The manufacturing industry is dynamic, and one innovative technology that has made a substantial impact is the CNC router with ATC (Automatic Tool Changer). Whether you are an industry expert or a newcomer in the CNC world, how a CNC router with ATC works will change how you approach your work. This comprehensive guide aims to prepare you for everything from operating CNC machines to understanding the extent of their benefits in precision, efficiency, and productivity. Most importantly, by the end of this guide, you will realize why incorporating an ATC CNC router into your operations is crucial for maintaining a competitive edge in a technology-dominated society.

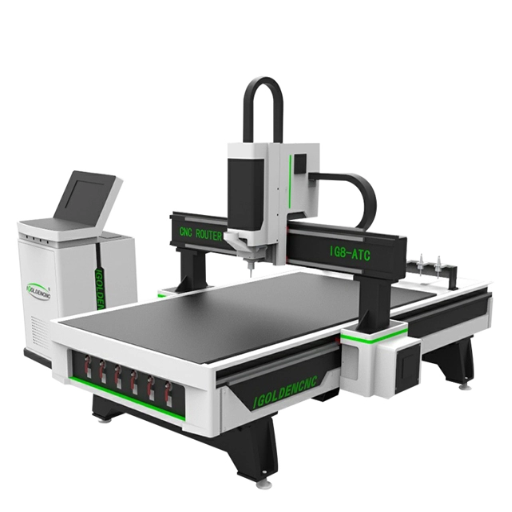

What is an ATC CNC Router?

An ATC CNC router, or Automatic Tool Change CNC router, is a computer-controlled cutting machine with a tool holding device that swaps out tools automatically while the machine is in operation. The machine can perform several functions, such as carving, engraving, and even cutting, without requiring a person to change the tools. The ATC system is effective for intricate and high-quantity production workflows because it increases efficiency, reduces downtime, and enhances precision.

How does an automatic tool changer work?

The automatic tool changer (ATC) functions as part of a more complex system that helps streamline switching tools during the operation of a CNC machine. At its core, the system uses a set of tool holders, an executive robotic arm, and control software that coordinates and automates the entire sequence of operations within the ATC. Typical ATC operations can be divided into three stages:

- Stage 1: Tool Selection. The control CNC software transmits an instruction to ATC, indicating the next tool to be fetched. The tool’s carousel or magazine contains many tools–depending on a machine’s specifications, a midrange CNC machine can store between 10 and 100 tools, with the higher-end models storing beyond 100.

- Stage 2: Tool Fetching. Tool selection completes the first step. A robotic arm controlled by pneumatic or hydraulic legs picks up the tool from the magazine storage. At the same time, the robotic arm also capably undoes the current tool in the spindle and places it back into its proper location.

- Stage 3: Tool Positioning. The tool is now locked to the spindle and positioned accurately. To ensure the tool is maintained at the right angle to the spindle and locked tightly prior to resuming the machining operation, advanced sensors are used to check the alignment. It is important that such steps are fulfilled, as a few seconds is all that is required to complete this CNC machine and other downstream systems to minimize downtime for continuous operations.

Modern ATC systems offer remarkable speed and precision. For example, newer models can perform tool changes in under 8 seconds, greatly enhancing production efficiency. Furthermore, some cutting-edge CNC machines have tool magazines that can hold 200 tools. Also, adding smart sensors and machine learning in some ATC systems optimally predicts tool performance, adjusts for wear, and replacements to maximize tool longevity and reliability.

Overall, the ATC is an innovative CNC technology that significantly improves productivity while simultaneously reducing labor costs and precision errors for aerospace, automotive, and woodworking industries.

What are the benefits of using an ATC CNC Router?

- Enhancing Productivity and Efficiency

An ATC CNC Router saves significant time when it comes to manually changing tools. Processing is faster, as automatic tool changes can occur within seconds, and operators can shift their focus onto other activities. This high level of efficiency is even more impactful in large-scale production settings.

- Precision and Consistency Are Enhanced

ATC CNC Routers ensure consistent results across multiple operations due to their ability to automatically switch tools with precision at the exact required position. Such precision eliminates human errors that can result from tool alterations, ensuring a seamless and precise output.

- Reduced Costs For Labor

Automated tool changes on an ATC CNC Router decrease the necessity for manual labor. This reduces operational costs as well as time. The workforce can be assigned more intricate operations, which optimizes resource allocation by default.

- Processing Versatility

Wood, metal, plastic, and composites are just some of the numerous materials ATC CNC Routers can handle. Their ability to change freely between various operations, such as cutting, drilling, and engraving, using multi-tools makes them extremely efficient in many industries.

- Durability and Long-Lasting Performance

ATC CNC Routers with innovative features like smart sensors and predictive maintenance algorithms have tool functionality and dramatically enhanced machine life. Prospects of wear and tear downtime are diminished, resulting in long-term cost efficiency for companies.

How to Choose the Best CNC Router Machine with ATC

- Machine Size and Work Area

Estimate your specific projects to ensure that the machine size fits your requirements. A larger area of work is appropriate for larger projects. However, a compact machine would be sufficient for smaller tasks.

- Tool Capacity

Evaluate the capacity of the ATC to hold the number of tools. With greater capacity, there are many undertakings, and tool changes are less frequent.

- Spindle Power

Machine spindle power should be balanced with the work and material to be handled. Denser materials require higher spindle power, while softer materials require less.

- Software Compatibility

Ensure your operating CNC router meets the software requirements. Search for systems that will not cause workflow disruptions and are easy to integrate with other programs.

- Build Quality

Select a machine made of materials with a high reputation to enhance its life span, precision, and long-term performance.

- Support and Warranty

They also provided full customer support. Contact them in cases before setting up, training processes, or maintenance.

Use the above guidelines when choosing your ATC CNC Router for productivity and specific preferences.

What features should you look for in a cnc router?

When selecting a CNC router for your applications, consider a few key features. Here are five of the most important to look for.

- Spindle Power

The spindle’s power determines the materials it can work on and the speeds of operation. Heavier-duty work or machining of dense materials, such as hardwood or aluminum, will require higher spindle power (6-12 kW).

- Work Area Size

Smaller projects would not need a larger than a 2’ x 3’ work area. Larger operations require more space, up to 4’ x 8’ or bigger, to accommodate bigger sheets of material. Thus, the size of the machine’s work area should be considered for the project.

- Precision And Accuracy

Exact and detailed cuts require tight tolerances such as ±0.001 inches. Other elements that ensure accurate and repeatable results, known repeatability, include the linear guides, ball screws and rigid frame.

- Tool Changer System

An Automatic Tool Changer (ATC) lets the CNC router change its tools automatically and quickly. There is no need for manual intervention, which increases efficiency and decreases downtime for multi-step projects.

- Controller and Software Ergonomics

The CNC router controller must be intuitive and efficient and work alongside widely accepted CAD/CAM programs. Real-time interaction, advanced monitoring, and sophisticated planning options can optimize workflows, and higher operational productivity helps, too.

Keeping these points in mind can help you choose the right CNC router for your needs while ensuring performance for years to come.

What is the difference between a 4-axis CNC and a 5×10 CNC Router?

The difference between a 4-axis CNC and a 5×10 CNC router is about axis and workspace: A 4-axis CNC has one rotational axis, while a 5×10 CNC router is named after the size of its table, 5 feet by 10 feet. This determines the size of the material that the machine can handle.

| Parameter | 4-Axis CNC | 5×10 CNC Router |

|---|---|---|

|

Axes |

4 (X, Y, Z, A) |

3 (X, Y, Z) |

|

Rotation |

1 rotational axis |

None |

|

Work Area |

Varies |

5×10 feet |

|

Flexibility |

High |

Moderate |

|

Applications |

3D carving, curves |

Large flat panels |

|

Setup |

Complex |

Simple |

|

Efficiency |

High for 3D tasks |

High for large cuts |

|

Precision |

High |

Moderate |

How important is the spindle in a CNC machine?

The spindle holds and rotates the cutting tool, which determines the workpiece’s accuracy and surface finish; this makes it one of the critical components. Its core performance determines the precision and surface polish of the finished product. A high-quality CNC spindle guarantees no vibration, power will always be delivered, and the accuracy will be maintained at the same level in each machining part.

The focus of the people who recently used the information available is the importance of the spindle speed and the torque, which makes the work with machines easier. That makes it essential when dealing with soft plastics and tough metals. The selection of air-cooled, water-cooled, and hybrid spindles depends on the application needs and the demand for temperature control. The design of the spindle, in conjunction with the machine, must ensure optimal performance, reliability, and durability.

Essentially, the spindle’s functions determine how well the CNC machine operates and the range of tasks it can perform. Thus, it is critical to select the right machine for particular manufacturing requirements.

Applications of an ATC CNC Router Machine

The ATC CNC Router Machine is popular in many industries for its efficiency and versatility. It routes the following:

- – Furniture Manufacturing: From design to crafting, it customizes furniture pieces and intricate designs with panel customization.

- – Signage Industry: Wood, acrylic, and aluminum signs and displays are professionally engraved and cut.

- – Cabinetry: Kitchen cabinets, drawer fronts, and other detailed woodworking items are made in bulk.

- Architectural Millwork: Custom decorative moldings and panels, along with other interior and exterior items, are designed and produced.

- Prototyping and Model Making: Through detailed prototyping, those in design and architecture are provided with high-quality 3D or physical models of the items.

These machines are sought after because they can further automate complex processes while increasing accuracy and production efficiency.

In what industries are CNC Routers commonly used?

CNC routers’ efficiency, precision, and versatility have made them useful in many industries. Here are a few key industries where CNC routers are critical, along with some information and statistics on their use:

- Woodworking and Furniture: Custom furniture, cabinetry, and other decorative wooden products require a substantial investment in time and materials. A recent study forecasts that the global woodworking machinery market, including CNC routers, will rise from $1.2 billion in 2020 to $1.76 billion in 2027, growing at a CAGR of 4.3% from 2023 to 2030, This growth is attributed to the increasing demand for CNC routers and ergonomic customizable furniture.

- Advertising and Signage: Businesses in this industry enjoy the fact that they can produce exact, long-lasting signs made of wood, aluminum, acrylic, and other materials. More robotic automation and CNC routers have become helpful in ensuring high-quality production of complex signage like 3D letters, logos, and other detailed shapes.

- Prototyping and Manufacturing: Rapid prototyping of components and tools is one of the first CNC router applications in the manufacturing industry. Studies show that the adoption of CNC technologies is rising, particularly focusing on increasing production pace and minimizing waste for the automotive and aerospace industries.

- **CNC routers in action:** CNC routers can manufacture Lattice screens, wall panels, and decorative molds that enhance the aesthetic beauty of buildings. These machines are heavily utilized in the construction field to offer fully custom interiors and various working parts for both residential and commercial edifices.

- **Corporate uses of plastics and composites:** Businesses that specialize in processing plastics utilize CNC routers to cut plastic materials, engrave them, and shape them into desired forms. These machines are widely accepted in various industries that deal with lightweight yet durable components because they guarantee good quality workmanship, smooth finishes, and precision.

- **Education and Research:** More and more colleges and universities are integrating CNC machines into their programs to teach students about modern manufacturing techniques. This is an essential step in addressing the innovation and skills shortage many industries face today, showcasing the capability of CNC routers.

The routers are also useful for carving and providing shapes to newly emerging materials, such as those utilized in renewable energy fields or even in art installations. Their benefits and usefulness within design and manufacturing processes cannot be ignored, and they are highly valued worldwide.

What types of materials can a cnc wood router cut?

The CNC wood router is an all-purpose tool that can machine countless materials, carving out a vital place in many industries. The following is a complete summary of the materials that can be used with a CNC wood router.

- Wood

A CNC wood router can cut softwoods like pine and fir and hardwoods like oak, walnut, and maple. It also processes manufactured wood products like MDF (medium-density fiberboard), plywood, and particleboard with great accuracy.

- Plastics

Many types of plastics encompass acrylic, PVC, polycarbonate, and HDPE (high-density polyethylene), which can be cut using CNC wood routers. These plastics are great for advertisement purposes, tool design, and bespoke products.

- Foam

Expanded polystyrene (EPS) and polyurethane foam are lightweight and soft materials that can be cut with CNC wood routers. These materials are commonly used in shipping, thermal insulation, and monumental art pieces.

- Composites

CNC wood routers can cut composite materials like carbon fiber and fiberglass panels. Working with composites requires special bits and slower cutting rates to achieve clean results.

Soft non-ferrous metals such as brass and aluminum can be machined into specific shapes by using a CNC wood router—not its intended purpose—after specialized bits have been fitted. Operating the router at low speeds with proper cooling will minimize damage to the machine and material.

CNC routers are highly valued in woodworking and prototyping because they accommodate many materials.

How to Maintain Your CNC Router with ATC

- Cleaning the Machine

After the operation, clean every machine part of the machine of dust, particles, and other waste. Take care to clean the spindle and tool holder, as they are critical components that could cause performance problems if not maintained properly.

- Check and Add Necessary Lubricant

All moving components like rails, bearings, ball screws, and guides should be checked for any sign of damage or misalignment. Lubricating should be done as per the instructions for each equipment to maintain fluid motion during operations.

- Check Tool Changer Calibration

Automatic tool changers (ATC) that are set to check pick and place functionalities must be regularly checked for proper function. Any misalignment detected must be corrected without delay to prevent malfunctions during operations.

- Control Electrical Cables and Power Connections

Electrical cables and connection points should also be scanned for loose or excessive damage; if found, they should be tightened or replaced to secure reliable power and signals.

- Execution of Scheduled Maintenance Tasks

Perform checks like filter replacements and spindle examinations according to the manufacturer’s guidelines. This minimizes the probability of severe problems arising later.

Ensure Balance of Attached Tools and Accessories

Attach high-grade bits only. Do not attach unbalanced tool holders or other poorly balanced tools, as they cause excessive wear and tear on the machine, leading to machine downtime.

If all steps are performed without failure, the CNC router with ATC will operate optimally and have a longer life span.

What are the common maintenance tips for an ATC Router?

The common maintenance tips for an ATC Router include regular cleaning, lubrication, inspection of components, maintaining a proper environment, and keeping spare parts handy.

| Parameter | Description |

|---|---|

|

Cleaning |

Remove dust/debris |

|

Lubrication |

Oil moving parts |

|

Inspection |

Check belts, screws |

|

Environment |

Ventilation, humidity |

|

Spare Parts |

Keep essentials ready |

How can you troubleshoot common issues with your CNC Router Machine?

Regular maintenance for the ATC Router involves cleaning, lubricating, inspecting parts, environmental upkeep, and ensuring readiness with spare peripherals, but it is not limited to these.

Regarding troubleshooting common issues with your CNC router machine, an orderly method is best for problem identification and resolution. Below are some steps that can help with common problems:

- Assess Power Supply and Connections

Your machine must have power and all connection points must be intact. Variables such as disconnected or loose cables might lead to numerous issues. Inconsistent power streams are notorious for causing problems.

- Check for Mechanical Interference

Physical debris may be lodged along the axes, rails, or spindle. Furthermore, thorough cleanings of the machine can prevent or solve problems related to dirt and chips.

- Realign and Recalibrate

Cutting inaccuracies are commonplace when misalignment or faulty calibration is present; consequently, realignment is necessary. Adjustment settings should be checked to ensure all axes are realigned as required.

- Tooling and Bits Check

If router bits are dull or incorrectly positioned, the machine is likely to perform poorly and shake. To mitigate this risk, ensure major machine components are secured and flammable components are not blocked.

- Evaluate Software and Post Processing Files

Erroneous inputs and G-code caused the machine to misbehave. Ensure the design files are verified by the software used and that settings are configured for optimal performance.

- Monitor Lubrication and Maintenance

Insufficient lubrication can cause premature wear or stuttering movements. Moving parts must be greased periodically, as per the manufacturer’s recommendations.

- Error Codes and Diagnostics

Always look for error codes that may appear on the display of your CNC controller. Look into your machine’s manual or contact the manufacturer for more insight and possible resolution methods.

If the situation continues after completing these steps, consider calling technical support or an expert. Preventative maintenance and routine servicing can substantially mitigate the chances of such issues reappearing.

Reference Sources

-

Design, Development, and Testing of 4 Tool Automatic CNC –

An analysis exploring the issues and progress in ATC production for CNC routers.

-

Reinventing the Dougong Joint Using Robotic Technologies –

This paper addresses the application of AXYZ ATC 4004 CNC routers in robotic processes.

-

Design and Analysis of a Desktop Multi-Axis Hybrid CNC Machine –

A comprehensive study of hybrid CNC devices including ATC features.

-

An Interim Study of Integrating Spindle, Laser, and Plotter in a CNC Router Machine –

An examination of ATC standard CNC routers and their advanced functionalities.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a CNC router with an automatic tool changer (ATC)?

A: A CNC router with an automatic tool changer (ATC) is a machine designed for woodworking that can automatically change its tools during the machining process. This allows for greater efficiency and versatility in tasks like cutting, engraving, and carving.

Q: How does the tool change process work in an ATC CNC machine?

A: The tool change process in an ATC CNC machine involves using a linear tool changer or rotary axis to automatically swap tools from a designated tool magazine without manual intervention, streamlining the workflow.

Q: What are the benefits of using a CNC router with a tool changer for woodworking?

A: The benefits include increased productivity due to reduced downtime during tool changes, the ability to perform various machining operations with one setup, and improved precision and consistency in woodworking projects.

Q: Where can I find a CNC router with an automatic tool changer for sale?

A: CNC routers with automatic tool changers are available through various manufacturers, online marketplaces, and specialized woodworking equipment retailers. It’s advisable to compare features and pricing to find the best ATC CNC machine.

Q: What tools can be used with an auto tool changer on a CNC router?

A: An auto tool changer on a CNC router can accommodate various types of tools, including routers, drill bits, engraving tools, and specialized bits, depending on the machine’s capabilities and the specific requirements of the woodworking task.

Q: What is the difference between a linear ATC CNC router and a rotary ATC CNC router?

A: A linear ATC CNC router uses a linear tool magazine to change tools in a straight line, while a rotary ATC CNC router employs a rotating mechanism to access tools. Both have their advantages depending on the space requirements and the speed of tool changes.

Q: Can a desktop CNC router have an automatic tool changer?

A: Yes, some desktop CNC routers are designed to be compatible with an auto tool changer, although they typically have a smaller capacity and may be best suited for lighter woodworking tasks or hobby projects.

Q: What should I consider when choosing the best ATC CNC router for my woodworking needs?

A: When choosing the best ATC CNC router, consider factors such as the size of the machine, the number of tools it can accommodate, its precision and speed, the type of materials you will be working with, and your budget.

Q: What are the typical applications of a CNC wood carving machine with an ATC?

A: Common applications of a CNC wood carving machine with an ATC include intricate wood engraving, furniture making, signage production, and creating decorative elements, as the automatic tool changer allows for quick transitions between different machining operations.