Laser-cutting technology changed the world due to its precision in cutting and manufacturing. CO2 laser cutting and fiber laser cutting are two popular options. But how do you know which one best accommodates your needs? This article analyses the differences between the two technologies, as well as their pros and applications. If you’re a business seeking to enhance efficiency or a passionate learner interested in the intricacies of laser cutting, you’ll find value in this guide. Join us as we explore performance, cost, and adaptability parameters to determine which is right for you.

What is the Difference Between CO2 Laser and Fiber Laser?

The main distinction between CO2 and fiber lasers lies in generating and delivering laser beams. For instance, CO2 lasers consist of a CO2 gas mix. Their laser beam cuts nonmetals like wood, plastics, and acrylics. Fiber lasers use optical fibers and diodes, which results in a stronger, highly focused beam. Hence, fiber lasers cut and engrave steel, aluminum, and brass metals.

Fiber lasers usually have the advantage of higher energy efficiency and speed and require less maintenance compared with CO2 lasers. However, CO2 lasers are optimal for applications requiring smooth finishes on non-metal surfaces. The materials and individual tasks determine the more appropriate choice between the two.

Understanding CO2 Laser Technology

The versatility and reliability of CO2 lasers make them ideal for cutting, engraving, and marking. These lasers emit a concentrated beam of infrared light through a gas mixture of carbon dioxide, nitrogen, and helium, powerfully excited by electrical discharge. CO2 lasers are a staple in the industry since their wavelength measures around 10.6 microns, and non-metals like wood, acrylic, plastics, and textiles easily absorb them.

CO2 lasers help achieve smooth, precise cuts on thicker materials and intricate patterns, which is why they are used in automotive manufacturing, sign-making, and packaging. They even have medical applications for surgical use.

Unsurprisingly, CO2 lasers with small engraving machines have lower power capabilities of less than 10 watts, while heavy-duty industrial cutters have hundreds of watts. 150-watt CO2 lasers offer unmatched edge quality compared to other technologies and with a fraction of their speed capabilities: 36 inches per second for thicker acrylics. Advanced cooling systems and superior optical design included in most CO2 laser systems help maintain beam stability and increase operational lifespan.

An additional benefit of CO2 lasers is the comparatively low cost of ownership. While CO2 lasers and their associated systems do need some periodic maintenance for the laser tube and optics, they often exhibit longer lifespans and reduced operational costs compared to non-metal material processing technologies.

Due to advancements in precision and energy use, CO2 lasers continue to be useful in fields that require high accuracy or where precision and smooth contours are crucial.

How Fiber Laser Technology Works

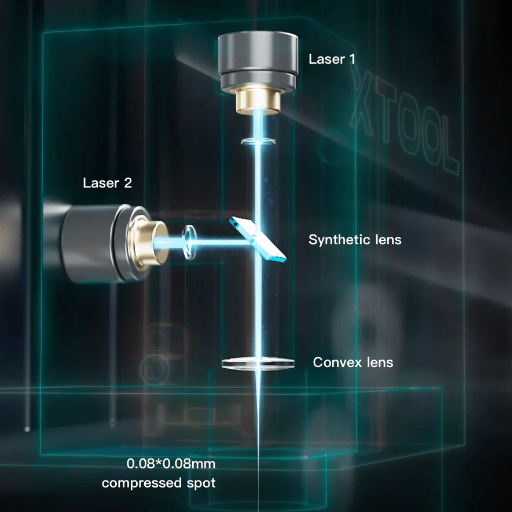

Fiber laser technology uses an optical fiber as the active gain medium to amplify light. This sophisticated system employs a diode pump light that is highly concentrated and directed into the doped fiber core, which contains rare earth elements like erbium, ytterbium, and neodymium. As a result, efficient and precise laser beam generation is possible. The laser light, which is guided through the optical fiber, emerges with minimal beam divergence and remarkable stability, which makes it ideal for high-precision applications.

Fiber lasers have marked advancements over traditional CO2 lasers. In addition to being more energy efficient, with conversion efficiencies reaching up to 30-50%, fiber lasers significantly lower operational energy consumption. Their compact design reduces the need for bulky components. There is also a lack of moving mirrors or gas refills, which drastically lowers maintenance requirements. Fiber lasers are particularly well suited for cutting, engraving, and welding metals. Fiber lasers also achieve astounding accuracy in marking applications with resolutions often in the micrometer range.

Moreover, fiber laser systems can work at higher power levels, from 20 watts to more than 10 kilowatts, allowing them to manage intricate and rough tasks. For example, they can cut thick metals like steel or aluminum quickly and accurately. Because of these advantages, fiber lasers are opted for in the automotive, aerospace, and electronics manufacturing industries,s where accuracy and productivity are crucial. Along with improvements to beam quality and control, other innovations are made possible by advancements in other industrial processes, which push the innovation limits of fiber laser technology.

Key Differences in Laser Beam Composition

In fiber laser technology, an optical fiber is used as the active gain medium that receives light and amplifies it. The complex system uses cone-shaped diode pump light intensely focused on the doped fiber core with elements such as erbium, ytterbium, or neodymium. This process makes the efficient and accurate generation of laser beams possible. The light generated through the optical fibers has a narrow divergence, thus emerging with a very stable beam, which is perfect for high-precision tasks.

Fiber lasers are more advanced than traditional CO2 lasers. They boast higher efficiency, with conversion rates suited to 30-50%, and consume significantly less power operationally. Their size leads to fewer bulky parts and lower mirror movement, thus minimizing maintenance to nearly gas-free refills. Fiber lasers are best suited for cutting, engraving, and welding metals. These fiber lasers also astoundingly achieve high precision with marking tasks, often in the micrometer range.

In addition, fiber laser systems can work from 20 watts to over 10 kilowatts, thus enabling them to tackle both detailed and rough tasks. For instance, they can rapidly and precisely cut thick metals like steel and aluminum. Because of these reasons, fiber lasers are chosen in the automotive, aerospace, and electronics manufacturing industries, where precision and efficiency are vital. Furthermore, technological progress in other industrial processes unlocks innovation possibilities in fiber laser technology, beam quality and control improvements.

What Are the Advantages of Fiber Laser Cutting?

Fiber laser cutting has many advantages, making it the preferred choice across various industries. To begin with, it is one of the fastest methods available and has high precision, which results in accurate cuts with minimal material being wasted. Additionally, fiber lasers have a lower energy consumption, leading to lower operational costs over time, making them more economical and energy-efficient. Other than this, they are also less demanding in maintenance and lifespan than other laser technologies. Metals and other materials can be cut with precise edges, showcasing the versatility of the fiber laser system. Due to all the advantages provided, modern manufacturing needs are best served with fiber laser cutting.

Faster Cutting Speeds with Fiber Lasers

One of the most essential reasons fiber lasers are preferred in modern manufacturing systems is their exceptional cutting speeds. The ability of fiber lasers to focus high-power laser beams into tiny areas facilitates rapid and precise cutting of materials. For example, a 4kW fiber laser can cut a 1mm thick stainless steel sheet at 40 meters per minute, significantly faster than traditional CO2 laser systems that operate at 20 meters per minute.

Also, the newest advancements in laser technologies allow fiber lasers to have optimized speed and accuracy with varying thicknesses and materials. These new changes result in thinner materials benefiting greatly from the increased cutting speeds, significantly improving factory floor production times. Furthermore, the time advantage is more pronounced when the secondary finishing processes are lowered considerably due to the high-quality edges resulting from the initial cut. The high-performance capabilities of fiber lasers are increasingly becoming a core reason for their adoption in various industrial sectors, including automotive, aerospace, and sheet metal fabrication.

Higher Efficiency in Cutting Metals

The epilog fiber laser 40w is a powerful device that surpasses all preservation standards, breaks through the maximum limits of efficiency, accomplishes ultra-thin precision, achieves speed-cutting of flat and volumetric shapes, and flex head UK fiber laser cuts 1mm stainless steel at an astonishing 40m per minute.

Reduce operational expenses and save operating resources, add precision guidance system lenses and laser cutters mounted on agile robots for flexible automation systems designed to cooperate with users.

Such technologies also gain from enhanced accuracy, achieving cuts that require almost no finishing work. This accuracy minimizes waste and improves product quality, optimizing production even more. Sectors such as automotive and aerospace have noted close to twenty percent reductions in material waste alongside considerable increases in production speed after adopting advanced fiber laser systems. All of these reasons are why fiber lasers are crucial in modern manufacturing.

Benefits of Fiber Laser for Non-Metallic Materials

Because of its accuracy and flexibility, fiber laser technology is advantageous for processing non-metallic materials. Unlike previous methods, fiber lasers are a contactless cutting and engraving system that protects finer materials like ceramics, plastics, glass, and composites from damage. For instance, fiber lasers can achieve cutting tolerances as fine as ±0.01 mm, which is essential for industries such as electronics and medical device manufacturing.

Moreover, fiber lasers outperform CO2 lasers in energy efficiency by up to 50% of operating costs without compromising throughput rates. Research shows that fiber lasers have automated and continuous operations that have increased textile and plastic processing productivity by 30%. Also, fiber lasers cut polymers and acrylics with precision and uniformity, ensuring minimal thermal sensitivity damage.

Another remarkable advantage is that fiber lasers are eco-friendly. They help sustain the environment because of their low energy consumption and lack of consumable parts. Because of these qualities, fiber lasers are perfect for non-metal production industries that focus on high-speed operations, accuracy, and environmental-friendly practices.

How Does CO2 Laser Cutting Compare to Fiber Laser Cutting?

There are differences between CO2 and fiber laser cutting in a few main areas. CO2 lasers are more appropriate for cutting non-metal materials like wood, glass, or acrylic because they have a longer wavelength. Meanwhile, fiber lasers, with their shorter wavelengths and higher energy density, easily cut metals, even highly reflective ones like copper and aluminum.

In contrast to CO2 lasers, fiber lasers tend to be more energy efficient, require less maintenance, and cut faster through thin metals. However, with increased thickness, CO2 lasers often prefer smoother edges on certain cuts. The difference comes down to what the material and the application need.

Cutting Speed Comparisons

Fiber lasers generally have the upper hand in speed, often outperforming CO2 lasers in cutting speed with thinner materials. When cutting thin gauge metals, fiber lasers can reach speeds three times that of CO2. For example, a fiber laser cutting 1mm stainless steel can do it at 20-25 m/min while a CO2 will do it at 8-10 m/min.

The variation in speed settles with thicker materials. For instance, regarding 10mm mild steel, a fiber laser may cut at a rate of about 1.5 to 2 m/min, as compared to a CO2 laser, which can achieve around 1 to 1.5 m/min. Nevertheless, CO2 lasers are sometimes favored on these thicker materials due to their edge quality.

The continued advancement of laser technology and beam quality dramatically increases the efficiency of fiber lasers for myriad applications. These lasers are exceptional in environments with high-speed production because of the reduced cycle times and increased throughput, which makes them beneficial for industries focused on productivity.

Material Compatibility: CO2 vs Fiber Laser

It’s important to note the specific advantages of lasers when analyzing the compatibility of CO2 and fiber lasers. CO2 lasers are proficient when working with nonmetal materials such as wood, acrylic, glass, leather, and various forms of plastic. Their long wavelength (~10.6 µm) is helpful in cutting and engraving as it yields smooth, high-quality edges after completion. Also, CO2 lasers are well known for their versatility, with thicker sheets of these materials used in artistry and sign design.

In contrast, fiber lasers cut with steel, aluminum, copper, and brass more effectively due to their shorter wavelength (~1.06 µm). For those materials, fiber lasers outcompete CO2 lasers during the cutting process of thin to medium-thickness metals. Engraving and marking metals is also more effective with fiber lasers as they provide great precision with minimal heat-affected zones. One of the best qualities of fiber lasers is their ability to cut reflective materials such as aluminum and copper, which are very difficult for CO2 lasers because of back-reflection problems.

Fiber lasers cut stainless steel over 4 mm thick at up to 300% of the speed CO2 lasers accomplish with finer cuts, all while being more energy efficient. In addition, fiber laser systems spend less overall energy and maintenance due to the absence of mirrors and fragile parts, making them more cost-effective in the long run.

For companies that need to work with both metallic and non-metallic materials, selective use of both hybrid solutions or laser types is often advised. The ideal laser to pick depends on the range of material types, thicknesses, and production standards that must be met with the application.

Cost Efficiency of CO2 Laser Cutting

CO2 lasers are still one of the most affordable options for cutting equipment for various industries because of their precision and effectiveness. One of the main advantages is that it can process a vast selection of materials, from non-metallic materials like wood, glass, and plastics to textiles, thereby eliminating extra equipment or steps. With the development of CO2 laser technology, energy efficiency has also improved, thus reducing the equipment’s cost.

For example, CO2 lasers usually have over 10,000-hour life spans on their laser tubes, limiting the need for costly replacements and repairs. With proper maintenance, some systems can achieve up to 10-20 mm/s cutting speeds on thicker materials, which significantly increases productivity for manufacturers. Moreover, CO2 lasers are usually less expensive than fiber lasers, which makes them ideal for small to medium enterprises that want to optimize operational efficiency without spending too much upfront.

New studies and industry reports claim that CO2 lasers have a competitive cost per hour of operation from $10-15, considering energy and maintenance expenses. This is advantageous for facilities focused on high-volume production or dealing with different materials. Due to these factors, CO2 laser cutting presents a cost-effective option for businesses looking for flexibility and accuracy while maintaining stringent financial limits.

What Materials Can Be Cut by Fiber Laser vs CO2 Laser?

While fiber and CO2 lasers can cut through many materials, their strength heavily relies on the type of materials being processed.

- Fiber Laser: Most effective on metals. Flexible cuts through steel, stainless steel, aluminum, brass, and copper. Fiber lasers work better on reflective materials, providing processing speeds and precision for thin to medium-thickness metals.

- CO2 Laser: Non-metal materials work best, including wood, acrylic, plastics, glass, leather, and textiles. Although CO2 lasers can cut through metals, they are ideally suited to thicker materials that are slower to process.

Where one laser excels may be a disadvantage for the other; determining which laser provides the most cut specific to the materials and requirements is vital.

Fiber Laser Cutting Range of Materials

At a time when the growth rate of advanced manufacturers was slower than expected, fiber lasers came into the spotlight recently due to their versatile applications, which include the cutting of high-precision materials at unmatched speed. The materials that can be processed include:

- Metals: Reflective and non-reflective metals are some of the primary materials utilized. They include stainless steel, carbon steel, aluminum, brass, and copper. Fiber lasers tend to work best when the material is within certain gauge limits from 0.5 to 25 mm, depending on the power of the laser. For industrial purposes, possessing 6kW or more power turns these lasers ideal for cutting clean and precise shapes out of thicker metals, thus boosting productivity.

- Alloys: Fiber lasers have profound advantages when cutting high-performance alloys utilized in the aerospace and automotive industries. Due to the precise and sharp cuts, complex, intricate designs can be easily dealt with.

- Thin Materials: Fiber lasers’ accuracy makes them the best solution for cutting sheets of low thickness. With unmatched focus and energy density, they can melt away material with the least amount of change to the rest of the metal’s thermal structure.

- Non-Metallic Materials: While fiber lasers are mostly meant for metals, they are capable of processing some non-metallic substances, such as plastics and composites, if said materials obey specific tolerances.

Because of fiber lasers, the rapid cutting speeds of high-quality cuts have become effortless. For instance, a fiber laser with a 2kW power output can slice through stainless steel with a thickness-dependent speed of more than 16 meters per minute. Also, the low maintenance required for this technology, combined with its long operational lifetime, makes it a good fit for high-throughput industries like manufacturing, shipbuilding, and electronics.

CO2 Laser Cutting for Thicker Materials

CO2 laser cutting remains a highly effective for processing thicker materials, such as carbon steel, stainless steel, and aluminum. Known for its longer wavelength than fiber lasers, a CO2 laser offers superior absorption in non-metallic materials, making it a versatile choice across various applications. One notable advantage is its ability to cleanly cut metals up to 25mm thick, depending on the material and the specific machine power settings.

For instance, a 4kW CO2 laser can efficiently cut 20mm carbon steel at approximately 600mm per minute using oxygen as an assist gas. When cutting thicker stainless steel, nitrogen is often used as an assist gas to achieve oxide-free edges. The edge finish from CO2 lasers is smooth, making it ideal for applications requiring fine precision, such as automotive components and architectural projects. Furthermore, the availability of high-powered CO2 lasers ensures compatibility with larger-scale applications, like aerospace parts and structural fabrications.

While CO2 lasers generally have higher maintenance requirements compared to fiber lasers, their robust capabilities for cutting thicker materials still make them indispensable for industries with demanding specifications. Additionally, beam delivery systems and machine software advancements have further enhanced efficiency, improving cutting speeds and reducing material waste.

Comparing Material Thickness Capabilities

Both CO2 and fiber lasers show distinct advantages to each application when discussing material thickness capabilities. CO2 lasers perform better with thicker materials like mild steel over twenty mm thick. CO2 lasers cut metals with greater thicknesses tend to yield smoother finishes, which is helpful in heavy industries such as shipbuilding and construction. For instance, CO2 laser cutters can cut mild steel to a thickness of 30mm with the right assist gases such as oxygen.

In contrast, fiber lasers are best suited for cutting thinner materials up to 10 to 15 mm for metals such as stainless steel and aluminum. Due to the shorter wavelength fiber lasers work at, higher precision and speed with thin material processing are achieved. Their advanced beam absorption tends to make fiber lasers more versatile with reflective materials such as brass and copper. Modern fiber lasers, for example, are capable of working on highly accurate reflective materials with thicknesses of 6 to 8 mm.

Some of these developments have been affected by breakthroughs in laser-powering technology. For example, high-power fiber lasers greater than 10 kW have started competing with CO2 lasers for mid-thick materials. They even cut steel and aluminum up to 25 mm thick in some instances. Investments in fiber lasers are further justified because they are often less maintained, experiencing low operational downtime and costs compared to CO2 systems.

Material selection, cutting needs, and production volume determine the most appropriate laser system. By adjusting the aforementioned developments with laser systems tailored for specific applications, performance and cost efficiency are optimized.

Which Laser Cutting Machine Should You Choose?

Every business has different requirements when it comes to the laser cutting machine. Fiber lasers are reputably known as the most precise and efficient cutters for steel and aluminum. On the other hand, for softer non-metal materials, CO2 laser systems are the preferred choice due to their versatility. Furthermore, the amount of produced goods, the required cutting speed, and money set aside for maintenance are also critical. Prioritize your goals so that you can choose the machine that will optimally accomplish your objectives.

Choosing Between CO2 Laser Cutter and Fiber Laser Cutter

- Compatibility of Materials

CO2 laser cutters are more convenient for non-metallic materials (wood, acrylic, plastic, glass). They are also useful in the packing, woodworking, and signage industries. Thus, the larger wavelengths of CO2 lasers help them effectively carry out these functions. On the other hand, fiber lasers are more advanced in cutting metals like stainless steel, carbon steel, aluminum, brass, and copper because of their smaller wavelengths. Fiber lasers are more effective at processing materials that tend to be more reflective.

- Efficiency and Speed

Laser CO2 models are better for intricate and wheelchair-requested cuts on thick materials, while fiber lasers are better for mass work on thin metal sheets. The latter are 2-3 times more efficient than CO2 lasers. Fiber laser models have a clear advantage when it comes to thin metal cutting—their speed and efficiency are unmatched.

- Operational Costs

Fiber laser systems prove to be cheaper over time for operational costs and maintenance needs, with less power required. Mirrors and moving parts in the laser source are not present. CO2 lasers might be cheaper for initial investments, but with lenses and mirrors as consumables, a bigger ongoing cost is needed to purchase these materials due to energy, further increasing the operating cost.

- Lifespan and Durability

Compared with other laser systems, fiber lasers have the longest lifespan, often exceeding 100k+ hours of use. This ensures minimal downtime for replacements and maintenance. On the contrary, CO2 laser systems tend to be less durable and long operational, and they tend to need tube replacements more frequently than their counterparts.

- Precision and Quality of Cut

Fiber lasers not only offer exemplary precision, especially when working with thin metals, but they also produce edges that are clean and free of burrs. CO2 lasers, on the other hand, can attain a smoother finish quality on non-metallic items, which is essential for projects focused on aesthetics.

- Emerging Data and Trends

New case studies suggest systems with fiber lasers are becoming more common in the aerospace, automotive, and electronic industries, where precision and cost efficiency are a priority. While some technical performance reports suggest the global market for fiber lasers will likely see a substantial increase in the coming years, indicating higher demand.

Considering these crucial factors and how they align with business objectives can facilitate a decision that maximizes performance while minimizing operation costs.

Factors to Consider When Selecting a Laser Cutting Machine

- Precision and Accuracy

Considered one of the most critical factors for laser cutting machines, **precision** impacts industries such as aerospace and medical applications where intricate detail or tight tolerances are required. Modern fiber laser machines can achieve accuracy levels up to ±0.03 mm, maintaining a high standard of cutting quality, even with complex geometrical shapes.

- Power and Cutting Capability

The amount of power a laser has determines the material thickness it can handle and the speed with which it can cut. A 3 kW laser, for example, is good enough for metals like stainless steel up to 20 mm in thickness. On the other hand, thicker materials are no match for high-power lasers (6 kW and above), as they slice through them with ease. Recent advances in laser technology have made it easier to cut with high power while preserving energy, thus boosting productivity.

- Material Compatibility

Different machines excel with other materials. For example, fiber lasers offer unparalleled speed and precision when cutting metals like Aluminum, brass, and copper. CO2 lasers are preferred over fiber lasers for non-metal materials such as acrylic and wood. It is always better to choose a machine specific to your target material to avoid wasting resources.

- Operational Speed and Efficiency

Cutting speed directly impacts production timelines. Studies indicate that modern fiber lasers can cut thin metals up to five times faster than traditional CO2 lasers. These machines have very limited warm-up times, which allows operators to maximize uptime.

- Operating Costs and Energy Efficiency

Calculating operating cost and expenses is vital despite the significant upfront costs. Fiber lasers offer a cost-efficient solution for firms with high production demands since they use, on average, 30% less energy than CO2 lasers—eco-friendly advancements in tooling further lower operational energy expenditure without compromising performance.

- Maintenance Requirements

Keeping a laser cutting machine in optimal operating condition requires routine maintenance. Compared to CO2 systems, fiber lasers are known to have lower maintenance needs, which help minimize downtime and augment servicing costs over the machine’s life cycle. This improves productivity and increases overall savings.

- Software and Automation Features

Advanced designing and automating software is often integrated into modern cutting machines. Features such as automatic laser focus adjustment, material sensing, and real-time performance monitoring enhance precision and productivity. Certain systems offer options for integration with Industry 4.0 platforms to facilitate data-driven workflows and predictive maintenance.

- Industry Trends and Growth Potential

The laser cutting industry is on the rise and is expected to surpass a $5.7 billion market value by 2030. Innovations in fiber laser technology are enabling easier scalability for companies looking to expand due to increased efficiency in laser cutting systems. Investing in adaptable machines guarantees sustained market competitiveness.

Taking these factors into account will enable the targeting of cutting machines that meet the requirements of a current business while also providing the flexibility to grow with industry changes.

Long-Term Cost Considerations for Laser Systems

In my consideration of long-term costs for a laser system, there are several critical considerations I focus on. The maintenance costs, the machine’s energy efficiency, and the accessibility of spare parts greatly affect the total ownership cost. Besides, I also analyze the machine’s expected age and its potential for future enhancements to ensure it maintains cost efficiency with advancing technology. That’s why I set up these variables from the start: to optimize the investment alongside the value over time.

Reference Sources

-

Study on Cutting Accuracy 2:

- Objective: Compare the cutting accuracy of 6mm thick S235JR steel plates using CO2 and fiber lasers.

- Findings: Fiber lasers produced more accurate cuts with smoother surfaces than CO2 lasers under similar energy conditions.

- Methodology: Dimensional accuracy and surface quality were analyzed per ISO standards.

-

Experimental Study on CFRP Composites 3:

- Objective: Investigated CO2 laser cutting of carbon fiber-reinforced plastic (CFRP) composites.

- Findings: Pulsed-mode CO2 lasers minimized the heat-affected zone (HAZ), preserving material strength better than continuous-wave mode.

- Methodology: Examined the influence of laser parameters on cut quality and HAZ.

-

Comparison of Steel Cutting 4:

- Objective: Compared CO2 and fiber lasers for cutting low-carbon and stainless steel.

- Findings: Fiber lasers achieved higher cutting speeds and smoother surfaces, especially in fusion cutting of stainless steel.

- Methodology: Measured absorbed laser energy and surface roughness under varying conditions.

- Top Co2 Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the difference between fiber and CO2 laser cutting?

A: The difference between fiber and CO2 laser cutting lies in the type of laser used. Fiber lasers utilize solid-state laser technology with a fiber optic cable to generate laser light, while CO2 lasers use a gas mixture to produce the laser beam. This results in different cutting methods and efficiencies for various materials.

Q: What are the advantages of using a fiber laser cutting machine over a CO2 laser?

A: Fiber lasers provide higher cutting speeds and better cut reflective materials such as metals. Additionally, fiber lasers are generally more energy-efficient and have lower operating costs than CO2 lasers, which can lead to significant savings in industrial applications.

Q: Can you explain how the cutting head differs between fiber and CO2 lasers?

A: The cutting head of a fiber laser is designed to handle the fiber optic beam more efficiently, allowing for better focus and precision during the cutting process. In contrast, a CO2 laser cutting head is optimized for the gas laser beam, which can be less efficient on certain materials.

Q: What materials are best suited for fiber and CO2 laser cutting?

A: Fiber lasers are particularly effective for cutting metals and reflective materials, while CO2 lasers are often preferred for non-metal materials such as wood, acrylic, and textiles. When comparing fiber laser capabilities, it’s essential to consider the specific material being cut.

Q: How do the costs of fiber lasers compare to CO2 lasers?

A: The cost of CO2 lasers can be lower upfront; however, fiber lasers are often more cost-effective in the long run due to their higher efficiency and lower maintenance costs. Fiber lasers also tend to have a longer lifespan, which can further justify their initial investment.

Q: Are fiber lasers less versatile than CO2 lasers?

A: Fiber lasers are not necessarily less versatile; they excel in cutting metals and certain plastics, whereas CO2 lasers are better for a broader range of non-metal materials. When comparing fiber laser capabilities, the choice depends on the specific applications and materials you intend to work with.

Q: What is the significance of using fiber optic technology in fiber laser cutting machines?

A: Using fiber optic technology in fiber laser cutting machines allows for the efficient transmission of the laser beam to the cutting head. This results in lower energy loss, higher beam quality, and improved cutting precision, making it a preferred choice in many industrial applications.

Q: How does the solid-state laser technology in fiber lasers impact their performance?

A: Solid-state laser technology in fiber lasers improves performance by providing a more stable and high-quality laser beam. This stability leads to better cutting precision and higher speeds, especially when compared to traditional CO2 laser systems.

Q: Which type of laser is the best choice for engraving and cutting applications?

A: The best choice for engraving and cutting depends on the specific materials and desired outcomes. Fiber lasers are superior for metal cutting and engraving, while CO2 lasers are more effective for organic materials. Assessing your needs will help determine which laser type fits best.