CO2 laser marking machines transformed the precision processes of industrial engraving, etching, and marking. Whether as a manufacturer, a DIY laser engraving hobbyist, or a business owner looking to explore new production strategies, RF laser engraving technology provides unrivaled precision, speed, and adaptability. But what distinguishes RF laser engraving from other engraving methods? What about efficiency, cost, and application comparisons?

This guide will teach you about CO2 laser marking machines that utilize RF technology, the science behind the devices, their practical applications across varying industries, and much more. Prepare to learn all the angles of CO2 laser marking devices and understand why they are renowned as modern manufacturing marvels.

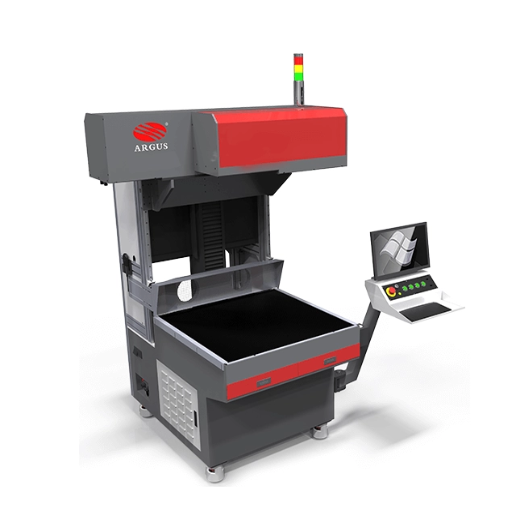

What is a CO2 Laser Marking Machine?

A CO2 Laser Marking Machine is a tool that utilizes a carbon dioxide gas laser to etch specific marks, patterns, or engravings on several types of materials. It does this by blasting a high-intensity laser beam onto the surface of a material. The mark might be permanent through engraving, alteration of the material’s color, or removing a layer. CO2 laser marking machines are popular as they work with materials such as glass, wood, paper, plastics, and ceramics. CO2 laser marking has a wide range of industrial applications, including decor marking, product labeling, decorative markings, and serial numbering, due to being fast, precise, and enduring.

How does a CO2 laser engraving machine work?

A CO2 laser engraving machine works by overcoming materials using a powerful, high-intensity laser beam that operates with a CO2 gas mixture. The laser has a wavelength measuring 10.6 micrometers, which places it in the infrared window. It passes through a set of mirrors and lenses that help direct and focus it on the workpiece surface. The sharp and focused beam reduces the workpiece to vapor, liquid, or solid (depending on the machine’s diverse power settings and attributes) due to the high energy produced at the focal point.

Various machines today have options to input designs using specialized software like AutoCAD, CorelDRAW, or even Adobe Illustrator. The machine renders these files and moves with unprecedented accuracy, achieving repeatability at exceptional standards. The sophisticated engraving devices don’t lag in achieving engraving rates beyond 1,000mm per sec and offering resolution levels rising to 1,000 dots per inch. This unparalleled performance and precision make laser machines suitable for fine detail engravings.

CO2 lasers can effectively cut and engrave various non-metallic materials such as wood, leather, fabric, rubber, and acrylic. They can also engrave anodized aluminum and coated metals. The power of these lasers varies from 20W for small applications to over 200W for industrial uses. Lower-powered lasers are limited to shallow engravings, while higher-powered lasers can process materials much faster. Newer models are equipped with air assist features that eliminate debris on the laser path, preventing damage to the machine. In contrast, others have advanced fume management equipment to maintain cleanliness during operations.

Optimizing performance relies on beam quality, lens alignment, and temperature control. With the rapid advancement in technology, some CO2 laser cutters now come equipped with AI-powered software and IoT systems that enable real-time monitoring of the machine’s performance. This, along with remote diagnosis capabilities, allows for little downtime, maximizing efficiency.

Due to their precision and adaptability, CO2 laser engraving machines have become essential in the design, artistic, industrial customization, and manufacturing industries.

What materials can be engraved with a CO2 laser?

CO2 laser engraving machines can engrave materials like acrylic, wood, glass, leather, and so on accurately and precisely. A detailed analysis of the materials engravable with CO2 laser:

- Wood

For engraving wood, the CO2 laser has no competition. The results are incredibly clean, and the engraved details are very clear. Their precision enables the crafting of custom logos, signs, and even more complex decorative pieces. Types of wood include MDF, hardwoods like maple or cherry, and plywood.

- Acrylic

Acrylic gives the CO2 laser engraver the best results. It is due to its smooth surface, which ensures that engraving is done on crisp edges. Its appeal is widespread in signage, art displays, and awards due to its professional look.

- Glass

CO2 lasers can etch designs into engraved glasses, bottles, and windows. The end result of the laser effect is a striking yet elegant frosted glass look. This works best as a personal gift or as decor.

- Leather

Engravable leather products include wallets, bags, and belts. CO2 laser engraving enhances the quality of the product. This is achieved by precisely burning a design into a product without damaging the texture, durability, or softness of the leather.

- Cardstock and Paper

With CO2 lasers, paper and cardstock can be engraved and cut with finesse. This is commonly utilized for custom invitations, business cards, and elaborate packaging designs.

These materials only demonstrate a small fraction of the possibilities when working with CO2 laser engravers, illustrating their versatility across industries and applications.

What are the key features of a CO2 laser marking machine?

- Precision Along with High Accuracy

With a CO2 laser marking machine, the error margins on intricate designs and text is strikingly low. This is extremely useful for industries such as electronics, jewelry, or custom branding that depend on high detail.

- Range Of Materials

These machines easily work on wood, paper, certain forms of plastic, glass, leather, and acrylic. This enables using these marking devices in construction, gift-giving, types, packaging, etc.

- Non-Contact Processing

As CO2 laser marking is a noncontact process, it uses a laser beam that does not touch the material being worked on directly. Hence, it greatly improves the equipment’s lifespan and ensures no damage or deformation occurs to delicate materials, yielding the utmost quality.

- Speed And Effectiveness

Operating CO2 laser marking machines can achieve incredibility high speeds, vastly improving production cycles. Quality is maintained even in high-demand industrial applications with fast turnaround times.

- Sustainability

Aside from the clear production advantages, CO2 laser marking machines also consume less energy than traditional marking techniques, making them eco-friendly. The less waste generated, the better, making these machines ideal for companies with sustainability goals.

Understanding RF Laser Technology

Using an RF source, RF (radio frequency) laser technology can be powered externally. This helps to control the laser very accurately, which means the marking or engraving will be consistent and of high quality. Compared to traditional DC-powered lasers, RF-powered lasers are smaller, more effective, and more maintenance-friendly. They are commonly used in industries because of their accuracy and ability to work at high speeds.

What is RF in the context of laser engraving?

RF or Radio Frequency indicates the external power supply used to energize the laser tube in some laser marking and engraving machines. Unlike conventional lasers that employ a direct current (DC) power source, RF-powered lasers employ radio frequency waves to excite the laser medium. This approach minimizes degradation of the medium, thus enhancing the efficiency and stability of the output. Such an increase in the yield produced by RF lasers comes at a cost, however: lower quality of beam consistency and accuracy, which is crucial for precise engravings or markings.

- Improved Beam Quality: Compared to DC lasers, RF lasers yield a steadier and smoother beam, which increases engraving accuracy and detail.

- Less Maintenance and High Durability: Contamination-free maintenance is easy and infrequent with no open electrical elements, especially in sealed RF systems.

- Increased Speed and Productivity: The technology allows for high-quality, fast marking and engraving, which is ideal for industrial environments with high production needs.

-

Increased Lifespan: Depending on usage and maintenance, RF lasers can last an average of 20,000 to 50,000 hours, making them more specialized than traditional lasers in terms of lifespan.

Data and Industry Insights:

- A study comparing RF lasers to DC-powered ones reveals that the former can perform up to 15% more efficiently economically by converting electrical energy to laser energy, thereby reducing energy expenditure and costs.

- Through RF technology, spot sizes are significantly reduced, thus achieving resolutions of a thousand dpi or higher, which is excellent for detailed and complicated designs.

- Market Research suggests that RF laser engravers’ dot precision and reliability are making them one of the most dominant tools in the aerospace, electronics, automotive, and medical industries.

In engraving applications, RF pays off in greater leaps of functionality and efficiency. Its reliability provides a distinct advantage for companies that need high-quality, high-speed, and low-cost solutions.

How does an RF metal tube enhance laser performance?

An RF (Radio Frequency) Metal Tube is Essential for the Maintenance of Stability and Accuracy During Laser Cutting and Engraving, As It Improves Their Performance. Unlike traditional glass tubes, RF metal tubes use more advanced technology that improves energy meshing and minimizes heat development, resulting in a stable, high-quality laser output. The metal sheath is also RF’s stronghold as it is relatively more durable, less susceptible to damage or failure, guaranteeing more extended service life, higher reliability, and sturdiness in harsh industrial surroundings.

One Key Advantage of RF Metal Tubes is Their Ability to Provide a More Stable Beam with a smaller focus spot and Size. This Improvement is Critical For Finer Engraving and Detailing, which is Very Demanding in the Electronics and Medical Device Sectors. For example, research indicates that RF lasers are capable of providing the needed beam quality with an M² of less than 1.2, which is excellent for precise work.

In addition, RF technology has been noted to greatly minimize power changes, boosting engraving speed and consistency. Some sources suggest that compared to CO2 lasers, RF lasers have a higher power efficiency rate (30 to 40 percent), meaning less energy and money will be spent by businesses. Moreover, these systems are fast in heating and cooling, enabling reduced downtime and increasing productivity without compromising system reliability.

The RF metal tubes also aid in long-term RF system sustainability as they require less maintenance and resources over time. RF systems typically function between 45,000 and 50,000 hours, which is considerably longer than their standard glass counterparts. This improves durability since replacements are needed less frequently, minimizing maintenance time and costs.

When these traits are merged with advancement in RF technology, businesses can achieve higher performance, finer engraving precision, and increased operational efficiency across varying tasks.

What are the advantages of using RF laser systems?

- Increased Lifespan

Unlike traditional glass lasers, RF laser systems have a longer operational lifespan of 45,000 to 50,000 hours. This helps users avoid larger operational costs. RF lasers also enable users to avoid frequent replacements, which leads to increased maintenance downtime.

- Reliable Performance

RF laser systems excel in complex design and manufacturing precision-machined components requiring stable and consistent power output. Such high-level frame construction ensures exceptional performance while optimizing error rates, achieving nonuniform results across a wide range of applications.

- Cutting Edge Engraving Quality

Superior Modulation control with enhanced beam quality allows for smoother edges and sharper cuts, enhancing precision for complex designs and aiding in better overall engraving detail. This enhances the overall broadcast’s capabilities for intricate designs, resulting in astounding results every time.

- Eco-friendly

Reliable output and lowered power consumption are RF systems’ standout features. Such unparalleled usage allows businesses to achieve greatly reduced operational costs, which helps EMF achieve modern eco-friendly objectives and drastically lowers their overall carbon footprint.

- Multi-Purpose

With the capability to operate on metals, plastics, and ceramics, RF lasers have become the go-to in the automotive and medical devices industry. Their adaptability helps carve new paths to explore therapeutically and examine their tremendous potential.

Technical Parameters of CO2 RF Laser Marking Machines

- Wavelength

Operates at a 10.6 µm wavelength, which is adequate for marking several materials.

- Power Output

According to the model and its application needs, power output ranges from 10W to 150W.

- Marking Speed

Will guarantee productivity by achieving marking speeds of up to 7,000 mm/s.

- Precision

It provides a marking accuracy of ±0.01 mm for many detailed and intricate designs.

- Cooling System

For operational stability, it has an air or water cooling system.

- Material Compatibility

Applicable to wood, glass, plastics, leather, textiles, and coated metals.

- Lifespan

Usage and maintenance will decide the expected lifespan, which for the RF laser source will be anywhere from 20,000 to 50,000 hours.

These parameters make CO2 RF laser marking machines versatile and efficient for diverse industrial applications.

What are the specifications of a 30W CO2 laser marking machine?

|

Key Point |

Specification |

|---|---|

|

Laser Power |

30 watts |

|

Marking Area |

110mm x 110mm (optional sizes) |

|

Engraving Depth |

≤ 0.3mm |

|

Marking Speed |

Up to 9,000mm/s |

|

Lifespan |

Over 20,000 hours |

|

Cooling Method |

Air cooling system |

|

Material Compatibility |

Wood, leather, acrylic, paper, glass, more |

How do you evaluate the laser power and speed?

When assessing the efficiency of a CO2 laser marking machine, one has to consider the quality of marking, efficiency, loading, and materials compatibility. The following are some of the essential considerations:

- Material Properties

Different materials require specific laser power and speeds. For instance:

-

-

- Metals such as stainless steel are harder, therefore, require greater laser power and slower marking speeds to engrave or mark deeply.

- Softer materials such as leather and wood can be effectively marked with lower power but at high speeds.

-

- Marking Depth and Quality

-

-

- Power 30W and above allows machine engraving of deeper and more detailed designs. However, marking at full power and for longer durations can lead to a loss of precision, as materials can be charred or burnt.

- Speed also determines how fast marks are made. For mass production, processes that require finer μm/m resolutions, a 9,000 mm/s speed becomes ideal. However, finer details may pose a challenge if speed is overly increased.

-

For industrial applications where throughput matters, striking a balance between higher speed and moderate power allows for quick production without sacrificing quality.

Artistic or custom projects might require fine-tuning lower speeds with careful power adjustments for optimal precision.

- Calibration and Testing

Test runs on sample materials can help you determine the correct combination of speed and power. As a starting point, use settings suggested by the manufacturer and then adjust based on visual evaluation of the outcomes. Most CO2 laser marking machines have accompanying software that allows for precise control; this software makes the necessary adjustments easy to accomplish.

- Guidelines According to the Type of Material

Wood: Fine engraving at 3,000 to 6,000 mm/s speeds requires 10 to 20W.

Glass: I prefer 20 to 30W of power. Cracks and other glass defects are more common when using higher speeds, so I recommend using lower ranges of 1,000 to 3,000 mm/s.

Paper: The best results can be achieved under 10W of power, exceeding 7,000 mm/s.

Considering these alongside setting changes based on the material and application will ensure precise marking results.

Applications of CO2 Laser Engraving

The accuracy and precision of CO2 lasers make engraving an easy task across many industries. The most popular uses for it include:

- Personalized Products: Laser engraving names, logos, or unique customizable designs on giftware like trophies and awards.

- Signage: Masterfully carving detailed signs from wood, glass, acrylic, and other materials for long-lasting use.

- Packaging: Engraving paper, cardboard, and plastics with batched codes, barcodes, and expiration dates.

- Industrial Uses: Indelibly etching clear text onto tools, machinery parts, or other components for easy identification.

- Art and Design: Designing beautiful decorative pieces or intricate prototypes by engraving delicate patterns.

These applications involve customizing various products using CO2 laser engraving, which seems to take precision to an entirely different level.

What industries benefit from CO2 laser engraving?

Laser marking with CO2 has increasingly become an essential resource for companies looking for engraving solutions because of its versatility and efficiency. These advantages are especially prominent in the following five industries:

- Manufacturing

In manufacturing, CO2 laser marking is utilized for product engraving to provide serial numbers, barcodes, and logos. This improves inventory management and service through brand enhancement and advertising. Multiple studies indicate that the coherent laser labelling market in manufacturing will expand by 6.8% CAGR within the next five years.

- Electronics

In Electronics, businesses apply CO2 laser marking to engrave small components like circuit boards, chips, and connectors. Precision engraving of minor marks is a trademark feature because durable markings are etched on small spaces, providing compliance with surpassing standards.

- Packaging

In packaging, information like expiration dates, lot numbers, and barcodes is directly marked on the paper, cardboard, and plastic wrap using CO2 laser engraving technology. This boosts product movement in the economy while also improving tracking criteria, adding to the $21 billion mark in global laser marking businesses.

- Jewelry and Fashion

The fashion and jewelry industries utilize CO2 laser engraving for some high-end fashion clothing items and modern jewelry, such as marking logos and intricately designing various patterns on leather, fabric, and metals. The high-level customization highly appeals to customers, making them add value to products laser marked by advanced technology.

- Education and Arts

Schools and educators use CO2 laser engraving to craft models and prototypes and create decorative art pieces. In architectural modeling and custom artwork sculpting, CO2 lasers enhance creativity and precision. The CO2 laser systems in the education sector help foster STEM initiatives in Engineering disciplines.

These sectors demonstrate the very best scope for changing and advancing the use of CO2 laser engraving technology; through innovation, they create sustainable growth.

How to compare CO2 galvo laser engravers?

|

Key Point |

CO2 Galvo Laser Engravers |

Other Engraving Machine |

|---|---|---|

|

Initial Cost |

Moderate, $10,000–$25,000 |

Varies, depends on type |

|

Operating Cost |

Medium, regular consumables |

Low to medium |

|

Maintenance |

Moderate, optics upkeep needed |

Varies by material |

|

Lifespan |

8,000–20,000 hours |

Depends on usage |

|

Material Compatibility |

Wood, acrylic, glass, leather |

Steel, plastics, and composites |

|

Engraving Speed |

Fast, 50″/s or higher |

Varies by process |

How is laser marking used in the production process?

In manufacturing processes, laser marking is used to leave a permanent mark on materials. I use this technology to engrave serial numbers, barcodes, logos, and other identifying information directly onto products. This method improves both cleanliness and durability, which in turn increases brand recognition while still being efficient for company workflows.

Reference Sources

1. Fabrication of Microchannels by Using the CO2 Galvo Laser Marking Machine and Thermo-mechanical Sealing Method

- Authors: H. A. Tam, N. V. Hung, N. Duc, D. H. Giang

- Publication Date: June 28, 2019

- Journal: VNU Journal of Science: Natural Sciences and Technology

- Summary: This study discusses the fabrication of microchannels using a 40W CO2 Galvo laser marking machine. The authors controlled the channel dimensions by adjusting the laser power, scanning speed, and scanning time. The results indicated that increasing laser power and decreasing scanning speed led to broader and deeper channels. The microchannels were successfully tested in laminar flow and droplet modes and sealed using a thermo-mechanical method at 220°C.

- Methodology: The authors created microchannels using a CO2 Galvo laser marking machine and analyzed the effects of various parameters on channel dimensions and surface roughness(Tam et al., 2019)

2. Optimization of Parameters for Laser Marking and Engraving on Plywood and Pine Wood Materials

- Authors: Artis Stanislavs Gusts, Imants Adijans

- Publication Date: April 23, 2021

- Journal: HUMAN. ENVIRONMENT. TECHNOLOGIES. Proceedings of the Students’ International Scientific and Practical Conference

- Summary: This publication shows the results of CO2 laser marking and engraving on plywood and pine materials at different speeds and powers. The authors measured the marked and engraved line depth for various combinations of speed and power ratios.

- Methodology: The study utilized a SUNTOP CC-9060 CO2 laser machine and an OLYMPUS OLS5000 laser microscope to analyze the effects of different parameters on engraving quality.(Gusts & Adijans, 2021)

3. Top Co2 Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a CO2 laser engraver, and how does it work?

A: A CO2 laser engraver is a type of laser marking machine that utilizes a CO2 laser tube to engrave or mark materials. It directs a focused beam of light onto the material’s surface, causing a reaction that results in engraving or marking. This process is known for its high precision and stable performance, making it ideal for various applications.

Q: Can a CO2 RF laser generator be used for engraving and cutting?

A: Yes, a CO2 RF laser generator can be used for engraving and cutting. The versatility of the laser allows it to handle non-metal materials, making it suitable for tasks like fine marking on wood, leather, and acrylic, as well as cutting intricate designs.

Q: What is the difference between a CO2 laser machine and a fiber laser?

A: The primary difference lies in the type of laser used. A CO2 laser machine uses a CO2 laser tube, which is effective for marking non-metal materials. In contrast, a fiber laser uses a solid-state laser, which is more efficient for marking metals. Each system has its advantages depending on the material being processed.

Q: How does the marking process work with a laser marking system?

A: The marking process in a laser marking system involves the laser beam being focused onto the material’s surface. As the laser moves across the material, it either engraves or marks the surface by altering its color or creating a cavity. This allows for durable, high-quality markings that are resistant to wear and tear.

Q: Is it possible to use Photoshop with a laser marking machine?

A: Yes, Photoshop can create designs for a laser marking machine. Users can prepare their artwork in Photoshop, export it in a compatible format, and then upload it to the marking system for engraving or cutting. This integration allows for creative flexibility in the design process.

Q: What materials can be marked with a co2 laser engraver?

A: A CO2 laser engraver is widely used for marking non-metal materials such as wood, leather, glass, acrylic, and certain plastics. Its ability to engrave intricate designs makes it a popular choice for various industries requiring fine marking.

Q: What are the benefits of using a high-quality CO2 laser marking system?

A: A high-quality CO2 laser marking system offers benefits such as high precision, stable performance, and the ability to handle a variety of materials efficiently. Additionally, it can improve production speed and streamline the marking process, especially in online marking applications.

Q: What is the significance of the laser tube in a CO2 laser marking machine?

A: The laser tube is a crucial component of a CO2 laser marking machine, as it generates the laser beam used for engraving and marking. The quality and efficiency of the CO2 laser tube directly affect the machine’s performance, including its speed and the quality of the markings produced.

Q: Can a CO2 laser machine be integrated with other communication instruments?

A: Yes, a CO2 laser machine can be integrated with various communication instruments to enhance its functionality. This integration can facilitate features like remote operation, data transfer, and synchronization with other machinery in a production line, improving overall efficiency.