With CO2 Galvo laser marking machines, speed and efficiency join precision, unlike any other technology. These machines serve various industries, from manufacturing to high-quality packaging and custom design crafting, to provide tailored solutions that meet versatile custom requirements. But what exactly sets laser CO2 Galvo marking machines apart from other technologies? How do they function, and what are their pros over other conventional methods of marking and etching? Well, look no further as this guide seeks to provide detailed answers from deep diving into the inner workings and technical details of Galvo laser systems to their practical benefits, exploring a range of applications that justify and advance their use in modern technology. Get set to uncover the underlying capabilities of CO2 Galvo technology and the unparalleled ease of precision control and productivity it brings for your operations.

What is a CO2 Galvo Laser Marking Machine?

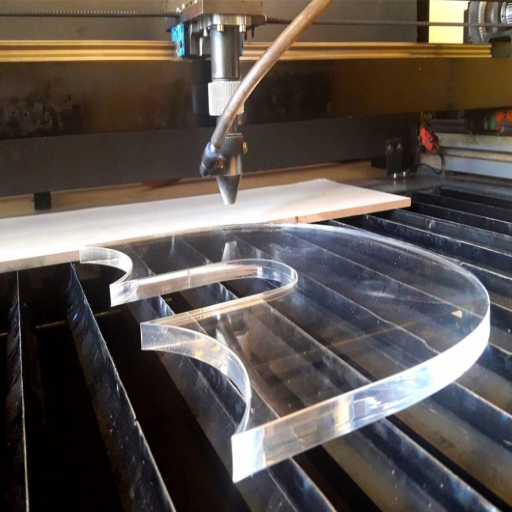

Marking or engraving materials quickly and accurately is accomplished using a CO2 Galvo laser marking machine, which incorporates CO2 lasers alongside galvo mirrors. The integral CO2 laser within the device produces an orange beam of light, and using galvo mirrors, the laser can redirect the light to text, designs, or custom logos onto various surfaces. This technology is beneficial for putting marks on wood, plastic, glass, leather, and acrylic, as they are non-metal materials. CO2 Galvo systems are highly regarded for their efficiency, resilience, and proficiency at high-speed marking in commercial and industrial use.

Understanding the CO2 Laser Technology

Companies use infrared CO2 lasers for cutting and engraving because the laser beam wavelengths work best with non-metal materials. CO2 lasers have also been helpful in many fields, such as automotives, packaging, and electronics. Modern CO2 systems have low operation costs while maintaining precision and efficiency. Furthermore, new features implemented into these systems have done wonders for beam cooling and quality, enabling over 30,000 streaming hours of non-stop usage, leading to higher efficiency and longer service life.

It’s also been noted that CO2 lasers are capable of engraving with depth accuracy ranges of over 1 millimeter, which is perfect for assistive drawing devices. As systems become more user-friendly through integration with automated processes, future standards of Industry 4.0 can allow for real-time monitoring of CO2 lasers, improving efficacy on the assembly line.

By enabling operation at 300 characters per second for advanced forms of marking per application, CO2 lasers demonstrate the ease of adjusting toolpaths in variable programming. As these tools become adept at functioning independently, the potential role of laser resolution and accuracy becomes essential in modern manufacturing, marking a new age in design.

Components of a Galvo Laser Marking System

|

Component |

Description |

|---|---|

|

Laser Source |

Generates the high-intensity laser beam |

|

Galvanometer |

Directs laser beam for precise marking |

|

Control System |

Manages laser operations and settings |

|

Optical Path |

Mirrors and lenses for beam focus |

|

Auxiliary Accessories |

Includes cooling, safety systems, and more |

What Are the Applications of CO2 Laser Marking?

Because of its exactness and flexibility, CO2 laser engraving is applied in many industries. It is usually executed on organic constituents like wood, leather, textile, paper, etc. Moreover, it can also be used on some coated plastics, glass, and metals. Packaging, electronics, and automotive industries use CO2 laser engraving for marking logos, serial numbers, product barcodes, and labeling. This kind of engraving guarantees unequivocal and irrevocable marks that are suitable and best for marking applications that need durability and meticulousness.

Uses for Non-Metal Materials

CO2 laser technology is well known throughout industries for its versatility and precision when marking or engraving non-metal materials. Below are some highlighted applications across multiple sectors:

- Packaging Industry

CO2 lasers are very useful in marking expiration dates, barcodes, and lot numbers on paper, cardboard, and plastics. As a 2023 market report states, the demand for sophisticated marking tools is increasing as the worldwide economy sustains growth at an 8.5% CAGR in the packaging laser marking industry. This underlines the demand for clear, durable markings on non-metal substrates.

- Textile and Fashion Industry

Lasers are used to engrave designs and patterns onto textiles such as denim, leather, and synthetic fabrics, safeguarding precision and material. Reports suggest that adopting CO2 laser marking in apparel and leather production has increased the efficiency of mass customization according to modern consumer demand.

- Automotive Industry

In automotive manufacturing, CO2 lasers are employed to mark part numbers, logos, or safety labels on dashboards and even seat fabrics. Supply chain manufacturers have to comply with traceability regulations, so the reliability and precision of CO2 engraving are of great value to them.

- Electronics Industry

In the ABS, polycarbonate, and silicone industries, CO2 lasers increase the efficiency of marking and labeling parts and casings. Proper marking, as in the IoT industry, helps seamlessly trace components.

- Arts and Crafts

CO2 lasers for engraving have gained traction from small businesses, artisans, and other industries due to creating personalized designs for wood, paper, and acrylic. 2022 saw an increase in demand for custom-tailored products. As such, surveys have indicated that laser-based craft businesses had an increase of 20% in revenue in 2022 due to customization demand.

The environmentally proficient CO2 laser technology has provided all the precision and reliability needed to transform the handling of non-metal materials in goods marking, enabling mass production and bespoke designs.

Industry Applications of CO2 Laser Marking

Since CO2 lasers are efficient with non-metal materials, these lasers are incorporated in many sectors. The following are five primary applications and their descriptions:

1. Packaging Sector

CO2 lasers are popular in the packaging sector because they mark expiration dates, barcodes, and lot numbers on paper, plastic, and cardboard economically and accurately. Markings done with laser precision have good contrast, which improves traceability.

2. Electronics Sector

Electronic manufacturers employ CO2 lasers to engrave circuit boards, plastics, and some electronic equipment. Markings made on these materials are precise, clear, and long-lasting. For instance, studying the impact of laser markings revealed a 15% reduction in identification errors in electronic production.

3. Textile and Apparel Sector

Other than cosmetics marking, CO2 lasers enable drawing of detailed logos and labeling on materials like leather, denim, and synthetic fabrics. The precision in detailing allowed without damaging the fabrics increases adoption for CO2 lasers, especially in high-end fashion production.

4. Automotive Sector

Markings like the vehicle’s part number and date of manufacture on components made of plastic, rubber, and other composite materials aid in tracking and controlling the quality in automotive production. CO2 lasers automate the procedure of marking vehicle parts for easier identification.

5. Medical Industry

CO2 laser marking has various applications in marking medical equipment, devices, tools, packages, and even marking for sterility and traceability. Due to the strict regulations imposed by the medical industry, this contactless technology is widely accepted.

Adaptability and reliability have made CO2 laser marking an essential part of modern industries, as it is precise and efficient in laser marking applications.

How to Choose the Right CO2 Laser Marking Machine?

CO2 laser marking devices need particular attention when it comes to purchasing one. It is essential to look at the traits mentioned below:

- Material Compatibility—Look at whether the machine will effectively mark the materials you need it for, which may include metals, plastics, glass, and wood.

- Marking Speed and Precision—In situations where productivity levels are high, go for devices that pay close attention to precision. Accuracy should not overshadow speed.

- Power and Wavelength—Other devices may perform better than others depending on the provided power and wavelength; select devices that display proper quality markings.

- Software and Usability—Make sure that the intuitive software is comfortable to control, making operation easier. This brings out the best in functionality.

- Maintenance and Reliability—Marking devices differ in standards. Some require frequent maintenance, and others don’t. Pick a device known for having the lowest maintenance time.

- Compliance and Safety—The demanded safety level for marking devices within the target industry must be checked to avoid problems. Ensure compliance.

- Budget and Support—In addition to the budget, striking the correct balance between customer service, warranties, and follow-up services should not be put aside.

Ensuring that all of the factors above are shown equally is the best way to strike a balance, ensuring productivity and efficiency in the long run.

Key Features to Consider in a Laser Marking Machine

When buying a laser marking machine, pay attention to the following features to ensure it meets necessary operational goals and measures. You don’t want to compromise on efficiency and reliability.

- Laser Power and Wavelength

When it comes to laser marking or engraving machines, as the power increases, the features and efficiency also improve. For example, engraving or high-speed marking on tougher materials requires a more powerful laser. Moreover, the laser diameter determines the types of materials that can be lasered. For example, a vaporized laser with a wavelength of 10.6 µm for CO2 lasers can achieve better results.

- Marking Speed and Precision

When dealing with vast quantities, the speed of the machine becomes paramount. Fitting machines equipped with enhanced galvanometer technology achieve better marking speeds while ensuring precision and accuracy of complex designs.

- Software And Control Options

Intuitive software makes it easy for non-designers to create unique designs and import files in various formats, such as DXF, PLT, or BMP. The best machines come with power and frequency control, marking different cases and requirements easily.

- Material Versatility

Laser engraving and marking machines ought to work on an extensive array of materials, such as metals, plastics, wood, glass, or even leather. This is an essential feature for providing adaptable solutions for various uses in different sectors and industries.

Cooling System

Water or air cooling is an example of an effective cooling system. Such systems offer great value by ensuring that the machine works within the best temperature limits. Maintaining optimal temperature is crucial for prolonging the machine’s lifetime by reducing overheating risks during sustained periods of usage, smoothing upkeep, and minimizing damage.

With these highlighted features, you can now make a more informed choice of a laser marking machine tailored specifically to your production objectives while ensuring sustained and dependable performance.

Difference Between 30W and 40W CO2 Lasers

|

Parameter |

30W CO2 Laser |

40W CO2 Laser |

|---|---|---|

|

Price Range |

$300-$500 |

$400-$700 |

|

Power Output |

30W |

40W |

|

Material Compatibility |

Cuts wood, acrylic, and leather |

Cuts thicker wood, acrylic, and leather |

|

Precision |

Suitable for fine details |

Better for thicker materials |

|

Operational Cost |

Low-medium (less electricity) |

Medium-high (more electricity) |

|

Efficiency |

Slower processing |

Faster processing |

|

Maintenance |

Moderate upkeep required |

Slightly higher upkeep |

What Are the Advantages of Using a CO2 Galvo Laser Engraver?

Barebones CO2 Galvo laser engravers are best suited for applications where high speed, flexibility, and efficiency are of the utmost importance due to their enormous benefits. Some of the many advantages include:

- Enhanced Speed of Engraving: Unlike traditional laser systems, galvo systems employ mirror-based laser positioning, allowing the system to engrave at far greater speeds.

- Versatility: Like many laser engravers, these devices can engrave on wood, glass, leather, acrylic, and countless other materials.

- Exceptional Accuracy: These engravers are highly regarded for their high-detail engraving, owing to their ability to create intricate patterns or text.

- Energy Efficient: Cost-effective long term, because galvo systems are engineered to minimize energy wastage.

- Low Maintenance: With robust construction, low moving parts, and a low-predictable hand system, wear and tear are less prevalent.

I immediately endorsed CO2 Galvo laser engravers for their unbeatable combination of speed, precision, and flexibility, all for professional/industrial use.

High Precision and Speed in Marking

In terms of speed and precision, CO2 Galvo laser engravers take the stand for being “The best,” and for good reason. These machines offer extreme versatility and ease while capable of incredible speed and precision. That unparalleled efficiency and comfort while dealing with the machines has streamlined my workflow like never before.

Comparison with Fiber Laser Engraving Machines

|

Parameter |

CO2 Laser |

Fiber Laser |

|---|---|---|

|

Material Compatibility |

Non-metals like wood, acrylic |

Metals, including reflective types |

|

Precision |

Good for detailed designs |

Superior for fine markings |

|

Cost |

Lower upfront, higher operation |

Higher upfront, reduced operation |

|

Maintenance |

Regular upkeep required |

Minimal maintenance needed |

|

Energy Efficiency |

Less efficient, higher power use |

Highly efficient, lower power use |

Reference Sources

1. Fabrication of Microchannels by Using the CO2 Galvo Laser Marking Machine and Thermo-mechanical Sealing Method

- Authors: H. A. Tam, N. V. Hung, N. Duc, D. H. Giang

- Publication Date: June 28, 2019

- Journal: VNU Journal of Science: Natural Sciences and Technology

- Summary: This study discusses the fabrication of microchannels using a 40W CO2 Galvo laser marking machine. The authors controlled the channel dimensions by adjusting the laser power, scanning speed, and scanning time. The results indicated that increasing laser power and decreasing scanning speed led to broader and deeper channels. The microchannels were successfully tested in laminar flow and droplet modes and sealed using a thermo-mechanical method at 220°C.

- Methodology: The authors utilized a CO2 Galvo laser marking machine to create microchannels and analyzed the effects of various parameters on channel dimensions and surface roughness. (Tam et al., 2019)

2. Optimization of Parameters for Laser Marking and Engraving on Plywood and Pine Wood Materials

- Authors: Artis Stanislavs Gusts, Imants Adijans

- Publication Date: April 23, 2021

- Journal: HUMAN. ENVIRONMENT. TECHNOLOGIES. Proceedings of the Students’ International Scientific and Practical Conference

- Summary: This publication shows the results of CO2 laser marking and engraving on plywood and pine materials at different speeds and powers. The authors measured the marked and engraved line depth for various combinations of speed and power ratios.

- Methodology: The study utilized a SUNTOP CC-9060 CO2 laser machine and an OLYMPUS OLS5000 laser microscope to analyze the effects of different parameters on engraving quality.(Gusts & Adijans, 2021)

3. Top Co2 Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a CO2 Galvo Laser, and how does it work?

A: A CO2 Galvo Laser is a type of laser marking machine that utilizes a CO2 laser source to engrave or mark various materials. It directs a laser beam through a system of mirrors controlled by a galvanometer, allowing for high-speed marking with precision.

Q: What are the advantages of using a laser marker with a galvanometer system?

A: A laser marker’s galvanometer system enables unparalleled speed and accuracy. This allows faster processing times and high-quality marking, making it ideal for intricate designs and detailed engraving projects.

Q: What types of materials can a CO2 laser engraver mark?

A: A CO2 laser engraver can mark organic materials like wood, acrylic, and leather. Additionally, it can engrave on some coated metals, although a fiber laser engraver may be more suitable for bare metals.

Q: How does marking speed affect the performance of a laser system?

A: Marking speed is crucial for productivity. A high marking speed allows for quicker processing of items, reducing production time while maintaining high-quality marking. The CO2 laser marking system is designed to optimize this speed effectively.

Q: What maximum marking depth is achievable with a CO2 laser marking machine?

A: The maximum marking depth depends on the material being marked and the settings of the CO2 laser marking system. Deeper markings can generally be achieved on softer materials, while harder materials may require multiple passes.

Q: Can a 30W CO2 galvo laser be used for industrial applications?

A: Yes, a 30W CO2 galvo laser is suitable for various industrial applications, including high-speed engraving and product marking. Its efficiency and advanced capabilities make it ideal for both small-scale and large-scale production.

Q: What is the difference between an RF CO2 laser and a CO2 glass tube laser?

A: An RF CO2 laser uses radio frequency technology to excite the gas mixture, providing a longer lifespan and stable output. In contrast, a CO2 glass tube laser typically has a shorter lifespan and may require more frequent maintenance.

Q: How can I integrate a rotary axis with my CO2 laser marking machine?

A: To integrate a rotary axis, ensure your CO2 laser marking system is compatible with rotary attachments. This setup allows for the engraving of cylindrical objects, enhancing the versatility of your laser engraver machine.

Q: What are some standard marking methods used in laser engraving?

A: Common marking methods include vector engraving, raster engraving, and cutting. Each method has its applications and is chosen based on the requirements of the engraving project and the material being used.

Q: How do I choose between a fiber laser marking machine and a CO2 laser engraver?

A: The choice depends on the materials you intend to work with. Fiber laser marking machines are better for marking metals and harder materials, while CO2 laser engravers excel at marking organic materials and plastics. Consider your specific engraving needs before deciding.