Acrylic is one of the most common and adaptable materials in modern design and engineering. Given its exceptional durability, acrylic is widely adopted for creating elaborate artistic structures and stunning business signs. Precision and artistry in craftsmanship are essential to achieve the best results with this material—it’s time for a CO2 laser cutting machine. In this article, we will cover everything you need to know about CO2 laser cutting machines and working with the material, from knowing the limits of the hardware and software to producing flawless results. If you are trying to acquire new skills or are a seasoned professional trying to refine your process, this guide will help you with practical advice that can profoundly improve your acrylic works.

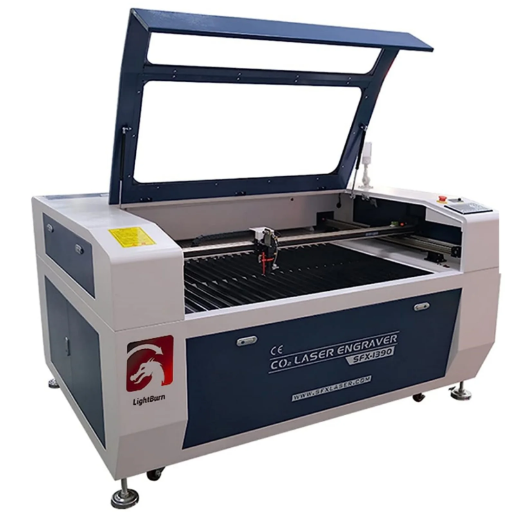

What is a CO2 Laser Cutting Machine?

A CO2 laser cutting machine benefits various industries, such as crafting and woodworking, due to its precise and quick engraving and cutting capabilities. As its name implies, the machine uses carbon dioxide gas lasers that emit powerful beams. Such beams cut detailed and clean sections out of non-metal materials, like wood and fabric, by vaporization, melting, or burning. CO2 lasers excel in cutting non-precious materials like acrylic. Moreover, CO2 laser cutting machines are known for speed and precision, even in complicated designs.

How does a CO2 laser cutting machine work?

A CO2 laser cutting machine works on the fundamentals of generating and manipulating a laser with extreme precision. A mixture of gas, predominantly carbon dioxide (CO2), nitrogen, helium, and occasionally hydrogen or xenon, is electrically activated in a sealed tube, resulting in a CO2 laser cutter that generates a concentrated beam of infrared light. It is then the CO2 laser cutter that produces a focused beam of infrared light.

A myriad of mirrors and a focusing lens are utilized to direct the beam towards the material to be cut. A lens is capable of focusing the beam to a specified point, which, in turn, amplifies the power as the laser is increased in intensity. The material can be cut deeply and cleanly in milliseconds, thanks to the intense energy the laser adds, which leads to heating the material to its vaporization or melting point. Thus, a clean cut can be attained because the gas commonly used to blow the molten material away, which is frequently nitrogen or oxygen, ensures smooth edges.

One of the most important benchmarks of performance in CO2 lasers is their wavelength, which lies around 10.6 microns. This enables CO2 lasers to perform exceptionally well in cutting wood, acrylic, plastic, glass, and textiles. Due to technological advancements, some machines are now able to cut soft materials like acrylic at speeds of 20 to 30 mm/s, depending on the power of the laser, which in industrial models ranges from 40W to over 400W.

Another hallmark of CO2 laser cutters is precision, as the most advanced machines can exceed a cutting accuracy of ±0.1 mm. This degree of perfection facilitates use in applications involving high levels of detail, including architectural models, electronics, custom jewelry, and other intricate designs. Moreover, modern software integration allows for the use of CAD and CAM systems, easing the uploading of patterns.

CO2 laser cutting machines are now deemed essential in contemporary production surroundings because they outperform other equipment in speed, adaptability, and precision. Their impact is noted in multiple industries such as manufacturing, prototyping, and craftsmanship.

What are the benefits of using a CO2 laser cutter?

- Precision and Accuracy in CO2 Laser Cutters

The CO2 laser cutters boast of being one of the highest precision laser cutters available today. They make it possible for intricate designs of elaborate details to be cut out. Due to the beam diameter being considerably smaller than other devices, they can achieve precision as high as ±0.001 inches in accuracy, essential for productivity reliant on consistently high precision.

- Width of Material Variety

CO2 laser cutters are also helpful in cutting and engraving various materials such as wood, acrylic, glass, plastics, textiles, and some metals. Owing to this superb range of material versatility, CO2 laser cutters are prominent across various applications in art, manufacturing, laser engraving, and design industries.

- Speed of CO2 Laser Cutters

The CO2 laser cutters outperform the traditional cutters in terms of production time. The traditional way of cutting through acrylics is 3mm thick but slower, while the UV laser cutters can do it at a pace of 300mm/s, guaranteeing mass and prototype production speed.

- Waste Reduction

Due to the precision, focus, and keen attention to detail in all aspects of CO2 laser cut machines, material wastage is on the lower end. Another plus is that the area affected by the heat is minimal, so additional, costly, time-consuming procedures do not have to be done, resulting in effective resource conservation.

- Cost Efficiency with Automation

CO2 laser cutters help provide long-term cost savings. They guarantee long-term savings due to their low maintenance needs and ability to connect with software for automated tasks. Automation becomes kinder to the human factor, minimizing slip-ups, and the industry can strategically plan its resources, whether it’s a minor or major undertaking.

What types of materials can a CO2 laser cutting machine cut?

CO2 laser cutting machines are versatile and can cut almost any material with great precision and efficiency. Below are five materials that can typically be cut using them.

- Wood

CO2 lasers offer great precision when cutting or engraving wood materials, especially plywood, MDF, Balsa wood, and even hardwood. Their application in crafting, furniture design, and architectural projects is immense, as they add fine details alongside clean edges.

- Acrylic

Due to its clarity, smoothness, and polish, acrylic is a popular material for laser work. CO2 lasers can create intricate designs on acrylic sheets, which makes them widely used in signage, decorations, and display stands.

- Fabric and Textiles

Several fabrics, including cotton, polyester, felt, and even leather, can be cut with precision using CO2 lasers, making them ideal for the fashion, upholstery, and custom accessory design industries.

- Paper and Cardboard

CO2 lasers are extremely efficient for custom packaging, invitations, and even artwork. They can engrave and cut paper products with utmost precision while ensuring attention to delicate designs.

- Plastics

These CO2 lasers can be used on plastics such as ABS, PET, and polycarbonate. This makes them essential to product prototyping, electronics manufacturing, and various industrial tasks.

Setting the appropriate laser power and speed is critical for achieving optimal cutting quality and minimal waste for each material.

How to Choose the Best Laser Cutter for Acrylic?

- A Cutting Laser’s Specs

For applications involving acrylics, choosing a laser cutter with a minimum power of 50 watts is prudent—increased wattage results in quicker cutting and improved edge smoothness.

- Acrylic Project Dimensions

Make sure the machine’s bed size is large enough for the dimensions of your acrylic works. A larger bed would be advantageous for bigger or multiple pieces.

- Design Complexity

For highly intricate designs, a CNC with a high precision rating would be ideal, as such equipment guarantees precise and accurate cuts.

- File Format

A good laser cutter should include software tailored to the user’s needs and capable of handling SVG or DXF design files.

- Cooling System

Always ensure the effectiveness of the cooling system in use, as this greatly influences the laser cutters’ performance in preventing overheating during prolonged usage.

These considerations will help you select the laser cutter best suited to your needs, especially for acrylics.

What features should you look for in an acrylic laser cutter?

- Power Capability

Select a laser engraver cutter with adequate power to cut through the required thicknesses of acrylic. Depending on your needs, it is always safe to go with a CO2 laser ranging from 40 to 150 watts or more.

- Work Table Dimensions

Estimate the dimensions of the working area according to the size of the acrylic sheets you would like to cut. Greater cutting areas, such as 20” x 28” or 24” x 36”, offer more options for large-scale projects.

- Cutting Precision

Check to see if the laser machine has a high level of engraving precision, which must be at least 1000 DPI. This ensures clean, detailed cuts and adept engravings on acrylic.

- Ventilation System

A good laser cutter should have some ventilation or an exhaust system. It should be able to get rid of the fumes and dust created during the cutting process.

- Focused Maintenance

The best option is a laser cutter that is easy to clean. Segregated mirrors, lenses, and trays make cleaning faster and increase the machine’s lifespan.

What is the difference between a desktop CO2 laser and a larger laser cutting machine?

|

Feature |

Desktop CO2 Laser |

Larger Laser Cutting Machine |

|---|---|---|

|

Workspace Size |

~20″x12″ |

Up to 48″x36″ |

|

Power |

40W–45W |

75W–100W+ |

|

Portability |

Easily portable |

Requires fixed installation |

|

Cost |

Lower, ~$2,500–$8,000 |

Higher, ~$10,000+ |

|

Typical Applications |

Small crafts, engraving |

Industrial-scale cutting, large projects |

What Are the Best Acrylic Projects for Laser Cutting?

The precision offered by laser cutters makes systems far sharper than any tool and more flexible than ever. Known for its versatility, acrylic can be used for building many different project,s such as

- Custom Signage – You can make corporate signs that have names easily,y or home signs.

- Jewelry – Unique design and patterns can be made for necklaces, bracelets, and intricate earrings.

- Keychains and Ornaments – Cutting keychains and ornaments serves both practical and aesthetic purposes

- Display Stands – Eye-catching and Sturdy artists can make stands to showcase their products like collectibles and popular merchandise.

- Art and Decorations – Using acrylic color options, wall art, and decorative pieces like panels can also be made.

- Templates and Stencils—These templates can be used repeatedly and are made for crafting, painting, and even engraving.

All of the projects listed above emphasize the versatility of acrylic while highlighting the advanced capabilities of laser cutters.

What types of acrylic are best for laser cutting?

When it comes to laser cutting, the two main types of acrylic used are cast and extruded. Each has unique pros depending on the project’s goals.

1. Cast Acrylic

Cast acrylic is often the preferred option for laser cutting applications with high edge and aesthetic finish standards. It does not need post-processing as the edge is already smooth and polished after laser cutting. This makes it ideal for intricate designs, decorative pieces, and custom signage. The optical clarity of cast acrylic is better than that of extruded acrylic, and it is available in a variety of finishes such as clear, frosted, and colored. Furthermore, the engraving is exceptionally well done, creating a frosted effect which enhances intricate designs.

- Thickness Range: 1mm to 20mm, but thicker sheets are also available.

- Application: High precision projects, artistic engravings, custom trophies.

- Cost: It is slightly more expensive than extruded acrylic, but the quality justifies the price.

2. Extruded Acrylic

Extruded acrylic is particularly popular for laser cutting because of its cost efficiency and uniform thickness. While extruded acrylic circumvents cut performance compared to cast acrylic, it cuts at a quicker pace, albeit with rougher edges that may need supplementary finishing. It is best suited for templates or other industrial components that are cost-sensitive and do not focus as much on visual factors. One drawback is the engraving quality, which is more pronounced than frosted on extruded acrylic compared to cast acrylic.

- Thickness Range: Typically a bit more slender, but still within the same range as cast acrylic.

- Applications: Stencils, functional parts, other projects with tighter budgets, and price-sensitive projects.

- Cost: Compared to cast acrylic, extruded acrylic is more affordable.

Material Thickness: Thicker sheets tend to have more powerful lasers, but both varieties of acrylic have different thicknesses. For example, a 40W CO2 laser can cut with good precision around 6 mm-thick sheets, while a 100W laser can cut 20 mm-thick sheets.

Edge Finish Requirements: Cast acrylic performs best in cases where granulated edges are important.

Engraving Needs: Out of the two acrylic options, cast acrylic provides more detailed frosted engravings than extruded acrylic.

Selecting the appropriate type of acrylic is related to a project’s specific considerations, such as its budget, level of design detail, and finishing touches. Both types yield optimal results under laser cutting.

How to create custom designs for laser cut acrylic?

The process of making unique designs for laser-cut acrylic requires a sharp blend of creativity along with an understanding of design software, the laser cutting process, and design precision. Here are tips and some guidelines that will assist you in achieving the best customized designs:

- Use Professional Design Software

You can start with free software like Adobe Illustrator, CorelDRAW, or Inkscape. All of them are compatible with developing vector graphics, which are critical for laser cutting. Save your works in compatible formats like SVG, DXF, or PDF to avoid processing issues with the laser cutter.

- Carrying out Accurate Measurements

Acrylics require exact measurements to achieve intricate designs. All laser cutters operate with excellent tolerances, so double-check the dimensions and scale to check if your design will fit on an acrylic sheet. When planning your layout, account for material thickness and kerf, or the amount of material a laser beam will take away. Selecting the Right Acrylic Thickness

Acrylic sheets are available in various thicknesses, typically from 1/16 inch (1.5mm) to 1 inch (25mm). Finer sheets work well with intricate detailing, while thicker sheets provide versatility and durability. As per industry statistics, 3mm and 6mm thick acrylic sheets are most commonly used for laser cutting because of the detail and sturdiness properties associated with these dimensions.

- Engineering Control Strategies

Consider controlling movement throughout the design process, especially during engraving and cutting operations, for optimal machine efficiency. Alongside machine functionality, shape configuration should optimize material utilization. As per industry standards, optimizing design increases the chances of reducing acrylic waste by up to 20 percent, significantly impacting material cost.

- Combine Techniques for Bespoke Custom Designs

With the aid of a laser, custom intricate designs can be created through a combination of cutting and engraving. Cutting creates shapes, while engraving enhances the item’s height or adds textural frost-like features. Cast acrylic is reportedly more suited for laser engraving than extruded acrylic because it delivers sharp frosted engravings.

- Try It Out

Before dedicating a complete acrylic sheet, test your design on a leftover piece. Adapting various parameters like power and speed of the laser may also be beneficial. Ensure that the checked outlines are precisely intended for the end design.

- Think About Colors and Transparency

Acrylic may be fully colored or transparent and won’t lose its properties. Make the best of those choices to create depth and detail in your designs. According to research, utilizing multiple colored acrylics in one project can enhance the impact and perceived value of the product by as much as 30%.

- Stay Updated on Laser Technology

Laser cutters just get better and better. The latest models have additional precision, increased cutting speeds, and more than one function for intricate designs. Following the developments in this area may help you accomplish more in less time.

Whatever the case, these suggestions will guide you toward crafting professional-grade custom designs with controlled quality and optimal efficiency, whether they are custom pieces of signage, functional parts made from acrylic or artistic renderings.

What are some popular acrylic laser cutting project ideas?

Some of the most popular projects that can be done using an acrylic laser cutter include custom keychains, awards plaques, decorative wall art, jewelry making, and even signage. Clocks, coasters, and lamp shades are also projects that I consider to be extremely creative The customization options offered by acrylic proves why it is still such a popular material.

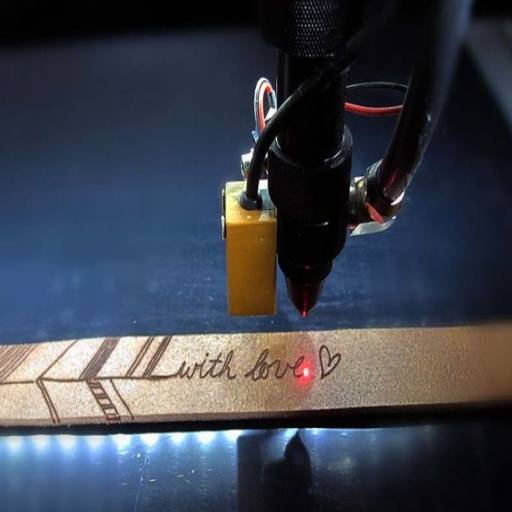

How to Engrave Acrylic with a Laser Cutting Machine?

If you have a laser cutting machine and want to engrave acrylic, here are some steps that you can follow.

The very first step is to carve an appropriate design. This should be done on a compatible design software. Always ensure the design software’s file types are supported by the kind of laser cutter you intend to use.

Choose the most appropriate type of acrylic. For engraving purposes, always use cast acrylic since it offers a smooth, frosted finish, unlike extruded acrylic, which offers a clear die-graved result.

The next step is to configure the machine settings. For each of the pointers set, the laser power and speed should be adjusted according to the thickness of the acrylic. Setting these pointers for the first time should always be done on used material to give the best results.

After that, you need to position the material by laying down the acrylic with a laser cut between the router’s bounds. The material should also be completely flat to allow for accurate layering.

Once that focus is achieved, the laser should be focused. When focusing, use the correct height pointer for ease of engraving.

Close monitoring of the acrylic as the shaping process is gradually applied can achieve the best results and ensure the aforementioned smooth operation.

Using a laser cutter to cut acrylic can deliver ‘professional-quality engravings’; all you need to do is follow these steps. Remember to prioritize safety and carefully read the machine’s manual before use.

How do you adjust settings for engraving different types of acrylic?

|

Parameter |

Black Steel Pipe |

Copper Pipe |

PEX Pipe |

Galvanized Steel Pipe |

Cast Iron Pipe |

CPVC Pipe |

|---|---|---|---|---|---|---|

|

Material Cost |

$30-$50 per section |

$2-$8 per foot |

$0.40-$2 per foot |

~$8 per foot |

$2-$10 per foot |

$0.50-$1 per foot |

|

Labor Cost |

Medium |

High |

Low |

High |

High |

Medium |

|

Lifespan |

50-100 years |

Up to 100 years |

50-70 years |

~40 years |

Up to 100 years |

50-70 years |

|

Corrosion Resistance |

Moderate |

Excellent |

Excellent |

Low |

Moderate |

High |

|

Common Uses |

Structural and gas lines |

High-end plumbing projects |

DIY plumbing, in-floor heating |

Older homes, high pressure uses |

Drainage, sewage systems |

Budget plumbing |

|

Durability |

High |

Very High |

High |

Moderate |

Very High |

High |

|

Installation Ease |

Moderate |

Difficult |

Easy |

Difficult |

Difficult |

Moderate |

|

Maintenance |

Moderate |

Low |

Low |

High |

Low |

Moderate |

What are the best practices for laser engraving acrylic?

When laser engraving acrylic, following best practices ensures a clean, precise, and professional result. Here are five key best practices to consider:

- Choose the Right Acrylic

Cast acrylic is the best option for laser engraving, providing a frosted, high-contrast finish. Avoid extruded acrylic for engraving projects, as it typically results in a lower-quality, translucent finish.

- Use Appropriate Settings

Adjust your laser cutter’s power and speed settings based on the thickness and type of acrylic. For example, a typical setting for 1/8-inch cast acrylic is 20% power and 100% speed, but configurations may vary by machine and material.

- Engrave on the Reverse Side

For clear acrylic, engraving on the reverse side provides a sleek, polished look when viewed from the front. This practice is especially recommended for signage or decorative pieces.

- Ensure Proper Focus

Properly focus the laser to achieve sharp engraving details. Regularly check the machine’s focus adjustments to avoid blurred or uneven results.

- Clean Thoroughly After Engraving

After engraving, clean the acrylic with a non-abrasive cleaner to remove residue or soot. This prevents scratches and keeps the acrylic surface looking pristine.

Reference Sources

1. Optimization of CO2 Laser Cutting Parameters

- Objective: Research often focuses on optimizing parameters such as laser power, cutting speed, and focal length to achieve the best cut quality and efficiency.

- Key Findings:

- Studies may identify optimal settings for different acrylic thicknesses to minimize thermal damage and achieve clean cuts.

- Investigations into the effects of varying assist gases (e.g., air, nitrogen) on cut quality and edge finish.

2. Material Interaction and Properties

- Objective: Understanding how acrylic responds to CO2 laser cutting is crucial for improving cutting precision.

- Key Findings:

- Research may explore the relationship between laser parameters and the physical properties of acrylic, such as melting point and thermal conductivity.

- Studies might analyze the kerf width and heat-affected zones to assess the impact of laser cutting on material integrity.

3. Top Co2 Laser Engraving Cutting Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is the best acrylic laser cutter for my needs?

A: The best acrylic laser cutter depends on your specific requirements, including the acrylic thickness you plan to cut. A 60W CO2 laser machine is sufficient for cutting and engraving cast and extruded acrylic for most applications. Consider an 80W or 100W CO2 laser cutter and engraver if you need to work with thicker acrylic.

Q: Can a laser cutter machine cut and engrave acrylic?

A: A laser cutter machine can cut and engrave acrylic materials. A CO2 laser cutter and engraver is particularly effective, providing precision and clean edges.

Q: What types of acrylic are suitable for laser cutting?

A: Both cast and extruded acrylic can be used for laser cutting. However, the results may vary, with cast acrylic often providing better clarity and less chipping during cutting.

Q: How does laser power affect the performance of a laser cutting and engraving machine?

A: Laser power significantly impacts the ability to cut through thicker acrylic and engraving speed. Generally, higher wattage (such as 80W or 100W) allows for faster cutting and the ability to work with thicker acrylic materials.

Q: What is the difference between a CO2 laser machine and a fiber laser?

A: A CO2 laser machine is best for cutting and engraving non-metal materials like acrylic, wood, and leather. In contrast, a fiber laser is more suitable for cutting metals. For acrylic cutting, a CO2 laser cutter and engraver is recommended.

Q: Can I use a desktop laser to cut thicker acrylic?

A: While desktop lasers, such as a 55W desktop CO2 laser, can cut acrylic, their effectiveness on thicker acrylic (over 10mm) may be limited. For thicker acrylic, a more powerful laser cutting machine would be advisable.

Q: What is the role of the laser tube in a laser engraving machine?

A: The laser tube generates the laser beam that the laser head focuses on to engrave and cut materials. The quality and power of the laser tube impact the efficiency and effectiveness of the laser cutting and engraving process.

Q: Can black acrylic be engraved with a CO2 laser cutter?

A: Black acrylic can be engraved using a CO2 laser cutter. The contrast created by the engraving process can enhance the design’s appearance, making it stand out effectively.

Q: What is the advantage of using an OMTech laser for acrylic cutting?

A: OMTech lasers are known for their reliability and precision. Their CO2 laser cutter and engraver models provide excellent performance for cutting and engraving acrylic, making them popular among hobbyists and professionals.