Copper, being such an adaptable and highly conductive metal, finds its use in the various branches of industries, ranging from electronics to architecture. Laser cutting is truly considered the best for the precision-oriented cutting of copper. The blog must explore the very soul of cutting copper with a laser technology and thereby wash light on why laser cutting is utilized when it comes to intricate and demanding designs. This will be an arsenal that equips you with the knowledge to take on the craft, from recognizing the hindrance copper poses owing to its reflectivity to countering said hindrance with modern laser solutions. The long walk-through will get down to nitty-gritty techniques and tools that make laser-cut copper a truly modernistic incarnation for an expert or just a curious onlooker.

Introduction to Copper Laser Cutting

Brief of Laser Cutting Technology

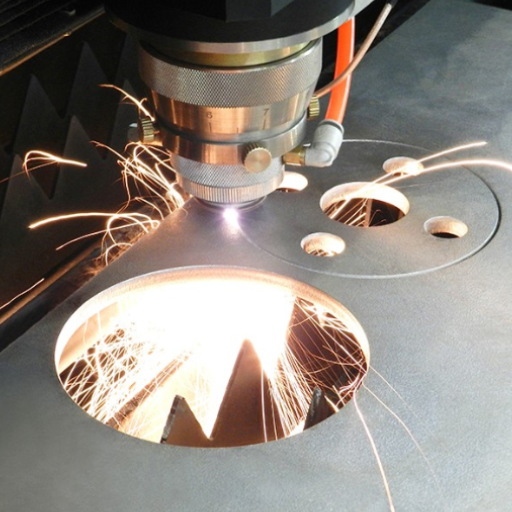

Laser cutting is a highly sophisticated, precise, and versatile manufacturing process that uses a thin collimated beam of light for cutting, engraving, or other manipulations on a wide variety of materials. The laser cutting concept involves utilizing the incapability of the laser beam and the material to convert it along the colored path by either melting, burning, or vaporizing the material.

Technology Evolution: The most modern laser systems use CO2, fiber, and Nd:YAG. But fiber laser technology has climbed the ladder of insertion rather rapidly due to its higher efficiencies, longer lifetime, and ability to work with some tricky reflective materials such as copper. Fiber lasers have a wavelength that is roughly ten times smaller than that of CO2 lasers and thus are better absorbed by metals, enabling them to perform finer and cleaner cuts on intricate design work.

The laser-cutting industry worldwide is experiencing rapid growth and is expected to continue doing so, with a CAGR of more than 9% between 2021 and 2028. This boom has been fostered by the accelerated adoption of the laser technology in the automotive, aerospace, electronic, and jewelry industries. Also, the laser cutting process is relatively cheaper because it entails lesser material wastage and process time than conventional techniques.

The integration of software and improvements in automation, such as CAD/CAM compatibility, also enhanced the precision and efficiency of laser cutters. Real-time monitoring and adaptive beam technologies enabled manufacturers to achieve precision cutting even with the most challenging materials, such as copper. The progression guarantees that the laser-cutting process remains one of the paramount manufacturing processes employed in modern industries and by creative enterprises.

Difficulties of Copper Cutting

Stripe copper presents certain cutting difficulties due to its peculiar properties. Copper has extremely high reflectivity, thereby reflecting away most of the laser energy used on it. This reflectivity decreases the efficiency of the laser and poses danger to the laser. The metal also has a very high thermal conductivity, which means that heat introduced by the laser into copper is quickly absorbed and thus it becomes difficult to get clean and precise cuts. Very special means, assist gases, and equipment are required to do laser processing on copper.

Advanced solutions for copper cutting challenges:

- Last-generation laser technologies: Fiber laser and high-power direct diode laser systems

- Wavelength optimization: Fiber lasers work at wavelengths better absorbed by copper

- Use of assist gas: Oxygen or nitrogen to improve cutting speed and edge quality

- Adaptive systems: Real-time monitoring with adaptive laser beam adjustments

In order to surmount such problems, much newer late-generation lasers such as fiber laser and high-power direct diode laser have been introduced. Fiber laser operates at an emission wavelength that copper absorbs better; hence it improves cutting efficiency and quality. In a study by TRUMPF, the leading laser manufacturer and marketing company, it was proved that copper sheets measuring up to 1 inch thick could be cut very accurately by fiber lasers under present test conditions. Furthermore, the use of assist gases like oxygen or nitrogen can increase the cutting speed and edge quality while also reducing oxidation.

Problems continue for thicker copper and in applications where surface finish is of prime concern. To address such problems, a combination of adaptive laser beam adjustments and real-time monitoring systems is implemented. These technologies act as a further impetus pushing the achievement envelope higher and higher, and rendering laser cutting a near-job in copper processing for electronics, automotive, and renewable energy industries.

Importance Across Industries

Laser cutting applications are distributed across various industries, thus conducting the production techniques of various industries with precise, fast, and flexible in-process copper cutting. Giving further evidence to the need for maximum precision cutting in the growing industries was the latest report, which states the global laser cutting machine market valued at around USD 4.9 billion in 2021 and were to grow from 2022-2030 at a CAGR of 9.5%.

| Industry | Primary Applications | Key Benefits | Market Impact |

|---|---|---|---|

| Electronics | Microcircuits, connectors, heat dissipation components, PCBs | Precision cutting of thin copper sheets | Enables intricate designs for smartphones, laptops, wearables |

| Automotive | Battery terminals, wiring systems, electric motor components | Lightweight, energy-efficient designs | Critical for EV growth (6.6M sales in 2021) |

| Renewable Energy | Solar and wind power components | Minimal material wastage, maximum performance | Supporting global climate targets by 2050 |

This is how laser cutting technologies benefit the electronics industry: witnessing a colossal rise in host devices, such as smartphones, laptops, and wearable gadgets, requires intricately designed copper components for heat dissipation and electrical conductivity. These recent inventions in laser technology now let copper sheets of infinitesimal thickness be cut for microcircuits and connectors.

Laser cutting also sets the stage for the automotive sector to meet the requirements of lightweight and energy-efficient design. Foremostly copper is in demand for electric and hybrid vehicles in battery terminals, wiring systems, and electric motor components. Also, whilst electric vehicle sales have doubled in the year 2021, up to 6.6 million, there finds laser cutting as a scalable and precise copper-processing method in the spotlight.

From a renewable energy perspective, laser-cut copper minimizes material waste, particularly in solar and wind power applications. With the worldwide initiative on clean energy gaining momentum, precise laser cutting will be keen to ensure the minimization of wastage and maximization of their performance. According to the International Renewable Energy Agency (IRENA), renewable energy installations need to be doubled by 2050 to meet global climate targets- hence the growing demand for laser cutting.

By merging technology with industry requirements, laser cutting continues to solidify its position as a crucial tool in supporting modern industries.

Why Copper is Challenging to Cut with Lasers

High Reflectivity and Its Impact

One among the obstacles in titanium biology is the high reflectivity of copper; copper materials’ surfaces reflect almost 95% of the incident laser light, particularly with infrared wavelengths. Reflection means laser energy is the least absorbed to perform accurate cutting; reflected laser beams may travel back and can damage the cutting apparatus.

Breakthrough Solution: Fiber lasers at or nearly at the green light wavelengths of 515–532 nm are ideally suited because copper much better absorbs green light than it does infrared light: 40% absorption compared to less than 5% for infrared lasers. Such absorption means faster cutting speeds and reduced energy consumption.

Recent advancements are made attempting to surmount these challenges. Cutting of copper has been made more efficient with the advent of fiber lasers, especially those utilizing shorter wavelengths.

Interestingly, the other solution of late has been to apply anti-reflective coatings to the laser optics combined with an adaptive optics system to operate safely from the possibility of damage by reflected beams. Industrial cases have sited data to assert that with fine-tuning on their application, fiber lasers cut thin copper sheets from 3 to 4 times faster than do the traditional CO2 lasers; hence, they have had much preference in industries such as electronics and automotive manufacturing where copper plays a key role.

With the optimization of new laser technology and operational methods, most of the problems put forth by copper and its inherent reflectivity toward copper laser cutting will be promptly overcome, and ensuring accurate, highly efficient, and safe laser cutting.

Thermal Conductivity Challenges

Copper’s intrawild thermal conductivity value one uses for such classification actually does unend the laser cutting processes. A thermal conductivity of about 400 W/m·K value makes copper very efficient to conduct heat. On the contrary, less maintenance of the highly localized thermal energy during laser cutting of copper is difficult as heat is rapidly dissipated into surrounding materials, preventing or insufficient heating of the cut zone itself or area, which applies irregular or uneven cutting in low-level precision.

Advanced Solutions for Thermal Management:

- Enhanced Absorption: From 5% (traditional lasers) to 40% (modern short-wavelength lasers)

- High-pressure assist gases: Nitrogen or oxygen for rapid molten material removal

- Adaptive cooling systems: Minimize thermal distortion during cutting

- Real-time monitoring: Dynamic laser intensity adjustment based on feedback

Accordingly, the technological development in laser has been given its all to intimate delivery of laser energy. From this study, it is evident that a fiber laser with a shorter wavelength will exhibit better absorption on copper, allowing it to reach an adequate temperature very quickly and efficiently. This study further proposes that copper’s energy absorption can be tremendously increased from its current value of nearly 5%, which is applicable in present traditional longer-wavelength lasers, to as much as 40%, using the new breed of short wavelength lasers. This enhanced absorption will thus largely eliminate dissipation effects, engendering smoother cutting, and better edge quality.

Further improvements are anticipated through the use of assistive technologies, such as high-pressure assist gases or adaptive cooling. For example, assist gases may enhance nitrogen or oxygen to remove molten material while reducing thermal distortion speedily. Some advanced monitoring mechanisms are demonstrating success in maintaining thermal stability during cutting by dynamically adjusting laser intensity in real-time based on feedback.

Therefore, this system of technology set is utilized partially to counter-act the effects brought about by copper’s high thermal conductivity towards successful manufacturing and durable results.

Material Thickness Considerations

Depending on the thickness of the material to be transformed hydrotectonically, laser cutting processes can be assigned to a particular range, especially in copper: thicker copper sheers need more laser power from the heat-conducting and reflecting properties of copper; fiber lasers of more than 6 kW power are usually adopted in cutting copper plates, 0.25 inches (6.35 mm) or thicker. Strong beam concentration and highly-developed beam-shaping techniques are paramount in controlling heat distribution to meet the requirements of smooth cutting.

| Copper Thickness | Recommended Laser Power | Cutting Speed | Special Requirements |

|---|---|---|---|

| 0.005 inches (0.127 mm) | Precision-focused lasers | Variable | Avoid distortion of fine details |

| Up to 1 mm | 3 kW fiber laser | Up to 30 m/min | Excellent edge quality control |

| 0.25 inches+ (6.35 mm) | 6+ kW fiber laser | Variable | Beam shaping, heat distribution control |

| Up to 8 mm | 6+ kW fiber laser | Optimized for thickness | Low dross formation maintenance |

On the other hand, thin copper materials used in electronics require precision-oriented lasers that do not distort fine detail. Excellent control of laser cutting copper sheets with thicknesses as low as 0.005 inches (0.127 mm) and good edge quality has been demonstrated by the latest lasers equipped with a feedback system.

Lately, nitrogen and oxygen have been considered as the assist gases to help thermal reactions during cutting. It is suggested that using nitrogen as the assist gas for thin materials may yield clean and oxide-free cuts, which are essential when conductivity and surface quality are critical.

Laser power, cutting speed, and assist gas can be manually or automatically selected based on the thickness and nature of the material to avail best performance and further save processing time. The treated process underscores the need for customized techniques to ensure a uniform and high-quality outcome, regardless of the material’s thickness.

Advanced Techniques for Cutting Copper

Effectiveness of Fiber Laser Cutting

Since fiber laser cutting is more precise, efficient, and fast for difficult materials like copper, this increase is now firmly established in the metal manufacturing industry. When reflecting bodies tend to be an obstacle to CO2 lasers, fiber lasers, with their shorter wavelengths and higher energy densities, can in fact cut through reflective metals. This novel patented technology is the ideal choice for manufacturers, offering clean cuts with a minimal heat-affected zone and very little surface damage.

Material utilization rate

Nowadays cutting speeds and accuracy of fiber lasers have been improved by modern developments. For example, in cutting thin copper sheets (maximum thickness of 1 mm), at a power of 3 kW, the cutting speed can reach up to 30 m/min; with a power of 6 kW and above, it is possible to cut thicker materials of copper, about 8 mm, with good edge quality and low dross formation.

Actually, factors such as beam focusing precision, the energy efficiency of the cutting procedure, and the ability to coordinate with automation render fiber laser cutting an efficient cutting method whereas fiber laser should be etching companies alongside a few manufacturers. Material use rates of above 90% have been reported in some instances using the fiber-laser setup, thus making it cost-effective and green.

This modern technology fulfills the needs of industries such as electronics, automobile, and aerospace to cut copper into extremely intricate geometric patterns with supreme precision and repeatability. Furthermore, with continued developments, fiber lasers are expected to remain essential in all other applications requiring high-end metal-cutting operations.

Role of Auxiliary Gases in Precision Cutting

These precision auxiliary gases in the process are used in laser cutting to cut various materials with minimal defects, including copper metals. Such gases usually include oxygen, nitrogen, and argon, all of which assist in the laser-cutting process by cooling the area of laser incidence and expeling molten material-aiding in improving the speed and quality of cuts.

| Gas Type | Primary Function | Best Applications | Performance Benefits |

|---|---|---|---|

| Oxygen | Creates exothermic reaction | Thick carbon steel | Faster cutting, may cause edge oxidation |

| Nitrogen | Prevents oxidation | Stainless steel, aluminum | Clean, oxide-free cuts, up to 40% speed increase |

| Argon | Excellent shielding capability | Exotic metals, special alloys | Superior protection for specialized materials |

The laser cutting of carbon steel, with oxygen at the side, is the mainstay and principle application of oxygen, primarily because it participates in an exothermic reaction with carbon steel and so generates more heat and fast cutting processes. It is the primary type of laser gas applied with thick materials and may lead to oxide formation on the edges. For clean cuts and oxide-free edges, nitrogen is used. Nitrogen acts as an inert atmosphere to hinder oxide formation. This cutting method, utilizing nitrogen, is effective for stainless steel and aluminum, particularly in the aerospace industry, where precision and aesthetics are crucial. Argon, on being less frequent, finds application for some cases, mostly with exotic metals or alloys, owing to its great shielding property.

So what takes away the actual dawning effect of auxiliary gases is that it can powerfully maximize cutting efficiency, according to the newest set of statistics from the industry. Studies have shown that nitrogen can increase the cutting speed of thin stainless steel by up to 40% when applied correctly, without compromising edge quality. A number of automated systems now incorporate gas sensor technology that dynamically adjusts pressure and flowrate to favor the highest performance of various applications of the cutting process. These advancements underscore the importance of auxiliary gases in achieving the highest precision and productivity standards.

Recent Advancements in Laser Technology

Recent achievements in laser technological research demonstrate the evolution of beam shaping systems that control the laser beam profile for various industrial applications. For example, a class of dynamic beam control systems was developed that allows lasers to change their intensity distributions in real-time, thereby improving cutting accuracy and gaining material efficiency. Industry sources report that this technology is also being used to increase processing speeds by approximately 30% in applications such as automotive component manufacturing and aerospace engineering.

Ultrafast Lasers

The latest developments within this technology are the widespread use of ultrafast lasers. They work in femtoseconds, thus allowing fabrication by micro-machining without enough heat disturbing the surroundings of the material. Studies have demonstrated that ultrafast lasers reduce material wastage by almost 20% and significantly increase production yield in industries where ultra-high precision is required, such as electronics fabrication.

Energy Saving

Another notable head is advancing the energy efficiency of laser systems. The high brightness diode lasers are purposely designed to consume 25% less energy than their conventional CO2 counterparts and nearly match their performance or even exceed it in some respects. This recent innovation is in line with worldwide efforts in sustainability to lessen the carbon footprint on industrial processes.

Advances in Artificial Intelligence

This introduced new twists to laser technology, incorporating AI. Presently, with AI systems, fault detection, and self-calibration occur in real-time, thus limiting downtime and ensuring performance consistency. Studies support that productivity has reportedly been increased by 15-20% through AI-enabled laser welding systems. This view of a partnership of AI with some of the world’s best laser systems is fast transforming the manufacturing domain and developing vectors for Industry 4.0.

The birth of these techniques emphasizes the very transient existence of laser technology, determining increased efficiency, precision, and sustainability to some industrial spheres.

Applications of Laser-Cut Copper

Applications in the Electronics Industry

Laser-cut copper assumes an important role in the electronics sector for it has better conductivity and greater flexibility. It is mostly used for manufacturing PCBs: the infrastructure of most of today’s electronics. Lasers with very high precision allow the creation of incredibly intricate designs on copper sheets, allowing detailed and compact designs of advanced electronic parts to come into being. Quite recently, it was claimed that laser technology has really advanced the manufacturing of battery packs with particular reference to EVs; recent figures suggest that laser cutting improves material utilization by nearly 20%, lowering scrap and thus retaining quality standards required for EV batteries.

5G Technology Impact: Further, with the growing emphasis of 5G, it leads to laser-cut copper use for antenna and communication components. Research indicates that laser technology reduces production lead time by almost 30% to avail the speed demanded in technological deployment.

Speed, precision, and eco-friendly nature genuinely usher laser-cut copper into innovative material by the electronics industry.

The Automotive and Aircraft Domains

In automobile and aerospace applications, scientific copper cutting is an extreme precision method, carrying an utmost importance in the manufacturing process. In the automobile field, copper parts are mostly essential for use in EVs, particularly for motors, batteries, and power inverters. As reported, on average, a single EV contains approximately 200 pounds of copper, thereby underscoring its significant role in clean energy-based solutions. Advanced laser cutting facilitates the fabrication of components with complex shapes, minimizing material wastage and promoting sustainability.

Copper, aerospace, and market by the year 2030

On the other hand, copper alloys began to be incorporated into aerospace applications as a result of the push for lighter and more efficient materials. Laser cutting of copper is done for aircraft electrical wiring, cooling, and heat exchangers. The extremely high heat and electrical conductivity ensure reliability and safety in harsh atmospheres. According to MarketsandMarkets, the aerospace and defense copper market is projected to reach USD 2.6 billion by 2030, clearly underscoring its significance.

Besides laser technology making sure that delays in production are minimal and resources are fully utilized, making components that must adhere to strict standards and tolerance will greatly benefit both sectors.

Art and Design Creations

In the realm of endless possibilities, copper has long been renowned for its beauty and durability. Artists and designers account for some very natural features of copper, which gradually change in appearance, ultimately creating unique and ever-evolving works of art. From finely detailed grandiose designs to the magni-colossal dimensions of architectural structures, copper is appreciated for its captivating looks and malleability.

Decorative Copper Market Trends:

- Market Growth: 5.2% CAGR expected between 2023 and 2028

- Recycling Leadership: 43% of copper worldwide is now sourced from recycling

- Interior Design Integration: Rises demand in furniture, lighting, and decorative items

- Sustainability Focus: Increasing use of recycled copper within design initiatives

According to , decorative copper has experienced unchecked demand growth in the interior design sphere, where copper is an important material in furniture, lighting, and decorative items. The decorative copper market, therefore, is expected to grow at about 5.2% CAGR between 2023 and 2028. Additionally, recycled copper is gaining popularity in sustainable design activities, with nearly 43% of the copper used in the world now coming from recycling.

Such a turn of events of copper in art and design attempts to link the old with the new, suggesting that from time immemorial this age-old material has been sustaining both ancient craftsmanship and modern etc.

Tips for Achieving the Best Results

Choosing the Proper Technique

Any work in copper necessitates proper tools dependent on art, design, or building. One must concentrate on the tools that best fit the task’s needs to achieve the best outcome. Shears or plasma cutters with fine quality would best do for accurately cutting and shaping without wastage. For soldering and joining, a well-tempered soldering iron can help create neat and strong joints. Sometimes, depending on the composition of the material itself, especially since recycled copper may require slightly different welding procedures, one might need to solder differently.

Industry Growth: With whatever recent trends Search has shown, the world runs steady at some 6% a year for the market of advanced tools in metalsmithing about designs offering ease of handling and optimal functioning of the tools. For example, hammer designs that take corporate needs into consideration today incorporate anti-vibration technology to reduce pinching issues on the hand while deliberately controlling movements for intricate details in copperworking.

Another thing worthy of consideration being that the safety equipment. It is reported that approximately 25 percent of minor injuries in metalworking are attributed to the lack of protective gear. One should always consider wearing heat-resistant gloves, safety goggles, and a sturdy apron when handling molten or sharp copper pieces.A combination of effective tools, paired with safety measures, ensures that the creator performs with great precision in an environment where efficiency is paramount, with minimal consideration for workplace hazards.

Laser Parameter Optimization

Only when laser parameters are kept optimized for copperworking projects with utmost precision and efficiency would the output be satisfying. The cuts or welds obtained through the laser fall into a certain quality scale, in which the laser power, pulse duration, focal spot diameter, and feed rate are considered to be of utmost importance. Therefore, based on the studies, lasers of short wavelength, commonly used for green or blue lasers, perform better against copper as a reflective material because there is the least amount of energy loss.

Key Parameters to Remember:

Laser-Power

This has to be adjusted in order to determine the depth of cuts or welds. For thin copper sheets, power levels between 100 and 200 W are considered good, while thicker materials will require up to 1000 W so as not to lose precision, charring, or melting.

Pulse Duration

To minimize the HAZ, either short-pulse or ultra-short-pulse laser has to be used. Nanosecond pulses seem to give the best results for detailed engraving, while femtosecond pulses are best for ultra-precise cutting.

Feed Rate

This slower the laser travels on the workpiece, the deeper it penetrates, causing heating. While faster feed rate would mean that the irradiation is not deep penetration into the material. For example, 25-50 mm/s is a nice feed rate when engraving extremely complex patterns on copper.

Gas Assistance

Assist gases such as oxygen or nitrogen may be used in the cutting process. Oxygen speeds up the cuts and deepens them, while nitrogen prevents oxidation for cleaner cuts.

| Parameter | Thin Copper Sheets | Thick Materials | Complex Engraving |

|---|---|---|---|

| Laser Power | 100-200 W | Up to 1000 W | Variable by design |

| Pulse Duration | Nanosecond | Femtosecond | Nanosecond |

| Feed Rate | Variable | Slower for depth | 25-50 mm/s |

| Assist Gas | Nitrogen (clean) | Oxygen (speed) | Nitrogen (precision) |

Supporting Data from Recent Inquiries:

- Journal of Laser Applications (2023): Green lasers at 532 nm reduced reflection by 50%, compared to standard CO2 lasers, thus enhancing energy efficiency and precision.

- Testing of a 1 mm copper sheet: 30% improvement in edge smoothness for pulse-duration-optimization measured under 150 W.

- GSI Laser tech report: Precision focal spot size adjustment led to 22% improvement in repeatability of engraving.

When one approaches the laser parameters accordingly, artisans and industrialists can expect better results with reduced wastage of materials and efficient ways of working copper.

Safety Considerations in Copper Cutting

The cutting of copper by laser or any other machine method should be priority in life and safety considerations, making it a safe job to undertake. Extreme temperature, bright light, flying debris, and toxic fumes come amongst the major hazards along the whole cutting process.

Personal Protective Equipment

The operators should wear the personal protective equipment which shall include the following:

- Eye goggles or laser safety glasses to shield the operators’ eyes from injury by laser beam exposure or debris. Laser exposure can mean permanent eye damage in particular with Class 4 lasers which are usually encountered in general copper cutting.

- Heat-resistant gloves to protect against burns from hot material and equipment.

- Protecting clothing, like apron or flame-retardant jacket, to decrease the risks of coming in contact with hot surfaces.

Ventilation Systems

Another unsafe practice during copper cutting is the production of toxic fumes. According to OSHA’s guidelines, there shall be installed a ventilation or fume extraction system capable of removing toxic particulates and harmful gases released in great quantity in thiocyanate disintegration of copper during the cutting process. Researchers concluded the airborne contaminants can be decreased by as much as 85% through proper ventilation, thus decreasing health risks for the workers.

Regular Maintenance and Training

To enhance safer operations:

- Machinery Maintenance: periodic checks of cutting machines to ensure that all safety features such as interlocks are in place and in proper working order, such as emergency stop and ventilation.

- Training of Operators: ensure that all workers are trained in laser safety standards; understand the working parameters of the machine, and know what emergency procedures to take when an accident occurs. On this note, the Laser Institute of America (LIA) reports that workplace accidents have decreased by about 30% through effective training.

Controlled Work Environment

Maintain a well-established and fire-free working environment. Fire hazards could be posed. Operators and persons in the vicinity can be protected from accidental exposure to stray laser beams by enclosing laser equipment with protective barriers.

85%

Reduction in airborne contaminants with proper ventilation

30%

Decrease in workplace accidents with comprehensive training

Adhering to these gains in safety and ensuring strict compliance with their guidelines will render several cutting setups used in several industrial sectors accordingly safe for workers without compromising the rate-taking in copper cutting processes.

Overcoming Common Challenges

Techniques for Reducing Reflectivity

When reflective materials like copper are used for cutting, the main issue faced is reflective nature. These problems arise when a large percent of the laser energy is reflected off by copper, reducing cutting efficiency and damaging the machine. Some ways to cope with reflectiveness are given below for improving work:

| Technique | Method | Effectiveness | Best Applications |

|---|---|---|---|

| Fiber Laser Usage | Lower wavelength systems | Up to 40% absorption vs 10% CO2 | General copper cutting |

| Absorptive Coatings | Black oxide coatings/sprays | Significant absorption improvement | Pre-cutting surface treatment |

| Dynamic Beam Shaping | Controlled energy distribution | Concentrated targeting | Advanced laser systems |

| Material Preheating | Temperature elevation | Up to 20% reflectivity reduction | Thick copper processing |

Using Fiber Laser

Fiber laser systems exhibit lower reflectivity and higher absorption capacity of laser energy on the copper surface compared to CO2 lasers. There are sources that indicate fiber lasers may reach an absorption level of approximately 40% on polished copper, whereas CO2 laser systems may achieve only about 10%.

Applying Coatings

Applying absorptive coatings to the copper surface before laser cutting significantly reduces its reflectivity. This method involves using black oxide coatings or other sprays to enhance the copper surface’s absorption of upward energy, thereby canceling out any laser losses caused by reflections.

Dynamic Beam Shaping

Top-of-the-line laser systems feature dynamic beam shaping technology, which enables proper energy distribution. By controlling the sharpness and intensity of the beam, manufacturers could in fact concentrate the energies onto smaller target spots, ensuring that high-reflective materials are cut with efficiency.

Preheating of Material

Preheating of the copper surface will reduce its reflectivity of it. Preheating can reduce the reflectivity of copper by 20%, hence increase the laser absorption and cutting properties.

Equipment Protection

Custom optical isolators and reflective beam traps can be integrated into the system to absorb or deflect energy that would otherwise stray and damage the laser equipment from reflected beams. Besides protecting equipment, the anti-reflective installation significantly enhances operational safety.

Pulse Modulation

Where cutting accuracy is of concern, it may improve when laser systems operate in pulse beam modes rather than CW. In the pulsed mode, energy is delivered in intervals; hence, it coagulates and ablates the surface layer, thereby reducing reflectance claims but clean cuts.

And when all combined, these processes drastically reduce the reflectance problems encountered during the machining of copper and other reflective metals. Modern-lately improved techniques in laser technology – specially process optimization- allow cutting facilities to maintain high levels of productivity while ensuring precise machining.

Strategies to Cut Thick Copper

Thick copper cutting has always been extremely challenging due to issues with thermal conductivity and reflectivity. However, technology development and its new approaches have somewhat simplified the task. Presented below are some advanced methods backed by state-of-the-art developments:

High-power fiber Laser

Sword cutting thick sheets of copper is one of the best applications for a laser due to its high energy efficiency and precision. It essentially works in shorter wavelengths of approximately 1.06 microns, which are partly absorbed by copper, as opposed to CO2 lasers. For instance, a 6 kW fiber laser can cut copper sheets up to 10 mm thick with high precision.

Maintain Beam Quality & Focus

Pressure should be focused on maintaining beam quality to achieve clean cuts as the end product. Hence, the cutting procedure can be enhanced by adaptive optics and a thorough control of the laser’s focal length. This avoids the possibility of heat diffusion, typically caused by copper’s high thermal conductivity, resulting in cleaner edges on thick materials.

Increase Active Cooling Facilities

Good heat treatment management during execution of thick copper cutting is vital. Active cooling treatments, such as water-assisted cutting or simple airflow, prevent overheating and warping, as well as other undesirable effects, while promoting fast cut speeds. In several highly demanding tasks, active cooling will promise workpiece stability by monitoring thermal expansion.

Treatment to Decrease Reflectivity of Coating

It was thought to improve the laser absorption by having antireflective coatings applied on the surface to defeat reflectivity of copper. No other advanced system can afford to use beam reflectors to protect the laser source and ensure uninterrupted process performance.

Nitrogen or Oxygen assist gas

These assist gases produce a seaming contrary to nitrogen while making copper cutting an exothermic reaction, thus producing a faster cut, and an excellent finish is created by nitrogen. A pressure assist gas apparatus is required for thick copper.

Advanced Cutting Parameters and Software

Advanced CNC software is adopted to control precisely the feed rate, laser power, and pulse modulation. Thick copper requires slower feed rates along constant pulse energy to maintain a balanced power great for actually avoiding defects or high heat build-up.

Data and Performance:

- Cutting Speed: Up to 2 m/min is achieved on 8 mm copper sheets by high-powered fiber lasers

- Increased Productivity: 30-40% increase in productivity with optimized cutting methods

- Less Post-Process: 20% reduction in finishing due to assist gases

- Efficiency Dominance: CO2 lasers are usually behind in terms of overall efficiencies

Recent industry reports state that high-powered fiber laser cutting was going at 2 m/min on 8 mm copper sheet, hence giving CO2 lasers a big lag. Companies reported about 30-40% increase in productivity and less material waste after going for optimization of cutting methods. Another 20% of post-processing can be reduced further by using assist gases as they help in giving a clean cut and cut back the finishing requirements.

Thus manufacturers, combining these advanced strategies, can circumvent the hurdles of thick copper cutting while meeting with precision and further by way of high production. The sure shot way to successful application in this challenging application is by a blend of modern laser technology and painstaking process optimization.

Importance of Equipment Maintenance

Maintenance becomes important for equipment since it offers a llife sustaining function of machines and is most pertinent, for the high-demand industries, such as manufacturing, in efficiency and performance. Newer research holds the concept that money lost from unplanned downtime due to equipment failure could be up to $260,000 per average hour, capturing the huge financial risks under prescription of bad maintenance.

$260K

Average cost per hour of unplanned downtime

33%

Reduction in downtime with preventive maintenance

20%

Increase in machine lifespan

25-30%

Maintenance cost reduction with predictive tech

Implementing preventive maintenance is the first step in addressing problems before they knock on downtime. Down-time reduction by one-third and an average life extension of 20 percent for the machines are the results of such an implementation. In this regard, regular cleaning of the laser optics, alignment checks, and monitoring of assist gas flow help maintain cutting quality and prevent sudden halts of operations due to component wear.

More and more, though, predictive maintenance methods like IoT sensors and machine learning algorithms are beginning to change the industrial landscape assertively regarding equipment maintenance. These new technologies would allow for almost real-time views on machine health so operators can obviate the developments of particular machine failures arising from wear and tear. It is established that businesses using predictive maintenance have cut by 25-30% concerning maintenance cost while raising operational efficiency by 20%.

The consistent upkeep of a well-maintained list with an up-to-date toolkit approach on machine maintenance not only ensures uninterrupted production but also steers away from operational interruptions and in the future will face the hurdles of starred-down operational expenditures. Maintenance is not just any necessity of operations; it needs to be an investment into long-term business performance.

Frequently Asked Questions

Laser cutting methods for copper offer numerous benefits, including precision and efficiency. High-powered lasers can cut through copper sheets with a clean cut, minimizing the kerf and reducing waste material. This method is particularly advantageous for producing intricate shapes and designs in copper parts, making it ideal for metal fabrication. Additionally, the use of fiber laser machines enhances the cutting speed and quality, especially for thicker materials. With customizable parameters, operators can achieve high-quality cuts that meet specific requirements for various applications.

The thickness of copper significantly influences the laser cutting process. Thicker materials require higher laser power levels to effectively cut through the workpiece, while thinner copper sheets can be cut using lower power settings. A CO2 laser is often effective for thin copper, while fiber lasers excel with thicker copper due to their concentrated laser beams. Moreover, when cutting thick material, it’s essential to consider assist gas, which helps to improve the cutting quality and speed. Understanding the thickness is crucial for selecting the appropriate cutting methods and achieving the desired results.

Yes, plasma cutters can be used for cutting copper, but there are some limitations to consider. Plasma cutting is effective for thicker copper sheets and can deliver high speeds, but it may not produce as clean a cut as laser cutting methods. Additionally, plasma cutting can generate more heat and potential distortion in the copper components, which is a concern for precision applications. For detailed work or thinner copper, laser cutting, especially with fiber laser technology, is often preferred due to its high-quality cut and reduced heat-affected zone.

When it comes to cutting copper, fiber lasers are generally considered the best option. Fiber laser machines emit laser beams with a wavelength that is highly effective for cutting metals, including copper. They provide a clean cut with minimal burr and offer a wide range of applications due to their versatility in handling different thicknesses. CO2 lasers can also be used for cutting copper, particularly for thinner sheets, but fiber lasers tend to outperform in terms of speed and efficiency. Choosing the right type of laser depends on the specific requirements of the project and the thickness of the copper material.

Assist gas plays a crucial role in the laser cutting process for copper. It helps to blow away molten metal from the cutting area, ensuring a clean cut and reducing the risk of dross formation. Common assist gases include oxygen and nitrogen, each serving different functions depending on the desired outcome. For instance, using oxygen can enhance the cutting speed and create a more aggressive cut, while nitrogen is often used to achieve a better surface finish on laser-cut copper. Understanding the properties of the assist gas and its interaction with the laser is vital for optimizing the cutting process.

Reference Sources

- IOP Science – A study on laser cutting of copper and copper alloys, discussing modern laser cutting systems and their precision: Study of Laser Cutting of Copper and Copper Alloys

- SPIE Digital Library – Research on the CO2 laser cutting process for copper sheets, addressing thermophysical challenges and solutions: Copper Sheet Laser Cutting – The Process And The Challenges

- Copper Development Association – An article on the copper vapor laser, explaining its mechanism and applications in cutting-edge technology: Copper at the Cutting Edge: The Copper Vapor Laser