When selecting between Continuous Wave (CW) and Pulsed laser machines for industrial cleaning, you either achieve remarkable efficiency or are mired in exasperating delays. Each technology provides distinct benefits for different applications, whether your focus is on tough rust, delicate coatings, or intricate geometries. What’s the best solution for your individual requirements? This article summarizes the main differences between the two systems and their strengths, challenges and ideal use cases. Numerous professionals have for decades already relied on laser cleaning, while upgrading machinery, or as a first venture into this type of cleaning, we will provide detailed guidance to help all readers make informed decisions that lead to the appropriate systems selection. These advanced systems reveal all their secrets to the eyes of the world and empower everyone to pick the one that best matches their cleaning objectives.

What is Laser Cleaning?

Laser cleaning is a cleaning method that employs an intense beam of laser to eliminate contaminants, residues, and even coatings from surfaces. It is precise, non-contact, and eco-friendly, which makes this method preferable in cases where delicate yet effective cleaning is required. Laser cleaning works by aiming laser energy towards a surface, and the energy enables a breakdown of the material without undermining the substrate.

Fundamental Aspects that Affect Laser Cleaning Efficacy

- Laser Wavelength: The wavelength of a laser will affect the efficiency of the material’s energy interaction. As an illustration, shorter laser wavelengths are far better when it comes to cleaning tasks, and intact surfaces require extra care. The laser cleaning process will utilize a range of ultraviolet (UV) and infrared (IR) lasers depending on the requirements of the work.

- Energy Density: Also referred to as fluence, this parameter defines energy concentration over a specific area. Densities of energy are useful when stubborn contaminants need removal but maintaining the balance of damaging the substrate is crucial.

- Pulse Duration: Period of time for a single laser pulse will determine the amount of material interaction that occurs. Slated to become more ubiquitous in high-tech practices due to their reduced heat-affected zones, inline lasers featuring pulse durations measured in picoseconds or femtoseconds are more frequently employed.

- Cleaning Speed: The speed at which the laser moves across a surface is crucial for ensuring uniform cleaning. Slower speeds typically allow for more thorough removal of contaminants, but optimizing speed is essential for maintaining efficiency in industrial applications.

Classification By Power, Type of Laser and Application Of Use

Laser cleaning machines are classified based on their power ratings, the type of laser used and the purpose intended:

High-Power Laser Cleaning Machines

These are used for rugged operations like rust and paint removal and for general industrial cleaning. They possess greater energy output with a deeper and faster cleaning rate even on tough surfaces.

Medium-Power Laser Cleaning Machines

Most effective for tasks that require careful cleaning, such as metal restoration, where the underlying surface should not be damaged.

Low-Power Laser Cleaning Machines

Effective in the performance of non-complex tasks such as cleaning and surface preparation requiring a high degree of precision and control.

Applications: When to Use Laser Cleaning

Laser cleaning is my go-to method when I need to achieve high accuracy and task efficiency. It effectively eliminates rust, paint, and other forms of contaminants from metallic surfaces while preserving the substrate material. Moreover, I appreciate its application in the aerospace or automotive industries, which are highly critical for part integrity. For precise restorations, as well as for bonding or coating applications, laser cleaning remains the safest and most effective option.

How Does Pulse Laser Cleaning Work?

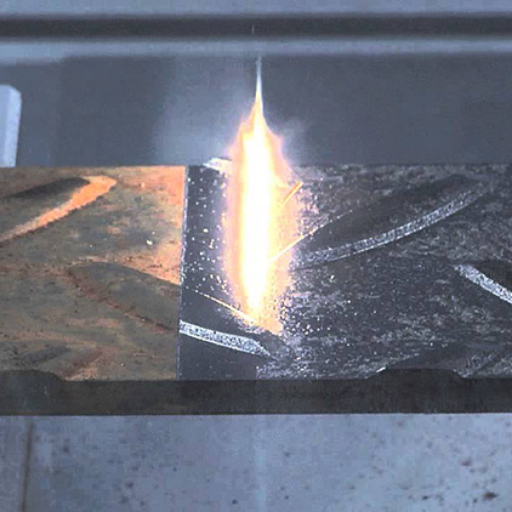

The pulse laser cleaning technique applies a short, precise, and high energy pulse to a surface making sure not to damage the base material underneath. As an effect of the applied pulse, unwanted materials like rust or paint are vaporized and heated. The precision offered guarantees that there is no collateral damage to the cleaned area.

Understanding The Technology of the Laser and Its Effectiveness

The pulse laser cleaning technique heavily relies on the ability of a pulse laser to emit energy bursts of immense concentration because doing so releases energy in increments of nanoseconds or femtoseconds. The energy is able to be used very efficiently as it is capable of eradicating unwanted materials, coatings, and oxides from surfaces. The efficiency of cleaning varies with the amount of energy focusing, or fluence, which in the case of a laser cleaning beam is referred to as fluence. It is highly regarded that the range of fluence is between 4 to 10 J/cm2 for most materials for cleaning effectiveness to be achieved alongside greatly minimized substrate damage.

Moreover, the cleaning efficiency is greatly determined by the repetition rate of the laser pulses utilized. Material removal is increased with higher repetition rates, such as several hundred kilohertz, but surrounding laser fluence may need to be reduced in order to prevent overheating of the target surface. Research has demonstrated that surfaces heavily contaminated with rust, for instance, are often thoroughly cleaned using repetition rates of 50-200 kHz, depending on the material and the thickness of the contamination.

The changes in contamination level (or in this case, the surface age) along with Ra are changes measured to evaluate system performance of industrial pulse lasers. For example, steel surfaces after laser cleaning exhibit a remarkable Ra reduction from over 2µm to below 0.5µm, demonstrating significant smooth restoration without abrasion. With such smooth surfaces restored in various regions, this data demonstrates precision by which pulse lasers operate, whether to clean artifacts of industrial heritage or to meticulously preserve and restore heritage artifacts.

Benefits of Utilizing Fiber Lasers

When it comes to lasers, efficiency is a marked advantage of pulsed fiber lasers and can be seen in use during material processing or cleaning procedures. Examples of these attributes include high pulse power and exceedingly short duration pulses which can achieve energy delivery with no thermal collateral damage to the surrounding area. With fiber lasers, regions of surface rust on metallic structures can be cleaned at a rate of 10 m²/hr while retaining the integrity of the substrate. This ability decreases warpage and discoloration risk which is critical during the production of aerospace and automotive components.

Research has also shown the additional benefits of using pulsed fiber lasers such as energy saving, when compared to other methods. Average power can be put lower while pulse duration and frequency can be tuned to have improved results, driving down the operational costs. An example can be seen with laser cleaning systems employing 100-W pulsed fiber lasers that perform well over energy consuming cleaning and treatment processes. These lasers have also excelled in micro machining where parts as small as 10 micrometers are executed with exceptional clarity. Such attributes make pulsed fiber lasers crucial in the progression of industrial and precision engineering applications.

Pulse Laser Cleaning Strategy and Methodology

While adopting a pulsed fiber laser cleaning technique, several critical parameters require strict control for maximum efficiency. One of the most important is the laser pulse’s duration since it determines the cleaning efficiency and the level of material interaction with the substrate. Rapid pulse durations within the nanosecond range enable accurate control over the ablation of contaminants and limit the inflow of heat to the material underneath. For example, it has been shown that for certain materials such as aluminum and brass, nanosecond pulses benefit the oxide layer’s removal without surface deformation.

Another important aspect to consider is the laser’s wavelength. A commonly used is 1064 nm, since the absorption rates for various materials like metals and polymers is verygood. Recent studies claim these values can reach as high as 10 cm²/s for removing different intensities and types of contaminants.How the beam is delivered also is crucial for achieving optimal results. Scanning systems which are normally improved with the addition of a galvanometer, facilitate the maneuvering of the laser beam to intricate surfaces and pattern movement for uniform treatment over the entire surface. With advanced beam control coupled with real-time surveillance, cleaning precision can be enhanced which in turn reduces operational downtimes and increases efficiency of the system.

Lastly, using pulsed fiber lasers, safety and greening of the environment should be concentrated more on. In comparison to traditional cleaning techniques, these systems produce a reduced amount of chemicals which aligns with green engineering. In addition, comprehensive adherence to prescribed operational ventilation guarantees safety as well as environmental protection during the work process.

An example of this is continued optimization of pulse duration, wavelength, and beam delivery systems, which helps in pushing the boundaries of what is achievable when it comes to precision cleaning using pulsed fiber lasers. All these while providing sustainable and reliable solutions for diverse industrial applications.

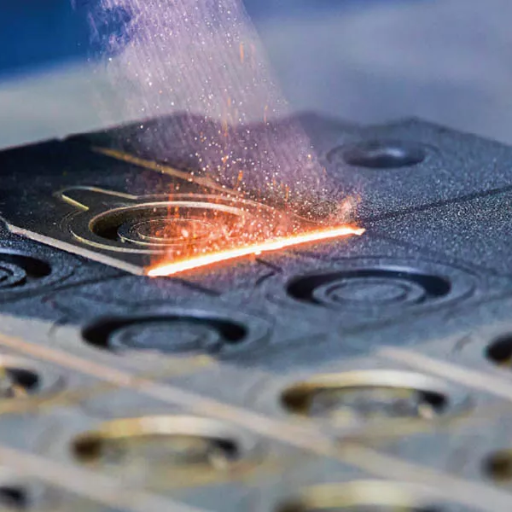

Exploring Continuous Laser Cleaning Technology

Contaminants on surfaces can be cleared using continuous laser cleaning technology which employs a constant laser beam. This method is quite efficient for processes involving extensive areas that require uniform cleaning. It is environmentally friendly because it provides uniform results, lessens surface damage, and lowers the use of harsh chemicals. Continuous laser cleaning is especially appropriate for aerospace and automotive industries, and manufacturing ones where accuracy and effectiveness are necessities.

Advantages of Continuous Wave Laser Cleaning

Continuous wave (CW) laser cleaning has a couple of distinct benefits. For one, there is no interruption in the flow of light which is what pulsed lasers provide. CW lasers, however, remove materials in a smoother and more uniform way. The preservation of the inner material is ideal when removing thin coatings, oxides, and other contaminants.

In comparison to other methods, CW laser cleaning enhances cleaning efficiency of large surface areas. For instance, during manufacturing, surfaces are cleaned at speeds of several square meters in an hour depending on the type of material and the power of the laser used. Furthermore, the systems achieve precision standards needed for detail work like removing fine residues in electronic components or sensitive substrates.Another notable advantage pertains to its impact on the environment. The CW laser cleaning process eliminates the use of caustic chemicals alongside water, which suppresses abrasive waste while also reducing the environmental footprint. Reports state that the use of CW lasers can reduce cleaning costs upwards of 30-40% compared to chemical cleaning methods. This furthers health and sustainability concerns by minimizing chemical exposure and supporting international sustainability initiatives.

Lastly, CW laser cleaning systems can be integrated into automated and robotic systems, improving safety and efficiency at the workplace. Adoption of CW laser technology is on the rise in aerospace and automotive industries to improve operational efficiency and high-performance standards as well as ensure dependable outcomes in mass production environments.

Advantages of Maintenance-Free Laser Cleaners

Clearing contaminants from engines and components at fuel-efficient rates, continuous wave (CW) laser cleaners offer unrivaled precision with environmental benefits across the board. Their ability to operate non-stop guarantees quality residual-free cleaning with no damage to underlying surfaces. The other day we reported on industry figures which approximated loss of contaminants by CW lasers at about 50cm2 per second, depending on the surface and the impurity. For industries that need things done fast and right, this is especially useful for aerospace and automotive industries known for large scale production due to the accuracy with which processing is performed.

In addition, the energy usage of CW laser systems is far lower than that of chemical and abrasive cleaning methods. Studies show, for instance, that the use of CW lasers can result in up to 60% energy savings which, in turn, lowers the operating cost and carbon footprint of the process. The CW laser systems require minimal upkeep, as they do not make use of consumable materials like solvents and brushes, further improving the long-term cost.

Furthermore, there is great flexibility in how one can apply CW laser technology. It can be used on precise and thin metallic films while also being able to clean rugged industrial parts, ensuring no damage is done to any of the components. Because of this, these systems can be employed by companies looking to operate in a more environmentally friendly manner, as well as reduce costs. With further advancements in automation incorporation, CW laser cleaners provide processes with great flexibility, proving them to be an answer for modern industrial cleaning needs.

Drawbacks of Continuous Lasers

Although continuous wave (CW) lasers have considerable benefits for industrial cleaning, there are some limitations to CW applications. The most notable of these is heat build-up over time and the potential for causing thermal damage to sensitive materials. Consider, for instance, precision parts, like electronic circuits or fragile alloys. Cleaning requires powerful lasers, but the balance has to be set so that the material is not devastated in the process.

Moreover, it is well documented that energy efficiency poses a problem on the macro scale. One report based on industrial benchmarks claims that Laser CW systems in certain operations are outperformed by pulsed laser systems by as much as 15-30% which translates to increased operational cost for large scale industrial plants. This also translates to lower/better (depending on the context) profit margins. Another problem is the lower processing speed; in tachyon applications like microfabrication and even more in nanopatterning, the pace is slower than with ultrafast systems.

In these cases, advanced cooling systems and other elements tend to optimize the lasers’ parameters at the expense of their aerospace grade reliability. Regardless, directed research and development efforts endeavor to resolve these gaps – improving performance, energy efficiency and material incompatibility weaknesses of CW lasers broadened for industrial use.

Comparing Pulse and Continuous Laser Cleaners

The working modes of pulse laser cleaners differ from those of continuous types and their applications as well. For action on sensitive surfaces or for minimal material removal, pulse lasers are the most effective because they emit short, high-energy bursts of light. For cleaning fairly large surfaces, the steady stream of light emitted by continuous wave (CW) lasers is appropriate and useful in many applications that require consistent energy delivery. As with most laser cleaning procedures, the choice of these two types depends on the material to be cleaned as well as the needed precision. For cleaning bare metals, pulse lasers do provide the most efficient options without incurring indirect damage, but CW lasers are generally preferred.

What Sets Pulse and Continuous Lasers Apart In Terms of Applications

Different applications and performance parameters define pulse lasers and continuous wave (CW) lasers as different from one another in their operational fundamentals. As an example, these latter typically operate at very high peak powers which may reach over several megawatts. They also sustain remarkably low average power, which translates to value quite significant in comparison. Such peak power enables highly precision materials to be processed with very little thermal damage to the region surrounding the area. For instance, lasers like these a lot are applied in electronics or in the manufacturing of medical devices which require an intricate design or a cleaned surface pattern.

The consistent output power of continuous wave lasers makes them suitable for applications demanding steady energy delivery. CW lasers find use in welding and other industrial operations like large-area cleaning and coating removal. They are particularly adept at those tasks where uniform heating is needed over the material being worked upon. In addition to these benefits, CW lasers tend to be more efficient in energy consumption over longer operational periods, which benefits industrial work.

One primary factor to be used for comparison is energy efficiency. Research shows that pulse lasers are more efficient for short, precision tasks, while clocked lasers are less efficient for short tasks but more efficient for sustained operations. For example, in the case of cleaning metal, a pulse laser would only use about 30%–40% of the energy a CW laser requires to achieve a similar result, depending on the material and cleaning requirements.

Things to Weigh: Cleaning Speed and Efficiency

When choosing between the pulse and CW lasers for industrial uses, both cleaning speed and efficiency matter. Since pulse lasers work at a higher peak power level than CW lasers, they provide energy in short “pulses” that foster precise and effective material removal that reduces damage to the substrate and material wastage. In this case, so called “cleaning efficiency” is achieved. For example, some studies indicate that pulse lasers may achieve cleaning efficiency rates of 80-90% on delicate surfaces with minimal impact on the material.

On the other hand, CW lasers are more advantageous when the operation requires high speed because of their continuous energy output. Their energy consumption, however, is generally higher which affects the operational cost. Recent results indicate that CW lasers achieve cleaning rates over 10 square meters per hour in repetitive large scale applications. These differences highlight the need to balance laser options for specific project needs with considerations on stress for the material, energy consumption, and targeted productivity.

Analyzing Important Aspects That Determine the Efficiency of Laser Cleaning

Performance and productivity of a laser cleaning method are influenced by a number of key factors. One of the foremost factors to focus on is the type of material to be cleaned. Metals (e.g. steel and aluminum) and their alloys differ in regard to their thermal conductivity and degree of surface oxidation, which affects laser cleaning. For instance, stronger power lasers tend to perform better when it comes to cleaning rust or coatings off steel surfaces due to achieving, on average, 99% cleaning efficiency.

Another one of the most important factors includes the laser’s pulse frequency and wavelength. Ultraviolet lasers are preferred because of their short wavelengths when delicately cleaning precision ceramics or instruments that require only thermal and mechanical impact. On the other hand, infrared lasers are more suitable for robust cleaning tasks such as thick grease or industrial contaminant cleaning due to their high energy density.

Moreover, the speed of cleaning as well as the area that needs to be covered is primarily controlled through the laser scanning rate and beam diameter. One of the benefits that come with modern laser systems is the adjustable beam size; under normal working conditions in midrange industry settings, these systems can clean up to 15–20 square meters per hour which is extremely advantageous for large scale operations.Lastly, we consider safety and the environment. Laser cleaning uses no chemicals, making it one of the most environmentally-friendly technologies for surface treatment. Its precision and non-contact cleaning features enable the operator to reduce waste, cut damage to the substrate, and lower costs for post-cleaning treatments. The developments of laser technology are setting even higher marks of versatility, effectiveness, and sustainability for these systems in surface cleaning processes.

How to Choose the Right Laser Cleaning Machine?

When selecting a laser cleaning machine, always take the following factors into consideration:

- Material Type: Select a machine that fits the material that you intend to clean, like metal, rubber, or stone.

- Power Requirements: Determine the level of laser power to use for the cleaning task. More power works better for heavy contaminants while delicate surfaces need less power.

- Portability: Think if a stationary unit set in one location is needed or a portable system is preferred for versatility.

- Safety Features: Machines with built-in protective features, such as guards or detection devices, are ideal for safe operation.

- Budget, Maintenance and Safety: The total cost, including the purchase and maintenance, should also not be disregarded.

Evaluating the Types of Cleaning Services Needed

To better evaluate your operational demands, first focus on identifying the unwanted materials and marking the areas to be cleaned. Define how often the area needs cleaning and how clean the area has to be after cleaning. Think about the dimensions of the area or items to be cleaned. Decide if manual or automated systems would be advantageous. Combine these elements with your objectives to come up with the most effective approach.

Power and Performance Evaluation of Lasers in Cleaning Processes

It is very important to grasp the dynamics of cleaning efficiency in relation to laser power. The value of a laser’s energy is determined by the laser power; therefore, begouing surface cleaning, the cleaning speed, and effectiveness are dependent on the level of laser power at work. Processing is faster with high power lasers, especially when the surface being cleaned is heavily soiled, thick, or caked with grime, while lower power lasers are suitable for faster, more precise cleaning without harming more delicate, precision engineered materials.

Recent developments in lasers demonstrates the need to properly customize power for each case. For example, industrial applications of lasers indicate that a rest or paint remover laser operating at a power of 1000W can clean at a phenomenal rate of 45 square meter per hour. Whereas the cleaning of more delicate surfaces like in the case of artwork restoration requires the use of lasers with powers ranging between 20W and 100W.

In addition, the selection of pulse frequency and energy density is equally important, as these parameters work in synergy with power towards achieving material removal efficiency without damage. In this case, optimizing combination of these parameters with surface material and the type of contaminant provides a reasonable level of risk and safety. Moreover, industry reports recommend combining certain power settings with automated controls to minimize operator involvement, which tremendously enhances productivity.

Factors Accepting Laser Cleaning Machine Prices

Considering the extent of cleaning, lower powered (20W to 50W) entry-level machines sell at approximately $8,000 to $15,000. These machines are designed for simple cleaning and small-scale tasks. On the other hand, industrial-grade machines (100W to about 1,000W and more) sell between $30,000 to over $100,000 due to enhanced performance in heavy-duty applications.

Automation controls increase productivity and precision, which is another factor of expense. Although the initial costs for these advanced features, deep cost savings are achieved with reduced labor, operational errors, and improved overall productivity.

Maintenance and operational costs also affect the value estimation. Because modern laser cleaners frequently run without chemicals, their consumables are at a bare minimum. This not only lowers maintenance costs, but also provides a cost effective and environmentally friendly solution. In addition, high efficiency models can reduce power usage, saving money and recovering the cost over time.

Ultimately, pricing is influenced by geographic location and supplier networks due to shipping costs, parts availability, and local demand conditions. These factors should be analyzed in combination with business operational needs to essentially balance value with cost when assessing the value of laser cleaning machines.

Reference sources

- Advances in Laser Cleaning of Artwork1:

- Key Findings: This study focused on optimizing pulse durations for cleaning delicate materials like encrusted stones and metals. It highlighted the importance of selecting pulse durations (tens of nanoseconds to microseconds) to minimize thermal and mechanical damage while maximizing cleaning efficiency.

- Methodology: The research combined physical modeling and experimental evidence to evaluate the effects of laser parameters on various substrates, including cultural heritage artifacts.

- Laser Cleaning and Its Advancements2:

- Key Findings: This chapter reviewed various laser cleaning methods, including pulsed and continuous wave (CW) lasers. It emphasized the eco-friendly nature of laser cleaning and its applications in industries like medical and aerospace.

- Methodology: The study discussed experimental solutions, challenges, and advancements in laser cleaning technologies, including machine learning applications for monitoring.

- Dynamic Monitoring in Laser Cleaning3:

- Key Findings: This paper reviewed online monitoring technologies for laser cleaning, such as wave vibration, plasma spectrum, and thermal radiation. It proposed integrating these methods with intelligent algorithms to enhance cleaning precision and prevent substrate damage.

- Methodology: The research analyzed the principles and applications of various monitoring techniques, focusing on their role in ensuring cleaning consistency and efficiency.

- Top Pulse Laser Cleaning Machines Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the difference between continuous and pulsed laser cleaning machines?

A: The difference is in how laser energy is emitted. Continuous laser cleaning machines give off a constant stream of laser energy. In contrast, pulsed laser cleaning machines utilize bursts of energy, offering more control during the cleaning process.

Q: When should I choose pulse laser cleaning over continuous laser cleaning?

A: Choose pulse laser cleaning for tasks that require high precision and control, such as cleaning delicate surfaces. It’s ideal for cleaning surfaces that need careful handling.

Q: What are the advantages of a continuous laser cleaning machine?

A: Continuous laser cleaning machines excel in the speedy cleaning of expansive areas. They are highly effective for those tasks that do not require attention to detail and are economically favorable in cases of bulk industrial cleaning.

Q: How do pulse laser cleaning machines achieve better cleaning results on sensitive materials?

A: Pulse cleaning machines use more controlled parameters, particularly the width of the pulse (pulse width), to clean sensitive materials without overheating or damaging the substrate.

Q: Can continuous and pulsed laser cleaners be used for mold cleaning?

A: Yes, both types can be used for cleaning molds. The difference is the material of the mold, the level of precision required, and Choice of Continuous vs Pulsed Laser.

Q: Are there any specific industries where continuous fiber lasers are more suitable?

A: Continuous fiber lasers are Better suited for high speed and large area cleaning applications like automotive, aerospace, and manufacturing industries. These sectors put a premium on fast service.

Q: Can a handheld laser be used for both continuous and pulsed laser cleaning?

A: Yes, handheld lasers can be made to employ either continuous or pulsed laser cleaning, but the choice will depend on the specific cleaning task and the desired cleaning result.

Q: What is the cleaning effect difference between pulse and continuous laser?

A: Pulse lasers have a more refined cleaning effect while preserving detail on the substrate pedetail work. Continuous lasers provide broader action and faster clean area but may require less delicate substrate.

Q: What is the importance of laser energy concerning the cleaning process in continuous and pulsed laser cleaning methods?

A: In continuous laser cleaning, the constant laser energy is efficient for bulk cleaning tasks. In pulsed cleaning, controlled energy bursts minimize the heat impact and permit selective material removal.

Q: What should be highlighted when opting for cleaning machinery over pulse laser technology?

A: Assess the workpiece material to be cleaned, the level of precision needed, the spatial extent of the surface area, and the possibility of inflicted damage. Pulse lasers are superior in precision and control while continuous ones are better in speed.

- The Ultimate Guide to Laser Surface Cleaning Safety: Protecting Yourself While Using a Laser Cleaner

- Pulse vs Beam vs Burst Lasers: Continuous Weapon Comparison?

- The Complete Laser Cutter Buying Guide: Choosing the Best Laser for Your Needs

- Extend the Service Life of Your CO2 Laser Tube: Essential Tips & Tricks