When it comes to precision cutting methods in modern manufacturing and fabrication, two technologies often dominate the conversation—laser cutting and plasma cutting. Both have revolutionized the way industries approach material processing, offering unique advantages tailored to different applications. But how do you determine which method is best suited for your needs? This blog will serve as a comprehensive guide, breaking down the key differences, benefits, and limitations of laser cutting and plasma cutting. Whether you’re looking for unparalleled precision, cost efficiency, or versatility in material handling, this article will provide you with the insights needed to make an informed decision. Join us as we explore these cutting-edge technologies and uncover the strengths of each approach.

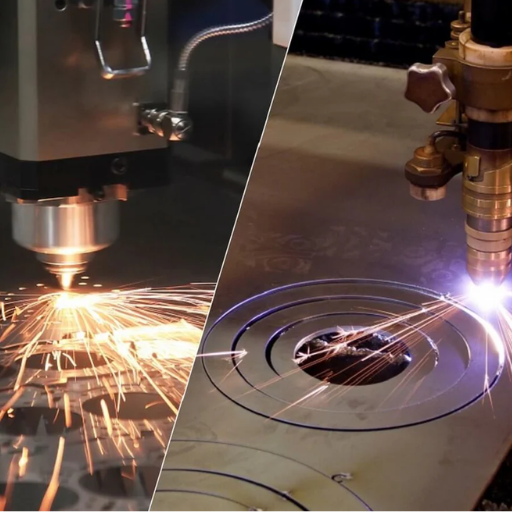

What Are the Key Differences Between Laser Cutting and Plasma Cutting?

Laser cutting and plasma cutting differ primarily in their methods, level of precision, and material compatibility. Laser cutting uses a focused beam of light to melt or vaporize materials, offering exceptional precision and clean edges, making it ideal for intricate designs and thinner materials such as metals, plastics, and wood. On the other hand, plasma cutting employs ionized gas (plasma) to cut through electrically conductive materials like steel and aluminum, excelling in cutting thicker materials but generally delivering less precision compared to laser cutting. Additionally, laser cutting operates at a slower speed for thicker materials, whereas plasma cutting is faster and more cost-effective when working with dense metals.

How Does a Laser Cutter Work Compared to a Plasma Cutter?

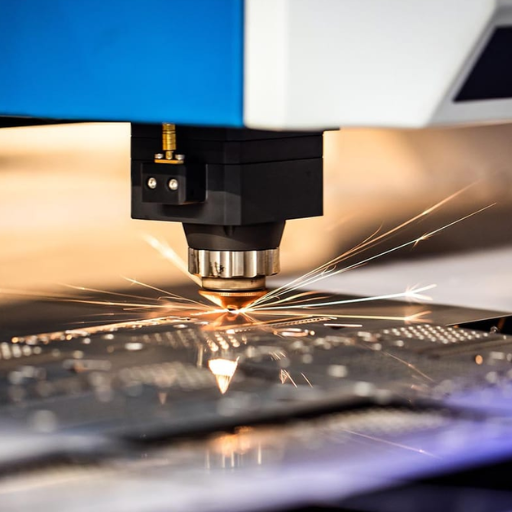

Laser cutters and plasma cutters operate on fundamentally different principles, each tailored for specific applications and material types. A laser cutter utilizes a high-powered laser beam, which is directed through optical systems to focus intense thermal energy onto a small area. This energy melts, burns, or vaporizes the material, resulting in a precise and clean cut. Laser cutters are particularly effective for cutting thinner materials with high precision, such as wood, plastics, and metals like stainless steel and aluminum. CO2 lasers and fiber lasers are common types, with fiber lasers providing superior performance on metals.

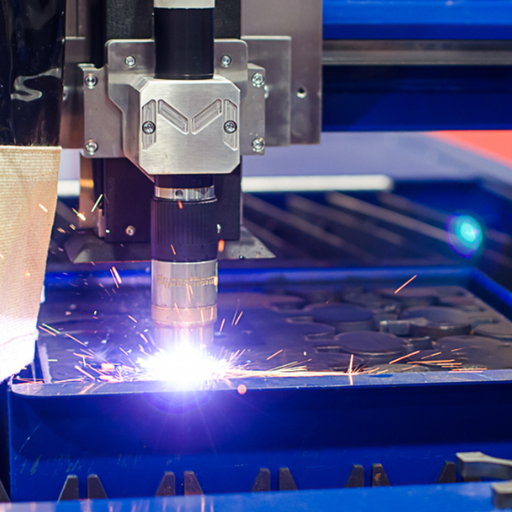

On the other hand, plasma cutters employ an accelerated jet of hot plasma, generated by ionizing gas, to cut through conductive materials. Plasma cutters excel at slicing thicker materials like mild steel, stainless steel, and aluminum at a faster speed compared to laser cutters. For example, a plasma cutter can efficiently process steel plates up to 1 inch thick, while a laser cutter is generally better suited for thin sheets up to 0.5 inches with finer detail. According to industry benchmarks, plasma cutting often results in a lower operating cost for heavy-duty applications, while laser cutting is more economical for precision work on thinner materials.

The choice between these technologies depends on the specific requirements of the project, with laser cutters standing out for detailed, intricate designs and plasma cutters leading in speed and cost-effectiveness for heavy-duty tasks. Both methods demonstrate remarkable advancements in modern manufacturing, thanks to their ability to deliver consistent and reliable performance across a range of applications.

What Materials Can Laser Cutting vs Plasma Cutting Handle?

Laser cutting and plasma cutting are both highly versatile technologies, but they differ significantly in the types of materials they can handle effectively.

Laser Cutting

Laser cutting excels in working with non-metallic and metallic materials alike, making it ideal for precision applications. It is commonly used on materials such as stainless steel, carbon steel, aluminum, brass, copper, wood, acrylic, and plastics. However, the efficiency of laser cutting depends on material thickness – high-powered lasers can cut metals up to 1 inch thick, but it is most effective for thinner materials where precision and intricate detailing are required. For non-metallic materials like plastics and wood, laser cutting offers clean edges without physical contact, which reduces the risk of material deformation. Additionally, advanced fiber lasers allow for faster processing of reflective metals, such as aluminum and gold, a feature that expands its application range in industries like aerospace and electronics.

Plasma Cutting

Plasma cutting, in contrast, is better suited to conductive metals and thicker materials. It is commonly used to cut steel, stainless steel, aluminum, cast iron, and other conductive alloys. Unlike laser cutting, plasma cutters can handle thicker metal sheets efficiently, often cutting materials up to 2 inches thick with ease. This makes it the go-to choice for heavy-duty industrial applications, such as shipbuilding, automotive repair, and construction. Plasma cutters are also faster compared to lasers when working on thick metals, providing cost-effective solutions for projects that prioritize speed over pinpoint precision.

Comparing the Cutting Process Efficiency and Precision

When evaluating the cutting process, factors such as speed, energy consumption, accuracy, and material adaptability are critical in determining overall efficiency and precision. Below is a breakdown of common cutting technologies:

Laser Cutting

Laser cutting is renowned for its high precision and clean edges, particularly effective for thin and medium-thickness materials like metals, plastics, and wood. Modern laser machines achieve cutting speeds of up to 20-30 m/min for thin sheets, depending on material type. This method has an advantage in minimizing waste but can consume significant energy—up to 10 kW for high-powered systems. Additionally, laser cutters struggle with reflective materials or excessively thick metals due to potential beam scatter and insufficient penetration.

Plasma Cutting

Plasma cutting excels in efficiency when working with thick, conductive metals such as steel and aluminum. With cutting speeds reaching 2 m/min for materials up to 25 mm thick, it is a preferred method in heavy industries. Plasma systems offer less precision compared to laser cutting, with a kerf width (cut width) of approximately 1.5 mm. The energy usage is relatively high, ranging between 6 and 12 kW during operation, but the robust performance for thicker materials makes it a cost-effective solution for industrial applications.

Waterjet Cutting

Waterjet cutting stands out for its ability to cut a vast range of materials, including ceramics, composites, and metals, without thermal distortion. Equipped with abrasive additives, waterjet systems can cut materials up to 200 mm thick with an accuracy of ±0.1 mm. However, the process is slower compared to laser or plasma techniques—cutting speeds can range from 0.2 to 2 m/min, depending on material and thickness. Waterjets are energy-intensive, with power consumptions reaching 20-30 kW, but their versatility and environmental friendliness (minimal waste generation) make them a popular choice.

Oxy-Fuel Cutting

This traditional method is still widely used for cutting very thick steel, often exceeding 300 mm. While oxy-fuel is less precise (kerf widths can exceed 2 mm), it is highly effective for rough-cutting applications. It operates at slower speeds than other technologies, averaging 0.2-0.5 m/min, but its equipment is relatively low-cost. Energy usage depends on the oxygen and fuel combination but is generally less efficient than modern methods.

How Does the Operating Cost Compare Between Laser and Plasma Cutting?

When comparing operating costs, plasma cutting generally has a lower overall cost than laser cutting. Plasma cutting equipment is typically less expensive to purchase, and it has lower maintenance requirements. Additionally, the consumables for plasma cutting, such as electrodes and nozzles, are relatively affordable.

Laser cutting, while offering greater precision and quality, comes with higher operating costs due to the expensive maintenance of optical systems, gas usage, and energy consumption. These higher costs are offset by its ability to produce intricate, high-quality cuts, making laser cutting more suitable for applications where precision is critical.

Ultimately, the choice depends on the required balance of cost-efficiency and cutting quality.

What Are the Consumable Costs for Each Cutting Method?

When considering the consumable costs for each cutting method, I find that plasma cutting generally incurs lower costs due to its reliance on electricity and compressed air, though replacement of torch consumables like nozzles and electrodes adds to expenses over time. For oxy-fuel cutting, the primary costs involve oxygen and fuel gases, which can be significant, especially during prolonged use. Meanwhile, laser cutting tends to have the highest consumable costs, as it requires precise gases like nitrogen or oxygen, alongside periodic maintenance of optics and the laser source itself.

Which Method Has Lower Operating Costs Over Time?

From my perspective, determining which method has lower operating costs over time depends on the specific application and usage patterns. Generally, plasma cutting offers a balance between initial costs and ongoing expenses, making it cost-effective for many users. Oxy-fuel cutting can also be affordable if the use of fuel gases is managed efficiently and the material being cut fits its capabilities. However, laser cutting, while precise and versatile, often incurs the highest costs due to its reliance on specialized gases and maintenance requirements.

Which Cutting Machine Is Right for Your Needs?

Choosing the right cutting machine depends on your specific requirements. If you need precise, detailed cuts and are working with thinner materials, a laser cutter is ideal, though it comes with higher costs. For thicker materials and rougher cuts, oxy-fuel cutting is a reliable and affordable option, especially for steel. If versatility, speed, and the ability to handle a variety of materials are your priorities, a plasma cutter is the most balanced choice. Consider the material type, budget, and production volume to determine which machine best suits your needs.

When to Choose a Laser Cutting Machine?

Laser cutting machines excel in applications requiring high precision and intricate designs. They are ideal for industries such as aerospace, automotive, jewelry, and signage production, where accuracy and clean edges are paramount. For instance, modern laser cutting machines can achieve tolerances as thin as 0.001 inches, ensuring detailed and flawless results.

Another compelling reason to opt for a laser cutting machine is its material versatility. These machines can cut through a wide range of materials, including metals, plastics, wood, acrylic, and even fabrics. Advanced CO2 and fiber laser technologies expand this versatility further. For example, fiber lasers are particularly efficient for cutting metals like stainless steel and aluminum due to their higher energy efficiency and shorter wavelength.

Costs are another consideration. While the initial investment in a laser cutting machine is higher compared to alternatives like plasma cutting or mechanical cutting, long-term productivity gains often offset this expense. Many laser cutting systems feature automation options, such as conveyor systems and material feeders, which significantly increase production speeds and reduce labor costs.

Additionally, technological advancements have boosted the energy efficiency of new models. By consuming less electricity per operation, modern machines can help businesses reduce running costs and environmental impact. Studies show that fiber lasers, for example, use up to 50% less energy than older laser technologies.

Ultimately, choose a laser cutting machine if your project demands exceptional precision, versatility across materials, and the capacity for high-volume production, particularly within industries relying on cutting-edge technology and intricate designs.

Why Opt for a Plasma Cutting Machine?

Plasma cutting machines are highly efficient tools designed to cut through electrically conductive materials with incredible precision and speed. This makes them particularly suitable for cutting metals like steel, aluminum, and copper. These machines operate by creating a superheated ionized gas, or plasma, which slices through materials at temperatures often exceeding 20,000°C.

One of the key advantages of plasma cutting is its ability to handle thick materials effectively. Modern plasma cutters can cut materials up to 2 inches thick, making them ideal for industries such as construction, automotive repair, and metal fabrication. Additionally, plasma cutting machines process materials faster compared to many alternatives, with cutting speeds often surpassing 20 inches per minute for medium-thickness metals.

Advancements in plasma cutting technology have introduced CNC (Computer Numerical Control) integration, ensuring exceptionally accurate and repeatable cuts, even for intricate designs. Furthermore, plasma cutters are known for their cost-efficiency. They generally have lower operating costs than comparable cutting methods, as they require less maintenance and consume fewer resources, such as compressed air or oxygen.

For businesses prioritizing speed, precision, and versatility, plasma cutting machines represent a practical investment. They deliver robust performance across a range of applications, from large-scale industrial projects to detailed, custom fabrication tasks.

Considerations for Metal Fabrication Projects

When planning metal fabrication projects, a few key considerations ensure efficiency and quality. First, choose the appropriate material based on the project’s structural and aesthetic requirements; factors like durability, weight, and corrosion resistance are critical. Next, select the ideal fabrication process, such as cutting, welding, or bending, to match the material and design specifications. Additionally, ensure precise measurements and clear design blueprints to minimize errors and material waste. Finally, consider the timeline and budget to allocate resources effectively, and collaborate with experienced professionals to achieve the desired results.

What Are the Advantages of Fiber Laser Cutting?

Fiber laser cutting offers several key advantages that make it a preferred choice for many industries. Firstly, it provides exceptional precision, allowing for clean and accurate cuts even on intricate designs. Secondly, it boasts faster cutting speeds compared to traditional methods, reducing production time. Thirdly, it is highly versatile, capable of handling a wide range of materials, including metals, plastics, and composites. Additionally, fiber lasers are energy-efficient and require minimal maintenance, resulting in cost savings over time. These benefits make fiber laser cutting a reliable and efficient solution for high-quality manufacturing needs.

Understanding the Laser Beam in Fiber Laser Cutting

At the core of fiber laser cutting lies the precision and intensity of the laser beam. This highly focused beam of light is produced by amplifying light through optical fibers that are infused with rare-earth elements such as ytterbium. The wavelength of fiber lasers typically ranges around 1.06 microns, which allows the beam to achieve high absorption rates on metals and other materials. This characteristic is key to its cutting efficiency and ability to handle diverse applications.

When it comes to power, modern fiber lasers boast impressive performance metrics. Current industrial fiber lasers operate at power levels ranging from a few hundred watts to over 10 kilowatts, depending on application requirements. Higher power lasers enable faster cutting speeds and the ability to process thicker materials with minimal distortion, making them invaluable in industries like aerospace, automotive, and electronics manufacturing.

Fiber lasers also exhibit higher beam quality, defined by a low beam parameter product (BPP). A lower BPP ensures the laser delivers maximum energy density to the material, allowing for more precise and clean cuts. This refinement significantly reduces the need for post-processing, saving time and resources.

Additionally, advancements in technology have made fiber laser systems more efficient, achieving optical efficiencies of over 35% in many cases. This substantial efficiency reduces energy consumption, aligning with sustainability goals and lowering operational costs. Further innovations, such as adaptive beam shaping and real-time monitoring systems, enhance accuracy and adaptability, ensuring consistent results across complex and intricate designs.

These qualities make the fiber laser beam a pinnacle of innovation in the realm of precision cutting, enabling manufacturers to push the boundaries of quality, speed, and versatility.

Benefits of Fiber Laser Cutters Over Other Technologies

- Enhanced Precision and Accuracy

Fiber laser cutters utilize highly focused laser beams to achieve unparalleled cutting precision. This level of accuracy allows for creating intricate designs and handling delicate materials with minimal errors. Studies indicate that fiber laser systems can reduce dimensional variability by up to 30% compared to traditional cutting technologies.

- Higher Cutting Speeds

Compared to CO₂ and plasma cutters, fiber lasers operate at significantly faster speeds, especially when working with thin materials. For example, fiber lasers can cut 1mm stainless steel at speeds up to 5 times faster than CO₂ lasers, increasing productivity and reducing turnaround times.

- Energy Efficiency

Fiber lasers use up to 50% less energy than CO₂ lasers for similar tasks, making them not only cost-effective but also environmentally friendly. The high efficiency of their diode-pumped technology results in lower electricity consumption and reduced heat generation.

- Low Maintenance Requirements

With fewer moving parts and no reliance on mirrors or gases, fiber laser cutters require minimal maintenance. Their solid-state design ensures longevity and reliability, cutting downtime and operational disruptions.

- Versatility Across Materials

Fiber laser cutters can handle a wide variety of materials, including metals, plastics, and composite materials. They excel in cutting reflective metals such as aluminum and brass, where traditional laser systems often struggle.

- Compact Design and Space Efficiency

Fiber lasers are compact and space-efficient, making them an ideal choice for facilities looking to optimize available floor space. Their all-in-one design reduces the need for additional equipment or components.

- Improved Safety Features

Many fiber laser systems come with built-in protective casings, sensors, and automated stop mechanisms to enhance workplace safety. Low levels of emitted heat also reduce the risk of material deformation and fire hazards.

- Cost-Effectiveness in the Long Term

Although the initial investment for fiber laser systems may be higher, their reduced operating costs, energy savings, and minimal maintenance needs ensure a quicker return on investment (ROI). Studies reveal that fiber laser cutters can reduce overall production costs by up to 20% over time.

These benefits make fiber laser cutters a revolutionary choice, paving the way for future advancements in manufacturing and design.

How Does Plasma Cutting Work in Different Applications?

The process of plasma cutting involves passing gas like oxygen, nitrogen, or argon at high speeds through a nozzle with an electric arc aimed at it. The resulting combination of the gas and electric arc forms plasma, whose extreme temperatures allow it to precisely cut through aluminum, steel, and stainless steel. During plasma cutting, a plasma arc that is electrically conductive is used to both melt and slice through the given material.

Plasma cutting is used for everything from industrial fabrication to automotive repair and even artistic metal working. It is plasma’s ability to handle large quantities of thick metals and warmth to cut complex shapes that made plasma cutters particularly valued. In industries where time and precision are core components of the job, plasma cutting makes an excellent addition to the list of tools used.

Exploring the Plasma Arc Technology

Plasma arc technology operates by generating an electric arc through a gas, which is then ionized to create plasma. This plasma reaches extremely high temperatures, allowing it to cut through various metals with remarkable precision and speed. The process involves directing the plasma stream through a constricted nozzle, focusing both heat and force to achieve clean, precise cuts. Key benefits of plasma arc technology include its ability to cut different metal types, handle varying thicknesses, and maintain efficiency in high-demand environments. Its reliability and effectiveness make it a critical tool in industries like manufacturing, construction, and automotive repair.

Using a Plasma Torch for Metal Cutting

Plasma torches offer a unique combination of precision, speed, and versatility, making them an essential tool for metalworkers across various industries. When it comes to cutting, plasma torches can handle a wide range of materials efficiently, including steel, aluminum, and other conductive metals. The speed of operation is notable; plasma cutters can slice through thin metal sheets at rates of up to 200 inches per minute (IPM) depending on the equipment and material type. They are also capable of cutting metals up to 1 inch thick or more with ease, depending on the model and amperage used.

Another significant advantage is the quality of the cuts. Plasma torches produce smooth, clean edges with minimal dross, reducing the need for extensive post-cut finishing. Additionally, modern plasma cutting systems integrate advanced technology such as CNC (computer numerical control), enabling automated and highly accurate patterns to be achieved for complex projects.

Energy efficiency is another key factor. Many modern plasma torches are designed to optimize power usage while minimizing waste, making them both cost-effective and environmentally friendly. With their ability to deliver consistent and impressive results, plasma torches stand out as a reliable solution for metal cutting needs in workshops and industrial settings.

Choosing Between Laser vs Plasma for Metal Cutting Needs

When choosing between laser and plasma cutting, consider the type of material, thickness, and precision required. Laser cutting excels in achieving fine detail and is most effective on thin materials like stainless steel, aluminum, or other non-ferrous metals. It offers high precision and a clean finish, making it ideal for intricate designs or projects requiring minimal post-processing.

Plasma cutting, on the other hand, is better suited for thicker and conductive materials such as steel, as it provides faster cutting speeds at a lower cost. It is less precise than laser cutting but highly efficient for industrial applications or jobs where precision is less critical.

Ultimately, the right choice depends on the specific needs of your project—prioritize laser cutting for accuracy and intricate work, and plasma cutting for cost efficiency and handling thicker materials.

Factors to Consider When Selecting a Cutting System

When deciding on the most suitable cutting system for your project, it’s essential to evaluate a range of factors to ensure optimal performance and efficiency. Below is a comprehensive list of the key factors to consider:

- Material Type and Thickness

-

-

- Laser cutting excels at handling thin materials like stainless steel, aluminum, and other non-ferrous metals, delivering precise and clean cuts.

- Plasma cutting is better suited for thicker and more conductive materials, such as steel plates up to several inches thick.

-

- Precision Requirements

-

-

- Projects requiring intricate designs or highly detailed cuts benefit greatly from laser cutting, as it produces a high degree of accuracy with minimal material distortion.

- For less detailed applications where precision is not critical, plasma cutting can be a cost-effective solution.

-

- Cutting Speed

-

-

- Plasma cutting offers faster cutting speeds, especially on thicker materials, which makes it ideal for large-scale industrial applications with tight deadlines.

- Laser cutting is generally slower but compensates by delivering unparalleled precision and quality.

-

- Cost Efficiency

-

-

- Laser cutting equipment typically involves higher upfront costs due to advanced technology and maintenance requirements. However, its precision and reduced waste may offset these costs over time for complex projects.

- Plasma cutting systems are more affordable upfront and provide excellent value for cutting thicker materials where extreme precision is not a priority.

-

- Edge Quality

-

-

- For clean, high-quality edges with minimal finishing required, laser cutting is the better choice.

- Plasma cutting edges can sometimes require additional finishing, especially when cutting thicker materials.

-

- Power Source and Energy Consumption

-

-

- Laser cutting consumes less energy for thin materials but may demand higher operating costs for thicker metals due to increased laser power requirements.

- Plasma cutting often requires more energy to generate and sustain the plasma arc but balances this by being faster for heavy-duty tasks.

-

- Production Volume

-

-

- Higher production volumes with repetitive designs may favor laser cutting due to its consistent precision and automation capabilities.

- Plasma cutting remains an ideal option for one-off projects or jobs with fewer pieces due to its speed and cost-effectiveness.

-

- Safety Concerns

-

-

- Laser cutting systems typically come equipped with enclosed units and safety mechanisms to manage intense light and heat, reducing risks to operators.

- Plasma cutting systems may present more safety challenges, such as handling sparks, fumes, and molten material, requiring proper safety protocols.

-

- Machine Maintenance and Operational Complexity

-

-

- Laser cutting systems can demand higher maintenance and technical expertise, especially for advanced machinery like fiber lasers.

- Plasma cutters are generally easier to maintain and repair, making them a convenient option for less technical environments.

-

By carefully evaluating these factors, you can make an informed decision that aligns with your project requirements, budget, and operational goals.

Comparing Cutting Technologies for Various Industries

Cutting technologies play a vital role in a wide range of industries, each requiring unique solutions tailored to specific materials, precision levels, and production speeds. Here is a closer look at how laser and plasma cutting technologies compare across various applications:

1. Manufacturing and Fabrication

Laser cutting systems have become a powerhouse in precision-driven manufacturing. With the ability to produce intricate designs with tolerances as tight as ±0.1 mm, they are ideal for creating components in automotive, aerospace, and electronics sectors. Fiber lasers, in particular, are highly effective for cutting reflective metals, such as aluminum and copper, due to their shorter wavelengths and efficiency.

Plasma cutting, on the other hand, is widely used in heavy fabrication and construction industries. Capable of cutting through thicker materials (up to 2 inches or 50 mm), plasma cutters excel in working with structural steel and large-scale metal assemblies. Their speed and cost-effectiveness make them a popular choice for industrial workshops.

2. Energy and Shipbuilding Sectors

For industries like energy production and shipbuilding, where handling massive steel plates is common, plasma cutting often dominates. Its ability to cut at high speeds and handle rugged environments makes it invaluable for tasks such as assembling oil rigs or ship hulls.

However, laser cutting is increasingly gaining traction in energy applications requiring fine detailing, such as manufacturing turbine blades or photovoltaic equipment, due to its unparalleled precision and minimal heat distortion.

3. Medical and Electronics Industries

Within the medical industry, laser cutting is indispensable for producing highly detailed surgical instruments and implantable medical devices. Its precision ensures clean edges and maintains the integrity of delicate materials like titanium or specialized plastics. Similarly, in electronics, laser systems enable micro-cutting of circuit boards and fine-featured components.

Plasma cutting is less commonly used in these sectors due to its comparatively lower precision but is occasionally employed for large-scale metal preparation tasks.

Reference Sources

-

Material and Technological Aspects while Processing of Selected Ultra High Strength Steel1:

- Focus: Examines the effects of laser and plasma cutting on ultra-high-strength steel.

- Key Findings: Laser cutting produces a smaller heat-affected zone (HAZ) compared to plasma cutting, resulting in better precision and less material distortion. Plasma cutting, however, is more cost-effective for thicker materials.

- Methodology: Comparative analysis of HAZ and material properties post-cutting.

-

Modeling and Prediction of Water-Jet-Guided Laser Cutting Depth for Inconel 718 Material2:

- Focus: Investigates water-jet-guided laser cutting as an alternative to traditional laser cutting.

- Key Findings: Water-jet-guided laser cutting reduces thermal damage and improves cutting quality compared to conventional laser methods. It is particularly effective for high-precision applications.

- Methodology: Orthogonal experiments and response surface methodology were used to optimize cutting parameters.

-

Comparison of Metal Water Jet Cutting with Laser and Plasma Cutting3:

- Focus: Compares water jet, laser, and plasma cutting technologies for metal processing.

- Key Findings: Laser cutting excels in precision and minimal material waste, while plasma cutting is faster and more economical for thicker materials. Water jet cutting offers versatility but at a higher operational cost.

- Methodology: Comparative analysis of cutting speed, precision, and cost-effectiveness.

- Top Laser Engraving and Cutting Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What are the key differences when comparing laser cutting and plasma cutting?

A: When comparing laser cutting and plasma cutting, the main differences lie in the cutting process, precision, and material compatibility. Laser cutting uses a focused laser beam for precision and is ideal for thinner materials, while plasma cutting uses an electric arc and compressed gas to cut through thicker materials like sheet metal.

Q: How do laser cutters use technology to achieve precision?

A: Laser cutters use a concentrated beam of light generated by a cnc laser system to cut or engrave materials with high precision. This method allows for intricate designs and is suitable for applications requiring detailed work.

Q: What advantages do laser cutting services offer over plasma cutting services?

A: Laser cutting services offer greater precision and cleaner cuts, making them ideal for applications requiring fine details. They are also more suitable for materials like wood, acrylic, and thin metals, whereas plasma cutting services excel in cutting thicker, conductive materials.

Q: Why might one choose plasma cutting services instead of laser cutting services for metal fabrication?

A: One might choose plasma cutting services over laser cutting services for metal fabrication when working with thicker metals. Plasma cutting is often faster and more cost-effective for cutting thick sheet metal and is more versatile in handling rough surfaces.

Q: Can laser cutting or plasma cutting be used for all types of metals?

A: Laser cutting and plasma cutting can be used for a variety of metals, but each has its limitations. Laser cutting is less effective on thicker metals, while plasma cutting is not ideal for non-conductive materials. Choosing between these methods depends on the material thickness and desired precision.

Q: How does a CNC plasma cutting machine differ from a CNC laser cutting machine in operation?

A: A CNC plasma cutting machine uses an electrical arc and compressed gas to melt and blow away molten metal, making it suitable for cutting thicker metals. In contrast, a cnc laser cutting machine uses a focused laser beam for precise cuts, ideal for thinner materials and intricate designs.

Q: Which cutting method is faster: laser or plasma cutting?

A: Plasma cutting is generally faster than laser cutting, especially for thicker materials, due to its ability to handle larger volumes of molten metal quickly. However, laser cutting provides higher precision, which can be more time-efficient for detailed work.

Q: What types of cutting machines use thermal cutting processes?

A: Both laser and plasma cutting machines use thermal cutting processes. Plasma cutting uses an electric arc for melting, while laser cutting employs a laser beam for heating and cutting through materials.

Q: What are the typical applications for CNC plasma cutting vs laser cutting?

A: CNC plasma cutting is typically used for cutting thick metals, such as steel and aluminum, in industrial applications. CNC laser cutting is favored for its precision and is often used for cutting thinner materials, engraving, and creating detailed designs in industries like automotive and electronics.

- CNC Router vs. CNC Mill: Key Differences Between a CNC

- Fiber vs. CO2 vs. UV: Which Laser Engraver is Right for You?

- Master the Art of Tree Trimming: Essential Pruning Tools and Techniques

- Understanding Fibre Laser Cutting Machines: A Comprehensive Guide

- Understanding Speed in Laser Marking: How to Optimize Your Laser Marking Machine

- The Complete Laser Cutter Buying Guide: Choosing the Best Laser for Your Needs

- The Ultimate Guide to Laser Surface Cleaning Safety: Protecting Yourself While Using a Laser Cleaner

- CNC Cutting vs Fiber Laser Cutting: Which is the Better Option?