Selecting an accurate cutting machine makes a significant difference, from complex woodwork to engravings or metal fabrication. In the cutting technology sphere, CNC routers and laser cutters are two renowned options. Although both machines provide remarkable versatility and precision, each serves distinct applications. This article walks you through the fundamental differences, pros, and cons of each tool, so you know which one matches your needs best. You’ll find out what cutting machine can improve your skills the most by the time you finish reading this.

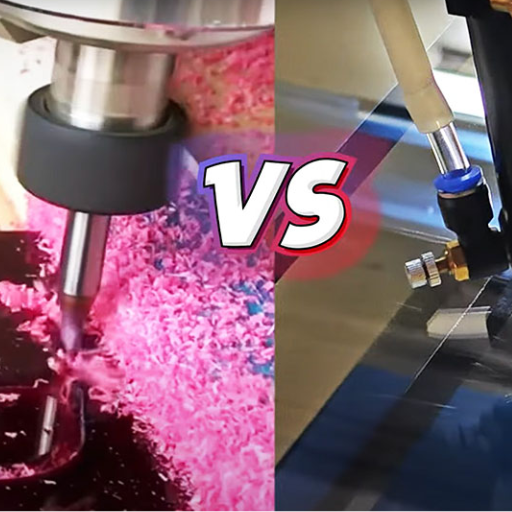

What is the difference between a CNC Router and a Laser Cutter?

The essential difference between CNC routers and laser cutters is in their methods of operation and the types of materials they work best with. A CNC router cuts wood, plastic, and soft metal by employing a spinning cutting tool that takes away layers of the material. It is also very effective for creating multi-dimensional complex designs. A laser cutter, on the other hand, employs a focused laser beam to either cut or engrave the material, achieving unparalleled precision. It works best on wood, acrylic, leather, and even some thin metals, and it is highly sought after where accuracy is crucial. Both tools have outstanding features, however, the most important consideration is the selection of material you are planning to use and the project you intend to carry out.

Understanding CNC Cutting and Laser Cutting Techniques

Both CNC cutting and laser cutting techniques have undergone tremendous advancements in recent years, driven primarily by innovations in technology and manufacturing needs. CNC cutting systems have greatly improved in speed, accuracy, and automation capabilities. Modern CNC machines are now equipped with multi-axis technology—ranging from 3-axis to 5-axis systems—which allows for greater flexibility in complex geometries. For example, industries such as aerospace and automotive are utilizing 5-axis CNC milling to handle advanced materials like titanium and carbon composites with remarkable precision.

Meanwhile, laser cutting technology has also made significant strides. Contemporary laser systems now feature higher wattage capabilities, enabling thicker materials to be cut efficiently—up to 30 mm for mild steel in some industrial systems. The adoption of fiber lasers has further elevated the field with benefits like faster processing speeds, energy efficiency, and the ability to work on reflective metals such as copper and aluminum. This superior efficiency has had a noteworthy impact on manufacturing industries, reducing production times while maintaining or even exceeding quality standards.

Additionally, both technologies have embraced automation and digitization. The integration of AI-driven software for design optimization and real-time process monitoring ensures reduced waste and enhanced productivity. Smart sensors and IoT connectivity further enhance the operational efficiencies of these systems, enabling predictive maintenance and seamless cross-platform coordination. These technological enhancements make CNC and laser cutting unparalleled tools in precision manufacturing across industries like healthcare, construction, and electronics.

How Does a Laser Beam Work Compared to a Router Bit?

A laser beam and a router bit operate on fundamentally different principles to achieve precision cutting or engraving. A laser beam utilizes amplified light energy to heat and vaporize material at the surface level. This focused beam, driven by a laser generator, cuts with incredible precision, typically leaving smooth, polished edges. For instance, CO2 lasers are widely used for non-metallic materials like wood and acrylic, while fiber lasers excel in cutting metals due to their wavelength and intensity. Laser cutting is non-contact, reducing the wear and tear associated with mechanical tools, and boasts a cutting tolerance as fine as ±0.001 inches, making it ideal for intricate designs.

On the other hand, a router bit is a mechanical, rotating cutting tool that physically removes material through direct contact. Router bits come in various shapes, sizes, and materials, allowing them to carve or engrave intricate designs into wood, plastic, and certain metals. Though less precise than lasers (with typical tolerances of ±0.005 inches), router bits are highly versatile, particularly for thicker materials or 3D shapes. The material removal process can leave more residue or rougher edges compared to lasers, often necessitating additional sanding or finishing.

Ultimately, both tools excel in their specific domains. Laser beams are suited for intricate and delicate designs with minimal cleanup required, while router bits shine in creating depth and handling more robust materials. Understanding these distinctions helps in selecting the optimal cutting method for your specific project needs.

Exploring the Cutting Tool Variations

Modern advancements in cutting tool technology have redefined their efficiency, precision, and adaptability. Tools such as CNC routers and laser cutters are increasingly integrated with smart automation, allowing users to achieve unparalleled accuracy and speed. For instance, CNC routers are now equipped with enhanced spindle speeds reaching upwards of 30,000 RPM, making them ideal for cutting through dense materials like hardwood and aluminum. Laser cutters, on the other hand, have become more versatile with the adoption of fiber laser technology, capable of cutting metals up to 25mm thick, all while maintaining precise tolerances within 0.02mm.

Material compatibility is another critical factor distinguishing cutting tools today. CNC routers excel in engraving and shaping wooden surfaces, plastics, and even softer metals like brass, whereas laser cutters can handle a wider range of materials, including stainless steel, titanium, and even fabrics or acrylics. Furthermore, the software integration in these tools has simplified the design-to-production workflow, enabling users to input complex CAD files for seamless processing.

Recent data also highlights a growing trend toward hybrid systems that combine router and laser cutting capabilities in a single machine. This dual-functionality minimizes the need for multiple setups, reducing production time by approximately 40% in industrial applications. Such innovations underline the importance of selecting tools not just for their immediate functionality but for their capacity to adapt to evolving project requirements.

How Does a CNC Router Work?

A CNC router works by following precise digital instructions to cut, carve, or shape materials such as wood, plastic, metal, or composites. The machine operates through three key components: a computer, a control unit, and the router itself. A CAD or CAM software generates the design, which is converted into a set of numerical instructions. These instructions guide the router across multiple axes—commonly X, Y, and Z—to execute the programmed design with high accuracy. The automated nature of a CNC router allows for consistent results, making it ideal for both simple and complex projects.

The Basics of Computer Numerical Control in Routing

CNC routing has revolutionized manufacturing and crafting by introducing unparalleled precision and efficiency. These computer-controlled systems can achieve tolerances as tight as ±0.001 inches, making them highly reliable for industries that demand precision, such as aerospace, automotive, and furniture production. For instance, in aerospace, CNC routers are used to cut lightweight composite materials and aluminum with incredible accuracy, ensuring both performance and safety standards are met.

One of the most remarkable advancements in CNC technology is its ability to handle a variety of materials. From wood and plastic to more demanding substrates like steel and carbon fiber, modern CNC routers are equipped with adaptive tooling systems that optimize cutting for each material type. This adaptability drastically reduces material waste, lowering production costs and promoting sustainable manufacturing practices. Additionally, CNC routers equipped with high-speed spindles can process materials up to 70% faster than traditional methods, significantly enhancing throughput.

The integration of smart technology, such as predictive maintenance and IoT-enabled connectivity, further elevates the capabilities of CNC routers. These advancements allow operators to monitor machine performance in real time, minimizing downtimes and streamlining operations. By combining speed, accuracy, and versatility, CNC routing continues to be a backbone of modern industries, driving innovation and superior craftsmanship.

Applications of CNC Routing in Woodworking

CNC routing has transformed the woodworking industry, offering unparalleled precision and efficiency for both mass production and custom designs. These machines excel in crafting intricate patterns, cutting complex shapes, and engraving detailed designs on various types of wood. For example, CNC routers can produce cabinetry, furniture, and decorative items with exceptional accuracy, significantly reducing material waste.

With modern advancements, CNC routers now accommodate 3D carving, enabling artisans to create sculptures and highly detailed reliefs in wood. Industry reports indicate that businesses using CNC routing in woodworking have seen up to a 30% reduction in production time and a substantial improvement in product consistency. Furthermore, these machines support a variety of tooling options, making it possible to seamlessly work on hardwood, softwood, plywood, and even MDF.

Another key benefit is the integration of computer-aided design (CAD), which allows craftsmen to prototype and simulate projects beforehand. This precision ensures fewer errors during production and enhances scalability. Additionally, CNC routing plays a vital role in sustainability by maximizing material usage and enabling renewable wood sources, making it an environmentally conscious choice for businesses. From small-scale workshops to large industrial operations, CNC routing empowers innovation and expands the boundaries of what’s achievable in modern woodworking.

Choosing the Right Materials Like Wood for CNC Machines

Choosing the right type of wood for CNC machining is a critical step that impacts the quality, durability, and precision of the final product. Different types of wood have unique properties, and understanding these characteristics can help ensure optimal performance during the machining process.

1. Wood Density and Hardness

The density and hardness of wood are important factors to consider because they influence how the material responds to cutting, shaping, and engraving. Softer woods like pine or cedar are easier to machine and ideal for projects requiring intricate details. However, they may lack the durability needed for heavy-duty applications. On the other hand, hardwoods such as oak, maple, and walnut offer exceptional strength and resilience, making them suitable for furniture or architectural elements.

2. Grain Pattern and Texture

The grain pattern and texture of the wood affect its appearance and machinability. Tight, uniform grains—such as those found in birch or cherry—offer consistency and can improve the smoothness of the final cut. Elaborate grain patterns, while visually appealing, may require additional precision during machining to prevent splintering or uneven edges.

3. Moisture Content

Moisture content plays a major role in how wood behaves under CNC machining. Wood with high moisture content can warp, shrink, or expand, leading to inaccuracies in the final product. Kiln-dried wood, which typically has moisture levels between 6% and 8%, is preferred for CNC machining because it ensures stability and reduces the risk of deformation during and after processing.

4. Specific Applications

The intended application of the final product will often determine the appropriate type of wood to use. For example:

Prototyping: MDF (medium-density fiberboard) is cost-effective and easy to machine, making it ideal for prototypes or test models.

Decorative Projects: Plywood offers versatility and affordability, and it works well for signage or decorative elements.

High-End Finishes: Exotic hardwoods like teak or mahogany are prized for their aesthetic appeal in luxury items.

5. Environmental and Cost Considerations

Sustainability is increasingly important in material selection. Opting for wood sourced from certified sustainable forests helps reduce the environmental impact of CNC machining. Additionally, the availability and cost of the wood should be factored in—local or readily accessible options typically provide better value without compromising quality.

How Does a Laser Cutter Operate?

A CNC router works by using computer-controlled movements to cut, carve, and shape materials with precision. The process begins with a digital design, typically created using CAD (Computer-Aided Design) software. This design is then converted into instructions via CAM (Computer-Aided Manufacturing) software, generating a toolpath that guides the machine.

The router operates along three axes—X (horizontal), Y (vertical), and Z (depth)—to move the cutting tool and shape the material. A spindle, equipped with a cutting bit, rotates at high speeds to remove material as the router follows the specified path. This automated process allows for consistent and accurate replication of the design across multiple items, making CNC routers ideal for industries such as woodworking, signage, and prototyping.

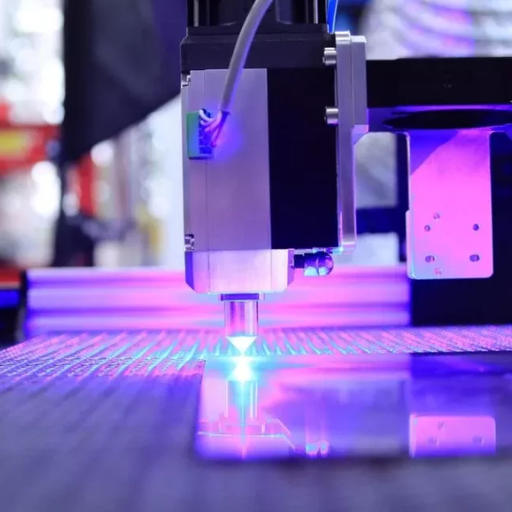

Principles of Laser Cutting and Laser Engraving

Laser cutting and laser engraving work by utilizing a focused laser beam to interact with a material’s surface. From my understanding, laser cutting involves cutting through a material entirely, while laser engraving modifies the surface to create designs, text, or patterns. The precision comes from controlling the laser’s power, speed, and focus to achieve the desired outcome, whether it’s a clean cut or a detailed engraving.

The Role of a CO2 Laser in Laser Cut Technology

From my understanding, a CO2 laser plays a crucial role in laser cut technology due to its versatility and efficiency. It operates by emitting a high-intensity infrared laser beam, which is capable of cutting through or engraving a wide range of materials like wood, acrylic, leather, and even some metals. The CO2 laser’s ability to deliver precise, clean cuts and intricate designs makes it a preferred choice for industrial and creative applications alike. By adjusting the laser’s power settings, it’s possible to customize the process for different materials and desired outcomes, ensuring exceptional quality and consistency.

Advantages of Using a Laser Beam to Cut Intricate Designs

One of the key advantages I’ve found in using a laser beam to cut intricate designs is the unparalleled precision it offers. The laser’s fine focus allows for incredibly detailed cuts, even on complex patterns, without sacrificing accuracy. Additionally, it’s a non-contact process, meaning there’s minimal risk of material deformation or damage, which is crucial for delicate projects. The ability to work with various materials, from wood to acrylic, further enhances its versatility and makes it an indispensable tool for achieving professional-quality results efficiently.

What are the Main Differences in Cutting Process?

Laser cutting and traditional cutting methods differ significantly in precision, speed, and versatility. Laser cutting uses a focused beam of light to achieve highly accurate and detailed cuts, making it ideal for intricate designs and delicate materials. It is a non-contact process, reducing the risk of material deformation. Traditional cutting methods, such as manual tools or mechanical blades, rely on physical force, which can lead to rougher edges and potential damage to the material. Additionally, laser cutting typically offers faster operation and can handle a broader range of materials, whereas traditional methods may be limited by the tool’s capabilities and the material’s properties. These differences make laser cutting a more efficient and flexible option for many applications.

Comparing Precision Cutting in Laser vs CNC

Laser cutting and CNC cutting each have unique strengths, making them suitable for distinct applications depending on the project’s requirements. Laser cutting excels in delivering unparalleled precision, typically achieving tolerances as tight as ±0.002 inches. This accuracy is ideal for intricate designs, fine details, and situations requiring minimal material wastage. Its non-contact process also reduces the risk of material deformation or contamination, a critical advantage in industries like aerospace and electronics.

On the other hand, CNC cutting, known for its versatility, utilizes various tools such as drills, lathes, and mills to shape materials with multi-dimensional complexity. For instance, CNC machines can produce deeper cuts and handle thicker materials like solid metals more efficiently compared to laser cutters. CNC cutting often achieves tolerances around ±0.005 inches, slightly less precise than lasers, but with the added benefit of being able to create three-dimensional components, such as gears or molds.

When comparing processing speeds, laser cutters are typically faster for intricate flat designs, especially in thin materials like metal sheets or acrylics, due to the concentrated energy beam. However, CNC machines are generally faster for bulk material removal or heavy-duty applications. Both technologies support a wide range of materials, but CNC can work with tougher substances, such as thicker steel and hard plastics, whereas laser cutting may be limited by material reflectivity and thickness.

Additionally, advancements in automation have greatly enhanced both processes. For instance, modern laser machines often integrate AI-driven sensors to optimize cut paths and reduce errors, while CNC systems utilize multi-axis configurations to handle complex part geometries seamlessly. Both technologies are continuing to evolve, allowing industries like automotive, medical, and construction to greatly benefit from their precision and reliability.

Selecting between laser and CNC cutting ultimately depends on the specific requirements of the task, including the precision needed, material type, and production complexity. Each method continues to play a vital role in manufacturing sectors worldwide, showcasing the innovation and adaptability of modern machining technologies.

Evaluating Speed and Efficiency of Each Machine

When comparing the speed and efficiency of laser cutting and CNC cutting machines, both offer distinct advantages depending on the context. Laser cutting is renowned for its exceptional speed, particularly when working with thin materials like sheet metal or acrylic. Modern laser cutters can achieve cutting speeds of up to 20-70 inches per minute (IPM) for materials ranging from 1/4-inch to 3/4-inch, depending on the laser power and material type. Additionally, laser cutting excels in precision and minimizing material waste, making it an ideal choice for high-volume or intricate designs.

On the other hand, CNC cutting machines, such as routers or milling machines, offer unparalleled versatility in handling a wide range of materials, including metals, plastics, and wood. While CNC cutting may not match the raw speed of laser cutting for thin materials, it compensates with its ability to produce deeper cuts and handle thicker or denser materials. Average CNC router cutting speeds can range from 50 to 80 IPM, but this varies significantly based on factors like the tool used, material hardness, and cutting depth.

For projects requiring rapid production of simple, thin parts, laser cutting is often the superior choice. However, when precision and material versatility are paramount, CNC cutting proves to be an invaluable tool in achieving efficiency across various manufacturing applications. Both technologies continue to evolve, incorporating advancements in automation and software that further enhance their respective speed and efficiency.

Cost Considerations: CNC vs Laser Cutter

When analyzing the cost differences between CNC machining and laser cutting, it’s essential to consider several factors, including initial investment, operational costs, and maintenance requirements. CNC machines typically have a higher upfront cost due to their complexity and versatility, often ranging from $50,000 to $150,000 for industrial-grade models. Conversely, laser cutters, depending on their power and capabilities, can start at around $10,000 and extend up to $100,000 or more for advanced systems designed for high-volume industrial work.

Operational costs can also vary significantly. CNC machines often use an array of cutting tools that require periodic replacement, especially when working with tougher materials. These tools can cost anywhere from $20 to $500 each, depending on the material and precision required. Additionally, CNC machining generates more physical waste since it involves subtracting material, which can increase material costs over time. On the other hand, laser cutters rely on electricity and consumables like assist gases (e.g., nitrogen or oxygen), which can add recurring costs. For example, operating a standard industrial laser cutter may consume about 5-10 kW per hour, with electricity costs adding up based on local energy rates.

Maintenance requirements also differ. CNC machines often require frequent calibration and part replacements, particularly for spindle motors, ball screws, and guides. Maintenance costs for CNC systems can range from $5,000 to $20,000 annually, depending on usage and the specific machine. Laser cutters generally have lower maintenance demands, with the primary expenses revolving around replacing laser tubes or diodes, which could cost between $1,000 and $10,000, depending on the type used.

Overall, the choice between CNC machining and laser cutting for cost efficiency depends heavily on the specific project requirements. CNC machines are better suited for highly complex, precise jobs and working with diverse materials like metals and plastics. Laser cutters, while potentially more economical for simpler designs and thinner materials, excel in speed and efficiency for cutting intricate shapes with minimal waste. For businesses, the decision often comes down to balancing short-term investment with long-term operational efficiency, supported by the specific demands of their production processes.

What Materials are Suitable for Each Cutting Machine?

- Laser Cutters

-

-

- Best for non-metallic materials such as wood, acrylic, fabric, and paper.

- Can also cut metals like stainless steel and aluminum when equipped with higher power settings.

- Ideal for thin, precise, and detailed cutting applications.

-

- Plasma Cutters

-

-

- Primarily used for conductive metals like steel, stainless steel, aluminum, brass, and copper.

- Suitable for medium to thick metal sheets, offering fast and efficient cuts.

-

- Waterjet Cutters

-

-

- Works on virtually any material, including metals, plastics, ceramics, glass, and stone.

- Excellent for thick or dense materials and heat-sensitive applications as it cuts without introducing heat.

-

Using Various Materials in CNC Routing

CNC routing is a highly versatile manufacturing process capable of working with a wide variety of materials, providing flexibility for various industries. Below are details on commonly used materials and their unique properties:

- Wood

-

-

- Widely used in furniture-making, signage, and models due to its availability and adaptability.

- Softwoods like pine are easier to machine, while hardwoods such as oak or maple provide durability and a refined finish.

- Speeds for routing should be adjusted based on wood density to prevent burning or damage.

-

- Plastics

-

-

- Popular options include acrylic, PVC, and polycarbonate for creating lightweight, precision parts.

- Acrylics are ideal for clear, polished finishes, often used in display cases or signs.

- Proper tooling is essential to avoid melting or warping, typically achieved with slower feed rates and adequate cooling.

-

- Metals

-

-

- CNC routing is effective for softer metals like aluminum and brass, often used in machine parts and artistic designs.

- Aluminum offers excellent machinability and corrosion resistance.

- Tools with higher rigidity and cooling systems are critical to achieving precise cuts in metallic materials.

-

- Composites

-

-

- Materials like MDF, plywood, and carbon fiber are commonly machined for structural and aesthetic applications.

- CNC routing ensures clean edges and reduces manual labor on layered or laminated surfaces.

- Certain composites may require specialized bits to minimize tool wear and maintain product consistency.

-

Modern CNC routers are equipped with smart controls and advanced software, allowing for intricate designs and high repeatability. Understanding the properties of each material ensures the selection of proper tools, speeds, and machining strategies, maximizing efficiency and output quality.

Capabilities of Laser Machines with Thick Materials

Laser machines have become indispensable tools for cutting and engraving thick materials, offering precision and consistency unmatched by traditional methods. These machines utilize high-powered laser beams to cut through robust materials like steel, aluminum, and hardwoods, achieving clean edges without requiring secondary finishing. With advances in laser technology, machines can now cut materials up to 30mm thick depending on the material type, power source, and machine configuration. For instance, a CO2 laser cutter with a power rating of 150W or higher can efficiently slice through up to 20mm of acrylic or 15mm of plywood in one pass.

Innovations such as fiber lasers have further extended capabilities in metal cutting, allowing for rapid and precise operations on materials like stainless steel and copper. With cutting speeds reaching up to 10 meters per minute for thinner metals, these machines reduce production time significantly. Additionally, features such as auto-focus capabilities and advanced cooling systems enhance performance, maintaining high-quality cuts while reducing the risk of overheating in thicker materials.

For industrial applications, laser machines are highly versatile, supporting intricate designs and large-scale production. Their ability to work seamlessly with CNC software ensures accuracy to within fractions of a millimeter, critical for demanding projects. Such precision and adaptability make laser systems an essential component in industries such as aerospace, automotive, and construction.

Special Cases: Plasma Cutters and Cut Metal

Plasma cutters are renowned for their efficiency and power, particularly in applications requiring the cutting of electrically conductive metals like steel, aluminum, and copper. These tools operate by generating a high-velocity jet of ionized gas, or plasma, which melts and blows away the material at the cut point. One of the advantages of plasma cutting is its ability to achieve high precision and smooth edges, even on thicker materials—up to 1 inch (25 mm) or more depending on the equipment. Advanced digital controllers further enhance accuracy, reducing the need for secondary processing.

When dealing with cut metal, combining plasma cutters with other advanced technologies like CNC systems or automated robotics creates unparalleled accuracy and repeatability. According to industry statistics, plasma cutting can often reduce metal wastage by over 25%, while increasing cutting speeds by 50% when compared to traditional methods like oxy-fuel cutting. These benefits are particularly valued in industries such as shipbuilding, manufacturing, and custom metal fabrication, where both speed and precision are crucial.

Additionally, innovations such as Hypertherm plasma systems have introduced features like FineCut consumables, which allow for finer and more intricate cuts on thinner metals, expanding the versatility of these tools even further. Plasma cutters continue to evolve, demonstrating how technological advancements are shaping efficient and sustainable metalworking practices across multiple sectors.

Which is Better: CNC vs Laser Cutter for Your Needs?

The choice between a CNC cutter and a laser cutter boils down to particular requirements that need to be met. Projects requiring elaborate engraving or other intricate designs will benefit from the use of a laser cutter as it provides the most precise cuts. On the other hand, CNC cutters have the upper hand when it comes to the variety of materials they can process; from thick metals to wood, they can handle heavy-duty applications as well as sculpt 3D shapes.

In cases where the type of material and operational cost are more important, then CNC machines take the advantage, processing robust materials at a lower cost. Still, when it comes to speed and precision for delicate work, laser cutters tend to be the better option. Knowing your budget, the materials you need to work with, and how complicated the project is will determine which choice is best suited for you and your needs.

Assessing Cutting Methods for Precision and Detail

When assessing cutting methods for precision and detail, modern technology has provided notable advancements in both laser cutting and CNC machining. Laser cutters are now capable of achieving precision levels up to ±0.003 inches, making them ideal for applications requiring intricate designs or fine detailing, such as jewelry making or the creation of custom engravings. These machines excel at cutting thin to medium-thick materials like plastics, paper, or wood with unparalleled accuracy and speed.

On the other hand, CNC machines, which leverage computer-aided design (CAD) files to control their operations, offer versatility in cutting a broad range of materials, including metals, composites, and hardwoods. A well-calibrated CNC machine can achieve accuracies of ±0.005 inches, ensuring reliable precision even for industrial applications. These machines handle heavy-duty tasks, such as carving, milling, or engraving thicker, more robust materials, making them an excellent choice for construction or manufacturing projects.

Statistical analyses highlight critical differences in operating efficiencies. For example, laser cutters generally operate faster, cutting at speeds up to 1,000 inches per minute for thin materials, which reduces lead time for production. Conversely, CNC machining offers slower throughput but compensates with more intricate 3D machining capabilities that laser cutters cannot easily replicate.

Costs also play a role in determining the best methodology. Laser cutting systems commonly range from $10,000 to $150,000, depending on configuration and power, while CNC machines may start from $5,000 for basic models but can exceed $200,000 for advanced setups supporting industrial workloads. These figures illustrate the importance of aligning budgetary goals with project demands to ensure efficiency and value.

Ultimately, selecting the right cutting method demands careful consideration of material type, project complexity, size, and the desired level of precision. With continuous innovation in both types of machinery, modern creators and manufacturers benefit from tools that balance speed, detail, and versatility to meet specific industry needs.

Choosing Between a CNC Router and a Laser Cutter for Workpiece Specifications

When deciding between a CNC router and a laser cutter, both define workpiece specifications and are tailored to different requirements. A CNC router does exceptionally well when cutting wood, plastic, and metal, as well as handling 3D designs with depth and contour. Alternately, a laser cutter is better suited for detailed cuts on thinner materials such as acrylic, paper, fabric, and some metals. While a laser cutter is better with intricate patterns, its accuracy drops severely with thicker materials. Determine the type of material you are working and what you need to achieve to select the appropriate machine tailored for you.

Future Trends in CNC and Laser Technologies

The future of CNC and laser technologies is marked by rapid advancement driven by automation, artificial intelligence (AI), and sustainability. CNC machines are increasingly incorporating AI algorithms to optimize production efficiency. For instance, predictive maintenance powered by AI can analyze machine performance and preemptively identify potential issues, reducing downtime by up to 30% based on recent technological assessments.

On the other hand, laser technology is advancing through innovations in fiber lasers, which offer higher energy efficiency and increased cutting speed compared to CO₂ lasers. Recent reports indicate that fiber lasers can achieve up to 4 times the throughput of traditional systems, making them a preferred choice in industries like aerospace and automotive manufacturing.

Another major trend is the integration of smart manufacturing systems. Both CNC and laser technologies are aligning with Industry 4.0 principles, enabling real-time data collection and connectivity. This shift allows operators to remotely monitor processes, make data-driven decisions, and achieve greater customization at scale.

Sustainability is also a growing focus, with manufacturers investing in greener practices such as waste recycling and energy-efficient machines. Studies reveal that smart laser systems can potentially reduce energy consumption by up to 50% compared to legacy models, aligning with global environmental goals.

Together, these trends are paving the way for enhanced precision, efficiency, and sustainability in CNC and laser technologies, fostering innovation across a range of industries.

Reference Sources

-

“Digital Fabrication in Architecture”1:

- Key Findings: This study highlights the use of CNC routing and laser cutting in architecture for creating intricate designs and sustainable building components. CNC routing is noted for its precision in carving materials like wood and metal, while laser cutting excels in intricate and precise cuts for materials like plastics and metals.

- Methodology: The research involved case studies showcasing the application of CNC and laser technologies in architectural projects, emphasizing their role in enhancing design flexibility and reducing material waste.

-

“Materials, Machines, Meanings: Design Strategies for Distributed Manufacturing”2:

- Key Findings: The paper discusses the complementary roles of CNC routers and laser cutters in distributed manufacturing. CNC routers are highlighted for their ability to carve wood and other materials, while laser cutters are praised for their precision in cutting and engraving.

- Methodology: The study explores design strategies to overcome material and functional limitations in distributed manufacturing, emphasizing the integration of CNC and laser technologies for creating functional and aesthetic products.

-

“Supporting Creative Learning for Rapid Prototyping and Additive Manufacturing”5:

- Key Findings: This research examines the educational use of CNC routers and laser cutters, emphasizing their role in fostering creative learning. It contrasts “top-down” and “bottom-up” learning approaches, showing how these technologies can enhance design education.

- Methodology: The study involved analyzing student projects and teaching strategies, focusing on how CNC and laser technologies can be integrated into design curricula to promote innovation and hands-on learning.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What are the main differences between a CNC router and a laser cutter?

A: The main differences between a CNC router and a laser cutter lie in their cutting mechanisms and applications. A CNC router machine uses rotary tools to cut and shape materials, making it ideal for wood, plastic, and softer metals. In contrast, a laser cutter uses a high-powered laser to cut through materials, offering precision and speed, especially suitable for intricate designs and thin materials like paper, acrylic, and textiles.

Q: How does a CNC router machine work compared to a laser cutter?

A: A CNC router machine works by using a rotating cutting tool to carve into the material, controlled by computer software. It is particularly effective for three-dimensional designs and can handle thicker materials. On the other hand, a laser cutter uses a laser head to emit a focused beam that melts or vaporizes the material, suitable for detailed and clean cuts in thinner materials.

Q: What are the advantages of using a laser cutting machine?

A: A laser cutting machine offers several advantages, including high precision, clean cuts, and the ability to cut intricate designs. It is also faster for certain materials and does not require physical contact with the material, reducing wear and tear on the machine. Laser cutting is generally more efficient for delicate and thin materials.

Q: Can a CNC router machine cut metal parts?

A: Yes, a CNC router machine can cut metal parts, but it is more commonly used for softer metals and materials like wood and plastic. For thicker or harder metals, CNC milling machines or specialized metal CNC routers are more appropriate.

Q: What materials can a CO2 laser engraver cut compared to a CNC router?

A: A CO2 laser engraver can cut materials such as acrylic, wood, paper, and fabric, excelling in precision and detail. Compared to CNC routers, which are better suited for wood, plastic, and softer metals, CO2 laser engravers are less effective on thicker or harder metals.

Q: Are there differences between CNC cutting and laser cutting in terms of speed and efficiency?

A: Yes, there are differences between CNC cutting and laser cutting in terms of speed and efficiency. Laser cutting is generally faster and more efficient for thin and delicate materials, providing precise and clean edges. CNC cutting, while potentially slower, is more versatile for thicker materials and 3D carving.

Q: How do I decide between using a CNC router or laser cutter for my project?

A: To decide between using a CNC router or laser cutter, consider the materials and designs involved in your project. If you need to cut thicker materials or require 3D shaping, a CNC router is more suitable. For intricate designs and thin materials, a laser cutter is the better choice.

Q: What types of projects are best suited for a laser engraver?

A: Laser engravers are best suited for projects requiring high precision and intricate designs, such as engraving personalized items, creating signage, cutting detailed patterns in fabric or paper, and marking metal parts. They excel in applications where detail and clean edges are essential.

Q: How does the power of the laser affect the cutting ability of laser cutters?

A: The power of the laser affects the cutting ability by determining the speed and thickness of materials that can be cut. A higher power laser can cut through thicker materials more quickly, while lower power lasers are suitable for engraving and cutting thinner materials.

Q: Are laser cutters and CNC routers used together in any industries?

A: Yes, laser cutters and CNC routers are often used together in industries where versatility and precision are needed. For example, in the sign-making industry, a CNC router can cut the base materials, while a laser cutter can add detailed designs and engravings. This combination allows for a wide range of cutting and shaping capabilities.