The introduction of CNC routers with laser functions has changed the transformation process of many ideas for creatives, businesses, and even casual tinkerers. These machines enable precision cutting and engraving, multifunctional operation, and more, creating amazing opportunities in various sectors like woodworking and product design. Be it an ‘old-timer’ who wishes to upgrade their tools or a novice wanting to dive into the multifaceted world of CNC and lasers, getting the right equipment is crucial for them to accomplish their objectives. This guide will discuss all the considerations you have to consider regarding the best laser cutter and engraver, along with other options available in the market, and CNC routers with laser functionalities. Prepare everything to help you achieve your creative self and amplify your work!

What is a CNC Router with a Laser?

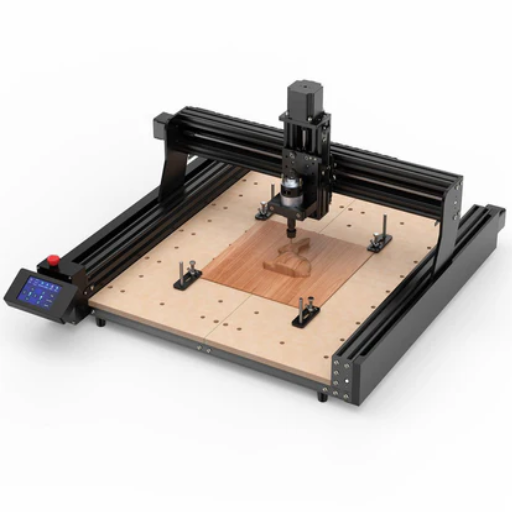

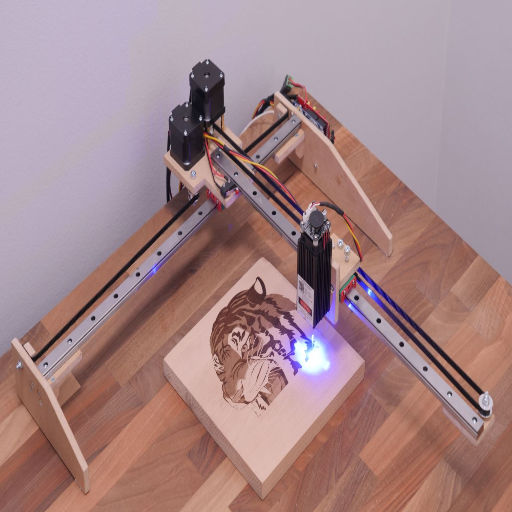

As the name suggests, a CNC Router with Laser is an all-in-one machine that integrates the traditional CNC router with a laser cutter or engraver. Users can effortlessly cut, engrave, and shape different materials such as wood, acrylic, plastics, and metals. The CNC router performs carving and routing, while cutting and engraving with the laser are done with utmost precision and minimal waste of material.

This blend of features makes the system perfect for intricate design projects requiring efficient material processing.

How Does a Laser Cutter Work?

Focusing on a laser beam using computer numerical control (CNC) technology allows precise cuts and engravings on different materials. While a laser source generates the beam, it is further amplified with specialized lenses and mirrors, concentrating the energy into a minimal focal point. This creates energy that can be used to heat, melt, vaporize, or any combination of the there,e the material it contacts. As a result, clean and accurate cuts or engravings are formed.

Modern laser cutters exploit new technologies to enhance efficiency and precision even further. For instance, carbon dioxide (C02) lasers work well with non-metal materials such as wood and acrylic, but lower intensity and speed fiber lasers are better suited for metals. These fiber lasers can achieve speeds of up to 1,400 inches per second while cutting thin materials, boosting productivity in industrial settings.

Lasercutters are capable of intricate designs for the manufacturing, electronic, and arts industries. Their precision is unmatched as it achieves tolerances of ±0.001; additionally, their non-contact process offers reduced material waste, conserving resources compared to traditional cutting practices. Recent statistics indicate that the global laser cutting market has seen increased adoption across sectors, with an estimated compound annual growth rate of 8.5% from 2022 to 2030.

State-of-the-art laser cutters offer real-time adjustable focus, multi-mode cutting features, and up-to-the-second surveillance, guaranteeing precision and quality for all tasks and simultaneous versatility to meet all demands.

Key Components of a CNC Laser Machine

Every CNC (Computer Numerical Control) laser machine includes important constituent parts that follow a specific function while working together for accurate engraving and cutting. We will elaborate more on the essential components and their functions below:

- Laser Source

The laser source forms the laser beam needed for etching or cutting. It is the heart of the machine. There are many types of laser sources, such as CO2 lasers, fiber lasers, and diode lasers. Fiber lasers are preferred in industrial work because of their efficiency, ability to precisely cut metals, longer life, and many other benefits. CO2 lasers are still mostly used in non-metal materials like wood, plastic, and acrylic.

– Market insight: The demand for industry and automotive fiber lasers is spearheading growth in the fiber laser market, which is projected to reach 7.6 billion dollars by 2028.

- Control System

The CNC control system is the brain of the machine. Setting parameters and monitoring progress are done in real time, which gives the operators some interactivity and engagement. Designs can be programmed with CAD or CAM, ensuring the CNC machine has a guided and path-structured approach to cutting different shapes.

- Laser Optics

Mirrors and lenses, together with the focusing systems, make up the laser optics, which focus and channel the beam onto the material’s surface. These elements guarantee that the beam’s power and accuracy are preserved during the entire process. One of the most recent developments is dynamic autofocus, which automatically changes the position of the lens to the proper height for optimal cutting for all material thicknesses.

- Worktable

The worktable is used to tether the material and has different designs depending on the application. For example, honeycomb worktables are commonly used to improve air flow during cutting to minimize material burns. Larger industrial CNC laser machines may have two worktables that operate simultaneously for loading and processing to improve productivity.

- Cooling System

When the laser source and other components are operating, the cooling system is required so that the temperature does not increase too much, preventing overheating. To maintain the temperature, water chillers are used as they provide cooling, prolonging the life of the laser and maintaining its performance.

- Exhaust System

The exhaust system removes smoke, fumes, and particulates from the cutting or engraving operations. Air filtration systems are important for protecting operators and helping maintain clean work areas, especially in businesses governed by stringent health regulations.

- Motion System

The motion system comprises motors, belts, and rails that navigate the laser head. It is one of the most critical elements, as its accuracy and speed define the quality of the work done. Today’s machines amalgamate servo motors and linear guides, which further enhance the speed and accuracy of the work.

- Power Supply

CNC laser machines are governed by strict power supply parameters. The type of laser, its type, its load, and its operational power all determine the shape of the power supply unit necessary for achieving the stability required by CNC systems.

Data Point: The working efficiency of fiber lasers is estimated to be approximately 30%, while older CO2 laser systems average 10-20%. Focus on sustainability surpasses the new CO2 systems.

Each of these parts works towards achieving CNC laser machines’ precision so deep that the margin surpasses human practicality and speed alongside reliability that can redefine set standards in industries such as automotive, aerospace, electronics, and manufacturing. Continual technological changes enable these machines to be smarter, leaner, and more efficient aligned with modern industrial needs.

CNC Router vs Laser: Which is Right for You?

In the CNC router vs laser cutter scenario, the decision depends on the user’s application and type of material.

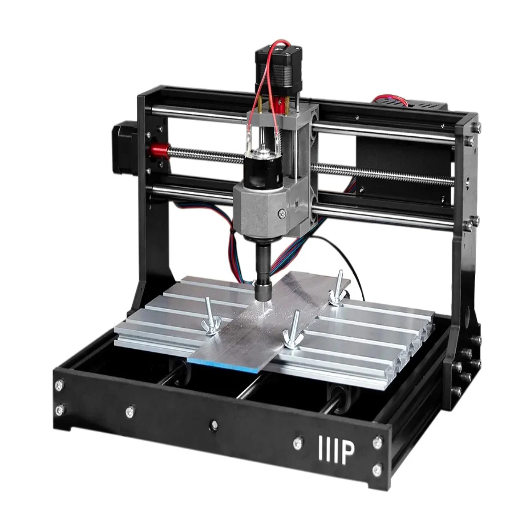

- CNC Router: Best suited for machining wood, plastic, and soft metals, CNC routers excel in 3D carving and sculpting, handling deeper projects with layered designs efficiently.

- Laser Cutter: This tool works best for thin acrylic, wood, fabric, and glass. As the name suggests, it is best for detailed work and provides precision cuts, engraving, and etching cleanly with minimal masking required.

Evaluate the materials, detail, and volume needed. The CNC router is more versatile with thick materials, whereas the laser cutter excels in detail for fine tasks.

Differences Between CNC Routers and Laser Cutters

CNC routers require physical contact to cut and carve, excelling in 3D designs and thicker material handling. Laser cutters, on the other hand, use heat and do not require contact to cut, making them ideal for thin materials and 2D intricate designs.

| Parameter | CNC Router | Laser Cutter |

|---|---|---|

|

Cutting Tool |

Router bit |

Laser beam |

|

Process Type |

Contact |

Non-contact |

|

Precision |

Moderate |

High |

|

Cutting Depth |

High |

Low |

|

Speed |

Slower |

Faster |

|

3D Capability |

Yes |

No |

|

Noise |

High |

Low |

|

Material Range |

Broad |

Limited |

|

Edge Finish |

Smooth |

Polished |

|

Setup Ease |

Complex |

Simple |

|

Maintenance |

Moderate |

High |

|

Cost |

Lower |

Higher |

|

Material Waste |

More |

Less |

|

Safety |

Moderate risk |

Enclosed safer |

Pros and Cons of Using a CNC Laser Machine

CNC laser machines are versatile in terms of precision, speed, and material, but high costs, material thickness, and possible heat damage restrict them.

| Parameter | Pros | Cons |

|---|---|---|

|

Precision |

High |

– |

|

Speed |

Fast |

– |

|

Material Range |

Versatile |

Limited thickness |

|

Clean Cuts |

Minimal debris |

Heat discoloration |

|

Automation |

Efficient |

Expertise needed |

|

Setup Cost |

– |

High |

|

Energy Use |

– |

High |

|

Fumes |

– |

Toxic gases possible |

When to Choose a Laser Engraver Over a CNC Router

The choice of a laser engraver and a CNC router solely depends on the needs of the specific project, required materials, precision needs, and overall detail required. Laser engravers best serve applications needing details as their lasers etch with extreme precision. CO2 laser engravers, for instance, have tolerances of up to ±0.1mm, perfect for engraving logos, patterns, or text onto wood, leather, glass, and acrylic.

Laser engravers are also quicker at engraving and cutting than CNC routers. Their lack of tool change for different operations leads to a significant reduction in downtime. Industry reports state that cnc laser engraving machines can save operational time up to 30% compared to cnc machines for detailed tasks.

Buy a laser engraver if you need to work with fine materials or detailed designs. They are faster and more precise. Due to their speed and precision, laser engravers work best when producing intricate designs such as artwork, jewelry engravings, or personalized items on mass.

However, laser engravers are not as good for working with thicker, harder materials like metal unless they have more advanced features like fiber lasers. While extremely precise, fiber laser engravers are efficient when cutting metals such as stainless steel. Unfortunately, these tools usually have higher upfront costs.

In conclusion, laser engravers are best suited for businesses and creators needing to capture intricate details requiring personalization in bulk production for faster throughput. Better understanding the limitations and requirements of your projects will allow you to determine when to use laser engravers instead of CNC routers.

How to Use a CNC Laser Engraver Effectively?

- Learn The Features of the Device

Get to know and review the user manual, as it contains details such as the device’s functions, such as the controls, and safety features, like the controls for the laser engraver.

- Create The Design

After ensuring that the laser engraver works with compatible design software, upload the design or create one from scratch. Make all necessary adjustments to your file so that it meets the engraver’s requirements.

- Choosing the Right Material

Collect the required materials, such as wood,auklic, or metal, because they all undergo laser burning. Furthermore, engraved results can only be achieved when the material is flat and clean.

- Turn Down the Power

When laser cutting wood, avoid damaging the material by burning too quickly. Adjust the speed and power focus to fit the materials at hand. For the best impact on results, settings can be changed when aiming for achievable precision and accuracy.

- Engage In A Trial Session

Pre-evaluate engravings by trying out a design on a cheaper alternative before committing to expensive materials. This involves verifying a presumed design match while confirming setting objects like the material and design.

- Follow the Intended Steps

Setting workspace boundaries encourages wearing protective gear and opening a window during running operations. Unattended running leaves the machine vulnerable to tampering, where observing actions while letting it run is safe.

- Scheduled Servicing

Cleaning the lens, mirrors, and workspace ensures longevity to the performance spare parts of the machine, while forgetting to service translates the opposite.

With the provided information, using CNC laser engravers will deliver precision and accuracy on the first attempt while keeping the finances in check since the procedures do not require a second attempt. Given everything, lowering the freely adjustable laser power while raising focus, speed, and order will increase laser cutting efficiency, resulting in fewer passes.

Setting Up Your Laser Cutting Machine

If you want to make sure your laser cutting machine is set up optimally, please follow these steps.

- Choosing the Correct Workspace

Ensure that the area where you place the laser cutting machine is clean and calm, well-ventilated, and has a stable, clear, and level surface. Make the machine entrance and direction booth easy passages for subsequent access and material handling.

- Exhaust System Setup

You need to connect the machine to a reasonable exhaust system that will remove smoke and fumes produced by its operation. Smoke and air circulation ventilation are crucial for safety, people’s movement, and air circulation.

- Checking the Connectors

All electrical connections containing the wiring should be adequately checked for integrity prior to powering on the machine. If needed, place the machine on an automatic voltage stabilizer to protect the system from power cuts and power on and off fluctuations.

- Machine Setup and Installation

Connect the computer unit to the machine via Bluetooth or utilize cables as per the manufacturer’s instructions. Follow the installation steps using the laser head aiming system step by step to ensure operational, cutting, or engraving accuracy.

- Selecting Your Materials

135 engrave materials that can be used with the laser cutter include, but are not limited to, wood, leather, and acrylic. Use clean materials free of dust, greasy marks, or residues that could lead to ineffective and inferior cuts.If you want to maintain high-performance levels and extend the longevity of your laser cutting machine, follow the steps and perform regular maintenance as outlined. Also, check forums and online platforms for more personalized tips based on your model or the projects you undertake.

Programming Your CNC Laser with CAD Software

Programming your CNC laser with CAD (Computer-Aided Design) Software brings you closer to converting creative designs into practical, precise, and manufacturable products. Start by creating or importing a vector-based design into CAD. Depending on your project requirements, these designs can range from patterns to texts or even structured components. Remember, the design should be as detailed as possible, and the sizes and tolerances of the materials used should be considered.

After preparing your design, set the parameters using the CNC laser cutter’s software. Adjust the speed, power, and frequency parameters based on the type and thickness of the material you are working with. For example, cutting wood could require faster cutting speeds but increase the power to prevent edge burning, and acrylics would need the opposite. With the wealth of knowledge available online, such as forums and Google resources, you are guaranteed to stay current on the recommended practices for your machine and materials.

Lastly, the virtual cutting process within the software is simulated to find and fix mistakes before running the design on the physical machine. This step enhances accuracy while reducing material waste. With the advancement of technology, some CAD software have CAM tools incorporated within them which permit the direct production of G-code files that control the laser during cutting or engraving. Because of this workflow alongside the advanced functions that CAD software has, professionals and enthusiasts alike can easily use their CNC laser cutters and get high quality results.

Tips for High Precision Engraving and Cutting

Maintaining high levels of precision during laser engraving and cutting involves several critical considerations. Here are five tips that we believe will help you:

- Select the Right Material

Various materials react differently to laser engraving and cutting. Take acrylic, for instance: It cleanly melts and gives smooth edges. In contrast, wood burns and may require additional sanding after being cut. Ensure that the material fits within the cutter’s specifications, as incompatibility may lead to unwanted artifacts during output.

- Calibrate the Focus of the Laser

Well-focused lasers yield flawless and smooth cuts. Almost all CNC laser cutters have a focus tool that adjusts the distance between the laser head and the workpiece for the best cut. Skewed focus will engrave blurry images, while cuts will be incomplete, if performed.

- Adjust Power and Feed Rate Accordingly

The speed of the laser must also be proportional to the power settings during cutting: higher power should be applied with a slower cutting speed. For example, slower speeds work better when the power is cranked up, especially when working with thick materials, and lower power with faster speeds is desirable for fine engravings. Always test scrap material to ensure balance before starting the actual project.

- Care of Laser Lens and Mirrors

With time, dust and other particles can obstruct the laser beam’s ability and accuracy due to power loss. The appropriate steps must be taken to clean the components and check for damages or signs of wear periodically.

- Air Assist and Ventilation

During the operation, proper ventilation, along with air assist systems, helps reduce smoke and grime that otherwise would reduce the quality of engraving and cutting. Not only does air assist help get rid of debris from the laser, but ventilation also stops the equipment from overheating while providing fresh air to the work area.

These suggestions help users maintain their equipment while achieving precise, quality engravings and cuts.

What Materials Can You Work With Using CNC Laser Machines?

A CNC laser machine can operate using various materials such as:

- Wood – Both soft and hardwood can be engraved and cut.

- Acrylic and Plastics – Commonly used in signage, displays, and decorative items.

- Metals – Depending on the machine’s power, you can engrave coated metals or cut thin sheets of certain metals.

- Leather – Custom designs on wallets, bags, and other accessories are crafted with leather.

- Paper and Cardboard – Detailed artworks can be made for packaging or crafting ,which require intricate designs.

- Glass – Glass can be carved for decorative purposes.

These machines give users the ability to perform intricate designs across many materials. However, always check for compatibility with your machine and ensure that you follow safety instructions.

Best Materials for Laser Cutting and Engraving

In order to engrave or cut a particular material with a laser, one must first consider its properties, the machine’s compatibility options, and the anticipated outcome. Each of the discussed materials possesses distinct qualities and uses, which are outlined in the list below.

1. Wood

Wood includes plywood, hardboard, and natural hardwoods. Such materials are relatively easy to laser engrave and yield particularly impressive results. Furthermore, wood is associated with responsive processing, while the cross-section is clean and produces intricate engravings.

Thickness Options: Wood is used in thicknesses from `1/8 inch` to `1 inch,` depending on the power of the laser.

Applications: Plywood is extensively used for custom signs, decorating furniture, and various ornaments. Its furniture-grade quality also makes it a suitable gift item. First-choice plywood, birch, and bamboo are widely available and easy to work with.

Statistics: According to Google Trends, engraved wooden goods are in the market throughout the year, with considerable activity around holidays.

2. Plexiglass

Acrylic is the best option for projects that require a glass-like finish, such as engraving or cutting, because its edges can be burned cleanly. Its numerous vivid colors further enhance its appeal.

Thickness Options: Usually comes in 1/8 inch to 1/2 inch panels.

Applications: Excellent for making LED light panels, signs, awards, and other elaborate decorations.

Interesting Fact: Of all materials, clear acrylic is the most sought-after online for laser cutting. People adore that it can be “flame-polished” and honed to a polished finish by the laser.

3. Metal (Coated or Anodized)

Features: Anodized and coated metals are easier to engrave than raw metals, which require high-capacity machines such as fiber laser cutters.

Uses: Often custom-engraved and used for branding, like anodized aluminum business cards, custom tumblers, name plates, and electronic devices.

Emerging markets: Google Search data suggests growing interest in custom stainless steel and anodized engravings for corporate gifts.

4. Leather

Features: Genuine leather and its synthetic counterparts are compatible with laser machines, facilitating etching and cutting.

Uses: Fashion goods like wallets, belts, bags, and décor items are well-tailored to these materials.

Statistics: Eye-catching patterns or ‘Custom laser-engraved leather goods’ have risen 25% in search queries in the last two years, showcasing the booming custom fashion trend.

5. Paper and Cardboard

This resilient, affordable, and eco-friendly material can be used to create intricate designs. It is best for crafting models, packaging, invitations, and more.

Insight: Biodegradable materials are gaining traction. Searches on “eco-friendly laser-cut packaging” doubled in 2020.

Uses: These interactable items include, but aren’t limited to, board games, event invitations, and eco-packaging.

6. Glass

Add sophisticated engravings to glass items to personalize them for professional or personal use, while wanting to add a soft, unique touch to decorative or functional items.

Applications: Frequently used to decorate glass wine tumblers, trophies, and windows.

Search Trends: The phrase “laser-engraved gifts for glasses” seems to be gaining popularity while people plan weddings or anniversaries, indicating that business is good during that season.

7. Fabric

Characteristics: Laser technology can cut and engrave fabrics such as cotton, felt, polyester, and denim with precision when setting the machine to standard.

Applications: Assembled in customizing clothing and textile items, home furnishing, and arts and crafts.

Note: Organic materials such as cotton show a steady demand, specifically for custom laser cutting, as indicated by Google Trends.

Working with Wood, Acrylic, and Plastic

Working with Wood, Acrylic, and Plastic

1. Wood

Characteristics: Wood is elegant. Owing to its availability, wood is one of the most popular materials for laser engraving and cutting. The natural patterns found in wood make it easy to create intricate borders.

Applications: Used widely in interior decor, custom gifts, and bespoke art items. There is a strong demand for custom wooden coasters, engraved plaques, and jewelry.

Trends: Google Search trends indicate an overall increase in “custom wood engraving” and “laser wood crafts” searches by over 50 percent in the last five years, suggesting unfulfilled demand for such services, particularly around the holidays.

2. Acrylic

Characteristics: Acrylic sheet is well appreciated for its superb cut and polish attributes. It is also flexible, offered in various tints and opaque and transparent options.

Applications: Acrylic is used extensively in signs, trophies, key chains, and other ornaments. Recently, acrylic signage, especially the ones LED lit, has become very trendy as they look clean and polished.

Trends: According to Google Search evidence, there has been a remarkable increase in searches for “acrylic laser cutting services” and “custom acrylic signage,” with spikes coming from the retail and interior design industries.

3. Plastic

Characteristics: Polymers such as Polypropylene, ABS, and PETG have flexible and durable properties, which make them suitable for laser applications. They can also easily be cut and engraved, making them useful in many industrial and imaginative fields.

Applications: These plastics are popular in industrial products, custom competitive packaging, promotional items, and prototype designs. Plastic is extremely useful as a less expensive method of achieving sophisticated designs.

Trends: According to Google Search Trends, “custom laser cut plastics” and “industrial laser cutting” have increased interest within the last year due to rapid prototyping and custom manufacturing innovations.

Creative and industrial possibilities are limitless when wood, acrylic, and plastic are combined. Following trends and using these and other materials can expand business opportunities both regionally and over the Internet.

Reference Sources

1. “An Interim Study of Integrating Spindle, Laser, and Plotter in a CNC Router Machine” (Jaafar et al., 2022) (2022)

- Key Findings: This study successfully integrated spindle engraving, laser cutting, and plotting functionalities into a single CNC machine, enabling multiple processes within a single coding process. The integrated system demonstrated high accuracy.

- Methodology: The researchers modified a commercially available CNC router to incorporate laser and plotter capabilities. They developed and improved the system to ensure high accuracy and efficiency, validating its performance through calibration.

2. “REM-CNC Router – CNC multifuncional Fresa e Laser de baixo custo construída reutilizando equipamentos de informática e lixo eletrônico” (Junior et al., 2020) (2020)

- Key Findings: This study describes the construction of a low-cost multifunctional CNC machine combining laser engraving and milling capabilities using recycled materials. The machine demonstrated the feasibility of creating a cost-effective and functional combined system.

- Methodology: The researchers built a CNC machine using recycled computer equipment and e-waste. The machine was designed to perform both laser engraving and milling operations, though not simultaneously.

3. “LOW COST MULTIFUNCTIONAL CNC LASER AND MILL BUILT FROM THE REUSE OF COMPUTER EQUIPMENT AND E-WASTE: REM-CNC ROUTER” (Júnior et al., 2022) (2022)

- Key Findings: This paper is essentially the same as the previous one, describing the creation of a low-cost multifunctional CNC machine combining laser and milling capabilities from recycled materials.

- Methodology: Similar to the previous study, this involved building a CNC machine from recycled components to perform laser engraving and milling.

4. Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is the main difference between a CNC router and a laser engraver?

A: The main difference lies in the technology used; a CNC router utilizes a spindle to cut and engrave materials, while a laser engraver uses a high-powered laser beam to cut or engrave. CNC machines are typically better for thicker materials, whereas laser engravers excel in precision and detail, especially for 2D and 3D designs.

Q: Which machine suits hobbyists: CNC routers or laser engravers?

A: Both machines have their advantages for hobbyists. CNC routers are versatile for larger projects and can handle a broader range of materials, while laser engravers, especially those with a laser attachment, provide high accuracy and detail for intricate designs. The choice often depends on the specific projects the hobbyist wishes to undertake.

Q: Can I add a laser attachment to my existing CNC machine?

A: Many hobbyists add a laser module to their CNC router to enhance its capabilities. This allows the machine to perform CNC routing and laser engraving, offering versatility for various projects.

Q: What types of materials can I use with a CNC laser cutting machine?

A: A CNC laser cutting machine can work with various materials, including wood, acrylic, paper, and some metals. The accuracy of laser engravers makes them particularly effective for engraving glass and other delicate materials.

Q: How does the accuracy of laser engraving compare to CNC routing?

A: Laser engraving generally offers higher precision due to its focused laser beam, which can create intricate designs with fine details. CNC routing, while also accurate, may not achieve the same level of detail, especially on softer materials.

Q: What is the learning curve associated with using a CNC machine compared to a laser kit?

A: CNC machines often have a steeper learning curve due to the complexity of the software and machine work involved in setting up and operating them. In contrast, laser kits tend to have simpler software and setup processes, making them more accessible for beginners.

Q: Is a CO2 laser engraver suitable for professional use?

A: Yes, a CO2 laser engraver is widely used in professional settings because it can cut and engrave a high-quality range of materials with precision. Many businesses rely on these machines for tasks requiring detailed work.

Q: What kind of CNC software is needed to operate a CNC router?

A: Operating a CNC router typically requires specific CNC software that allows users to design projects and control the machine’s movements. This software helps generate tool paths and manage the machine’s work efficiently.

Q: Can I use a laser kit for cutting and engraving?

A: Many laser kits are designed to cut and engrave, providing flexibility for various applications. However, the material’s thickness will determine the cutting effectiveness, as some kits are better suited for engraving than for cutting thicker materials.

Q: What is a laser bundle, and how is it different from a standard CNC setup?

A: A laser bundle typically includes a laser module and accompanying accessories to enhance the capabilities of a CNC machine. Unlike a standard CNC setup, which may only include routing tools, a laser bundle enables users to incorporate laser engraving and cutting functionalities into their projects.