Constructing a guitar is more than simply crafting a musical instrument: it synthesizes skill, art, and passion. The advent of CNC routers has completely transformed the guitar-making world for modern luthiers and guitar fans because of their unprecedented speed and efficiency. However, with many tools and techniques available, the world of CNC in guitar building can be somewhat perplexing. This is where this guide comes into play.

This guide serves all types of builders—from experienced luthiers who wish to integrate modern technology into their work to hobbyists designing their first custom guitar. We start by picking the most suitable CNC router and go through all the fundamental techniques step by step, ensuring all your needs are met. Prepare yourself to harness the true power of CNC technology and change guitar-making techniques for good!

What is a CNC Router and How Does it Work for Guitar Making?

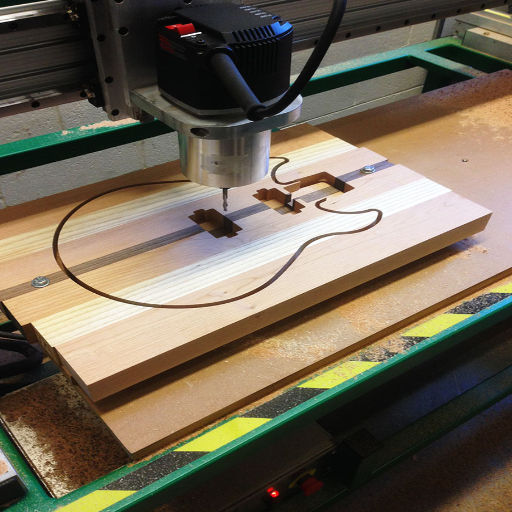

A CNC (Computer Numerical Control) router is a machine that cuts, carves, and shapes various materials like wood, metal, or plastic. When constructing guitars, a CNC router automates complex steps like cutting body shapes, carving neck profiles, and executing inlays from digital design files. The machine must be given a computer program that commands the movement of the cutting instrument. The paths it takes are definite, so the work is done consistently and accurately. This results in the ability to detail and repeat designs more than was possible with time-consuming hand work, something enduring craftsmen needed to rely on in the past.

How CNC Machines Automate Guitar Production

CNC equipment transforms the process of making guitars by making complex procedures far more precise and efficient. Tools like fret slotting, cavity carving, and body contour shaping have become remarkably consistent. Recent industry data shows CNC routers can shave 50% off the manufacturing time compared to traditional handcrafting, all while reducing error rates.

Current CNC technology has incorporated CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, which gives luthiers the capability to virtually design 3-dimensional models of guitars. These cutting paths can be programmed into the machine, ensuring every shape is executed. For example, CNC machines uphold tolerances of 0.001 inches, making it possible for parts to fit together with impeccable precision. This degree of accuracy is indispensable when dealing with intricate inlays or custom fretwork patterns.

CNC machines also enable the mass production of expertly crafted guitars without compromising on quality. Digital files can be reused to make identical parts, which makes it easier to scale up production. More advanced models, such as 5-axis CNC machines, even make it possible to carve complex profiles for guitar necks and headstock angles, eliminating a lot of tedious work.

With the use of automation and digital technology, CNC machines have emerged as valuable time-saving tools, notably in the guitar-making industry. They have also reduced time wastage and enhanced accuracy, allowing guitar makers to meet the sophisticated demands of contemporary musicians while innovatively designing new models.

The Components of a CNC Router for Making Guitars

The elements of a CNC router used for constructing guitars include the spindle, router bits, control software, the vacuum table, and the frame.

| Component | Details |

|---|---|

|

Spindle |

High-speed motor |

|

Bits |

Cutting tools |

|

Software |

CAD/CAM control |

|

Table |

Vacuum hold-down |

|

Frame |

Rigid structure |

Why Use a CNC Router for Building Guitars?

Because of their precision, accuracy, and consistency, CNC routers have become highly popular in the construction of guitars. The routers guarantee flawless contouring of parts such as the body and neck, which ensures smooth joints and an immaculate surface. CNC routers eliminate the need to perform manual repetitive processes, thereby increasing the production speed and quality of products manufactured. The routers also assist craftsmen with more creative designs that are impossible with hand tools, enabling guitar makers to surpass imaginative limits without sacrificing precision.

Benefits of CNC Technology in Guitar Making

- Precision and Reliability

Most CNC routers have proven their exceptional capabilities in making guitar parts and components. Their level of precision ensures that every part, like the neck or body, matches perfectly. Production consistency means no differences within identical models; this attribute is vital for the accuracy value of quality control.

- Saving Time

CNC Technology has proven very efficient in saving time in production because of the automation robots provide for repetitive functions. Tasks that include intricate designing, shaping, and cutting, which would ordinarily take hours, can be done in mere minutes with a CNC router.

- Ability To Construct Complicated Designs

With the help of computers, soft CNC machines can accomplish intricate and imaginative tasks with designs that would be too tedious or impossible to achieve with manually operated hand tools. Guitar makers can employ new shapes and patterns, which helps broaden the scope of creativity.

- Reduction of waste and Cost Efficiency

CNC routers reduce expense by increasing profit margins through low material costs. This is due to the reduced use of materials because of the increased production of identical parts. The corporation becomes more cost-efficient and eco-friendly.

- Flexibility and Growth Potential

CNC technology readily allows custom designs tailored to specific client needs with little extra work. It also provides flexibility with scale, from creating a single custom guitar to hundreds of identical units quickly and effortlessly.

Precision and Accuracy in CNC Guitar Production

CNC (Computer Numerical Control) technology is famous for its unmatched accuracy and precision, which are critical details in making quality guitars. CNC routers have tolerances as tight as 0.001 of an inch, guaranteeing that every part is manufactured to exact requirements. This makes fitting possible to maximize sound quality. This level of precision greatly reduces the possibility of gaps or misalignments, which are detrimental to the instrument’s tone or playability.

In addition, CNC machines utilize cutting-edge software together with precise cutting tools to reproduce intricate designs and details repeatedly without deviation. Placement and spacing of frets, which is vital to crossstring intonation, can be machined with precision. As recently reported, CNC production of guitars lessens manual mistakes in the process by 95%. The CNC method greatly enhances precision and consistency in production while also reducing costs from materials wasted due to errors.

This precision can be demonstrated in the example of neck carving of a guitar. Uniformity and symmetry across multiple units are achieved through CNC machines, which provide uniform repeatability. Modern ergonomic shapes demanded by players are produced seamlessly. With real-time QC systems, CNC production has earned a reputation for consistently high quality, fueling the increasing preference for CNC guitars among professionals and enthusiasts.

Choosing the Best CNC Router for Guitar Building

When searching for the best CNC router for building guitars, keep these main points in mind:

- Precision and Accuracy

Seek out the highest level of precision for intricate designs and consistent results. Precision matters when creating parts like the guitar neck or the fretboard.

- Work Area Size

Check that the router’s work area can fit the guitar body and neck templates.

- Material Compatibility

Ensure the machine can work with standard materials seasoned guitar builders use, such as composites and hardwoods.

- Durability and Build Quality

Selecting a router with strong build quality and the ability to handle frequent use can achieve long-term reliability.

- Ease of Use

Good CNC software and controls are essential, especially for beginners, making ease of use a crucial factor.

- Budget

Ensure all considerations are met within a reasonable budget, ensuring essential features are included while extras are omitted.

- Conclusion

Focusing on the factors outlined above will help you greatly improve the efficiency of your guitar-building process.

Top Features to Look for in a CNC Machine

Parts like the spindle, work area, and machine body contribute to the efficiency of a CNC machine when making guitars and other wooden items. In this section, we will discuss these features in more detail.

- Strong Spindle

The spindle piece single-handedly affects how accurately the CNC machine cuts. During my research, I came across a spindle with a 24000 mm per minute rate, which would allow a CNC machine to cut wood, plastic, metals, etc., seamlessly.

- Deep Working Area

When dealing with bulk orders, a larger workspace plays a vital role, which is why a CNC work area should be a minimum of 24” x 48” when building guitars.

- Strong Frame

The frame of the CNC machine acts as the backbone allowing it to be stable when making cuts, This reduces any machine vibrations leading towards more intricate cuts.

- Advanced Software Compatibility

It is essential that CAD and CAM software are flexible and easy to work with. Make certain that CNC machines can work with industry-grade software, such as Fusion 360 and VCarve Pro, as these will streamline the design and machining workflows and provide numerous options for customization.

- Accurate Linear Motion System

The presence of a reliable linear motion system utilizing ball screws or linear rails makes accurate positioning and smooth motion possible. This ensures that your guitar designs’ intricate details are reproduced accurately every time without getting off track in measurements or cuts.

This approach will allow you to select a CNC machine that delivers precision while optimally increasing productivity and meeting the requirements of guitar building or other detailed handwork.

Comparison of Affordable CNC Routers for Guitar Makers

The cheapest CNC routers well-suited for guitar makers are Maslow CNC, MakerMade M2, BobsCNC Quantum Max, Shapeoko Pro XXL, and X-Carve Pro 4×4123.

|

CNC Model |

Price ($) |

Cutting Area |

Speed (in/min) |

Frame Material |

Router Included |

Precision (in) |

|---|---|---|---|---|---|---|

|

Maslow CNC |

549 |

4×8 ft |

40 |

Wood |

No |

~0.004 |

|

MakerMade M2 |

1198 |

4×8 ft |

40 |

Metal |

No |

~0.004 |

|

BobsCNC Quantum |

1280 |

50.5x24x22 in |

200 |

Wood |

Yes |

0.002-0.004 |

|

Shapeoko Pro XXL |

1970 |

33x33x4 in |

100 |

Metal |

No |

~0.002 |

|

X-Carve Pro 4×4 |

10475 |

4×4 ft |

150 |

Metal |

Yes |

0.001 |

How to Set Up a CNC Router for Guitar Production?

- Prepare the Workspace

Ensure the area is leveled while keeping the assembly space uncluttered and free from tools. Everything should be organized. The CNC router must rest alongside an adequate power supply and a Computer.

- Install the Software

Confirm the installation of the required CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software for your CNC router. Adjust the settings as necessary for your specific router.

- Secure the Materials

Clamp the guitar blank or wood piece securely using a vacuum table to the router’s bed to prevent movement during the operation. Utilizing a foam layer when mounting the piece aids in stabilizing the blank.

- Calibrate the Machine

Ensure basic machine calibration for the cutting tool with a reset position on the material (usually one corner of the material). Confirm accurate alignment of the toolpath with corrective measures and precision checks.

- Load the Design File

Import the Right file, pre-cut the design file for the guitar into the software, and preset the confirm dimensions along with the tool and the order of cuts.

- Test the System

Conduct a dry test of cutting the path, checking for tool path failure. Measurement failure considerations should be changed before actual measurement commences cutting.

- Now Start The Cuts

Switch on the machine and monitor its functioning. Be prepared to stop the machine if changes need to be made.

Implementing the above-mentioned steps will allow you to set your CNC router to efficiently produce quality guitars without making mistakes.

Step-by-Step CNC Setup for Guitar Making

- Selection and Preparation of Materials

The initial step involves selecting high-grade tonewoods that resonate well with your guitar’s style and sound preferences. Popular options include mahogany, maple, spruce, and rosewood. Ensure that the wood you choose is well-seasoned and has no warped areas or defects. Recent trends indicate that many luthiers have started using alternative udulation tonewoods like ovangkol and walnut because of their sustainability and distinct tonal characteristics. For acoustic guitar sides and backs, seasoned wood planks should have a uniform thickness of around 0.75 inches. A planer or drum sander can be used to achieve this.

- CAD Design and CAM Configuration

Begin developing the guitar’s body, neckline, and components using CAD software like Fusion 360, AutoCAD, or Rhino. Ensure that each component comes with a fitting bound by the industry standards to guarantee playability, like the standard scale lengths of 25.5 inches for most electric guitars. Such dimensions should be adequate for the overall ergonomics of the instrument. After finishing the design, import it into the toolpath generating software called CAM. It is best to start with something simple, like Vectric Aspire or Autodesk Fusion 360, since more advanced CAM packages tend to lack simulation tools that show you how the router will cut.

- Tool Configuration and Selection

When choosing the cutting tools, consider the material and design. End mills, ball nose bits, and V bits are popularly used for wood cutting and detail engraving. For example, a 1/8 upcut bit is great for intricate contour cuts, and a 1/4 downcut spiral bit cuts softer woods with less tear-out. Check manufacturer guidelines for recommended feed rates and spindle speeds; usually, hardwoods require 80 to 120 IPM with 16,000 to 18,000 RPM spindles.

- Machining Setup and Tooling

CNC routers need to be zeroed to the material surface and edges to cut the parts accurately. Use a touch plate or a probe to perform precision zeroing. The wood block also needs to be firmly secured so that it does not move during the machining process. Recently, a spoil board substructure has been designed, which allows for exact gripping and repeatable placements during subsequent cuts, reducing error.

- Test-Verify and Pass

Before engaging in the cutting routine, ensure that you perform a “dry run” or an air pass to check if your toolpaths match the intended design. Recent feedback from CNC machine users highlights simulation features in contemporary CAM software that can detect clashes or path overlaps. Avoid making adjustments that might create material wastage.

- Initiate the Cutting Process and Start Monitoring

Observe the spindle and material as you commence the actual cutting operation. Remember to employ a dust-collecting apparatus to avoid complications resulting from wood debris. Studies indicate that CNC output quality improves when temperatures and vibrations are constant. The machine may be paused if mid-process changes to feed speed or bit depth are required.

Combining these actions with the most recent digital or automated technologies offers guitar makers unparalleled precision, waste minimization, and the ability to manufacture professional-grade instruments.

Essential Software for CNC Guitar Projects

Critical programs for executing CNC guitar designs are Fusion 360, Rhino 3D, VCarve Pro, Aspire, and MeshCAM.

| Software | Type | Price ($) | Pros | Cons |

|---|---|---|---|---|

| Fusion 360 | CAD/CAM | Free-$495 | Versatile, integrated | Steep learning |

| Rhino 3D | CAD | ~995 | NURBS modeling | Complex interface |

| VCarve Pro | CAM | ~699 | User-friendly | Limited 3D design |

| Aspire | CAD/CAM | ~1995 | Advanced 3D tools | High cost |

| MeshCAM | CAM | ~250 | Intuitive, 3D focus | Limited CAD tools |

Reference Sources

-

Examines the application of CNC routers in creating various parts of guitars, such as bodies, necks, and fretboards.

-

Man–machine–music: Resonances of craft and technology in a study of guitar building –

This paper looks into how CNC routers are used in the artistry of the guitar, including the usage of big companies such as Taylor Guitars.

-

This is a project on the concept of integrating high-quality features into a cost-effective design of a CNC router, with the aim of building the first prototype.

-

Explores CAD/CAM technologies in relation to the wrists electric guitar.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What are CNC routers for guitar making?

A: CNC routers for guitar making are specialized computer-controlled machines designed to automate the woodworking process of building guitars. They allow luthiers to create precise cuts and intricate designs for various guitar parts, including bodies, necks, and headstocks.

Q: How can I use a CNC machine to make guitars?

A: You can use a CNC machine to make guitars and automate the routing and machining of guitar bodies and necks. You can design your guitar components using 2D and 3D modeling software and then program the CNC to execute those designs accurately.

Q: What is the advantage of using CNC routers in guitar manufacturing?

A: The advantage of using CNC routers in guitar manufacturing includes producing clean finishes, achieving high precision, and efficiently creating unique pieces. CNC’s automation allows luthiers to focus on creativity while ensuring consistent build quality.

Q: Can I build a guitar with a CNC if I am a beginner?

A: You can build a guitar with a CNC even as a beginner. However, starting with simpler designs and familiarizing yourself with the CNC machine, its controller, and the programming needed for routing before attempting more complex guitar-making projects is recommended.

Q: What types of guitars can I create using CNC routers?

A: Using CNC routers, you can create various guitars, including acoustic guitars, electric guitars like Fender and PRS models, and even custom one-off designs. The versatility of CNC technology allows for a wide range of guitar shapes and styles.

Q: What materials are best for machining guitar bodies on CNC routers?

A: Common materials for machining guitar bodies on CNC routers include solid woods like mahogany, maple, and alder. Each wood type offers different tonal qualities and aesthetics, making them suitable for different guitar styles and preferences.

Q: How do I ensure my CNC router produces clean finishes on guitar parts?

A: To ensure your CNC router produces clean finishes on guitar parts, use the right cutting tools, calibrate your machine properly, and choose appropriate feed rates. Additionally, sanding and finishing after machining can enhance the overall look of your guitar.

Q: What is the role of jigs in CNC guitar making?

A: Jigs play a crucial role in CNC guitar making. They help secure the wood in place and guide the CNC router during the machining process. Using jigs ensures that every part is consistently cut to the desired specifications, leading to better alignment and fit during assembly.

Q: Can CNC routers help in creating guitar necks and headstocks?

A: CNC routers are excellent for creating guitar necks and headstocks. They allow for precise routing of the acoustic guitar neck profiles and headstock shapes, making it easier to achieve the exact dimensions and contours required for optimal playability.

Q: What are the best practices for using a CNC machine for guitar making?

A: Best practices for using a CNC machine for guitar making include thoroughly planning your designs using 3D modeling software, properly setting up your materials and jigs, regularly maintaining your CNC machine, and experimenting with different settings to find the best results for each project.