm³, so it is much lighter than steel and other similar metals but still has very good strength. This property is a major advantage in the transport industry like aviation and automotive where reducing weight means less fuel needed, lower emissions and thus better performance.

Besides, the lightweight aluminum still delivers on its durability making it a prime material for load-bearing structures, portable devices, and even sports equipment that requires top performance. The engineers and designers are able to play with both the strength and weight of the material to come up with a perfect mix of performance and integrity, the latter still being one of the main factors to its worldwide use.

Density’s Contribution to Material Costs Reduction

Materials with lower density such as aluminum have a very important part in cutting down the material costs as they consume less raw material by weight to produce the same performance as the denser counterparts. This in turn brings about the same amount of savings in transportation, processing, and manufacturing costs as the handling of lighter materials implies.

Industry Example:

The aerospace industry and the automotive sector are both able to benefit at the same time from having lighter structures which lead to savings in fuel consumption and from reduced part production costs. Recent search data indicates that companies are becoming more and more conscious of the importance of durable materials that are lightweight, thus, the cost of resources is being balanced with the longevity of the products, which is a clear indication of a shift in the direction of resource optimization and e-co-friendly practices.

Manufacturers using low-density materials can come up with creative ways of producing goods that are cheaper and at the same time environmentally friendly.

Lightweight Aluminum’s Environmental Benefits

Lightweight aluminum is not only nice to work with but it is also nice to the environment, especially if you consider the current trends from the search engine. One of the greatest benefits is aluminum’s high recyclability, to be one of the most efficiently recycled materials worldwide. Thus, this property leads to the demand for a reduced amount of virgin material coming from mining which literally co-relates to lower energy and less greenhouse gas emissions being generated.

Furthermore, the search reveals that both industries and consumers are increasingly in search of materials that the carbon footprints are low both in manufacturing and usage.

Environmental Advantages:

- Reduced Energy Requirement: One more benefit is that of reduced electrical energy requirement in production, which is again passively supported via the use of aluminum in transportation.

- Lower Emissions: It is possible to build lighter vehicles with aluminum, hence, letting them consume less fuel and emitting less, too, while the whole operational lifetime of cars, airplanes, and other transportation modes goes on.

- Sustainability Focus: Recent search data has shown this quality to be in line with the growing demand for eco-friendly transport solutions.

Lightweight aluminum claims these merits thereby doing its part in meeting the environmental challenges and at the same time satisfying a more sustainability-minded public.

Applications of Aluminum Based on Its Density

Construction: Structures That Are Lightweight but Tough

The ultimate strength of aluminum plus its extremely lightweight nature has made the metal so popular for modern construction. Lately, energy-efficient and sustainable materials for buildings are the significant topics of searches, according to data trends from search engine, which indicates a huge rise in the number of inquiries.

Aluminum resolves such issues by making it possible to design long-lasting structures that people do not need a lot of resources for carrying and putting up, thus causing an overall cut in emissions. The metal’s property of being resistant to corrosion also cuts down the costs of maintenance and increases the number of years buildings stay usable. It also concurs with the growing demand for both economic and environmental sustainability in construction. This emphasizes the central position that aluminum assumes as a remedy for the challenges that are facing the contemporary constructions industry.

Transportation: The Aerospace and Automotive Industries

Aluminum has offered a strong yet light alternative to the traditional materials and thus the aeronautics and car industries have been using it. The material’s properties enable its high strength-to-weight ratio which makes it possible to carry out manufacturing of airplanes and cars, thus lightening the overall weight and saving up on fuel.

Statistical Insight: Recently, data have shown that aluminum usage in the automotive sector has sharply increased and that this has been one of the reasons for a 30 percent vehicle weight reduction which, turned out to be of an enhancing nature for performance and emission lowering.

All and all, the aluminum alloys are basic to producing light but strong components that are able to endure very extreme conditions at high altitudes in the aerospace industry. These breakthroughs point out that aluminum is part of the solution when it comes to modern-day transport issues like sustainability and energy efficiency together with the rising demand for less polluted and more nature-friendly traveling means.

Manufacturing and Consumer Goods

The application of aluminum is not just limited to transportation; rather its versatility has extended to manufacturing and even consumer goods production. The non-combustible, light nature of aluminum together with its recyclability has made it the most suitable material for a variety of applications such as packaging, household appliances, and electronics.

For instance, beverage cans are usually made up of aluminum as its unique property allows the contents to be sealed effectively and also the metal can be recycled infinitely without any degradation in the quality. Likewise, modern gadgets like smartphones and laptops often incorporate aluminum into their designs for the sake of durability and sleek aesthetics.

Current trend data from search engine suggests the consumer demand for sustainable and eco-friendly products is on the rise. Aluminum is one of the most recyclable materials that suit this demand and thus contributes to the circular economy. The industries are sending the message of going green by using recycled aluminum for new products thus passing the practical aspect along with a lesser impact on the environment. Thus, the trend confirms that aluminum has a role to play in the future of sustainable manufacturing and consumer goods.

Aluminum Alloys and Density Variations

Overview of Common Aluminum Alloys

Two main types of aluminum alloys are classified: wrought and casting alloys. Each type is further divided into families depending on the features and use they are meant for. Some of the most popular aluminum alloys are the 1000, 3000, 5000, 6000, and 7000 series.

1000 Series

These alloys consist of pure aluminum and have been noted for their excellent resistance to corrosion and high heat conduction properties. Due to these qualities, they are mostly used in the chemical industry and electric power sectors.

3000 Series

Manganese is added in the metal composition, which makes these alloys the best at rusting resistance among ally materials with a little bit of weight. Hence their applications are in making roofs, walls of buildings, and cans for soft drinks.

5000 Series

The main alloying element in this series is magnesium, which gives the metal excellent corrosion resistance in marine environments, hence it is used for shipbuilding and offshore structures.

6000 Series

This series, which is composed of magnesium and silicon, is very flexible, providing medium tension as well as easy prevention against rust and fine cutting. It finds a place in the automobile, construction, and space industry side-wise.

7000 Series

Their strength ranking and high zinc content are the factors that lead to the prominence of these zinc-containing metals in the aerospace and military industries, where performance and durability are the most important considerations.

A broad selection of aluminum alloys allows the producers to create the material according to the specific requirements of the customer, advantages from the different properties like resistances to heat, corrosion, and weight, etc. The fertile ground for variety alongside the recycling aspect of aluminum strengthens its role in the present-day industry and technology.

The Density Changes Induced by Alloying Elements

Densities of materials greatly affected by the presence of alloying elements due to the changes in the atomic structure and distribution of the base metal. By way of example, tungsten or molybdenum which are high mass elements that when joined with the base metal, the overall density of the alloy gets higher. On the other hand, light elements like aluminum, magnesium, or lithium reduce density and hence their contribution to lightweight alloys, which are perfect for the aerospace and automotive industries.

It is found that the density of alloying elements is the only thing that is changed and the material properties such as strength, corrosion resistance, and thermal conductivity are also affected. Such differences make it possible to adjust the alloys according to the engineering demands, i.e., density and functionality can be balanced in accordance with the application. The improvement of the design of the alloy has allowed the industry to come up with new materials that not only meet the modern performance but also have the advantage of being light and cost-effective.

Specific Alloys and Their Applications – Examples

| Alloy Type | Composition | Key Properties | Common Applications |

|---|---|---|---|

| Stainless Steel | Iron + Chromium + Nickel | Excellent corrosion resistance, long-lasting, rust-free | Kitchen utensils, construction materials, medical instruments |

| Aluminum Alloys | Aluminum + Copper/Magnesium/Silicon/Zinc | Strong yet lightweight | Aerospace, automotive sectors where weight reduction is necessary |

| Titanium Alloys | Titanium-based | High strength-to-weight ratio, excellent corrosion resistance, biocompatible | Aerospace, medical implants, sports equipment, surgical instruments, prosthetics |

| Brass | Copper + Zinc | Highly flexible, attractive look, good machinability, corrosion-resistant | Decorative items, musical instruments, plumbing fixtures |

| Nickel-Based Superalloys | Nickel + Cobalt/Chromium/Molybdenum | Excellent thermal strength, non-oxidizing at high temperatures | Jet engines, power plants, gas turbines |

The above cases serve as examples as to how the strategic application of alloy design has been done in different industries, where the properties of materials have been adjusted to certain functional and performance requirements. Materiel science advancements will lead to the continuous expansion of specialized alloys usage which in turn will invigorate the innovation across different domains.

Frequently Asked Questions (FAQ)

What is the density of aluminum compared to other metals?

Aluminum has a density of about 2.7 grams per cubic centimeter, so it is considered a light metal which is much lighter than iron, for example, with a density of around 7.87 grams per cubic centimeter. The aluminum density being low-it is less than that of iron for example- leads thus to aluminum being a preferred metal for different applications like lightening the heavy metal structure and the aluminum industry. The specific gravity of aluminum, which is its density compared with that of a reference substance, is also quite low thus contributing to its lightness. This rare feature promotes the use of aluminum in various industries such as kitchenware and aerospace, where weight saving is critical, and the need for the lifting of weight is not an hassle.

How does temperature affect the density of aluminum?

Aluminum’s density is versatile depending on the temperature changes. The heating of aluminum causes a series of events to happen, which in the end lowers the density of the metal hence giving it lightness. This aspect becomes more and more significant when it comes to establishing and maintaining high-quality standards such as those needed in the case of aluminum parts manufacturing for the aviation and automotive industries where precision is critical. The room temperature mass density of aluminum is a perfect example, but one has to consult either the technical journals or the Aluminum Association to get the values for the different temperatures. The temperature’s effect on the density variation of aluminum is central to the metal’s performance under different environmental conditions.

What is the specific gravity of pure aluminum?

The specific gravity of pure aluminum is around 2.7 which implies that the material’s density is that of water. The measurement denotes that aluminum is lighter than many other metallic substances and a main reason for the metal being widely used in light construction and manufacturing. The relative density of aluminum allows it to be applied in many sectors such as the production of lightweight frames for vehicles and domestic goods. Moreover, the specific gravity of aluminum being relatively low not only makes the metal a good heat and electricity conductor but also widens its application area in the industrial sector.

How can one detect the density of aluminum?

The detection of aluminum density is performed with the help of various techniques including mass and volume measurement by the balance and the graduated cylinder respectively. Whereby, the density of aluminum can be easily obtained by mass divided by volume. This method, though simple, is widely used in the aluminum industry to control the quality of the ready products. Sophisticated techniques such as ultrasonic testing have also been reported to be used for measuring the density of aluminum found in sheets and extrusions, for example. It is always worth the effort to take precise measurements which eventually saves the quality of aluminum products, especially when it comes to high-end applications.

Why is aluminum considered a commercially valuable metal?

Aluminum is considered a metal of great commercial value because of its properties that are unique among other metals, they include, low density, high corrosion resistance, and high strength-to-weight ratio. Landscape, performance and durability are among the main concerns that aluminum has been versatile to meet by the properties of aluminum which however is still less expensive than heavier metals. These properties are what keep the aluminum industry alive, they range from construction to consumer goods that use aluminum in one way or the other. The recycling of aluminum is another aspect that boosts its value as it is able to become a part of the sustainable practices of various sectors. Its wide applicability is the reason why it is becoming the major component in many production processes from the making of cooking utensils to the very advanced aerospace components.

Reference Sources

MIT – Aluminum Properties

This page provides detailed material properties of aluminum, including its density.

Princeton University – Aluminum Overview

This resource includes aluminum’s density and other physical properties.

Florida State College – Density

A lecture slide discussing density, including aluminum.