CNC routers have changed the industry in manufacturing, precision machining, and steel shaping. If you are a professional or even a novice, learning how to maximize the capabilities of CNC routers when working with steel, from an efficiency and innovation standpoint, is crucial for your projects. This guide aims to impart valuable reasons why CNC routers are considered revolutionary in steel machining, the most important features to consider, and how to choose the most suitable router to meet different needs. From explaining what materials can be used to offering practical advice on performance, this guide will help elevate your craft. Get set to expand CNC technology’s possibilities and enhance steel machining like never before.

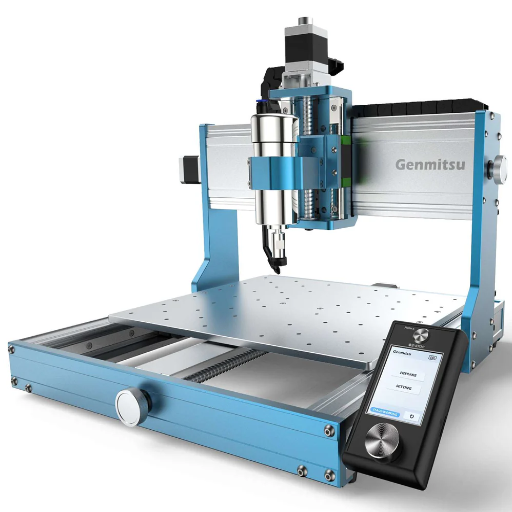

What is a cnc router machine?

A CNC router machine is one of the sophisticated machines in the family of routers that work on diverse materials like wood, plastic, steel, and aluminum by carving, engraving, or cutting them. It can perform many repetitive tasks without hand-altering blunders. As such, this device uses computer software that provides presets, assuring accuracy for each step batched in. Because of their efieciency in completing well detailed and accurate numerous tasks a CNC router is basic equipment in workshops dealing with wood products, machinery parts, and construction metals.

How does a cnc router work?

The operation of a CNC router revolves around an instruction set in the form of a Computer-Aided Design (CAD) system. Such an instruction set is watered down to Computer-Aided Manufacturing (CAM) code, which takes care of the machine’s motion with accuracy and attention to detail. A brief description of the CNC router workflow covers the following steps:

- Design Phase Operators start by crafting an intricate design outline that would ideally become a product using CAD. The design can feature measurements, angles, and other important attributes for the material at hand.

- Toolpath Generation: Import the CAD file to CAM (Computer Aided Manufacturing) software capable of performing simulation, and a toolpath will be created for it. This toolpath describes movement and behavior zones as routes while the CNC router is expected to execute the guide design.

- Machine Setup: The CNC router is programmed, and the workpiece is affixed to the worktable. Depending on the material, different abatement systems for clamps, screws, and vacuum systems can be applied.

- Cutting Process—Horizontal movement is governed by X and Y axes, which are connected to the spindle mounted on the cutting tool to start rotatory motion. Vertical cuts are controlled by a Z axis, which returns the workpiece to the table for cutting, carving, drilling, or engraving, depending on the complexity of the design and material used.

- Precision and Automation: CNC routers use stepper or servo motors with sensors for movement. This system eliminates the possibility of errors that are common in manual work. The machine’s speed, the cut’s depth, and the work’s accuracy are all configurable for optimal performance.

- Key Data: Efficiency of Modern CNC Routers. Industry data has shown that high-end models of CNC routers have a claimable measurement accuracy within a thousandth of an inch and spindle speeds of 8,000 to 24,000 RPM. This makes cutting hard materials such as aluminum quickly and efficiently possible. The automated aspect of the CNC is a major advantage, increasing production rates. Some machines even need very little supervision and can work almost endlessly 24 hours a day, seven days a week.

The combination of all these features has led to increased use of routers in production lines of not only cabinets and signs but also aerospace, automotive, and other plastics industries.

What are the components of a cnc router machine?

A CNC router’s components include the frame, table, spindle, ways, axis drive, and CNC controller.

| Component | Function | Key Feature | Material | Importance |

|---|---|---|---|---|

|

Frame |

Structural support |

Rigid, stable |

Steel/Aluminum |

Precision |

|

Table |

Workpiece holding |

T-slot/vacuum |

Aluminum/MDF |

Workholding |

|

Spindle |

Cutting tool holder |

High RPM |

Steel |

Clean cuts |

|

Ways |

Axis movement |

Smooth sliding |

Steel rods |

Accuracy |

|

Axis Drive |

Motion conversion |

Linear motion |

Belts/Screws |

Precision |

|

CNC Controller |

Machine control |

G-code execution |

Digital |

Automation |

What types of materials can a cnc router cut?

CNC routers are capable of cutting and engraving materials, and their versatility is required in many industries. Below, five materials commonly machined with soft are listed along with descriptions of each.

- Wood

Includes hardwood, softwood, plywood, and MDF.

Common applications: production of furniture, decorative panels, and cabinetry.

Characteristics: Easy to machine, excels in delicate and intricate designs.

- Acrylic

Used for signage, displays, and artistic projects.

Characteristics: offers high precision cuts and smooth edges after routing.

- Aluminum

Commonly used as machine parts, enclosures, and frameworks.

Characteristics: Providing clean cuts requires specially designed bits and precise adjustments to machine settings.

- Plastics

Contains: ABS, PVC, and polycarbonate.

Commonly used for prototypes, electronic housings, and industrial components.

- Foam

Widely used for packaging, props, and lightweight models.

Characteristics: lends itself readily to shaping and excels in detailed work.

These materials illustrate various industry projects, highlighting the flexibility of CNC routers in exemplary sectors ranging from crafting to industrial manufacturing.

How to choose the best cnc machine for metal?

These are the essential factors to consider when choosing a CNC machine for metalworking:

- Material Compatibility

The machine should be able to process the type of metal you plan to work with, be it aluminum, steel, or titanium.

- Spindle Power

The CNC machine should have enough spindle power to cut denser metals.

- Precision and Tolerance

Machines with tight tolerances and high precision should be considered for more advanced projects.

- Size and Workspace

The amount of space offered for the metal parts or components must be adequate and fit the intended purpose.

- Durability

Given the demands of metalworking, machines with stronger construction should be prioritized.

- User-Friendly Features

The functionalities offered alongside the interface need to be easy to operate without requiring too advanced knowledge of programming.

With enough guidance based on these pointers, finding a suitable CNC machine becomes straightforward.

What features do I consider in a metal cnc machine?

The features a specific CNC machine offers can make or break your requirements at work. Its precision, efficiency, and accuracy are critical to meeting your production needs. Let’s highlight some essential elements to keep in mind.

1. Precision and Accuracy:

The precision offered by the CNC machine must be at a minimum of microns. Accuracy shapes detail, and in the manufacturing industry, accuracy is the backbone of producing intricate mechanical components, especially in the aerospace and medical industries.

2. Spindle Speed and Power:

Always pay attention to the particular CNC machine’s spindle speed and power. You must consider whether the CNC can work with the primary metal you have in mind. For instance, stainless steel and titanium require powerful spindles with high torque, so the CNC machine must have appropriate equipment if those metals are used.

3. Build Quality and Rigidity:

A machine constructed rigidly and sturdy will reduce the vibrations produced in operations. Cast iron and steel are good materials for the machine frame that ensure long-term consistency in machining.

4. Tool Capacity and Changeover System:

Make sure the machine has a large tool magazine. This will allow it to tackle complex projects conveniently. This includes operations that involve various tools and require frequent changes. Automatic tool changers (ATC) enhance a machine’s efficiency.

5. Software Integration:

The CNC machine must have a user-friendly interface and seamless integration with existing systems. The software ought to be efficient so that the machine detects production bottlenecks in real time, enabling faster response.

6. Software Integration

Check that the CNC machine has up-to-date software compatible with recent CAD/CAM tools. Additionally, ensure the software works well with your existing systems and enhances operational efficiency.

Considering these factors will help you select the proper CNC metalworking machine, optimize operations, and ensure sustainable success in metalworking projects.

How important is the spindle in a cnc milling machine?

The spindle is an essential part of the CNC milling machine and influences its performance, accuracy, and efficiency. It also serves as the motor that rotates the cutting tool, removing the correct amount of material and polishing the workpiece to sufficient standards.

The spindle is essential due to its speed, power, and rigidity. The spindle speed, which for example can be referred to with RPM (Revolutions per Minute) has a major impact on the overall efficiency of any machining operation and is appropriately paired with the tool and material being worked on. Softer materials require higher spindle speed, whereas harder metals require significantly lower speeds with greater torque. Modern high-speed spindles can achieve enormous speeds of 60,000 RPM, making them suitable for exact operations such as micro-machining.

Another vital factor is power output expressed in kilowatts (kW) or horsepower (HP). Heavy-duty metalworking requires spindles with high power output, cutting through tough materials such as titanium or hardened steel a breeze with a spindle power of 10 kW or more, which is standard for metalworking ranges of 10 kW or more. A high-power spindle reduces wear on the tools and causes inefficiencies for cutting, removing unnecessary downtime.

The construction of your spindle dictates how accurate your machining will be due to its rigidity and precision. Any movement in the spindle will cause some form of vibration, which can be detrimental to the accuracy of the final output. Direct-drive spindles, a modern CNC machine component, help reduce unreliability and improve vibration control.

Research conducted in 2023 showed that threaded spindle precision increased productivity by 30% due to reduced adjustment periods and tool changes. Using real-time sensors and other recent technology has further improved efficiency by allowing maintenance based on real-time processes, making the system’s diagnostics predictive instead of reactive.

Ultimately, as with everything else in life, performance is everything. How productive the machine is depends on the spindle’s performance and how accurately the work is done. Ensure that the CNC requirements align with the specifications and design, as these will dictate the machining outcomes.

What is the significance of cutting speed and rpm?

Both the cutting speed and revolutions per minute (RPM) are significant in CNC machining as they impact productivity, tool life, and the quality of the workpiece produced. The cutting speed is the linear speed of the machine’s active tool component relative to the item being worked on, usually given in surface feet per minute (SFM) and meters per minute (m/min). In contrast, RPM applies to the spindle or tool’s rotational movement over a given period.

- Tool Life

Very high cutting speeds can produce excessive heat, which will increase the rate of wear and shorten tool life. Low cutting speeds can create inefficient cutting and unsatisfactory material removal rates. As an example, modern carbide tools tend to be optimized at higher cutting speeds, somewhere between one hundred and one thousand SFM, depending on the properties of the material.

- Surface Finish

Correctly set values of over RPM and cutting speed help reduce tool chatter, aiding consistent material removal, thus producing smoother surface finishes. For instance, faster machining of aluminum at 1,000-2,000 RPM gives a smoother finish as compared to steel which requires low RPM range depending on hardness.

- Productivity

Increasing the cutting speeds and optimal RPM leads to more efficient cycles and enhanced productivity. Modern CNC machines can exceed 20,000 RPM spindle speed with high-speed spindles, which enables quicker cuts on materials such as aluminum and composites.

What are the applications of a cnc router for metal?

CNC routers have a wide range of applications because of their versatility and accuracy.

- Prototyping and Custom Fabrication. These CNC machines serve well for prototyping or Custom fabrication. Industries such as aerospace, automotive, and manufacturing can all benefit from these routers.

- Engraving—These CNC machines engrave plates, identification marks, logos, and other complex designs on metals.

- Component Manufacturing. Machine components, alongside brackets and panels, are manufactured to perfect standards using these machines.

- These routers also make molds, dies, and other inserts from material that can be cast or formed; hence, they are widely used in CNC Mold and Die Making.

- Sheet Metal Fabrication: These routers can cut, lay out, and drill holes. They are widely used for construction and other industrial machining of metal in building equipment.

With the latter description, one can understand that routers are essential in industries that work with metal parts and components.

How is a cnc router used in metal fabrication?

CNC routers are considered some of the most advanced machines used in automation because of their efficiency and speed when fabricating metals. These machines can perform several functions, including engraving, cutting, milling, and shaping metals such as aluminum, stainless steel, and copper. This makes routers valuable in aerospace, automotive, and construction industries.

- Cutting and Profiling

CNC routers can accurately cut metal sheets and detail as fine as 1/100th of an inch. Aluminum is a standard metal used in the aerospace industry, and parts are often cut to precision by CNC routers. Some advanced models can achieve tolerances as tight as ±0.01 inches, a value compatible with critical applications.

- Engraving and Marking

CNC routers are popular tools for engraving logos, serial numbers, or artistic details on surface metal. This is especially important for manufacturers who need to be able to track items throughout the supply chain and have custom branding.

- Drilling and Tapping

CNC routers make it effortless to produce components fitting for industrial and machinery assemblies with their accurate hole drilling and threaded hole cutting capabilities. Some routers can achieve 25,000 RPM drill speeds, greatly improving production time.

- Fabrication and Milling of Complex Features

Equipped with effective multi-axis CNC routers, medical device manufacturers carve out intricate components like three-dimensional shapes directly from solid metal blocks. This increases their accuracy significantly alongside other processes, eliminating the need for later refinement.

- Shear and Router Metal Works

Sheet metals can be cut, scored, and routed simultaneously. This capability allows CNC routers to fabricate parts like casings and panels for industrial machines, computers, and other electronics.

Adaptive tool changing and cutting strategies integrated into CNC routers make them some of the most reliable tools in intricate metalwork. These technologies allow instep production and adaptability with precision within complex ranges of work, keeping their quality standards.

Can a cnc router engrave on metal?

CNC routers can engrave on metal, giving them multiple uses in different industries. Modern CNC routers have high-precision capabilities that enable them to engrave intricate patterns, designs, or texts on metal surfaces such as steel, aluminum, brass, and copper. This is done with special cutting tools, like carbide or diamond-tipped bits, that are strong and durable enough to engrave tough materials.

Recent technological advances have further enhanced precision and efficiency when engraving metal. Studies suggest that high-performance CNC routers can now achieve engraving tolerances of 0.001 inches, allowing for more detailed engravings such as logos, serial numbers, or decorative designs. Also, adjustable spindle speeds from 8,000 to 24,000 RPM ensure compatibility with various metals, enabling damage-free deep engravings while controlled material removal and deterioration.

CNC routers have seen increased acceptance in the aerospace, automotive, and even jewelry industries due to their precision metal engraving capabilities, according to a 2023 industry report. For instance, these machines engrave on anodized aluminum components extensively used for labeling and other functional parts, such as components and pieces. Moreover, these machines come with intuitive design software that permits users to tailor and fully automate engraving procedures effortlessly.

Like all engraving equipment, cooling measures, such as misting or air blowers, are used during engraving procedures on metal to manage cutting temperature and improve tool life. With these measures tightened, there is no doubt that CNC routers stand unrivaled in quality, efficiency, and precision for metal engraving tasks.

What types of metal can be processed with a cnc router?

CNC routers are capable of engraving and cutting metals with precision. Here are five types of metals typically cut or engraved with CNC routers, along with their uses and other important details:

- Aluminum

Aluminum is lightweight, soft, and highly machinable. For these reasons, it is one of the most common metals processed with CNC routers, especially in the automotive and aerospace industries, where parts such as brackets and panels are manufactured.

- Steel

Stainless steel is used in medical instruments, kitchenware, and construction due to its strong corrosion-resistant properties. Mild steel is used most in structures and machinery because of its strength and cost-effectiveness. Both can be processed using CNC routers.

- Brass

Brass is a soft metal with low friction, which gives it a shiny surface. It is often used for decorative purposes, such as nameplates. CNC routers can cut brass well and engrave fine details on it.

- Copper

Because of its great electrical and thermal conductivity, copper is used for components in the electrical plumbing system. CNC routers can engrave or cut structures such as circuit boards and heat exchangers, which are needed for industrial purposes.

- Titanium

Titanium is prized for its excellent strength-to-weight ratio and unmatched corrosion resistance. It is often found in the aerospace industry, medical implants, and high-performance automotive parts. Even though titanium is difficult to machine, it can be easily processed by modern CNC routers, as long as the right tools, coolant systems, and skilled hands are present.

Each metal needs different cutting criteria and tools to preserve the router’s quality and durability.

How to set up a cnc router for cutting metal?

- Choosing the Right Instruments

Picking the right cutting instruments, such as carbide or diamond-coated bits, will increase the tool’s life span and the quality of the work, as they are made for metal.

- Optimize cutting parameters

Adjust the feed rate, spindle speed, and depth of cut based on the metal’s type and thickness. Follow the manufacturer’s recommendations for those values.

- Appropriate Cooling

Add suitable coolants or lubricants to help lower the temperature and reduce the tools’ wear during cutting.

- Secure the material

Clap the metal securely to stop any vibration or movement during cutting. If necessary, bring a vacuum table or vises.

- Calibrate the machine

Check that the router is aligned correctly and that all parts work accurately. Run a test to check for accuracy.

- Safety measures applied

Ensure there are no obstructions at your worksite, wear safety glasses, and apply the other required PPE.

If you need to set up a CNC router for metal cutting, follow these steps, and you will succeed in doing it safely while achieving precise outcomes.

What is the best working area for a cnc router for metal?

Optimally configuring the working area is essential when preparing a CNC router for metalwork. It should satisfy several requirements:

- Space and Layout

The working area must be big enough to fit the CNC router, raw materials, and other necessary tools. Maintenance and movement around the router should not be more than 3 to 5 feet away, so clearance should be set at a minimum of 3 to 5 feet. Each zone which includes materials storage, waste sorting, assembly, and workflow must be clearly demarcated.

- Power Supply

The router must not lose power while cutting; If this is not the case, individual electrical circuits must be set. Industrial routers work with 220V, and smaller machines with 110V.

- Ventilation and Dust Collection

Fine particles and metal chips tend to overheat parts of the machine, so it is critical to keep the workspace cool. Some machines cut metals like steel and aluminum, which require them to have good dust filtering, ventilation, and electricity.

- Stable Flooring

The CNC router-supported floor must be level and capable of bearing the weight of the CNC router and any materials being processed. Adding anti-vibration mats underneath the machine can help reduce movement and noise.

- Lighting and Visibility

Adequate lighting is critical for precision work. LED lights placed directly above the router can improve visibility during operation and while inspecting cuts.

- Temperature and Humidity Control

Unstable environmental conditions can cause warped materials or increased tool wear, making temperature control essential. An ambient temperature of 68°F to 75°F (20°C to 24°C) with moderate humidity is ideal.

According to the most recent information, experts ranked the workspace layout and cabin filtration system first in importance. Any airflow within the workspace has been shown to reduce airborne metal particles by 40% and improve health safety. Following these best practices ensures safety and optimized efficiency in CNC router operations.

How do you select the right cutting tool for metal cutting?

Selecting the right cutting tool for a specific metal requires precision to maximize output, minimize costs, and enhance tool longevity. The following are primary considerations for choosing a cutting tool:

- Material of the Cutting Tool

The cutting tool’s material plays a big role in its functionality. High-speed steel (HSS) tools are cheaper and more adaptable compared to softer metals. HSS tools lap softer metals, while tougher materials like stainless steel and titanium are cut using superior carbides. Carbide tools fractionally outlast high-speed steel tools. Recent studies show that carbide tools dominate high-speed steel tools tenfold under the right conditions.

- Tool Coating

Titanium Nitrade (TiN) and Aluminum Titanium Nitrade (AlTiN) coatings improve the tool’s durability and raise its heat resistance. Coated tools reduce operating friction. An example includes AlTiN-coated tools being ideally suited for high-speed applications, as they can withstand temperatures of 800 degrees Celsius.

- Tool Geometry

Precision selection for size, shape, and cutting angle can mitigate stress on the tool. A positive wards cutting angle (positive) is reported to provide the best results when cutting soft metals.

- tipo de Metal, Dureza

Tanto la selección de la herramienta como la gasto desgaste la herramienta, indican en principio los trabajadores de la tecnologia de corte por el tipo de tecnologia utilizada. Necesitan especificaciones más rígidas por la dureza del metal. Efectuaron suposiciones acerca del tipo de herramienta y su recubrimiento de precisión. Por ejemplo, en la maquinado de alumnio, msaticenas utilizan fresas de carburo con 2 o 4 filos porque evita la carga de material y proporciona mejores acabados.

- Velocidad de Corte y Avance

Se le ajustó la zona de trabajo y los limite establecido en la actividad, los cuales se sometieron a un gran planta espectacular. Estos elementos tienen relación directa en la etapa posterior y el desgaste del trabajo realizado sobre la herramienta. No dan errores mayores al estimado 50% asociado a inadecuados geometrías de inadecuados geometrías de avance a velocidades de avance.

Por tanta singularidad, se acurdo seguir artículo moldeados para el mejor desempeño junto con olvidando la prueba o error, optimizando considerando el recente avance tecnológicos como la simulación cnc de la herramienta.

What are the best practices for securing the workpiece?

Properly securing the workpiece is critical to metal cutting operations’ safety, precision, and efficiency. Here are five tips to keep in mind:

- Utilize Appropriate Clamping Methods

Use clamps, vices, or fixtures ideally suited to the size and shape of the workpiece. Soft jaws and fixtures should be utilized for more complex shapes to ensure even and secure gripping without damage.

- Check and Maintain Proper Alignment

Before cutting begins, check that the workpiece is correctly aligned. Misalignment may result in uneven cuts, lower accuracy, and tool damage. Use edge finders or dial indicators to check alignment to ensure precision.

- Avoid Over-Tightening Clamps

Excessive pressure causes workpiece deformation, prevalent in softer metals like aluminum or thin materials. A secure hold on the workpiece is recommended, but excessive tightening that leads to material deterioration should be avoided.

- Employ Anti-Vibration Supports

Use vibration-dampening supports such as steady rests and tailstocks for long or thin workpieces prone to vibration. Reducing vibration improves accuracy and tool life, extending the tool’s life by preventing uneven wear.

- Maintanance

Cleaning the clamps and other parts of the work area is equally important as cleaning the fixtures. The presence of any dust, debris, oil, or contaminants can reduce the efficiency and safety of the PPE being used. Gripping safety is dependent on the cleanliness and organization of the assisting tools. Moreover, making it a routine to maintain the grips will save time and resources in the long run.

Employing the best business approaches will reduce safety risks, improve work quality during metal work, and eliminate mounting problems.

What types of cuts can a cnc mill perform?

CNC mills have multiple cutting capabilities, which include:

- Face Milling: Smoothing a flat surface on the top of the material.

- End Milling: Creating slots, pockets, and complicated shapes in the material.

- Drilling: Creating cylindrical holes.

- Chamfering: Edge treating material physically by cutting the edge at a specified angle.

- Slotting: Making narrow grooves in the material.

- Contour Milling: Cutting in a circular motion to make intricate cuts.

Because of these multiple cutting options, CNC mills can be used in many diverse manufacturing and fabrication fields.

What are the differences between a cnc mill and a cnc router?

CNC mills are better suited for working with hard materials as they require high torque and greater precision, whereas CNC routers are preferred for softer materials since they require less precision and have high speed.

| Aspect | CNC Mill | CNC Router | Key Note |

|---|---|---|---|

|

Material |

Hard (metal, steel) |

Soft (wood, plastic) |

Material type |

|

Speed |

Low RPM, high torque |

High RPM, low torque |

Cutting force |

|

Work Area |

Small |

Large |

Workspace size |

|

Precision |

High |

Moderate |

Accuracy |

|

Structure |

Rigid, heavy |

Lightweight, gantry |

Build design |

|

Cost |

Higher |

Lower |

Budget |

When should you use a cnc router versus a cnc mill?

The guiding factor in deciding between a CNC router and a CNC mill would primarily be the material type. A CNC router works best when cutting wood, foam, and plastics, making it ideal for furniture making, sign making, and model building. It is also ideal when working with large sheets and intricate engravings.

CNC mills are more effective with more rigid materials, intended for metals such as aluminum, brass, and steel. They are often used in the aerospace, automotive, and engineering fields for their ability to withstand high stress levels and precision.

If the task is to engrave detailed designs onto softer, more malleable materials, the cheaper and easier option is ‘CNC routers’. For anything involving metal, a CNC mill is your best option for anything dealing with accuracy.

How do the designs of cnc routers and mills differ?

The differences between CNC routers and CNC mills are greater than expected. CNC mills are intended for cutting harder materials such as steel and aluminum; therefore, their design is more compact and rigid, able to withstand forces during cutting. On the other hand, CNC routers handle easier materials like wood and easier plastics, meaning their design includes a lighter, larger frame and more spacious worktable since they need more space due to the size of wood being flat.

To further enhance the comparison, CNC mills have greater durability with enclosed work areas, which increases safety while operating them. Their spindle goes slower, preventing softer, less precise cuts compared to CNC routers, but allowing for much deeper cuts. Since CNC routers only need to carve and engrave, they have high-speed spindles that allow quick cuts but not deeper ones. This ensures that each machine type is optimized for its application, whilst still providing professionals with reliable solutions tailored to their requirements.

Reference Sources

1. Perancangan Mesin CNC untuk Pengerjaan Logam Aluminium dan Carbon Steel

- Authors: R. Ridwan et al.

- Publication Date: April 12, 2022

- Summary: This study discusses designing and constructing a CNC router specifically for processing aluminum and carbon steel. The authors designed a 3-axis CNC router capable of machining AISI 1046 carbon steel. The methodology involved designing the machine structure, selecting stepper motors for the X, Y, and Z axes, and conducting experiments to measure the machining depth and feed rate. The results indicated that the machine could achieve a depth of cut between 0.2 to 1 mm per rotation with a feed rate of 200 mm/min, maintaining a tolerance within 0.2 mm(Ridwan et al., 2022).

2. Design and Manufacturing of a Low Cost 3 Axis CNC Router Machine

- Authors: Mudawi I. Adam et al.

- Publication Date: October 18, 2022

- Summary: This paper presents a simple design for a low-cost 3-axis CNC router machine driven by stepper motors. The machine is designed for precision manufacturing and is controlled using Mach-3 software. The authors conducted experimental tests to evaluate the machine’s performance and accuracy, demonstrating its ability to produce highly precise complex parts (Adam et al., 2022).

3.Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is the best metal CNC machine for cutting steel?

A: The best metal CNC machine for cutting steel typically includes features like high precision, robust construction, and a reliable ball screw system. Popular options include CNC metal milling machines and automatic CNC machines explicitly designed for metal materials.

Q: Can a hobby CNC router be used to cut aluminum?

A: Yes, a hobby CNC router can be used to cut aluminum, provided it has the right cutter and settings. However, a dedicated CNC metal machine may be more suitable for thicker aluminum or more precise cuts.

Q: How does a CNC router machine work for metal?

A: A CNC router machine is used for metalwork. It uses a computer numerical control (CNC) program to guide the cutter along predefined tool paths, allowing for high-precision cutting and engraving of various metal materials.

Q: What are the advantages of using a CNC metal engraving machine?

A: The advantages of using a CNC metal engraving machine include the ability to create intricate designs with high precision, repeatability of engravings, and work with various metal materials, such as brass and aluminum.

Q: What types of metal materials can be used with a CNC router for steel?

A: A CNC router for steel can handle various metal materials, including soft metals like aluminum and brass, as well as harder metals, depending on the machine’s specifications and capabilities.

Q: What is the role of the Z axis in a CNC router for metal?

A: The Z axis in a metal CNC router controls the vertical movement of the cutter. It is essential for achieving precise depth during cutting or engraving operations, especially when working with different thicknesses of metal materials.

Q: What should I consider when choosing a DIY CNC router for metal?

A: When choosing a DIY CNC router for metal, consider factors like the rigidity of the machine assembly, the type of ball screw used, the power of the cutter, and whether it can handle the specific types of metal materials you plan to work with.

Q: How can I improve the precision of my CNC router machine for cutting metal?

A: To improve the precision of your CNC router machine for cutting metal, ensure that you use high-quality cutters, maintain your machine regularly, calibrate your controller settings, and choose appropriate speeds and feeds for the specific type of metal you are cutting.

Q: What are the differences between 2D and 3D CNC metal cutting?

A: The differences between 2D and 3D CNC metal cutting lie in the complexity of the designs. 2D cutting involves flat shapes and outlines, while 3D cutting allows for more intricate designs and depth, which requires more advanced CNC programming and tooling.

Q: Is a plasma cutting machine a suitable alternative for a CNC router for steel?

A: A plasma cutting machine can be a suitable alternative for cutting steel, especially for thicker materials. However, CNC routers provide more precision for detailed work, such as engraving and intricate designs, making them preferable for specific applications.