For all DIY enthusiasts, makers, and hobbyists, CNC routers widen the creative possibilities with precision like never before. A CNC router can transform your home workshop into a world of options, whether performing detailed woodworking, engraving logos on metal, or dealing with plastic and acrylic. However, with endless options available in the market, selecting the ideal one for your needs can be pretty overwhelming. Consider yourself lucky, as this guide intends to help you with the best CNC routers for home use, highlight key features to consider, and provide recommendations that aid in making informed decisions.

What is a CNC Router Machine and How Does it Work?

To understand the specifics, CNC router machines are computer-controlled devices, which means they rely on computers for accurate instructions and, therefore, eliminate human error. For every command issued, it provides two simplest resources; It operates by cutting, carving, or shaping wood, plastic, and steel, automating the movement of a powerful cutting tool that slices and ascends in multiple directions. Each CNC router machine begins with a digital blueprint created on CAD software, where the design is submitted, and is then translated into commands for the CNC Router Machine. The digital outline is then followed step by step.

CNC routers are excellent tools for both professionals and hobbyists due to their precise measurements, maximum productivity, and adept handling of intricate tasks.

Key Components of a CNC Router

A CNC router’s parts are the frame, table, spindle, ways, axis drive, controller, and software.

| Key Point | Description |

|---|---|

|

Frame |

Provides stability |

|

Table |

Holds workpiece |

|

Spindle |

Cutting tool motor |

|

Ways |

Enables movement |

|

Axis Drive |

Converts motion |

|

Controller |

Executes G-code |

|

Software |

Designs & instructions |

How CNC Routing Works in Woodworking

CNC woodworking is the combination of craftsmanship and technology that seamlessly achieves complex wood designs. The initial step involves designing the wood structure on CAD and turning it into G-code, which is a CNC interpreter. The CNC machine executes the command programmed into it, using the right router and wood piece set, and the appropriate bit is installed. The machine will automatically follow the instructions and carve, cut, or engrave the wood.

Modern CNC machines are equipped with highly sophisticated automatic tool changers and vacuum tables, which increase material holding stability, alongside dust collecting units, which ensure work during clean CNC programming. CNC machines’ precision significantly outmatches manual work as they offer detailed, complex joinery, multifarious cuts, and repetitive cuts with minimal material wastage. In addition, CNC routing has transformed and modernized many industries, enabling craftsmen and manufacturers to produce the formerly manual-dominated tasks efficiently.

What to Look for in the Best CNC Router for Beginners?

The following is a list of considerations that must be kept in mind when selecting the CNC routers for beginners:

- User-friendly: Choose a device with clear guidelines regarding its assembly and usage. A step-by-step manual or video guide makes this dual-layered.

- Safety Features: Protective components, such as emergency power cut-off, ensure peace of mind when using the machine.

- Pricing: Courses and maintenance often come at a hidden cost. Pick a router that is user-friendly for both initial investment and machine upkeep.

- Maintenance and Repair: Refurbishing or replacing machine parts should be simple, as the user should not have to perform frequent, complication-riddled, typically complex steps.

- Cutting Area: Tailor the device’s total dimensions squared to fit your workspace without excessive, unneeded space.

- Protective Features: Functionality such as shields over the cutting space, along with basic stops, should be present.

- Software: Unencumbered or expensive CAD programs and artifacts tailored for beginners are preferred.

If all of these are ticked off, rest assured that you have come close to a model that meets all the demands placed on it while remaining respectable in the eyes of an artist with little experience.

Essential Features for Beginner CNC Routers

- User-Friendly Interface

An entry-level CNC router should provide a manageable and straightforward interface. Many basic models have touchscreens or simple buttons and dials so that users can easily operate the device. Also, it is a plus when the software integrates with Easel or Carbide Create, as it is simple to use.

- Compact Design

Due to limited workspace, beginners need compact and lightweight devices. Small devices can fit on a standard workbench. Hobbyists can also store or move such devices, making them easily portable.

- Durable Build Material

Even beginners should use CNC routers with sturdy frames made of aluminum or steel. Such materials ensure adequate support and dampen vibrations during use, enhancing safety and cut accuracy.

- Variable Spindle Speed

Some of the best-value CNC routers allow users to set the spindle speed for soft materials and wood. This feature helps work with various types of wood, plastic, and softer metals while minimizing wear and tear on the machine or damage to the material.

- The Help From Simplistic Kits Or Fully Assembled Ones

Users with little to no experience will appreciate simple or fully assembled routers due to the detailed instruction guides that come with them. Thoroughly set-up models guarantee that the user can start working on their craft in a timely manner without any hassle.

Common Mistakes Beginners Make with CNC Machines

- Rectification of the Selected Material

A typical scenario for many newbies is using incorrect material, leading to an inefficient outcome or tool wear. A good example is soft aluminum alloy, which might be more suitable for novices than stainless steel because the latter involves advanced techniques and tooling.

- Incorrect Tooling Arrangement

The improper securing of the cutting tools or the use of unfit cutting tools is equally damaging to the workpiece and the CNC machine. Novices do not pay much attention to tool selection because of the material, speed of cut, and plunge depth, which results in improper machining.

- Ignoring Machine Maintenance

Regular machine maintenance, such as cleaning, removing excess debris, lubricating machinery components, and overall calibration, is not typical for beginners. Ignoring basic and periodic maintenance can lead to malfunctions or excessive wear, which hinders the machine’s functionality, longevity, and precision.

- Failure to Grasp Operating CNC Software

Beginners have an expectation that sandblasting or other software will overwrite some of the tasks for them, which is not true. Skipping test runs and neglecting preproduction checks with the software can lead to significant production costs.

- Disregarding Safety Protocols

Amateur operators sometimes fail to pay attention to the most basic safety protocols, such as wearing the correct protective equipment or switching off the machine before making adjustments. Such negligence can result in accidents and injuries while operating the CNC machine.

Choosing Between a Desktop CNC and a Larger Machine

Space, budget, project complexity, and compatibility with materials influence the decision to get a desktop CNC or a bigger machine.

| Key Point | Desktop CNC | Larger Machine |

|---|---|---|

|

Size |

Compact, space-saving |

Large, needs space |

|

Cost |

Affordable |

Expensive |

|

Precision |

High for small tasks |

High for large tasks |

|

Materials |

Soft metals, wood |

Hard metals, industrial |

|

Ease of Use |

Beginner-friendly |

Requires expertise |

|

Applications |

DIY, small projects |

Industrial, large-scale |

What Are the Benefits of Using a CNC Router for Wood Carving?

Employing CNC routers for wood carving presents several notable advantages, including:

- Accuracy and Consistency

CNC routers ensure accurate and consistent carvings on wood, ensuring high precision that is almost impossible to achieve with manual tools. Each design can be replicated to exact measurements repeatedly.

- Speed

These machines expedite the step of carving intricate designs into wood compared to manual methods, offsetting the time spent completing several steps.

- Ease of Executing Complicated Patterns

CNC routers are able to execute complex and intricate patterns seamlessly, which provides creative flexibility with little increase in labor, which means little increase in the effort required.

- Less Waste

The accuracy of the CNC routers Jeeps makes them cost-effective and environmentally sustainable over time, with little reduction in material.

- Software Synergy

Users can readily customize and edit their designs with access to simple design software that allows them to create and import designs digitally.

These reasons contribute to the growing popularity of CNC routers among professionals and amateurs alike, especially when carrying out wood carving projects.

Precision and Accuracy in Woodworking Projects

The CNC router is one of the most recent technological innovations in woodworking, precision, and accuracy cutting techniques. It integrates automated systems with skilled computers that work rapidly to accomplish detailed designs with intricate precision. CNC routers far exceed manual methods in terms of accuracy and reproducibility. Google’s recent statistics show that many people are searching about the captured Cu engraved on the routers and why they are so accurate and repeatable. This is because the router’s function is based on digital design files, which provide step-by-step instructions, and software paired with highly accurate cutting hardware that work at micrometer levels, guiding them to execute cuts, engravings, and carvings in intricate projects. These machines streamline complex work by guaranteeing uniformity in details and repeating steps. Besides improving the end product quality, CNC routers also automate time-consuming processes, drive down material costs, and eliminate human supervision, thus making it essential in woodworking.

Versatility: From Wood to Acrylic and MDF

CNC routers stand out for their wide-ranging capabilities, as they can work with various materials. No matter the material, intricate designs on wood, as well as precise cuts into acrylic and MDF, are done flawlessly by these machines. Their versatility is specially crafted for different material surfaces, which enhances it further by aiding with other specialized bits to help achieve clean edges and professional polish. The newer data from Google’s engine indicates that the demand for CNC routers is increasing in furniture making, signage, and prototyping industries. This clearly shows CNC routers’ critical role in novel furniture production technologies. From small creative endeavors to massive industrial tasks, this versatility is why it is a preferred CNC router in woodworking and advanced crafts.

Time-Saving Advantages of CNC Wood Carving

CNC woodworking machines save substantial amounts of time by automating processes that, when conducted by hand, could take hours or even days. Businesses in furniture production and custom woodworking strive to improve their productivity. This is evident from the information on Google’s search engine, as over the past years. With the Automated Precision and Control provided by CNC routers, production speed has improved tremendously. Stopping the need for redundant adjustments where results are done repeatedly allows automated systems to achieve consistency. With equipment operated using CNC technology, businesses have an easier time meeting deadlines and managing high demands, as complex tasks like intricate engravings or detailed patterns, which required a substantial amount of time, are now done within minutes. Quality control and innovation are two areas where unnecessary automatic work can be removed. Focusing efforts in these two areas tremendously assists businesses in enhancing productivity and craftsmanship alongside reworking their brand value.

What Are the Best CNC Router Kits Available on the Market?

While searching for the top CNC router kits, reputation, operational efficiency, and functionality rank high. Consider the following recommendations:

- X-Carve by Inventables

This kit is great for both experts and novices. It has robust customer support, tailored software, and a remarkable working area.

- Shapeoko 4 by Carbide 3D

The Shapeoko 4 is excellent for anyone searching for efficiency and accuracy. This machine is known for its modular design and ease of construction, which allows for many different types of use.

- BobsCNC Evolution Series

This kit is targeted at hobbyists, which makes it affordable. The materials used in construction are premium, and they come with great guidance for their clients.

- Genmitsu CNC 3018-PRO

While budget-friendly, the Genmitsu contains all the basic features necessary for beginners, alongside additional tools such as offline control.

- LongMill by Sienci Labs

The LongMill is an excellent option for those looking for sturdy construction at a reasonable price. It is balanced in versatility and pricing.

These kits have advantages and disadvantages, and depending on the user’s requirements and expertise, one can be chosen.

Comparing Popular CNC Router Brands

FoxAlien, MYSWEETY, Genmitsu, SainSmart, and BobsCNC are industry leaders in CNC routers. Each offers unique advantages, such as user-friendliness, rapid cutting, and versatile material usage.

| Brand | Feature | Strength |

|---|---|---|

|

FoxAlien |

Best Overall |

High power, LCD screen |

|

MYSWEETY |

Most Protection |

Versatile, beginner-friendly |

|

Genmitsu |

Cutting Speed |

High RPM, no assembly |

|

SainSmart |

Easiest to Use |

Quiet, stable, protective |

|

BobsCNC |

Easy Connection |

Sturdy, USB-friendly |

Features to Consider in a CNC Router Kit

Several features require special attention when purchasing a CNC router kit. In this section, we highlight five of the most important features to look for.

- Build Quality and Durability

The build materials of the router kit directly determine its lifetime and performance. Try to go for kits with frames made of solid materials like aluminum or steel. A strong and rigid frame offers stability and accuracy while cutting and reduces vibrations during operations.

- Cutting Area Size

The size of the cutting area best defines the maximum dimensions of the materials you can work with. Whether your projects involve small workpieces or larger designs, ensure the router you choose can accommodate the scaling you need.

- Spindle Power and Speed

A kit’s cutting ability is directly linked to the spindle’s power and speed. Tougher materials like hardwood or aluminum require high spindle power, while adjustable speed settings are needed for detailed work to add versatility.

- Software Compatibility

Check that the CNC router kit works with well-known software like GRBL, Easel, or Mach3. Simplified software integration further enhances ease of operation, accommodating virtually everyone, from novices to seasoned professionals.

- Ease of Assembly and Use

A CNC router kit should provide ergonomic instructions that enable novices to progress through the assembly step by step. Efficient use starts with an ergonomic design. Users who have never assembled such devices will appreciate pre-assembled components and user-friendly guides.

Achieving these parameters lets you make the right choice and buy a CNC router kit suitable for your skills and project needs..

Reference Sources

1. Digital Fabrication in Architecture

- Key Findings: This paper analyzes the impact of digital fabrication on architecture, focusing on CNC routing, 3D printing, and laser cutting. It notes the ability to manufacture sophisticated and precise geometries and reduced material waste efficiency. The case studies illustrate how CNC routers were applied for registering complex building parts and for sustainable design.

- Methodology: This research comprises a literature analysis, a series of case studies, and an evaluation of architecture’s application of digital fabrication techniques.

2. Proposal of a Process of Mass Customization of Kitchen Cabinetry

- Key Findings: This study is based on applying Building Information Modeling (BIM) with CNC routers for mass customization in SMEs. It shows that CNC machines can be utilized efficiently for custom cabinetry production, lowering expenses and increasing accuracy.

- Methodology: The study uses action research, which includes repetitive cycles of design, development, and assessment. It combines BIM models with CNC instructions to optimize production workflow.

3. Experimentation of Joints in Subtractive Digital Manufacturing

- Key Findings:This document looks into implementing the production of structural joints using CNC routers within social housing projects. The work considers joint designs in terms of cost efficiency and mechanical integrity within the scope of the Wikihouse system.

- Methodology: The study incorporates some degree of testing with the CNC machined joints by measuring the results against the benchmarks for machining time, material scrap, and ease of assembly.

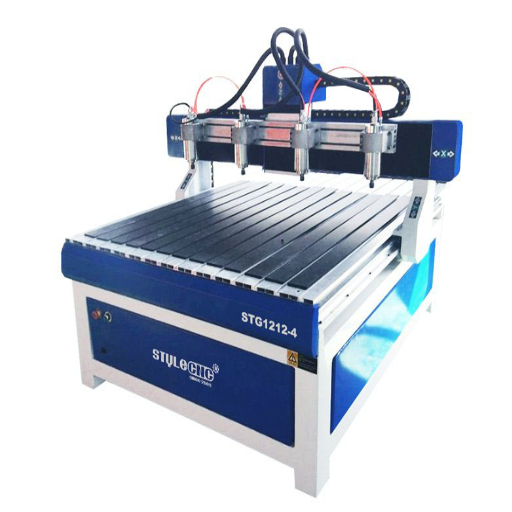

4. Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a CNC router, and how does it work?

A: A CNC router is a computer-controlled cutting machine that utilizes a spindle and router bit to mill various materials such as wood, acrylic, MDF, and nylon. It operates on a 3-axis system, allowing precise movements to create intricate designs and shapes.

Q: What are the benefits of using a hobby CNC router for home use?

A hobby CNC router offers several benefits, including the ability to create custom projects, high precision in fabricating parts, and versatility in working with materials like wood and metal. It allows DIY CNC projects and can be a great addition to any workshop.

Q: How do I choose the best CNC router for my needs?

A: When selecting the best machine, consider the work area size (e.g., 4×4 or 4×8), spindle power, and the materials you plan to work with. Look for a machine that fits your projects, whether a compact or a high-end pro CNC router.

Q: What is the learning curve of using a CNC milling machine?

A: The learning curve can vary depending on your experience with similar tools. Beginners may need time to understand CNC programming, the use of the controller, and how to operate the machine tool effectively. Online resources and tutorials can aid in this process.

Q: Can I use a CNC router for engraving?

A: Yes, a CNC router is an excellent choice for engraving. With the right router bit and settings, you can engrave intricate designs on various materials, including wood and acrylic. An engraving machine can also enhance your capabilities for detailed work.

Q: What materials can I work with using a DIY CNC router?

A: A DIY CNC router can work with various materials, including wood, acrylic, MDF, and nylon. Depending on the router’s specifications, you can also venture into metal carving, making it a versatile machine for various fabrication projects.

Q: How important are limit switches in a CNC router setup?

A: Limit switches are crucial for ensuring the safety and accuracy of a CNC router. They help prevent the machine from moving beyond its designated work area and protect the equipment from damage during operation.

Q: What are the advantages of using a 3018 Pro Max CNC router?

A: The 3018 Pro Max CNC router is popular for its compact size and affordability, making it ideal for hobbyists. It offers high precision, easy setup, and compatibility with various materials, making it perfect for DIY projects and small-scale fabrication.

Q: What role does a stepper motor play in a CNC router?

A: The stepper motor is a key component of a CNC router, enabling precise movement along the axes. It converts electrical pulses from the controller into mechanical movement, allowing for accurate positioning and control during the milling or engraving.