Navigating the world of CNC machining can be daunting, especially when faced with the choice between a CNC router and a CNC mill. Both are powerful tools that have revolutionized modern manufacturing, yet they serve distinct purposes, excelling in different applications. Whether you’re a seasoned machinist, an engineering professional, or a hobbyist, understanding the fundamental differences between these two machines is crucial for selecting the right one for your needs. This article dives into the key distinctions between CNC routers and CNC mills—covering their capabilities, materials, and ideal applications—so you can make an informed decision with confidence.

What is a cnc mill and how does it work?

A CNC mill, or Computer Numerical Control mill, is a machine used to manufacture parts by cutting, drilling, or shaping materials like metal, wood, or plastic. It operates using a pre-programmed software file that guides the machine’s movements with incredible precision. The process begins with a digital design, which is converted into instructions that the CNC mill follows to perform automated, accurate cutting or shaping tasks. By removing material from a solid block, the CNC mill creates components with high precision and repeatability, making it an essential tool in industries like manufacturing, automotive, and aerospace.

Understanding the cnc milling machine

A CNC milling machine is a highly advanced tool that integrates multiple components to achieve its functionality. The primary sections include the controller, spindle, cutting tools, work surface, and axes. The controller acts as the brain of the machine, processing the programmed instructions to execute precise movements. The spindle is responsible for rotating the cutting tool at varying speeds, depending on the specific material and task. Cutting tools come in a variety of shapes and sizes, tailored to different materials and cutting requirements.

Modern CNC milling machines typically operate on three to five axes, with three being the standard linear X, Y, and Z axes, and some advanced models incorporating rotational axes (A and B) for added flexibility. Multi-axis systems significantly reduce the need for repositioning workpieces, enabling highly complex shapes to be machined in a single setup. Studies show that machines with five axes can improve efficiency by 20-30% in aerospace applications, where intricate geometries are common. Additionally, innovations like automatic tool changers (ATC) and coolant systems further enhance the machine’s speed and precision, making it indispensable in high-demand industries.

The role of the cutting tool in a CNC mill

The cutting tool is a critical component in a CNC mill, directly influencing the quality, precision, and efficiency of the machining process. These tools are designed to remove material from a workpiece with optimal speed and accuracy, accommodating various materials such as metal, plastic, and composites. The performance of a cutting tool depends on its material composition, coating, geometry, and cutting-edge design.

Modern advancements in cutting tool technology have introduced highly durable materials like carbide, high-speed steel (HSS), and polycrystalline diamond (PCD). For instance, carbide tools are known to sustain high temperatures and maintain sharpness during intensive machining, leading to a reduced need for frequent replacements. Studies indicate that coated tools, such as those with titanium nitride (TiN) or aluminum oxide layers, can increase machining efficiency by up to 25% by improving wear resistance and reducing heat generation.

Additionally, the geometry of the cutting tool plays a significant role in achieving precise cuts. Features such as rake angle, helix angle, and flute design determine the tool’s effectiveness in chip removal and surface finish quality. Innovations like variable flute geometries have been shown to reduce vibration and chatter during high-speed milling, improving overall productivity.

The correct selection and maintenance of cutting tools are essential for achieving long tool life and consistent performance. Regular monitoring for wear, proper cooling during operation, and adherence to recommended speeds and feeds can extend the lifespan of the tool while ensuring optimal machining outcomes. With the rapid pace of technological evolution in the CNC industry, cutting tools continue to evolve, driving higher levels of precision and efficiency across manufacturing sectors.

Common applications of cnc mills

CNC mills are integral to a wide range of industries due to their precision, versatility, and efficiency. Below is an overview of the most common applications and their remarkable impact across sectors.

1. Aerospace Industry

CNC milling is pivotal in the aerospace industry, where precision is non-negotiable. Components like engine parts, airframe structures, and turbine blades are crafted with extreme accuracy to meet stringent safety regulations. CNC mills can work with high-performance materials such as titanium and aluminum, ensuring durability and optimal weight management. For example, aerospace milling often achieves tolerances as fine as 0.0001 inches, essential for maintaining performance in harsh conditions.

2. Automotive Manufacturing

CNC mills are widely employed in the automotive sector for the production of parts such as engine blocks, gearboxes, and custom components for performance vehicles. The ability to handle high volumes without sacrificing quality or detail is crucial for meeting market demands. Automotive manufacturers often rely on 5-axis CNC milling to create complex geometries, enhancing fuel efficiency and overall vehicle performance.

3. Medical Device Production

The medical industry depends heavily on CNC mills for creating implants, surgical instruments, and diagnostic devices. Due to the need for biocompatible materials like stainless steel and titanium, CNC mills must operate with impeccable precision to avoid even minor errors. For instance, orthopedic implants produced with CNC milling boast intricate designs tailored to individual patients, significantly improving surgical outcomes.

4. Electronics Industry

CNC milling is increasingly utilized in the electronics sector for components like heat sinks, connectors, and casings. Given the miniaturization trends in modern devices, CNC mills excel by producing high-precision parts at microscopic scales. Innovative capabilities, such as micromachining, enable manufacturers to create intricate designs necessary for products like smartphones and advanced computing systems.

5. Prototyping and Custom Manufacturing

CNC milling is indispensable for prototyping applications across all industries. It offers unmatched speed and accuracy for creating prototype parts and functional testing units, significantly reducing time-to-market for new products. Additionally, it is a go-to solution for custom manufacturing needs, from bespoke machine parts to artisan-crafted designs.

6. Energy Sector

The energy industry uses CNC mills to produce components for wind turbines, hydraulic systems, and piping used in renewable and traditional energy systems. By machining robust materials such as stainless steel and alloys, CNC mills ensure these parts can withstand extreme environmental conditions while maintaining efficiency and safety.

What is a cnc router and how does it function?

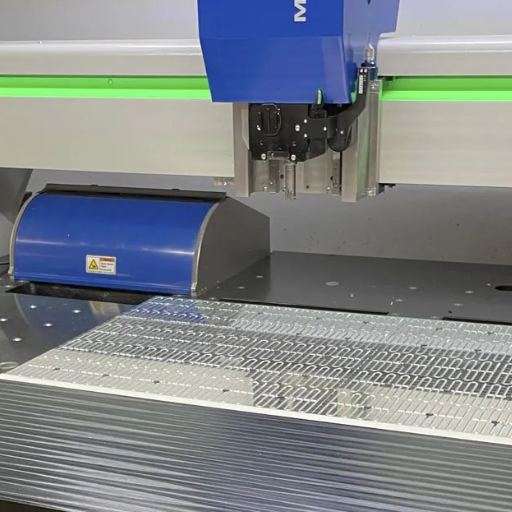

A CNC router is a computer-controlled cutting machine used to carve, cut, and engrave a variety of materials such as wood, metal, plastic, and foam. It functions by following a set of pre-programmed instructions, often derived from CAD (Computer-Aided Design) software, to guide its movements with precision. The router moves along three axes (X, Y, and Z), allowing for intricate designs and accurate cuts. By automating the process, CNC routers minimize human error and boost efficiency, making them invaluable tools for industries like woodworking, signage, and prototyping.

Exploring the cnc router design

Modern CNC router designs are characterized by their precision engineering and robust construction, tailored to meet the demands of various industries. At the core of these machines is a high-torque spindle, which operates at variable speeds to cut, carve, and engrave different materials effectively. Most CNC routers are equipped with stepper or servo motors, ensuring accurate positioning and smooth movement along the X, Y, and Z axes, often achieving tolerances as precise as ±0.001 inches.

Another fundamental aspect of CNC routers is the bed size, which can range from smaller desktop models to large industrial formats, accommodating materials from a few inches to several feet in width and length. Materials commonly worked with include wood, plastics, metals like aluminum, and composite materials, further enhancing versatility. Advanced routers often feature vacuum tables or clamps for secure material holding during operations.

Additionally, CNC routers now integrate cutting-edge control systems and user-friendly interfaces. Many systems rely on touchscreen technology or advanced software integration, including compatibility with CAD and CAM (Computer-Aided Manufacturing) programs. Efficiency is further amplified by the inclusion of automated tool changers (ATCs), which enable seamless transitions between bits for complex jobs.

Data suggests that these advancements not only reduce operating time but also significantly lower material waste. With improved durability and user-focused design, CNC routers continue to evolve, driving innovation across sectors such as manufacturing, art, and engineering.

How cnc routers typically operate

CNC routers operate by following computer-generated instructions to precisely cut, carve, or engrave materials like wood, metal, plastic, or foam. The process begins with CAD (Computer-Aided Design) software, where users create a digital design. This design is then converted into G-code, a standardized programming language that dictates the tool’s movements, speed, and cutting depth. Once loaded into the machine’s controller, the CNC router executes a series of automated actions based on the instructions.

Key aspects of CNC router operation include the use of stepper or servo motors to drive the tool’s motion along the X, Y, and Z axes, delivering precision down to fractions of a millimeter. High-speed spindles, often reaching speeds of 20,000 RPM or more, ensure smooth and accurate cutting. Advanced models feature vacuum systems to hold workpieces firmly in place during operation, minimizing errors or material shifting.

Recent performance metrics highlight the capabilities of modern CNC routers, showcasing cutting speeds of up to 500 inches per minute (IPM) and repeatable accuracy within 0.001 inches. These machines are commonly integrated with features like automatic tool changers to handle multi-step processes efficiently, reducing manual intervention. Furthermore, innovations like touch probes and real-time toolpath monitoring enhance versatility and operational safety, making CNC routers indispensable tools across industries.

Applications of cnc routing in woodworking

CNC routing has revolutionized the woodworking industry, offering precision and automation that traditional methods cannot match. These machines are extensively used for crafting furniture, cabinetry, decorative panels, and intricate carvings with only minimal human intervention. By utilizing computer-generated designs, CNC routers can execute highly detailed cuts, curves, and patterns that ensure consistent quality across products.

One key advantage of CNC routing in woodworking is its ability to maximize material utilization. Modern CNC software optimizes cutting paths, reducing waste by as much as 15-30% compared to manual processes. This efficiency not only minimizes costs but also supports sustainable practices vital to the industry. Additionally, CNC routers excel in handling a variety of materials, including hardwood, softwood, plywood, and MDF, broadening their versatility for diverse applications.

Another significant benefit lies in mass production capabilities. CNC routers can produce identical components at high speed without compromising on detail, crucial for industries producing assembly-line furniture or large-scale interior installations. For example, custom cabinetry that would traditionally take days to manufacture can now be completed in hours, boosting overall productivity.

Safety and precision are further enhanced by technological advancements like dust collection systems, ensuring a cleaner workplace, and high-quality spindles that improve accuracy. With these innovations, CNC routing allows woodworking professionals to meet a wide range of demands, from high-volume projects to bespoke, artisan-level designs, maintaining a competitive edge in an evolving market.

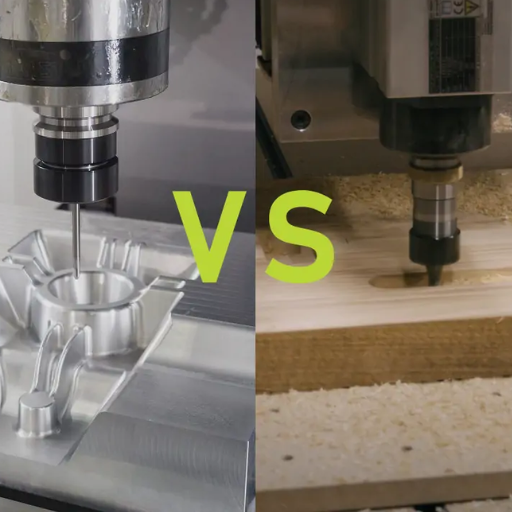

What are the differences between cnc routers vs cnc mills?

The main difference in the functionalities of both CNC routers and CNC mills can be viewed through the scope of their operation and capabilities. For example, CNC routers are perfect for creating complex designs on large wooden, plastic, or foam projects and are extremely fast due to being lighter and designed to operate at high speeds.

CNC mills, on the other hand, have a heavier build and are slower, but they exhibit extreme detail when cutting harder materials such as metals. They are better equipped for detailed work on small parts, but offer great reliability, depth and precision to their measurements, making them ideal for projects requiring high accuracy.

The decision between using a CNC router or a mill greatly relies on the material being used, required scale and precision for the project.

Key differences in design and operation

When considering the key differences in design and operation, I would say that CNC routers are typically designed for lighter materials like wood or plastic, and they operate faster to handle larger sheets with efficiency. On the other hand, CNC mills are built for precision with harder materials, like metal, and work at slower speeds to ensure intricate detail. The core distinction lies in their structure and intended applications—routers prioritize speed and scale, while mills focus on precision and strength.

Comparison of precision and accuracy

When comparing precision and accuracy, I would say precision refers to the consistency of repeatable measurements or actions, while accuracy is about how close those results are to the true or intended value. For example, in CNC operations, precision ensures that the machine repeatedly performs the same task consistently, whereas accuracy ensures that the task aligns with the exact specifications or design intended. Both are essential, but they serve different aspects of quality and performance.

Working with softer materials like wood vs metal

When working with softer materials like wood compared to metal, I find the techniques and tools I use differ significantly. Wood is more forgiving, allowing for quicker adjustments and easier cutting, but it requires careful handling to prevent splintering. Metal, on the other hand, demands precision and sturdier tools due to its hardness, but the results often provide higher durability and stability.

How to choose the right cnc machine for your needs?

Choosing the right CNC machine requires careful consideration of your project requirements, budget, and long-term goals. Here’s a straightforward process to guide your decision:

- Define Your Application

Determine the type of material you’ll be working with (e.g., wood, metal, plastic) and the specific tasks you need the machine to perform, such as cutting, drilling, or engraving.

- Consider the Machine Size and Capacity

Evaluate the size of the parts or materials you’ll be machining. Ensure the machine’s workspace dimensions match your project needs.

- Look at Precision and Speed

Assess the accuracy and speed requirements for your work. For intricate designs, prioritize machines with high precision and reliable repeatability.

- Evaluate Software Compatibility

Ensure the CNC machine is compatible with software you’re proficient in or consider machines that come with user-friendly software options.

- Set a Realistic Budget

Balance functionality and cost. Factor in any additional expenses for tools, maintenance, and training when setting your budget.

Factors to consider when selecting a cnc machine

When choosing the right CNC machine, several critical factors come into play. Below is a comprehensive list to ensure an informed and efficient decision-making process:

- Machine Type and Functionality

Evaluate the type of CNC machine that matches your specific project requirements. Popular options include CNC routers, CNC milling machines, and CNC lathes. Analyze whether you need multi-axis functionality (e.g., 3-axis, 4-axis, or 5-axis) for handling more complex designs and shapes.

- Material Compatibility

Ensure the CNC machine can process the materials you work with, such as wood, metal, plastic, or composites. Some machines are optimized for specific materials, directly impacting precision and durability.

- Machine Size and Workspace

Consider the machine’s physical dimensions and how much workshop space it requires. Also, take note of the working area for your projects. A larger working area is ideal for bigger cuts and bulkier projects, but compact models may be preferable for smaller work environments.

- Precision and Accuracy

Look for machines with high precision and repeatability. Machines with accuracy tolerance of ±0.001 inches or better are often preferred for detailed work.

- Power and Speed

Analyze the spindle motor power and maximum speed of the CNC machine. Higher-powered machines allow for faster cuts in tough materials, while adjustable speeds provide greater control for delicate tasks.

- Software Compatibility

Confirm that the CNC machine is compatible with user-friendly and versatile CAD/CAM software. Popular software solutions include Fusion 360, AutoCAD, and Mastercam. Ease of integration with existing workflow is a key consideration.

- Durability and Build Quality

Machines with rigid frames, usually made of cast iron or steel, offer greater stability, reducing vibrations during operation. Durability ensures long-term use even under challenging conditions.

- Automation Features

Look for CNC machines equipped with automation options such as tool changers, advanced controllers, or smart sensors. These features can streamline production and reduce downtime.

- Maintenance and Support

Choose machines that come with easy-to-maintain components and accessible customer support services. Warranty terms and availability of spare parts should also factor into your decision.

- Cost of Ownership

Aside from the upfront purchase price, calculate the total cost of ownership including energy consumption, tooling, upgrades, and operating expenses. Comparing efficiency metrics among machines can help lower production costs in the long term.

- Manufacturer Reputation

Compare different brands and manufacturers by reviewing customer feedback, warranty options, and post-purchase support. Reputable manufacturers typically provide ongoing support for their products.

Advantages of diy cnc projects

DIY CNC projects offer numerous benefits for hobbyists, small business owners, and enthusiasts alike. One major advantage is cost savings. Building your own CNC machine can be significantly cheaper compared to purchasing a pre-assembled one, allowing you to save on upfront costs. For example, DIY CNC kits often range between $200 and $1,000, depending on the complexity and components, while pre-built machines can easily cost upwards of $2,000 or more.

Another advantage is customization. DIY CNC projects enable you to design a machine tailored to your specific needs, whether you’re creating intricate woodworking designs, precision metalwork, or smaller-scale prototypes. This level of control is invaluable for those with niche requirements or specialized workflows. Additionally, assembling a machine yourself grants a deeper understanding of its mechanics, which can be helpful when troubleshooting or making upgrades in the future.

DIY CNC machines also open doors to continuous learning and skill-building. From mechanical assembly to software programming, users enhance their technical knowledge and problem-solving abilities throughout the process. This hands-on experience is especially beneficial for beginners or students entering the world of Computer Numerical Control systems.

Finally, the flexibility of maintaining and upgrading your own CNC machine ensures longevity and adaptability. Components like stepper motors, controllers, and spindle kits can be upgraded incrementally without the need for replacing the entire system. This approach not only avoids obsolescence but also creates an opportunity for experimentation and innovation, making DIY CNC projects a rewarding and cost-effective investment.

Comparing best cnc routers and mills

When evaluating the best CNC routers and mills, it’s crucial to consider factors such as precision, speed, durability, price range, and the type of materials they can handle. Below is a detailed comparison based on current specifications and capabilities to help you make an informed decision:

- CNC Routers

CNC routers are primarily designed for cutting softer materials like wood, plastics, foam, and soft metals such as aluminum. Their high-speed spindles make them efficient for intricate and detailed designs, making them a favorite among hobbyists, sign makers, and small-scale manufacturers. Modern CNC routers often come with advanced features such as touchscreen interfaces, Wi-Fi connectivity, and compatibility with an extensive range of CAD/CAM software. Popular options include the Shapeoko 4 by Carbide 3D, which offers robust precision with a working area of 33″ x 33″, and the X-Carve by Inventables, known for its customizable features.

Average Price Range: $1,000 – $4,000

Material Suitability: Wood, plastics, soft metals

Best For: High-speed precision cuts and lightweight materials

- CNC Mills

On the other hand, CNC mills are designed for heavy-duty tasks and can handle hard materials such as steel, bronze, and titanium, alongside softer materials. They are slower than routers but provide unmatched accuracy and versatility, making them indispensable in industrial applications or projects requiring extreme precision. Options like the Tormach 1100MX stand out with their compact build, 75 IPM cutting speed, and high rigidity, while machines like the Haas Mini Mill Series offer an industrial-grade option with powerful spindle motors and a spacious worktable.

Average Price Range: $5,000 – $50,000+

Material Suitability: Hard metals, alloys, wood

Best For: Industrial-grade precision and versatility in material handling

Can a cnc router and a cnc mill be used interchangeably?

While CNC routers and CNC mills share similarities in their ability to cut and shape materials, they are not entirely interchangeable due to key differences in design and function. CNC routers are better suited for softer materials like wood, plastic, and certain composites, excelling in speed and larger surface area coverage. CNC mills, on the other hand, are designed for precision machining of harder materials like metals and alloys, offering greater rigidity and accuracy for intricate tasks. Choosing between the two depends on the material, level of detail, and the specific application required.

Understanding the two machines in different contexts

When considering the application of CNC routers and CNC mills, it’s crucial to understand their specialized roles across different industries. CNC routers are extensively used in woodworking, sign-making, cabinetry, and model prototyping. These machines are perfect for cutting, engraving, and shaping softer materials on a large scale. For instance, CNC routers can achieve feed rates of up to 200 inches per minute, making them ideal for projects requiring speed and efficiency. Additionally, their multi-axis capability allows for intricate curve designs and detailed carvings.

On the other hand, CNC mills are indispensable in industries like aerospace, automotive, and medical device manufacturing. They excel in the precision machining of tougher materials such as steel, titanium, and aluminum. Advanced CNC mills can operate with tolerances as tight as ±0.0001 inches, ensuring exceptional accuracy for critical components like engine parts or surgical instruments. Additionally, the spindle speeds on modern CNC mills can exceed 20,000 RPM, enabling them to handle high-performance machining tasks with ease.

Ultimately, the choice between these two machines depends on the specific demands of a project, including material hardness, desired speed, and level of complexity. By aligning the machine capabilities with project requirements, manufacturers can achieve optimal results, maximizing efficiency and precision in their operations.

When to use a cnc router vs a cnc mill

Choosing between a CNC router and a CNC mill requires understanding their distinct capabilities and suitability for various applications. CNC routers are optimized for cutting softer materials such as wood, plastic, and foam. Their high-speed spindles, often exceeding 20,000 RPM, make them ideal for tasks that demand fast material removal and detailed cutting on large surface areas. They are commonly employed in industries like sign-making, cabinetry, and prototyping, where precision and speed on softer materials are key.

On the other hand, CNC mills are designed to handle harder, denser materials, including metals like steel, aluminum, and titanium. With lower spindle speeds but greater torque, they excel at precise machining of intricate components. CNC mills are indispensable in industries such as aerospace, automotive, and industrial manufacturing, where durability, accuracy, and complexity are paramount.

According to industry data, CNC routers typically offer larger work areas, making them better suited for oversized projects. For example, a standard CNC router might support workpieces up to 5×10 feet, whereas CNC mills usually accommodate smaller dimensions due to their heavier, more rigid construction. However, CNC mills often provide more robust features, such as rigid tapping and multi-axis machining, enabling them to perform highly detailed tasks with minimal material distortion.

When deciding which machine to use, manufacturers should consider the material type, project size, and required level of detail. For projects requiring high-speed, large-format processing of non-metallic materials, a CNC router is the superior choice. Conversely, for applications demanding precision machining of dense, hard materials, a CNC mill offers unparalleled performance. Evaluating these factors ensures a match between machine capability and production needs, fostering efficiency and high-quality outcomes in any machining endeavor.

Exploring the limitations of routers and mills

While CNC routers and mills are both invaluable tools in modern manufacturing, they come with specific limitations that can impact their usability in certain scenarios. CNC routers, for instance, are generally optimized for cutting softer or non-metallic materials such as wood, plastic, and foam. While they excel in large-format processing and high-speed cutting, their power and rigidity are insufficient for efficiently machining dense, hard metals like steel or titanium. Furthermore, the quality of fine details can sometimes be limited compared to CNC mills, particularly when working on intricate designs with extremely tight tolerances.

On the other hand, CNC mills are designed to handle high-precision machining of harder materials, but their capabilities come at the trade-off of speed and cost. Milling operations are generally slower compared to routing, given the greater precision and cutting forces required. Additionally, CNC mills are often more expensive to purchase and maintain, making them less economical for businesses focused on high-speed production of less durable materials. The milling process also generates higher operational noise and requires more energy, which may lead to increased long-term expenses.

Recent industry data highlights that for tasks involving large-scale material removal on softer substrates, CNC routers can operate up to 3-5 times faster than mills, saving significant production time. However, for machining metal parts with tolerances as fine as ±0.0001 inches, CNC mills offer unrivaled accuracy. This distinction underscores the importance of selecting the right tool based on material, project complexity, and production objectives to effectively mitigate these limitations.

Reference Sources

-

“Three Axis Deviation Analysis of CNC Milling Machine”1:

- Key Findings: This study analyzed the precision of a self-designed 3-axis CNC milling machine. The deviations on the X, Y, and Z axes were measured, showing values within ISO 2768 tolerance standards. However, improvements in design and calibration were suggested for higher precision.

- Methodology: Measurements were conducted using a dial indicator and parallel plates to assess straightness and flatness across the machine’s axes.

-

“Structural Design of a CNC Router Based on Optimization Technique”2:

- Key Findings: The research focused on optimizing the structural design of a CNC router to enhance its technical and aesthetic performance while reducing material usage. The study highlighted the high applicability of structural optimization in CNC router design.

- Methodology: Optimization techniques were applied to the router’s structural design, ensuring it met technical and aesthetic requirements while minimizing material consumption.

-

“Kaji Eksprimental Pembandingan Ketelitian Mesin CNC Milling Dengan Kontrol SMC Dan Mesin CNC Milling Dengan Kontrol ESP32 Wifi”3:

- Key Findings: This experimental study compared the accuracy of CNC milling machines using SMC controllers versus ESP32 WiFi controllers. The SMC-controlled machine demonstrated higher accuracy with fewer tolerance exceedances.

- Methodology: The study involved machining tests on Teflon Rod material, comparing dimensional accuracy across multiple trials for both control systems.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is the primary difference between a CNC mill and a CNC router?

A: The primary difference between a CNC mill and a CNC router lies in their design and intended use. CNC mills are designed for precision cutting of harder materials like metals, whereas CNC routers are generally used for softer materials like wood and plastic. This distinction is crucial when choosing which machine tool to use for specific projects.

Q: How do the machining speeds of CNC mills and CNC routers compare?

A: CNC routers typically offer faster machining speeds than CNC mills, as they are designed to cut softer materials that require less force. On the other hand, CNC mills operate at slower speeds to ensure precision when cutting harder materials.

Q: Can CNC mills and CNC routers perform similar tasks?

A: While both CNC mills and CNC routers can cut and shape materials, they are tailored for different applications. CNC mills are better suited for precision work on metal and other hard materials, while CNC routers excel in cutting and shaping softer materials like wood and plastic. Understanding the specific capabilities of each can help in choosing the right machine tool for the job.

Q: What types of materials can a CNC router’s tools cut?

A: A CNC router’s tools, such as router bits, are designed to cut soft materials like wood, plastic, and certain types of foam. They are not typically used for cutting hard metals, which is where CNC mills and their end mills come into play.

Q: How do different types of CNC machines affect production?

A: Different types of CNC machines, such as CNC mills and CNC routers, offer varied capabilities that affect production. CNC mills provide high precision for hard material machining, making them ideal for detailed metalwork. CNC routers, with their ability to work quickly with soft materials, are perfect for tasks like cabinetry and sign-making. Choosing the right CNC machinery can significantly impact production efficiency and quality.

Q: What are the key components of a CNC mill vs a CNC router?

A: A CNC mill typically features a robust frame and powerful spindle designed for heavy-duty tasks, with a focus on precision. In contrast, a CNC router often has a lighter frame and a high-speed spindle, optimized for speed and agility in cutting soft materials. These differences highlight the distinct applications for each type of machine tool.

Q: How does a machining center differ from a CNC router?

A: A machining center is a more advanced form of CNC mill that incorporates multiple axes, tool changers, and automation capabilities for complex and precise manufacturing tasks. In contrast, a CNC router is simpler, designed for faster, less complex cutting tasks primarily with wood and plastic. The machining center is typically used in industrial settings requiring high precision and versatility.

Q: What factors should be considered when choosing between a CNC mill and a CNC router?

A: When choosing between a CNC mill and a CNC router, consider the material you will be working with, the precision required, and the complexity of the tasks. CNC mills are better for hard materials and intricate precision work, while CNC routers are more efficient for larger, less detailed projects involving soft materials.

Q: Are there differences between CNC milling and CNC routing in terms of operation?

A: Yes, there are differences between CNC milling and CNC routing in terms of operation. CNC milling involves the use of end mills and other cutters to remove material from a workpiece, often requiring a more complex setup and slower operation for precision. CNC routing, however, typically involves faster passes with router bits, making it suitable for swift and efficient shaping of soft materials.

- Understanding CO2 Laser Cutting vs. Fiber Laser Cutting Machines

- UV Laser vs Fiber Laser Marking Machine: Choose Your UV Marking

- Discover the Versatility of a CO2 Laser: What It Can Cut, Etch, or Mark?

- Choose the Right Laser Wattage for Engraving & Marking

- Laser Rust Removal: Pulse Laser Cleaner for Rust, Oxidation & More

- The Ultimate Guide to Choosing Your First CNC Machine for Home Workshop

- Exploring the 5 Different Types of CNC Machines: A Comprehensive Guide

- Unlocking the Power of Laser Cleaning for Glass Surfaces: Revolutionary Mould Cleaning Technology