The process of sign creation has changed quite a bit over the years. Newer methods bring together enthusiasm, skill, and care, all powered by advanced technology. A CNC router is arguably the most critical equipment that has changed how signs are created and produced. For sign makers and those just starting to dabble in this craft, this guide aims to assist you in everything sign making with a CNC router, including its functionalities, sophisticated design methods, and realistic style recommendations. Consider this a one-stop shop guide for improving your skills. So, why are CNC routers trusted in the sign-making and personalization industry? Let’s explore the answer together, step by step.

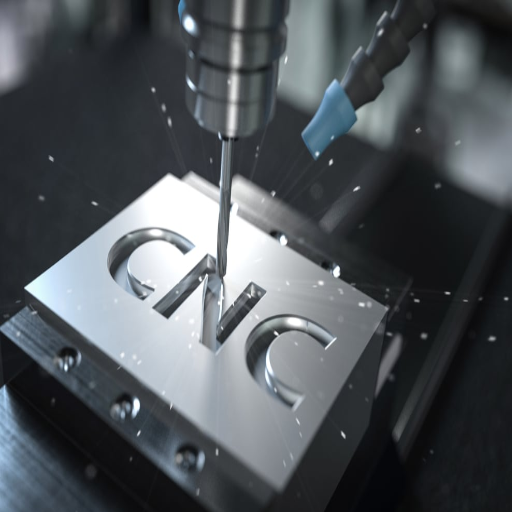

What is a CNC Router for Sign Making?

A CNC router for sign making is a device that uses a computer to cut, engrave, and shape foam, wood, plastic, and even metal into customized signs. It uses digital files that it converts into a program. Then the files are executed one after another to achieve accurate and precise patterns that can be repeated multiple times. This tool is preferred because it can accurately and efficiently perform intricate designs, making it extremely useful for professional and small-scale sign-making tasks.

How does a CNC Router work in the sign-making process?

A CNC router (Computer Numerical Control) cuts materials into parts and designs using a computer that digitally sets the instructions it follows. The process starts by developing a design file in a CAD or CAM software application that outlines the shapes, patterns, and dimensions the sign is meant to have. After creating a design, it gets converted into G-code, which is basically the CNC router’s programming language.

Typically, a CNC router is equipped with a spindle, an array of cutting tools, and a powerful multi-dimensional axis system, often equipped with three and theoretically up to five axes. The material under instruction goes through a securing process and is held in position at the router’s work surface or vacuum bed. After cutting the portions, the router is programmed with the necessary coordinates to execute precise cuts, engravings, or carvings, considering that a user can achieve tolerances of 0.001 inches.

Today’s CNC routers combine modern technologies for optimal performance and dependability. For instance, some machines have automated tool changers, which reduce setup time by automatically changing out tools during different phases of the process. In addition, these machines can be used with almost any material, such as wood, acrylics, PVC, aluminum, and composites, which increases their usefulness in different applications of sign-making.

As per the industry statistics, productivity is estimated to increase by over 70% with CNC routers compared to manual cutting processes, owing to automation and non-stop functioning. They are also famous for cutting down on material waste by a significant margin with their precise calculations, along with optimization algorithms. Whether it is ramping up the production of commercial signage or delicate custom designs, CNC routers are indispensable in contemporary sign-making businesses.

What materials can be used with a CNC Router for sign making?

Sign making involves various materials that CNC routers can work with. Such machines can create works with precision on wood, acrylic, aluminum, and dibond. Here is a short description of these materials:

- Wood:

CNC routers work best when wood is the material. Wood is renowned for its aesthetic appeal and ease of operation. Experts back up claims that CNC routers and wood are a perfect pair, as signs made of wood can be intricately done, and even 3D carvings can be managed.

- Acrylic:

Acrylic is another fine material for artwork. It is mainly used to make modern signs. While working with acrylic, CNC routers cut, engrave, and polish edges, which makes the product very durable. Injuries from UV lights are not an issue at all. Acrylic is perfect for products that are put outside, as the outer conditions don’t matter. It is also claimed that acrylic products usually have a fine reputation because they are professionally crafted and adaptable for different purposes.

- Aluminum and Dibond:

Both materials are lightweight and durable. Because of these reasons, they can handle outdoor conditions. Signs made from aluminum sheets and aluminum composite panels of Dibond are easy to work with. Special bits on CNC routers let craftsmen cut, shape, and polish edges precisely, which is crucial for the result. ** PVC Foam Board**

PVC foam board is a lightweight and flexible material used in both indoor and outdoor sign projects. It can be easily engineered using CNC routers that carve detailed text and designs. Furthermore, PVC foam board remains cost-effective and resistant to weather.

- Plastics

Other plastics, such as polycarbonate and HDPE (high-density polyethylene), can be routed with CNC machines. These materials, along with acrylic, possess a high degree of durability, are weather-resistant, and are easy to machine, making them suitable for demanding sign projects.

- Foam and Urethane Board

High-density urethane (HDU) foam, along with other foam boards, is an ideal material for creating dimensional signs. HDU foam is one of the preferred materials in the sign-making industry because it can be carved into intricate shapes while being extremely smooth and waterproof.

- Glass (with Limitations)

While specific CNC glass routers featuring diamond-tipped tools lack widespread use, some can engrave glass surfaces. Glass is more often engraved on signs for aesthetic purposes.

Thanks to the compatibility of CNC routers, manufacturers can produce quality signs for distinct applications and environments using diverse materials. In addition, adaptive cutting algorithms and more efficient tool paths greatly enhance productivity while reducing material waste, making these options increasingly sustainable.

What are the advantages of using a CNC Router to create signs?

- High Precision and Accuracy

CNC routers perform exceptionally well with measurement-sensitive tasks, as they can cut with tolerances as high as ±0.001 inches. This makes them ideal for professional signage, where accuracy, detail, and uniformity are of the utmost importance.

- Versatility with Materials

CNC Routers can be used for different purposes, as they can carve wood, metal, acrylic, PVC, foam, and composite materials. This enables manufacturers to create signage for every industry and environment, whether outdoor exposure is needed or durable indoor elegance.

- Enhanced Efficiency and Speed

Besides saving valuable time compared to hand-cutting methods, the automated processes offered by CNC routers also enhance productivity. CNC routers further reduce lead time while maintaining quality guarantees and improving productivity, which is vital for large-scale production.

- Cost-Effective Production

CNC Routers improve cost efficiency with precise cutting algorithms that minimize material waste and yield reusable designs. Producing large batches with reduced errors reduces most businesses’ accumulated production costs.

- Creative Flexibility

CNC Routers offer limitless potential by enabling the engraving, etching, and carving of three-dimensional text with significant ease and speed, which ensures the creation of unique and eye-catching signs.

How to Choose the Best CNC Router for Sign Making?

When selecting the CNC router that best fits your sign-making needs, pay attention to these considerations:

- Compatible Materials—CNC routers offer an enormous advantage in cutting and engraving certain materials, such as gold or wood.

- Size of Work Area and Table Size—Get a machine with a workspace large enough to accommodate all your projects, typically sized for your projects.

- Speed and Precision—The faster and more precise the CNC router, the more professional and cleaner the sign will look, so prefer routers known for that.

- Compatible Software- Check the router’s design programs; some are more complicated than others and have differing creative limits.

- Build Quality and Durability—A CNC router with thicker beams is advisable for consistent performance despite intensive work, making it an excellent long-term investment.

- Support, Maintenance, and Spare Parts- Well-known companies recommend routers, as they guarantee service, training, spare parts, and maintenance.

With these considerations, the sign-making will be more efficient, versatile, and resonating with long-lasting value.

What features should you look for in a CNC Router machine?

Features that increase a CNC router machine’s performance, efficiency, and adaptability are critical for selecting the right one. These five key features warrant your attention.

- Cutting Area And Table Size

Ensure that the machine you are looking at has enough cutting area for your projects. A 4×8-foot table is perfect for large-scale industrial work, and compact tables work best for small-scale tasks and hobbyist work. The table size should be considered along with the volume of work and the size of the material.

- Spindle Power

Thick woods and aluminum pose a challenge when cutting and require a powerful spindle. The higher the horsepower, the smoother and faster the cuts will be. So, choose the right spindle power depending on what materials you plan on working with. Spindle power is mainly from 1HP to 20HP.

- Ease Of Software Integration

Purchasing a machine that supports easy-to-operate CAD/CAM software programs like VCarve Pro or Fusion 360 would be a great choice. This support facilitates design and programming, which in turn increases productivity.

- Accuracy And Precision

Professional quality work is fundamental for intricate designs and outputs using tight tolerances, and that is only possible with advanced, precise CNC routers. Look for ones with ball screw drives or linear guides as they provide tight repeatability with high accuracy.

- Dust Collection System

A clean workspace requires a built-in dust collection system. With minimal maintenance requirements, dust extraction improves cleanliness and enhances productivity by preventing debris build-up during operational hours.

Whichever CNC router machine you choose, paying attention to these factors will help you address your requirements while achieving long-term dependability and performance.

How does the budget affect your choice of a CNC Router for signs?

The budget takes precedence as a critical factor for deciding which CNC router to purchase for sign-making. CNC routers come in various price points relative to features, build quality, and technology. For instance, entry-level CNC routers can be purchased for between $2,000 and $5,000. This range is perfect for hobbyists or small-scale operations that want to get into sign-making without spending too much. Of course, these models do not feature advanced functionalities like automated tool changers or super-speed cutting.

For medium-sized businesses or people who want a higher production capacity, mid-tier CNC routers offer a good mix of price and quality with features for $5,000 to $15,000. These models often come with upgraded motors, better construction materials, and a larger working area, enhancing speed and precision for sign-making.

High-end CNC routers are great for large-scale industrial operations and can be expensive, costing anywhere from $15,000 to over $100,000. These models come equipped with advanced features such as 5-axis capabilities, integrated design software, and sophisticated dust collection systems, and are perfect for intricate sign designs while maximizing production efficiency.

The economic value of a cnc router greatly depends on characteristics such as the spindle power, software inclusions, and material compatibility in the case of wood and metal working machines. For example, a router spindle that exceeds 6kW can rout much more rigid material like hardwood and aluminum, which is sometimes required to produce high-end signs. Also, larger work beds, such as 4′ x 8′ for CNC routers, often come at a premium because they can cut larger signboards.

As with other tools, the available budget outlines the kind of CNC router one can purchase, as well as its functionality, life span, and construction quality. In the case of a sign-making business, CNC routers should be viewed as a long-term investment. Hence, continuous costs like maintenance, parts replacement, and software upgrades must also be considered in addition to the initial purchase price.

What are the Best Practices for Using a CNC Router in Sign Making?

- Picking pre-determined high-quality brands that work well together greatly increases the potential of making signs out of wood and aluminum, which many companies strive for. Other materials that can be used for CNC include wood, PS, acrylic, PVC, and aluminum.

- Perform regular inspection and cleaning of the CNC trapezoidal stepper motor four-bearing router so that no dirt gets stuck to the machine and all parts are working in good condition.

- Check the thickness and kind of cutting required to select and utilize the right tool for the task, as this promotes efficiency and accuracy in the engraving process.

- Ensure that the material is used clean. Determine material scrap or excess, which must be minimal to ensure smooth cuts, low tool wear, and extended tool life.

- Run the system parameters and conduct a trial run with the machine, starting from the cuts until final details, so that in the real tasks, the anticipated mistakes or adjustments would take place in line with making adjustments on reserve materials.

These techniques allow the user to benefit from the added efficiency and capabilities of modern CNC design routers while achieving outstanding, high-detail graphics suitable for any level of design work.

How do you set up your CNC router for optimal performance?

It needs to be properly configured to achieve precision, efficiency, and longevity with a CNC machine. This guide provides the steps necessary to achieve optimal performance:

Identify the Appropriate Work Environment: Position the CNC router in a clean, ventilated, dust-free area where the vibrations are minimal. When placed on a level countertop, this will enhance the machine’s accuracy and reduce its vibrations even more.

Run a Check on the Machine: A CNC router undergoes heavy usage, which could sometimes leave it worn down and battered. It is essential to thoroughly check the machine for loose bolts and worn-down parts to avoid incurring additional costs through corrective maintenance; if needed, complete the necessary modifications.

Make Sure Software is Updated and Calibrated: Make sure the router’s software and firmware are updated. The machine must be calibrated properly by setting the axis limits, aligning the cutting tools, and zeroing the machine to the material.

Use Properly Sized Bits: Pick cutting bits that align with the material you plan on carving. High-quality and sharp bits improve precision in cutting and reduce tool wear.

Check Spindle and Feed Rates: Spindle speed alongside feed rates should be modified for the type of material and its thickness, check within the instructions or well-known building sites for CNC routers for values of the producers.

Clamp the Workpiece Accurately: Firmly clamping the workpiece to the work bed prevents any degrees of shifting during the operation phase. Vacuum tables or special fixtures are more effective when profiling parts that have complicated shapes, enhancing the overall stability of the unit.

Lubricate Moving Parts: Always use suitable lubricants on the moving parts like rails and screws. This reduces the friction on the router and allows for longer life while ensuring smooth operation.

Test with Dry Runs: A dry run of the cutting process without the cutting tool engaged can also be used. This validates the toolpath without the risk of potential mistakes.

Completing these setup steps carefully and accurately allows for better results in your CNC projects while minimizing errors and downtime. Configuring the machine properly also optimizes material consumption and extends the operational life of the CNC equipment.

What are the best techniques for carving intricate designs?

Techniques that offer speed and creative potential, such as relief carving, chip carving, sculptural carving, and CNC carving, all have specific intricacy when it comes to carving detailed designs.

| Technique | Pros | Cons |

|---|---|---|

|

Relief |

3D effect, detailed |

Time-intensive |

|

Chip |

Geometric, precise |

Requires a steady hand |

|

Sculptural |

Realistic, creative |

Complex, skill-heavy |

|

CNC |

Automated, precise |

High initial cost |

What Types of Sign-Making Applications are Suitable for CNC Routers?

CNC routers have a lot of versatility and can be used in various branches of sign-making, like:

- Dimensional Signs: Consistency in crafting 3D lettering, symbols, and decorative features is provided.

- Engraved Signs: Award plaques and other custom signs require detailed engraving, which can be provided.

- Cut out letters and shapes: Storefronts and displays require letters and shapes made of certain materials, which can be done.

- Wayfinding and Informational signs: Navigation or instructional signs of high detail and professionalism can be made.

- Custom designs: Branding for certain companies requires intricate or special signs to be made.

CNC routers must focus on precise and replicable features for wood, acrylic, or metal.

How can CNC technology enhance professional sign-making?

CNC technology improves professional signage by allowing quality results throughout various materials due to consistent and precise production processes. With computers, sign makers can achieve sharp details and intricate designs with clean cuts that are much easier than with traditional methods. The optimized cutting paths also minimize material waste, making this technology cost-effective and eco-friendly. Based on Google’s search trends, customized and appealing business signs make exemplary marketing tools that captivate consumers’ attention, and businesses are searching for these increasingly, reinforcing the idea that competition is growing. Dimensional letters, elaborate logos, and layered signs sculpted from one material are effortlessly customized with CNC machines. In addition, the routers expedite production workflows, enhancing critical efficiency and speed in meeting tight deadlines. There is unmatched flexibility from the vast range of materials these sign makers use: wood, acrylic, metal, composite panels, and more, allowing for diverse client needs.

What are the popular sign-making applications using CNC routers?

CNC routers are unrivaled in modern sign making because of their accuracy and flexibility. As per the most recent trending searches and data, some of the emerging applications include:

- Three-Dimensional Lettering and Logos

For storefronts and corporate signs, CNC routers can produce intricate three-dimensional letters and logos with fine detail. Such constructions add a professional effect and dimension that is very visually appealing.

- Custom Engraving

Plaques, awards, and bespoke wall art can be produced because CNC routers engrave designs, texts, or patterns on a multitude of materials flawlessly.

- Illuminated Signs

Other than that, CNC routers make the manufacture of backlit or illuminated signs easy. They can shape and cut the materials required for LED displays and lightbox panels, which augments vibrancy.

- ADA-COMPLIANT SIGNAGE

Automated cutting and engraving braille text into signs makes CNC routers a lot more accessible and easy to use when producing ADA-compliant signage.

- Wayfinding and Directional Signs

CNC routers can produce more sophisticated wayfinding signs with greater efficiency and precision than simple directional signs, greatly aiding business productivity and improving appearance.

- Event Decorative Signage

Personalized decorative signage and elaborate graphics for patterns are made using CNC routers for weddings, corporate events, and festivals to add decor for the specific occasion.

Due to their capability of working with various materials and complex designs, CNC routers have made their mark in sign making, whether for small-scale or big commercial projects.

How does CNC sign making differ from traditional methods?

Traditional sign-making methods differ from CNC sign-making methods in the following: marking out, engraving, cutting speed, and throughput; dimensional, reproducibility, and duplication; the range of materials that can be used; the level of automation; and the economics of producing the signs.

| Parameter | CNC Sign Making | Traditional Methods |

|---|---|---|

|

Precision |

High |

Moderate |

|

Speed |

Fast |

Slow |

|

Consistency |

Uniform |

Variable |

|

Materials |

Versatile |

Limited |

|

Automation |

Yes |

No |

|

Cost |

Efficient long-term |

High labor costs |

Reference Sources

-

Let’s dive into CNC routers and their applications, including making sign boards and wood panels.

-

A study from MIT on CNC router modernization and its applications.

-

Prototyping and sign-making are disciplines that examine CNC routers.

-

Prototyping Guide for Engineering Students –

An informative book for students of engineering containing CNC router applications.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a sign-making CNC router?

A: A sign-making CNC router is a specialized CNC machine designed to create signs. It can carve, engrave, and cut various materials such as wood, plastic, and non-ferrous metals, making it ideal for sign makers producing high-quality signage.

Q: How does a CNC machine work for sign making?

A: CNC machines for sign making operate using Computer Numerical Control technology, allowing precise movements and operations. The machine follows a pre-programmed design to create intricate 2D and 3D shapes, ensuring consistent results across multiple signs.

Q: What types of materials can a sign-making machine work with?

A: A sign-making machine can work with various materials, including wood, MDF, plastic, and some non-ferrous metals. This versatility allows sign makers to create multiple types of signage, from simple wooden signs to complex 3D designs.

Q: What are the benefits of using a CNC sign-making machine?

A: The benefits of using a CNC sign-making machine include increased precision, efficiency, and the ability to create intricate designs that would be difficult or impossible to achieve by hand. Additionally, CNC routers deliver consistent quality across multiple projects, making them ideal for sign-making businesses.

Q: Can a wood CNC router be used for sign making?

A: A wood CNC router is commonly used for sign making. It excels at carving and shaping wood, allowing sign makers to create detailed designs in various types of wood, including MDF and hardwoods.

Q: What is the recommended CNC for a sign-making business?

A: The recommended CNC for a sign-making business typically includes features such as a powerful spindle, a rotary axis for 3D work, and compatibility with tangential knife systems for cutting various materials. When selecting a CNC machine, it’s essential to consider your business’s specific needs.

Q: What is a rotary axis, and why is it important for a sign maker?

A: A rotary axis is an additional feature on some CNC routers that allows the machine to rotate material while cutting or engraving. This is particularly important for sign makers who want to create cylindrical or rounded signage, enabling them to work on multiple sides of a piece without manual repositioning.

Q: How do laser machines compare to CNC routers for sign making?

A: Laser machines are often used for sign making because they can cut and engrave with high precision. However, they may be limited in the types of materials they can handle compared to CNC routers, which can work with a broader range of materials, including thicker substrates and those that require milling.

Q: What is a vision recognition system in a CNC sign-making machine?

A: A vision recognition system allows a CNC sign-making machine to accurately identify and register the materials’ position. This technology enhances precision and ensures that designs align correctly, especially when working with multiple tool setups or complex designs.